6

1. Next, position the T100 Turbo Unit as far away as practical and possible from the area where you

will spray.

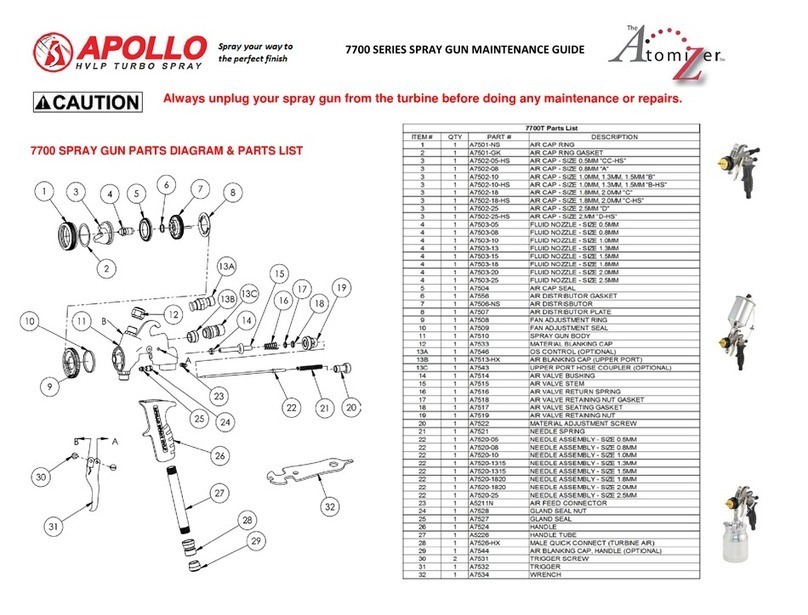

2. Attach the remaining end of the hose to the T6000 Spray Gun as follows:

a. Locate the coupler at the rear top of the T6000 Spray Gun. See T6000 diagram.

b. Pull back on the collar of the black connector on the air hose.

c. Push the connector over the coupler and release. Figure 7.

d. Your Spray Gun should now be firmly attached to the air hose.

Using Your Apollo T6000 Spray Gun

Your Apollo T6000 spray gun is certified by Apollo Sprayers. This means your spray gun only uses

about 3 PSI and is genuine HVLP. There are many small passageways for the air to travel inside the

spray gun. If one of these air passages becomes blocked, or build-up of material starts to occur, your

spray pattern will become distorted, therefore, always keep your spray gun clean. Your Apollo T6000

spray gun comes fitted with a custom tanning needle and nozzle specifically designed for spraying

tanning solutions. Using this size tip/nozzle and needle you can achieve from a 1/4" line up to a 6"

