6

General Description

This series of displays accepts industrial sensors to allow various physical measurements to

be made, such a weight, temperature, pressure, humidity etc. Different models are available

for different sensor types.

The main function of this series is to give a clear numeric readout of the variable being

monitored. Most models include an excitation power output, to power the sensor directly.

Various digit heights are available, to suit the maximum viewing distance required in each

installation. For every 10 metres of viewing distance required, use 1” of digit height.

Various optional output modules are also available to give alarm relay outputs, analogue

output or digital communications, or any combination of these options.

Displays are programmed using front panel pushbuttons. The front panel buttons can be

disabled. In addition, you can connect 4 remote wired pushbuttons to the display, so that you

can make adjustments while the display is mounted in an inaccessible location.

Power supply options: 100-240 VAC, 48VAC or 11-30VDC

These displays must be installed fully assembled, and must be installed according to local

electrical installation rules.

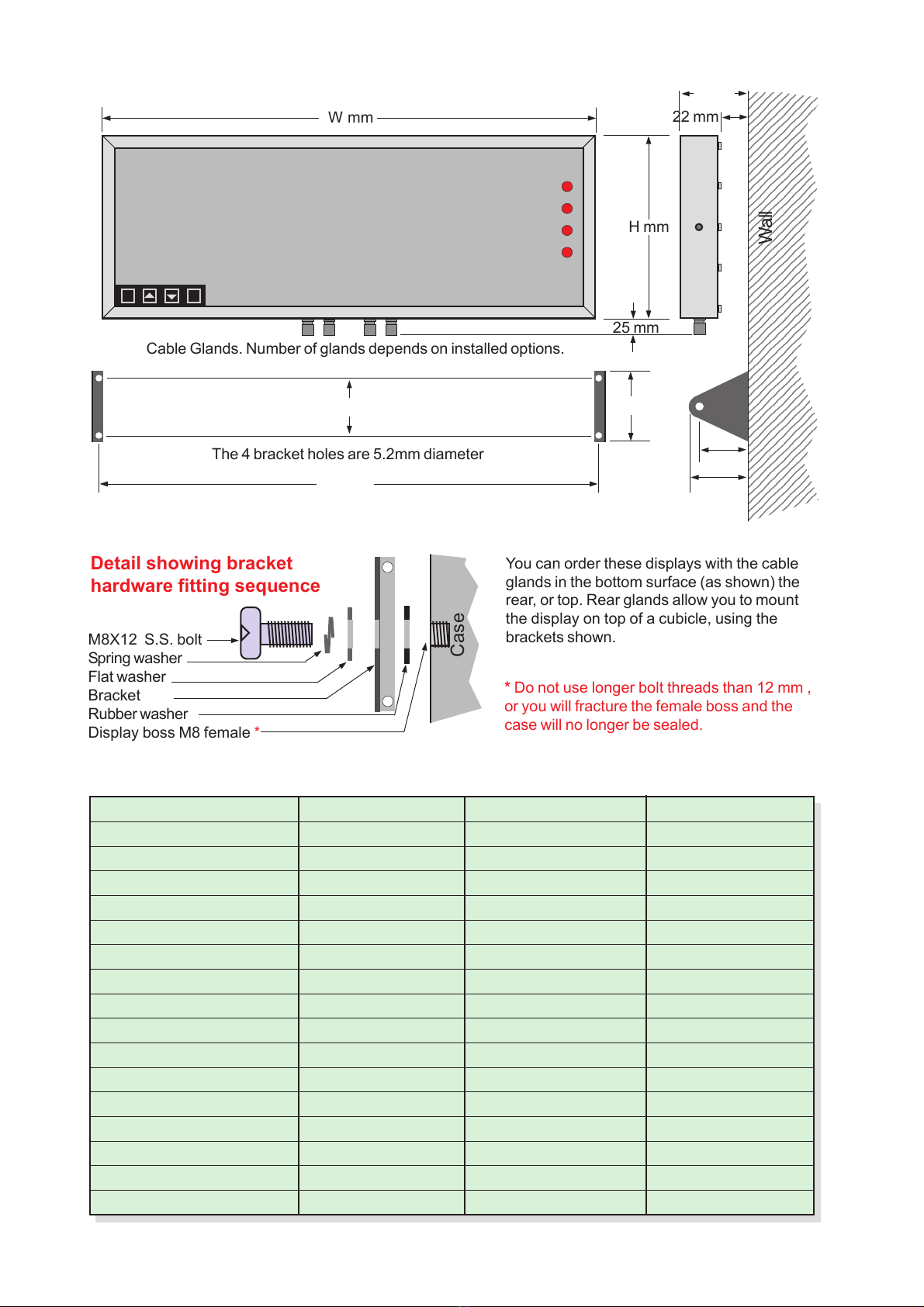

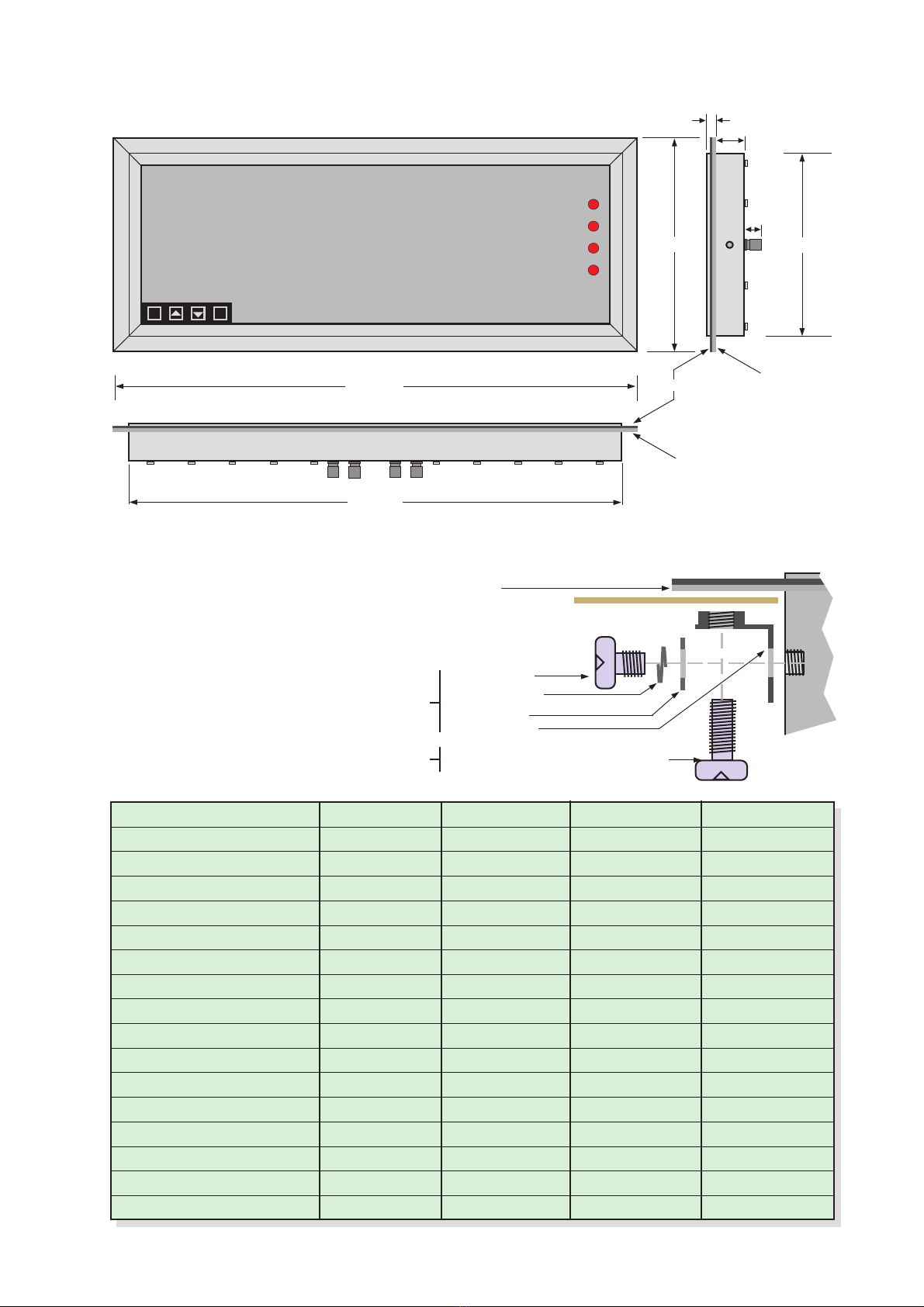

When properly installed, and provided they have been ordered with cable glands exiting the

lower surface of the case, they provide ingress protection to IP65 / NEMA4X from all directions.

Safety

Obey all safety warnings in this manual, and install the display according to local wiring and

installation regulations. Failure to follow these guidelines may cause damage to the display,

connected equipment, or may be harmful to personnel.

Any moving mechanical device controlled by this equipment must have suitable access guards

to prevent injury to personnel if the display should fail.

!

Caution: There is a risk of electrical

shock if this display is not properly installed

Caution: Risk of danger: Read the whole

manual before you install this display