MicroFab Technologies MJ-AB-01 User manual

MicroFab Technologies, Inc.

www.microfab.com

MJ-AB User’s

Manual

MJ-AB User’s Manual

MicroFab Technologies

1104 Summit Avenue, Suite #110

Plano, Texas 75074

Phone 972.578.8076 • Fax 972.423.2438

Notice:

The information contained in this document is subject to change without notice.

MicroFab makes no warranty of any kind with regard to this material, including but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. MicroFab shall not be liable for errors

contained herein or for incidental or consequential damages in connection with the furnishing, performance, or

use of this material.

Warranty

The MJ-AB jetting device is warranted against defects in material and workmanship for a period of thirty days

from date of shipment. During the warranty period, MicroFab will, at its option, either repair or replace devices

that prove to be defective.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance by Buyer,

Buyer-supplied software or interfacing, unauthorized modification or misuse, or operation outside of the

environmental specifications for the product. MicroFab makes no claim that the jetting device will perform

with all fluids introduced to the device, or that the device will work at all frequencies and operating parameters

selected by the Buyer.

MicroFab Technologies

1104 Summit Avenue, Suite #110

Plano, Texas 75074

Phone 972.578.8076 • Fax 972.423.2438

Equipment Series: MJ-AB Jetting Device

Mfg Date: Indicated by device Serial No.

General Safety Considerations

Warning The jetting device itself presents no general chemical hazard. However, safety measures

should be followed as outlined in the MSDS for fluids to be dispensed.

Warning If this product is not used as specified, the protection provided by the equipment could

be impaired. This product must be used in a normal condition only (in which all means

for protection are intact).

Table of Contents

SECTION 1 - GENERAL INFORMATION 1

Introduction ...............................................................................1

Technical Specification.............................................................1

Facility Requirements................................................................2

Pneumatics ..................................................................................... 2

Electrical......................................................................................... 3

SECTION 2 - EQUIPMENT RATINGS 5

Supply Voltage...........................................................................5

Range of environmental conditions...........................................5

EQUIPMENT INSTALLATION 5

Unpacking and Inspection.........................................................5

Assembly....................................................................................6

Instructions for Protective Earthing..........................................6

Ventilation .................................................................................6

EQUIPMENT OPERATION 7

Hardware Overview ...................................................................7

Principles of Operation ..............................................................8

Initializing Jetting Hardware.....................................................8

Setup steps: .................................................................................. 10

Notes: ............................................................................................ 11

