CONTENTS Page

Description ............................................................................................................................... 1

Safety ....................................................................................................................................... 2

Operator protection ................................................................................................................... 2

Preparing for spraying .............................................................................................................. 3

Mixing, filling and calibration .............................................................................................. 4 - 7

Before spraying ........................................................................................................................ 8

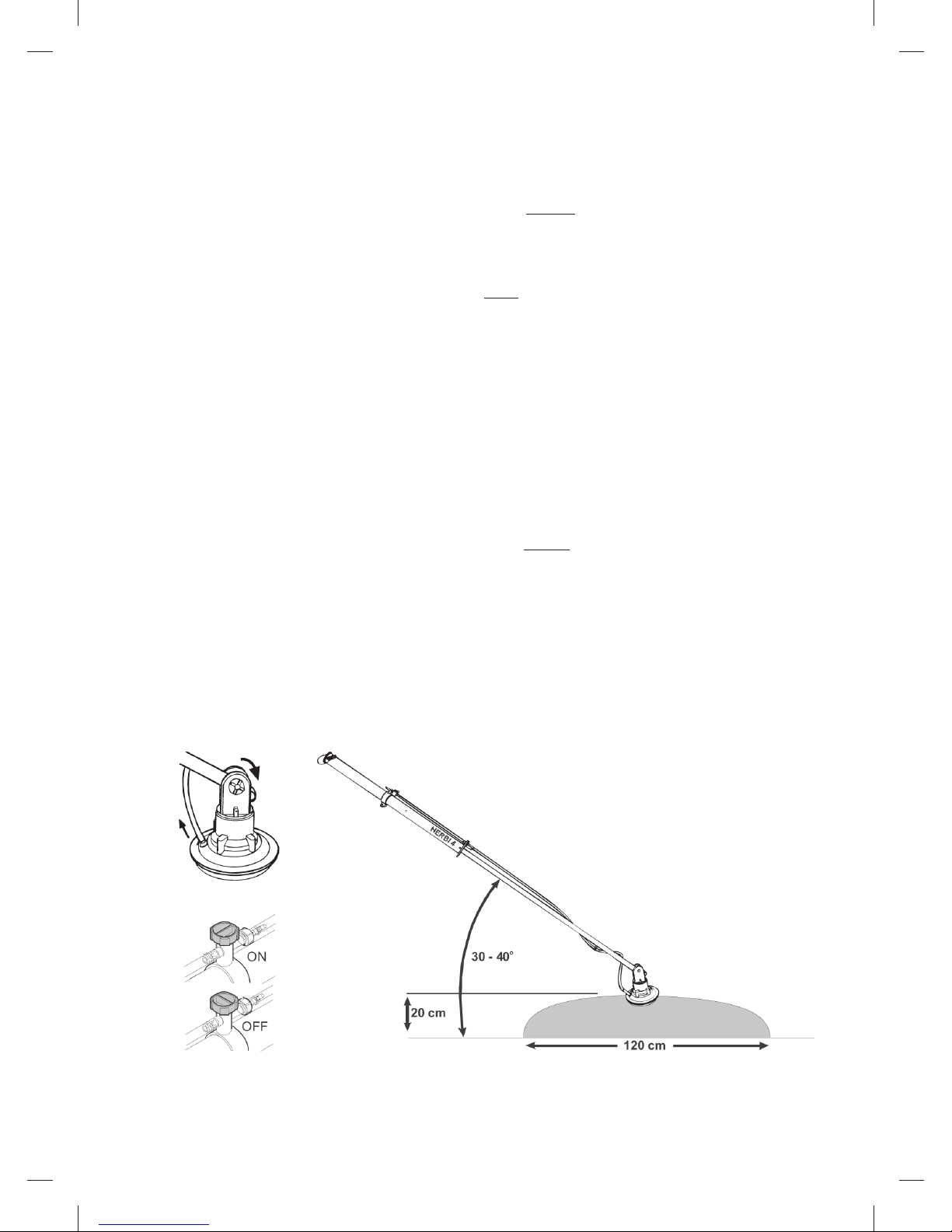

To start spraying ....................................................................................................................... 8

To stop spraying ....................................................................................................................... 9

After spraying ........................................................................................................................ 10