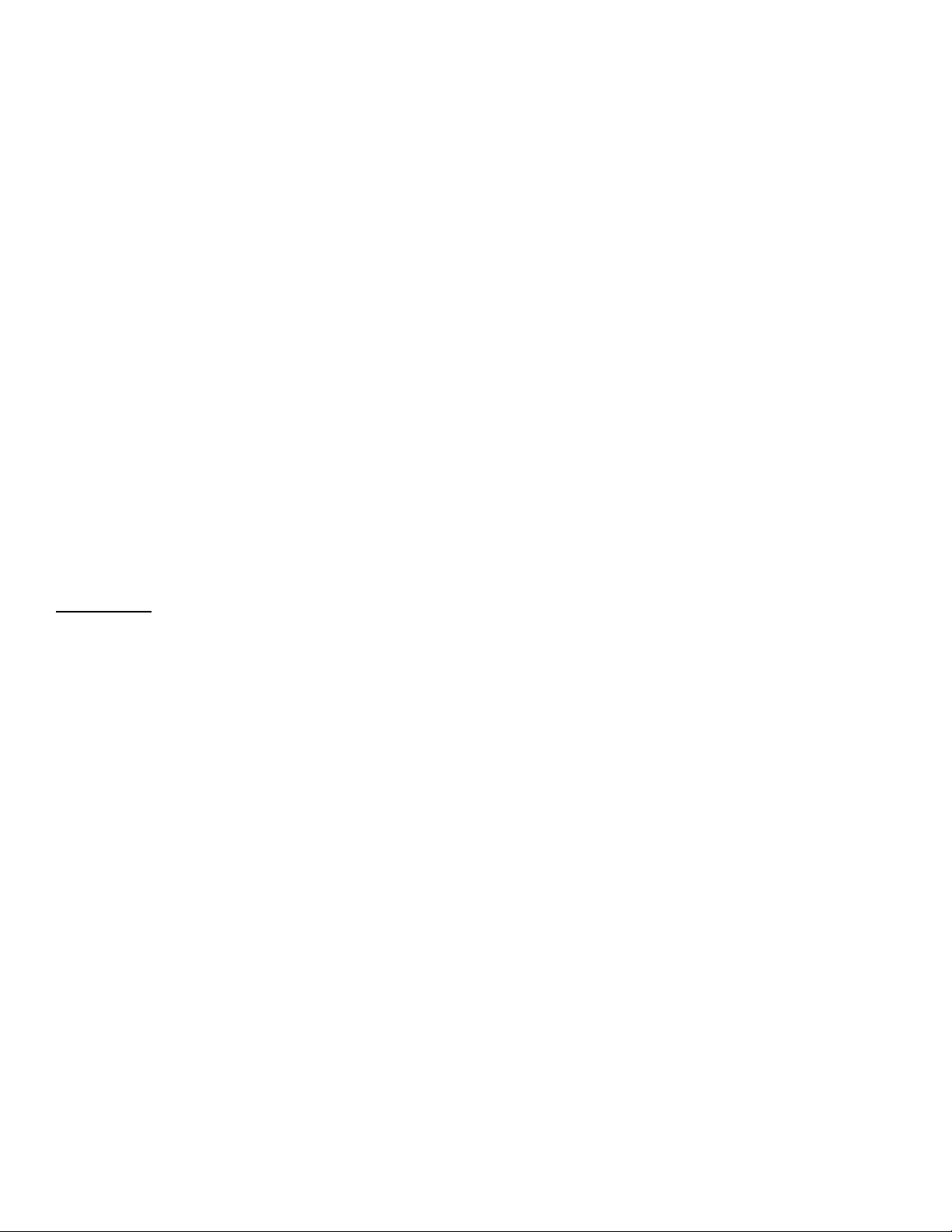

wide fan pattern. To do this, rotate the Air Cap (#2) to the desired fan pattern type, then open the

solution flow screw (#10) counter-clockwise and move the spray gun closer or further away from your

work piece until you get the desired width of pattern. The closer you are to the clients body the

smaller the fan. The farther back you hold the spray gun from the clients body the larger the fan

pattern will be. A little practice will enable you to master this technique in no time flat! Never hold the

spray gun more than 6-8” away from the client.

PRACTICE:

VERY IMPORTANT!! To fill the cup with solution hold the black cup lid tight and remove the cup from

your spray gun. DO NOT HOLD THE SPRAY GUN HANDLE AND REMOVE THE CUP. Fill the cup

approximately half way with some water. Hold the black lid assembly and re-attach the cup to the

body of the spray gun and hand tighten to create a good seal. Attach the spray gun to the air hose.

Attach the other end of the air hose to the turbine unit. Turn the turbine unit on. You will notice air

is now flowing through the air cap all the time, this is normal and correct. Position the air cap

(#2) in the horizontal or vertical position, turn the solution flow screw (#10) clockwise until closed.

Now open the solution screw slowly until you have it open 1 full turn. Point the spray gun away from

yourself (and anyone else) and pull the trigger all the way back. You should see a “V” shaped mist (or

triangle) called a fan pattern. Now, with the trigger depressed, if you turn the material flow screw,

(#10) clockwise (closing) making very small adjustments at a time, you will notice that the fan pattern

is beginning to get smaller. Now, reverse this and notice the pattern will get larger. Take a large piece