SUPPLEMENTAL PARTS 12

FACTORY SUPPORT 13

MJ-AB USER’S MANUAL

Section 1 - General Information

Introduction

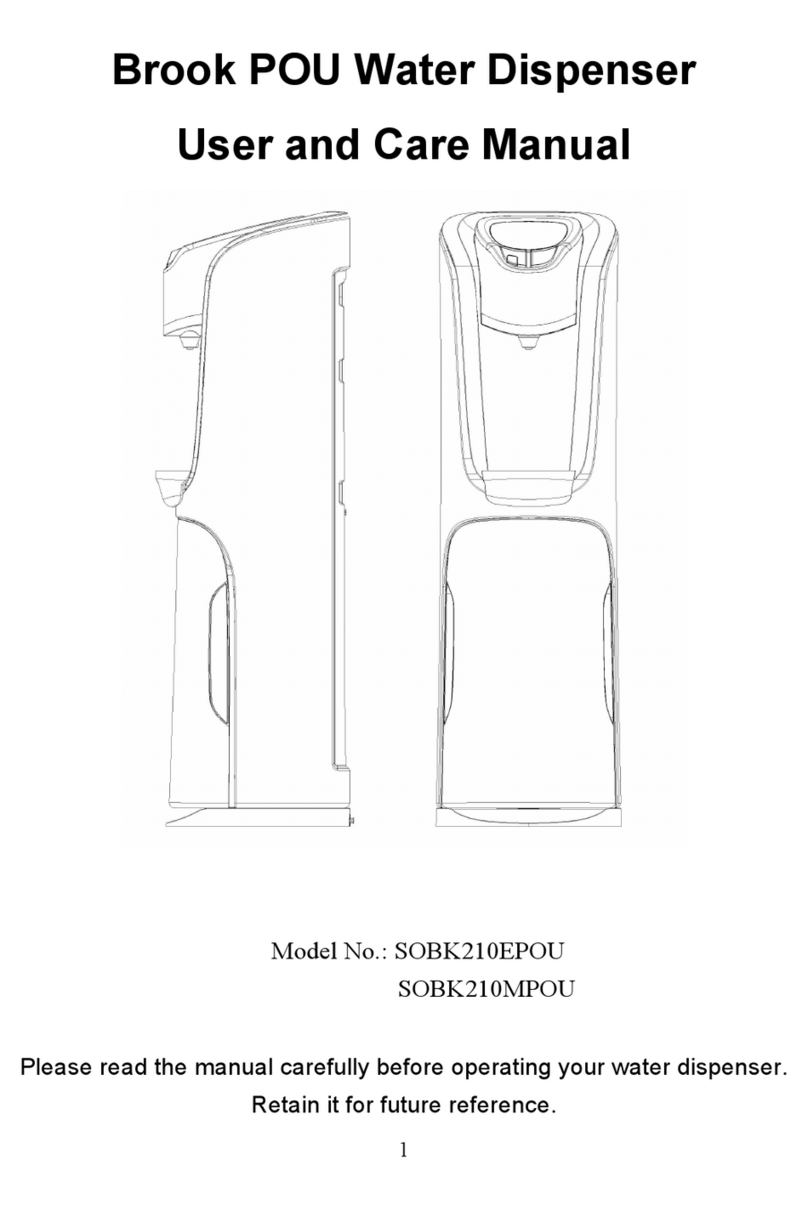

MicroFab’s MJ-AB jetting device has been developed to dispense single drops of

solvents, water-based fluids, and inks. With proper fluid preparation and device

maintenance, the jetting device will provide reliable delivery of fluid micro-drops.

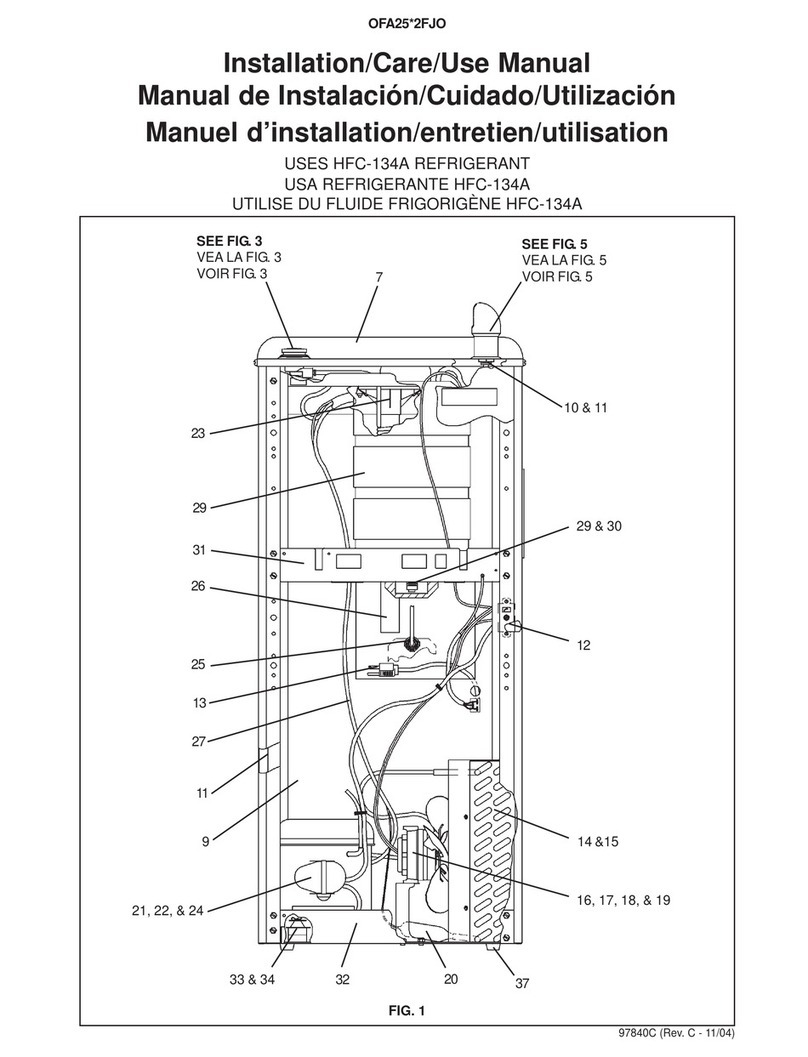

Figure 1 - MJ-AB-01 Jetting Device

Technical Specification

The MJ-AB jetting device design has successfully jetted a wide variety of fluids.

Performance of the jetting device is closely tied to the characteristics of the fluid in use.

Typical fluids successfully jetted in this device have viscosities less than 40 centipoise

and surface tensions in the range of 0.02-0.07 N/m. Fluids with properties outside

these limits can be jetted if changes to the properties can be achieved with solvents or

changes in temperature.

The jetting device can be provided with orifice sizes ranging from 30-60 microns.

Depending on the operating parameters and the fluid, these devices can produce drops

ranging from 50-200 picoliters in volume.

Operating Range

Operating temperature between 20 and 150°C.