Storage, recharging and maintaining the battery ...................................................................... 11

Troubleshooting ..................................................................................................................... 12

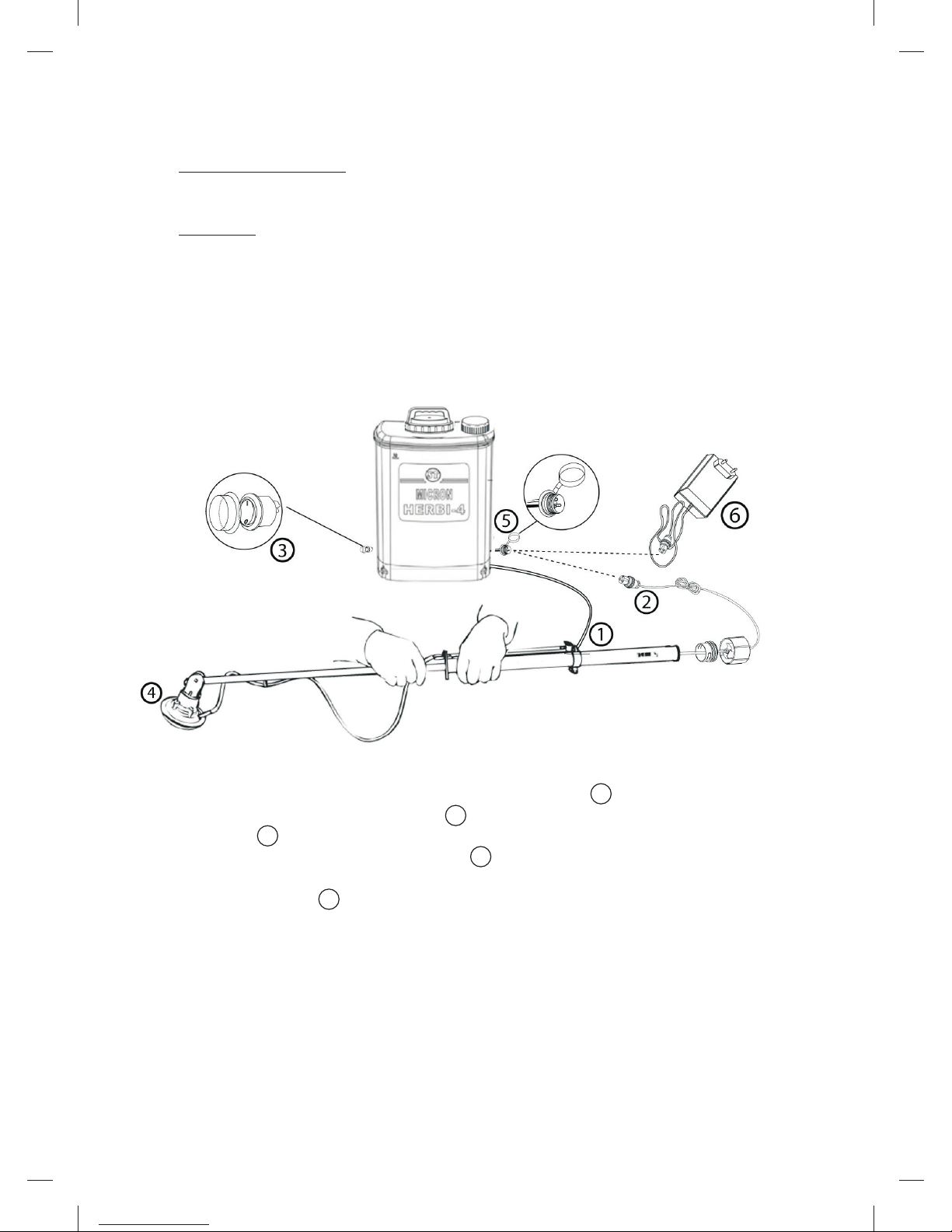

Diagram/Parts List ........................................................................................................... 13 - 14