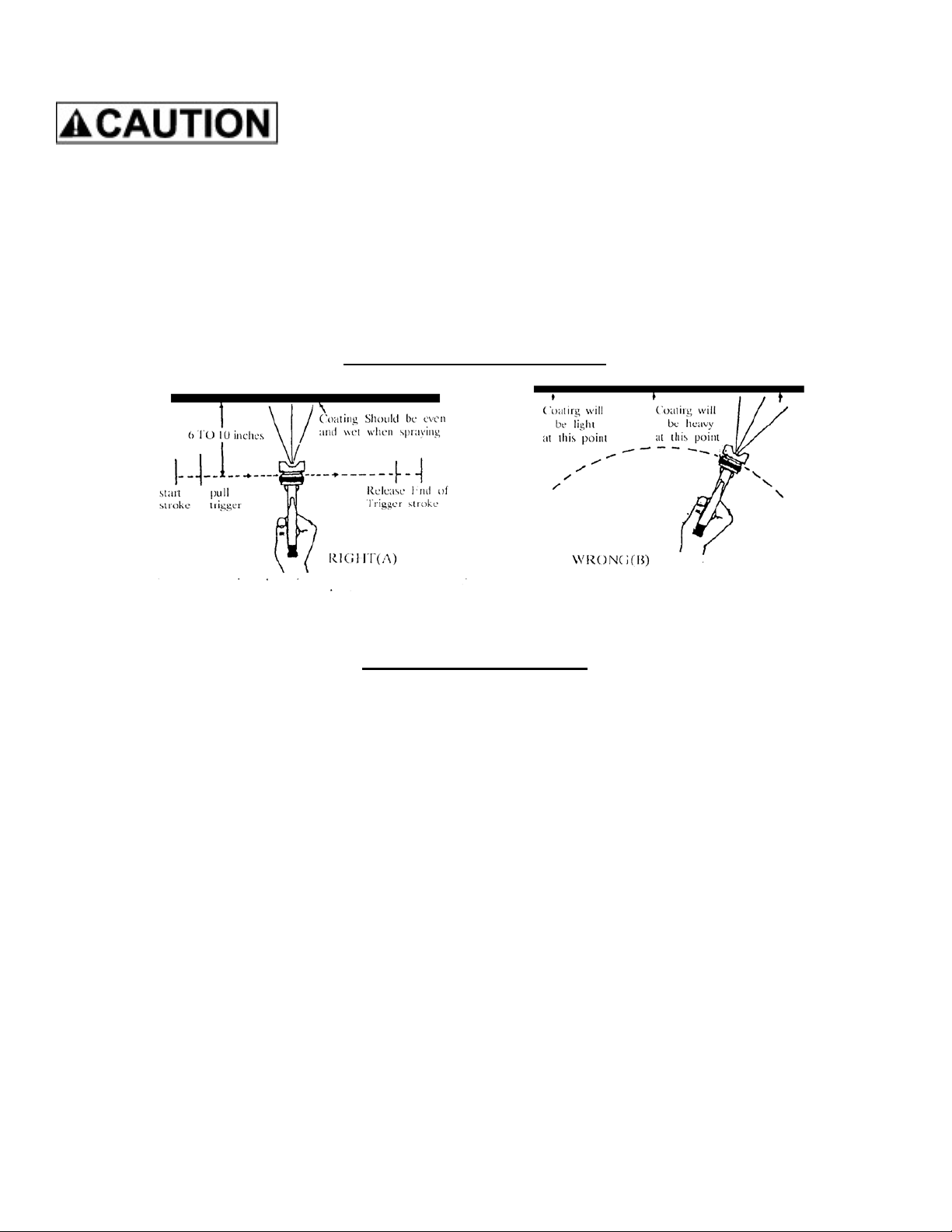

of cardboard and direct the pattern at the surface, hold the spray gun approximately 6" from the

surface. Pull the trigger. Observe the outline and size of the pattern. Now, turn the solution flow

screw clockwise (closing). Move the spray gun an inch or two closer to the surface. Pull the trigger.

Notice the pattern has become smaller. You can continue reducing the solution flow and move the

spray gun even closer to the surface and the pattern will continue to get smaller and smaller. Next,

rotate the air cap to a diagonal position (See Spray Patterns, Pg. 5). Vary the solution flow and the

distance of the spray gun from the work surface. Notice the change in pattern size.