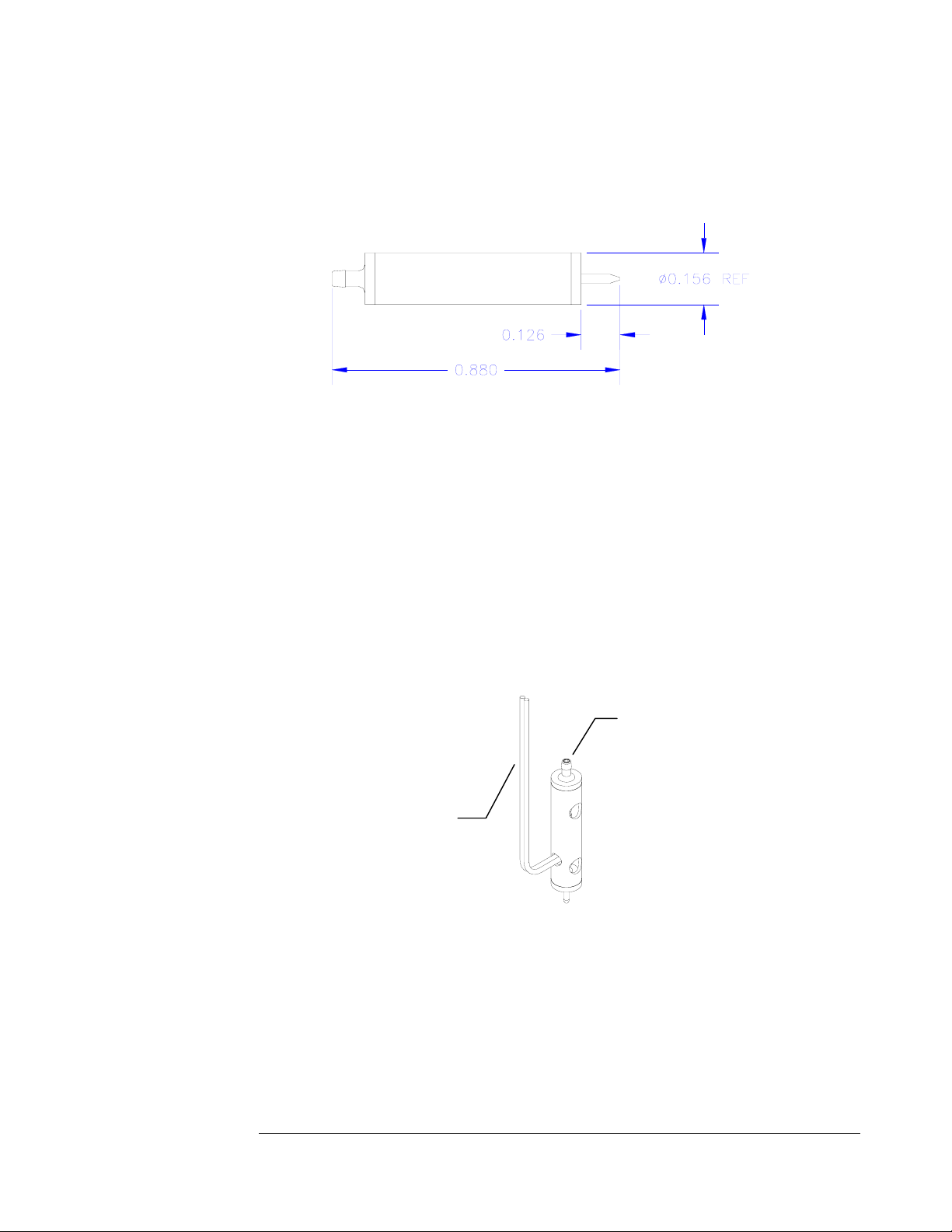

Physical Dimensions

Physical dimensions are shown in Figure 2.

1

MJ-AB USER’S MANUAL

Figure 2 - Device Dimensions

Power Requirements

Required power - 115VAC/2A max; 50/60 Hz (for JetDrive electronics;

JetDrive can also be configured for 240V installation).

Facility Requirements

The jetting device, by itself, requires no connection to lab or machine power.

However, the support equipment for the jet does require some typical lab support.

Figure 3 - Fluid & Electrical

Electrical signa

l

Fluid Inlet

Pneumatics

Depending on the viscosity and contact angle of the fluid, the jetting device can require

either positive or negative pressure at the fluid inlet. There are two typical ways to

provide this backpressure. First, the backpressure can be provided by either a positive

2

MJ-AB USER’S MANUAL

or negative pressure head provided by positioning the fluid reservoir. If the reservoir is

mounted a few inches above the jetting device, a constant positive pressure will be

provided. If it is mounted a few inches below, the orifice will realize a negative

pressure.

The second approach is to regulate existing compressed air or vacuum sources. By

inserting a pressure or vacuum regulator between the source and the jetting device, the

pressure can be adjusted. MicroFab provides such capability in it’s CT-PT-01

pneumatics panel. In this case, the lab facilities must provide a +15 PSIG source,

either through an air compressor or through a compressed gas tank. For negative

pressure, the regulator should be connected to a vacuum source of –24 in. Hg.

The two installations are shown side by side in Figure 4.