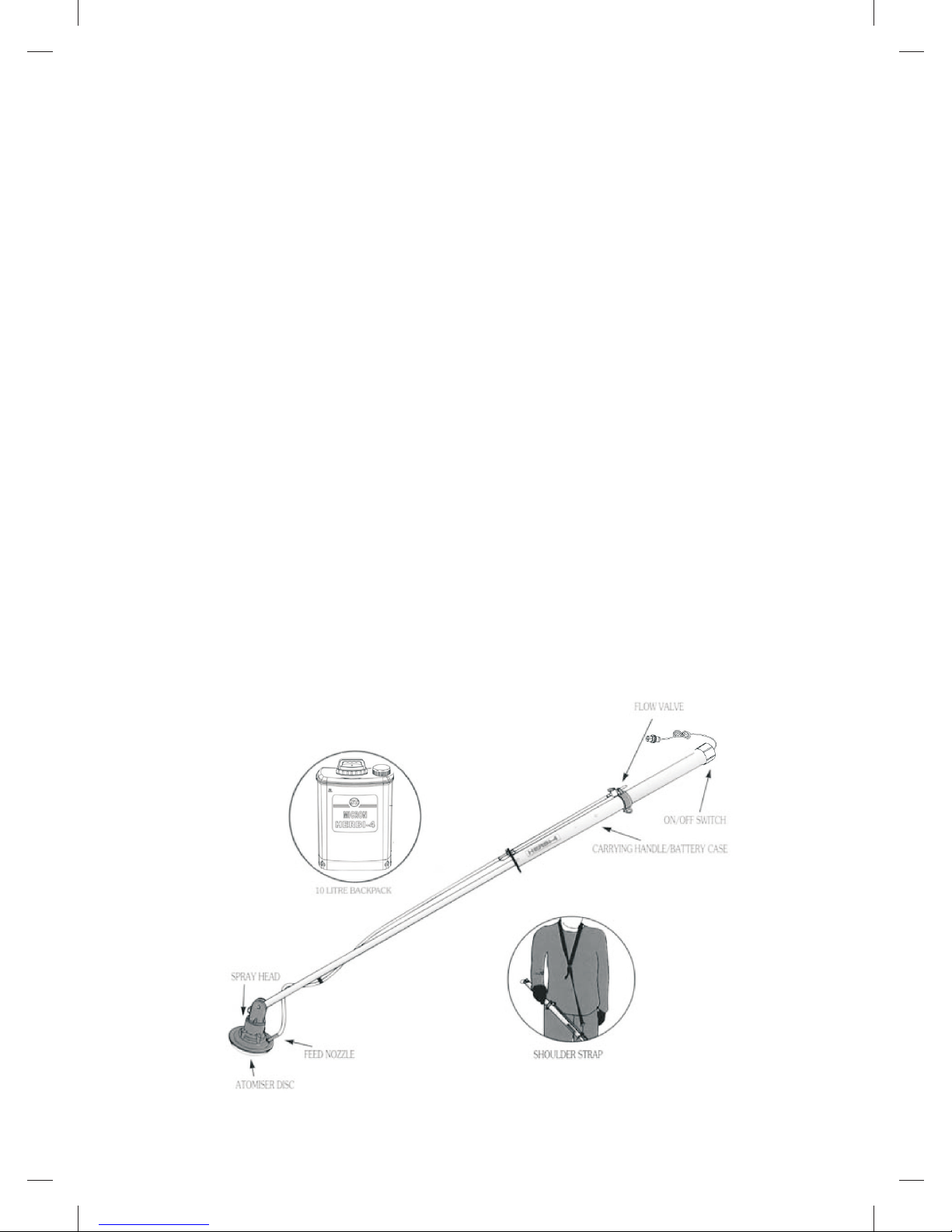

DESCRIPTION

The HERBI-4 is a simple robust hand-held spinning disc Controlled Droplet

Application (CDA) sprayer powered by 6 volt 3 Ah LSA battery, with one set of good

quality battery giving over 20 hours spraying time. It is designed to apply herbicides in

a 1.2m wide band at low volumes (10 to 30 litres/hectare). A governed electric motor

spins the atomiser disc at a constant 2,000 rpm to produce uniform spray droplets of

around 250 micron; large enough to minimise any risk of spray drift. Liquid is fed by

gravity through colour coded feed nozzles. The HERBI-4 can apply herbicides to

borders, pathways, ditches and larger areas by making a series of consecutive spray

passes. The weight of the machine ready to spray, with the ST 10 litre backpack.

1

DIAGRAM 1