Figure 4 - Back Pressure Control

Pneumatics Panel

Reservoir

Jetting Device

Electrical

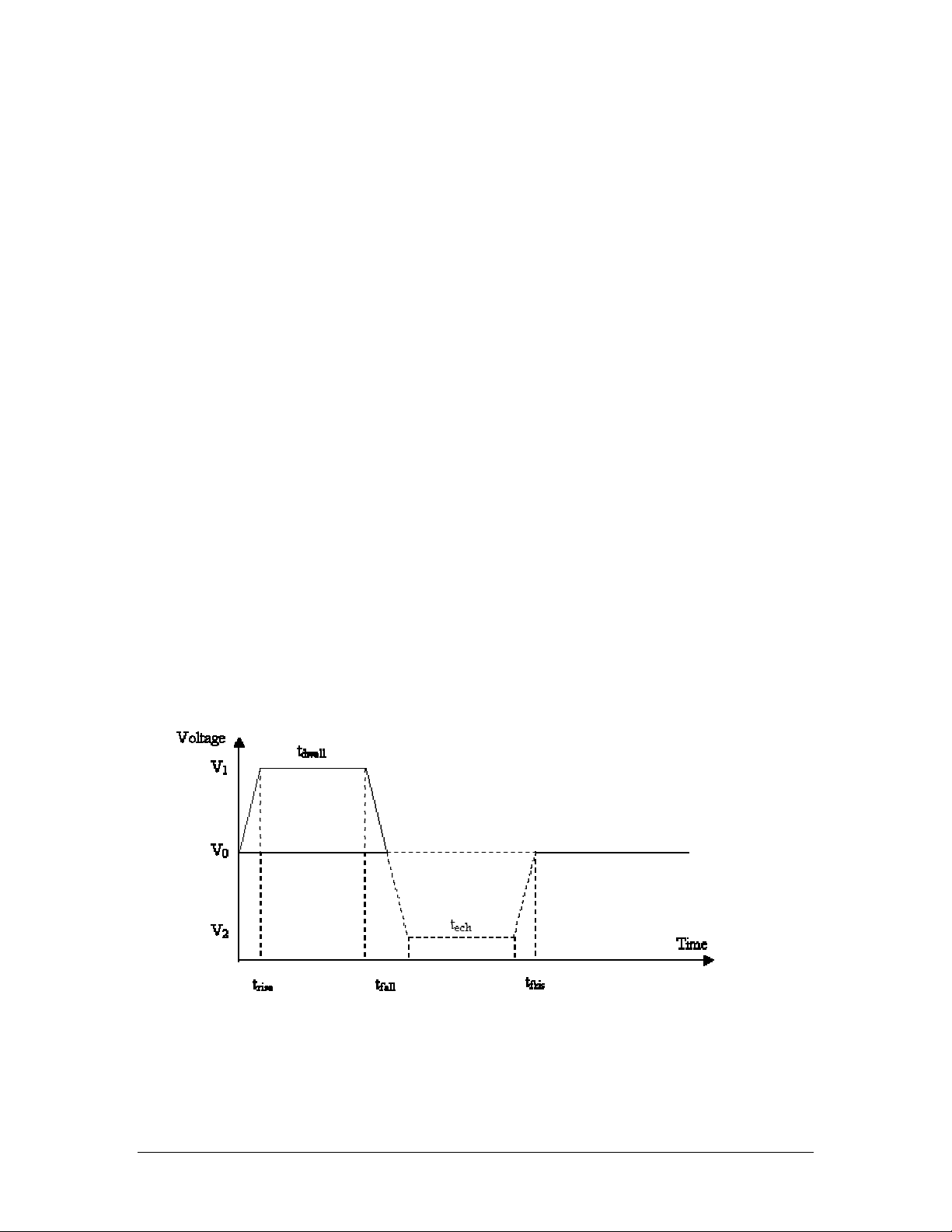

In order to generate drops, a pulse is sent to the PZT surrounding the glass capillary.

The shape of this waveform is shown in Figure 5. The minimum to maximum range

Figure 5 - Waveform Definitio

n

3

MJ-AB USER’S MANUAL

for the jetting device is listed in Table 1.

Table 1 - Voltage Pulse Parameters

Voltage level 1 0 to 100 V

Voltage level 2 -100 to 0 V

trise 1 – 300 µs

tdwell 3 – 800 µs

tfall 1 – 300 µs

tech 3 – 800 µs

tfris 1 – 300 µs

Frequency 1 Hz to 20 kHz

MicroFab offers a controller (part no. CT-M3-01) that has been designed to meet or

exceed these parameters. However the same function can be accomplished by

properly implementing a waveform generator and a voltage amplifier from qualified

manufacturers. It is important in either arrangement, however, to make sure that the

output connector from the voltage source mates with the connector provided on the

jetting device.

4

Section 2 - Equipment Ratings

Supply Voltage

Consult the manufacturer’s data sheet for supply voltage requirements of the pulse generator used

for operation.

Range of environmental conditions

The MJ-AB device has been successfully operated in the temperature range of 20°to 150°C. It is

intended for use in a normal laboratory environment.

Equipment Installation

Unpacking and Inspection

When received, the MJ-AB device will be individually packaged in a plastic box and a bag. The

glass tip of the jetting device will be covered by a protective shell. After verifying that the box is

labeled with the desired orifice diameter, the device can be removed from its bag and inspected.

Plastic bag

Box

Jetting Device

Tip cover

Figure 6 - MJ-AB Packing

5

While removing the protective cap, be sure to pull straight away from the device. The glass tip

can be broken or damaged if the cap is pulled to the side during removal.

Assembly

The jetting device should be physically mounted by light clamping around the 0.156” case. No

attempt should be made to hold the jetting device by the glass tip.

Provisions must be made for routing tubing to the fluid fitting of the device. The outside

diameter of the barbed fitting is 0.051” at the largest portion of the barb. Flexible tubing which is

nominally 1/32” I.D. will fit securely over the barb.

In many cases it is advisable to use a filter compatible with the fluid to be jetted. Orifice sizes for

a MicroFab jetting device typically range from 30 to 60 µm. Filter sizes of 7 µm and smaller will

reduce the risk of contaminants clogging the orifices. It is important that the selected filter is

compatible with the fluid to be jetted and that adequate flow through the filter can be maintained.

Instructions for Protective Grounding

Protective grounding for the JetDrive III controller is provided through the ground terminal of

the plug providing power. Source power to the controller, or to a wave form generator selected

as an alternate, must provide protective grounding to this terminal in order to minimize the

hazard of a possible shock.

Ventilation

The MJ-AB jetting device itself requires no special ventilation for operation. However it is

possible that the fluid being dispensed will require a unique environment for reliable operation.

As an example, fluids that quickly dry in contact with air may need an elevated humidity to slow

this process. Additionally, the dispensed fluid may emit volatile fumes that must be captured and

disposed of. Both of these situations are the responsibility of the user of the device and beyond

MicroFab’s control.

6

Equipment Operation

Hardware Overview

Figure 7 shows a typical set-up for a jetting test station. The key components are:

1. Jetting device (in this case, shown in a PH-03 print head for ease of mounting)

2. Fluid reservoir (shown with static pressure control)

3. Drive electronics with strobe interface

4. Drop observation camera and monitor

Video Camera and Lens

Camera Power

Supply

To 110 VAC

Video Monitor

To 110 VAC

Drive

Electronics Box

Strobe Interface

Box (see text)

Print

Head

Reservoir

Strobe LED

Video Camera and Lens

Camera Power

Supply

To 110 VAC

Video Monitor

To 110 VAC

Drive

Electronics Box

Strobe Interface

Box (see text)

Print

Head

Reservoir

Strobe LED

Figure 7 - Typical Set-up

Not shown in the figure is a personal computer. A PC is required in order to serve as the user

interface to download operating parameters to the drive electronics box. The software required

to perform this interface is included with the drive electronics (JetDrive III). For systems where

the voltage pulse is supplied by other equipment, variations on the figure will occur, although the

same components are required.

7

Principles of Operation

The MJ-AB device consists of an annular piezoelectric actuator bonded to a glass capillary that is

connected at one end to the fluid supply and at the other end has an orifice generally in the range

of 30-60um. By applying a voltage to the PZT actuator, the cross-section of the tube capillary is

reduced/increased producing pressure variations of the fluid enclosed in the tube. These pressure

variations propagate in the glass tube towards the orifice. The sudden change in cross-section

(acoustic impedance) at the orifice, causes a drop to be formed. This mode of producing drops is

called drop on demand (DOD).

The same device can be used for continuous drop generation when the fluid is pressurized and a

sinusoidal signal is applied to the actuator. A Rayleigh type instability results in the break-off of

the fluid column into droplets. The continuous jetting results in a higher throughput.

A wide range of fluids can be dispensed with the requirement that the viscosity has to be lower

than 40 centipoise. Drop volume is a function of the fluid, orifice diameter, and actuator driving

parameters (voltage and timings) usually ranging from 50 picoliters to 200 picoliters. The

operating frequency is limited by the total driving time of the actuator and on the dispensed fluid.

Initializing Jetting Hardware

Hardware

The jetting device is the key element of the dispensing system. Each device is polished and

extensively cleaned prior to shipment. Maintaining this cleanliness is extremely important to the

successful operation of the device. In many systems provided by MicroFab, a filter is supplied

prior to the inlet fitting of the jet. The fluid line or fittings between the filter and the device, and

between the filter and the reservoir, should be flushed and cleaned to assure that no particulates

are accumulated in the plumbing. In addition, compatibility of the fluid under test and each

plumbing element should be understood by the user. If the fluid to be dispensed chemically

attacks any of the plumbing components, the resulting contamination may result in a “clog” at the

orifice.

Final testing of the jetting device prior to shipment is done using Isopropyl Alcohol. During

initial testing of the MJ-AB device, this fluid is recommended to help demonstrate that all parts of

the system are operating normally. After new operators are comfortable with dispensing IPA, the

actual fluid to be tested can be loaded into the reservoir.

Observation system

To observe the drop formation, a CCD camera can be used to observe the jet tip. MicroFab

offers a suitable system (model no. CM-VS-01). An appropriate microscope can also replace the

camera.

The total magnification to the display should be in the range of 50 to 100 times. An LED

synchronized with the PZT pulse provides lighting. The delay between the PZT pulse and LED

pulse is adjustable, allowing the capture of the drop formation at different stages of development.

8

Drive electronics

To use the device as a drop on demand dispenser the waveform presented in Figure 8 has to be

supplied to the red wire of the piezoelectric actuator with the black/blue wire connected to the

ground of the drive electronics unit. The driving signal can be unipolar or bipolar, depending on

the fluid used. The parameters are trise = initial rise time; tdwell = time at high voltage (V1); tfall =

transition time from high voltage to low voltage; techo = time at low voltage (V2); tfrise = final rise

time. The voltage V0is normally set to zero and V1= -V2. The piezoelectric actuator has a

capacitance of about 1 nanoFarad.

The length of device and the jetted fluid dictates the timings. To minimize the driving voltage the

rise and fall times should be short (2-3ms). An optimum value for the dwell time is approximated

as:

tdwell=2 L/c (1)

where L is the distance between the middle of the piezoelectric element to the device end and c is

the speed of sound in the dispensed fluid. For the MJ-AB device, the value of L is approximately

0.434” (11 mm). Typical dwell time values are between 15 to 35 ms. The echo time techo (if using a

bipolar waveform) should be adjusted for a clean break-off of the drop (generally about twice the

dwell time).

To achieve larger drop volumes with the same device (drop volume is also a function of the

orifice diameter) longer rise and dwell time values can be used (which also results in an increase in

the voltages V1and V2).

The LED signal should be synchronized with the driving signal and have an adjustable delay from

the beginning of the pulse. By adjusting the delay the drop formation will be “frozen” at that time

from the beginning of the PZT pulse.

Figure 8 - Waveform Set-up

9

Setup and operation

Important:

The glass tip of device is very fragile! Care should be taken to remove the

protective cap along the device axis otherwise the glass capillary outside the device will

break. A gentle twist is usually required to pull the cap directly off the device. Also use

care not to touch the fluid end of the device possibly contaminating it.

Setup steps:

1. Verify that the tip of the jetting device is visible when the camera is on. Check focus

and camera calibration.

2. Verify that the device is full of fluid by purging under positive pressure. This is

accomplished by turning the purge knob on the pneumatics panel. Alternately,

positive pressure can be applied to a syringe body by making a pneumatic connection

to the syringe, or pressing the plunger to achieve roughly 10-15 psig. After a few

seconds, turn the pressure off.

3. Switch the pneumatics panel from Purge to On to transfer control to the fine adjust

pressure regulator. Adjust the large, fine adjust, regulator until the fluid meniscus is

flush with the device frontal face. Often a lint free swab is useful in cleaning the front

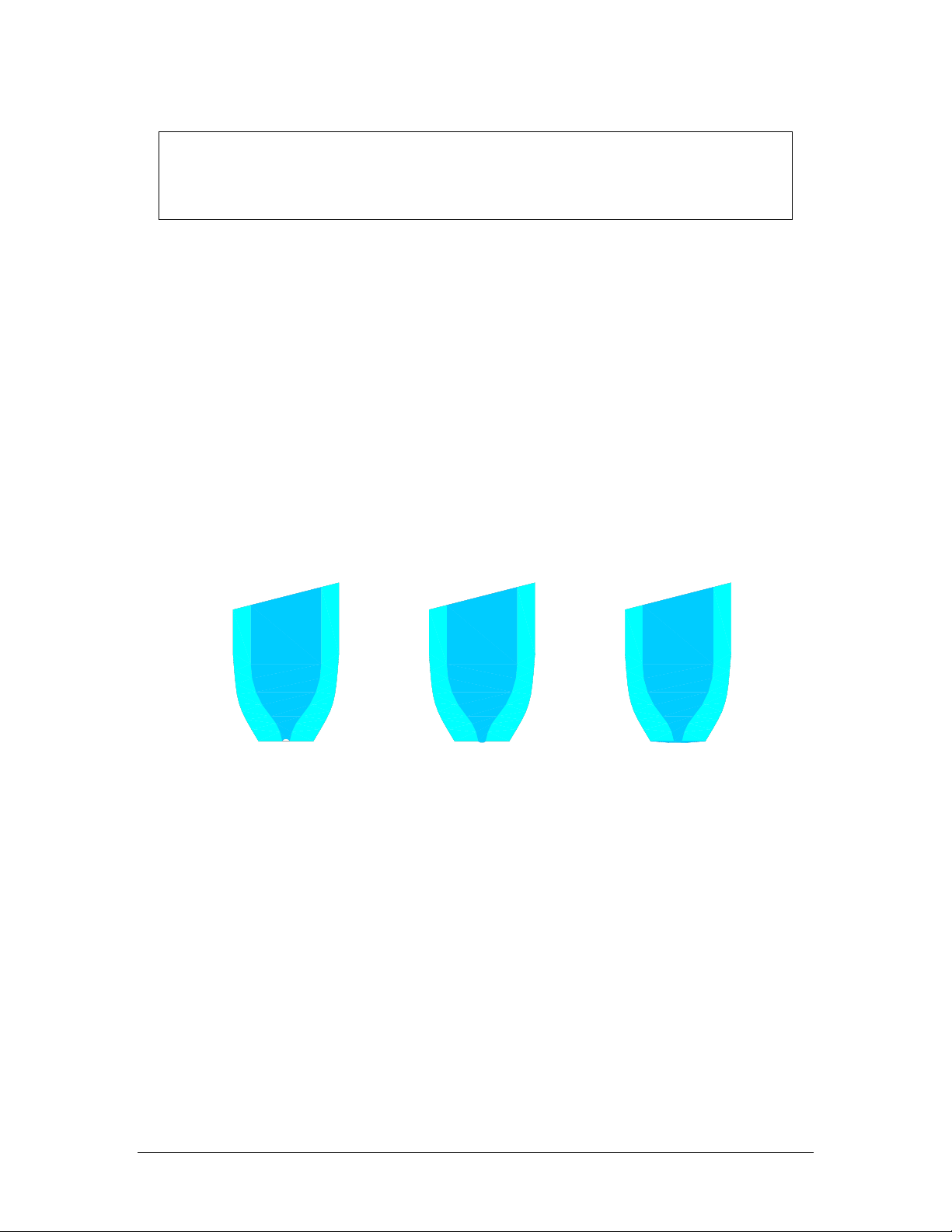

face of the orifice in order to verify the pressure level. Figure 9 shows possible

situations that arise at the orifice.

Negative Pressure Meniscus Positive Pressure Meniscus Fluid Wetting OrificeNegative Pressure Meniscus Positive Pressure Meniscus Fluid Wetting Orifice

Figure 9 - Meniscus variations

4. Initialize the pulse to the jetting device. Set the signal frequency between 60 and 100

Hz. Set V1to 20 V and t1between 25 and 30µs. The rise and fall times are adjustable

and should be set to 2-3 µs. If an echo pulse is used, set V1to 15 V and V2to –15 V

and t2to 50 µs (twice t1). The echo pulse is used to optimize the drop break-off, so

for initial studies, using a unipolar pulse is recommended. An oscilloscope is often

useful in order to verify or observe the voltage pulse.

5. Be sure the output of the drive electronics box or high voltage amplifier is OFF.

Connect the output from the drive electronics to the device (ground to the device

black/blue wire and signal to the red wire). Turn the output to the electronics unit or

amplifier to on.

CAUTION:

High voltage is present at the cable ends to the device.

10

6. After initiating the jetting pulses in their baseline values, adjust the delay control of

the strobe interface, and you should be able to observe the meniscus moving. If this

is not observed, pressurize the reservoir to 5-15 psi, and you should observe radial

perturbations on the cylindrical fluid column exiting the device. The perturbations

will move along the column when changing the delay. This demonstrates that the

PZT actuator is seeing a voltage pulse and it’s motion disturbs the fluid column.

Adjusting this “stimulation” pulse is the next step.

7. If the meniscus is moving at the device orifice but no drop is formed, position the

delay so you can see the meniscus at the maximum position outside the glass.

Increase the applied voltage in 2 V increments. This should produce an increase of

the meniscus excursion and, at a certain voltage level, should produce a drop.

8. Adjust the t1interval at constant voltage (change t1up and down from the previous

set value) for the maximum velocity. If satellites (smaller drops) are formed, the

voltage should be decreased.

9. Perform fine-tuning (for stable drop formation and no satellite operation) by

adjusting the timings and voltage around the values determined above.

Notes:

An increase of the voltage produces an increase in velocity.

Beyond a certain voltage level satellites start forming. Also, high voltage results in

air ingestion.

Drops are formed at a certain range for tdwell. Increasing tdwell results in no drops.

Increasing t1further will produce again drops (of larger volume).

Changing the operating frequency might require additional tuning.

Basic Drop Formation Troubleshooting

No drops formed

Set the delay to zero then increase to about 3 times t1.

Check (visualize with an oscilloscope) that the drive waveform is the same waveform you

wanted.

Inspect the tip. Turning the LED strobe off and lighting constantly (with a white

background) will show you a change in the light reflection when no fluid is present in the

nozzle. Purge to recover the meniscus or to eliminate any large air bubbles observed in

the nozzle area.

Pressurize the reservoir. If no fluid is purged, the device is clogged. Several possible

techniques exist for removing a clog from the orifice. Contact MicroFab for determining

the best solution for your system.

Repeat steps 3 to 9 in the setup procedure

11

No drops are formed with a fluid puddle formed on the device tip

Wipe of the front surface with a cotton swab until dry and readjust the reservoir back

pressure if necessary.

Air may have been ingested through the orifice – Purge the device, or decrease the

voltage to the device

Satellites are formed in addition to the main drop – Decrease the voltage to the device or

adjust the dwell time.

Jet is not straight

Could be produced by a low velocity drop. In this case increase the velocity (increase the

voltage or adjust the tdwell)

Could be produced by non-uniform wetting. Wipe off the device face until dry and

readjust the syringe level if necessary.

Could be a foreign particle at, or in the orifice, use cleaning procedures.

Supplemental Parts

In many instances, the MJ-AB jetting device is purchased as a “stand-alone” component of a

larger subsystem. In order to make both fluid and electrical connections, details regarding the

electrical connector, tubing, etc., is required. Below is a partial listing of some of these items that

are known to interface correctly with the supplied device. This is, in no way, an endorsement of these

products, or does it attempt to address questions of fluid / material compatibility.

Electrical connector

The default connector is Molex P.N. 50-57-9402

The appropriate mating connector is Molex P.N. 70107-0001, with two

Molex male crimp terminals, P.N. 16-02-0115

When mounted in a PH-03 print head, the connector is Molex P.N. 22-11-2022

The appropriate mating connector is Molex P.N. 22-01-3027 with two Molex

spring crimp terminals, P.N. 08-56-0110.

Fluid connection

Cole-Parmer: C-flex tubing, P.N. 6424-60

12

13

Factory Support

For any questions regarding the MJ-AB-01 jetting device, or ink jet technology, contact

MicroFab Technologies

1104 Summit Avenue, Suite #110

Plano, Texas 75074

Phone 972.578.8076 • Fax 972.423.2438

or

Table of contents

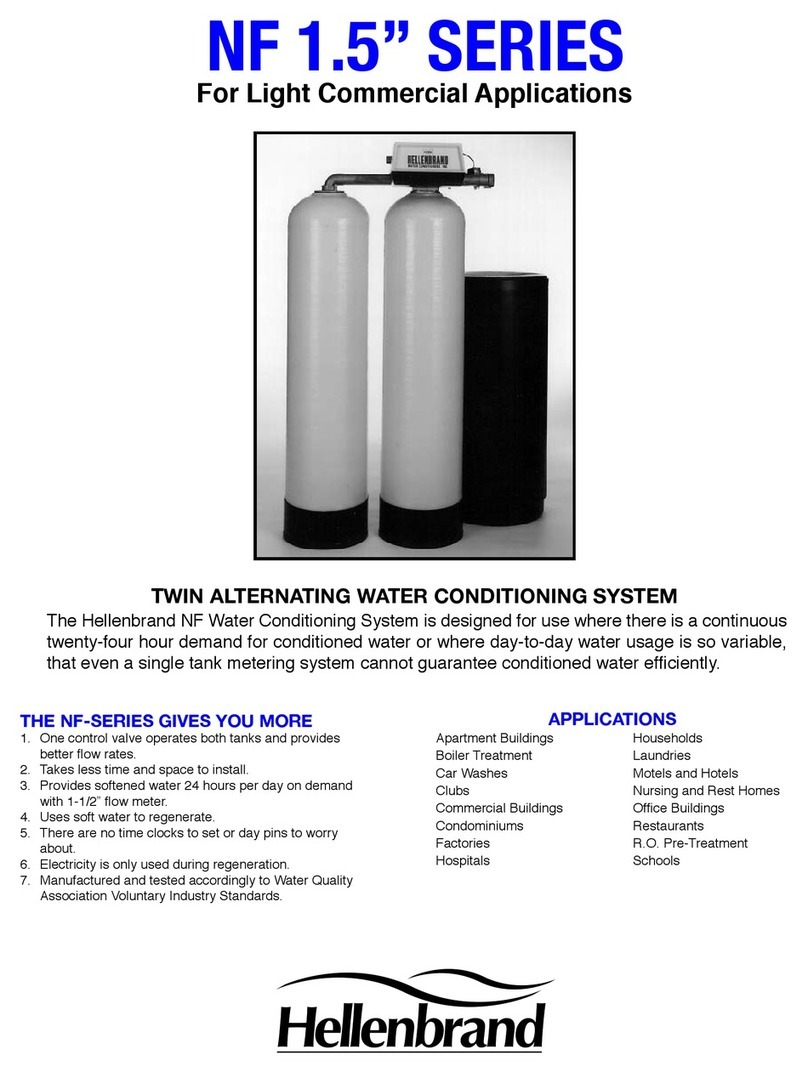

Popular Water Dispenser manuals by other brands

Hellenbrand

Hellenbrand Twin Alternating Water Conditioning System NF 1.5"... Specifications

APURO

APURO K711-A instruction manual

Applied Membranes

Applied Membranes AA Series Operation manual

GE

GE SmartWater GXCF05D owner's manual

Whirlpool

Whirlpool WHESCS Installation and operation manual

Electrolux

Electrolux ES11S manual