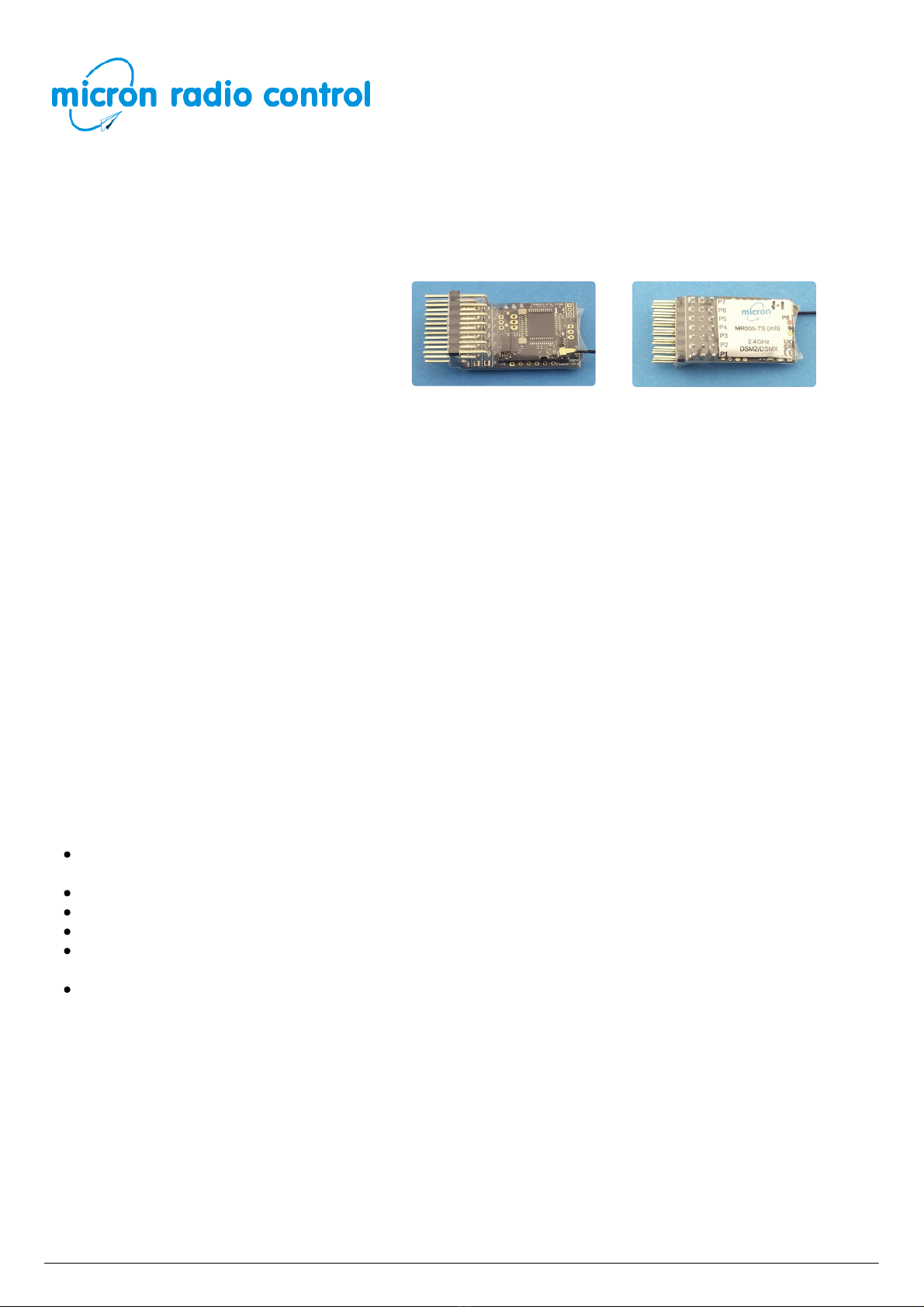

MR005 Bottom

MR005 Top

Uplands House, Castle Howard Road, Malton YO17 6NJ

www.micronradiocontrol.co.uk

+44 (0)1653 696008

Micron MR005 2.4GHz DSM2/DSMX Receiver

This document is regularly updated and the most recent version may be found online at

http://micronrc.uk/mr005 where you will be able to view larger versions of the images.

MR005 is a 7 channel DSM2/DSMX

compatible receiver designed for model

railway layout control. It has 7 JR/Futaba

style pin sets to which servos or LEDs may be

connected. MR005-7S has 7 servo outputs,

MR005-7X has 7 on/off outputs (0V / 3.3V)

to which LEDs may be directly connected as

there is a 220 ohm series resistor on the receiver board. MR005 with a combination of servo and on/off

outputs, or different R/C channel to receiver output mappings, is available to special order. MR005 is

small (30x18x11mm) and it weighs 4.5g.

Each MR005 output is controlled by one R/C channel (e.g one switch on Tx27v2). Receiver state (servo

position or on/off setting) is saved once a minute and restored when the receiver is switched on. This

allows MR005 to be switched on without the transmitter being switched on.

MR005 requires binding with your transmitter before use. All versions of MR005 are manual bind so will

not go into bind mode if the transmitter is not switched on. Once bound, the transmitter should normally

be switched on before the MR005.

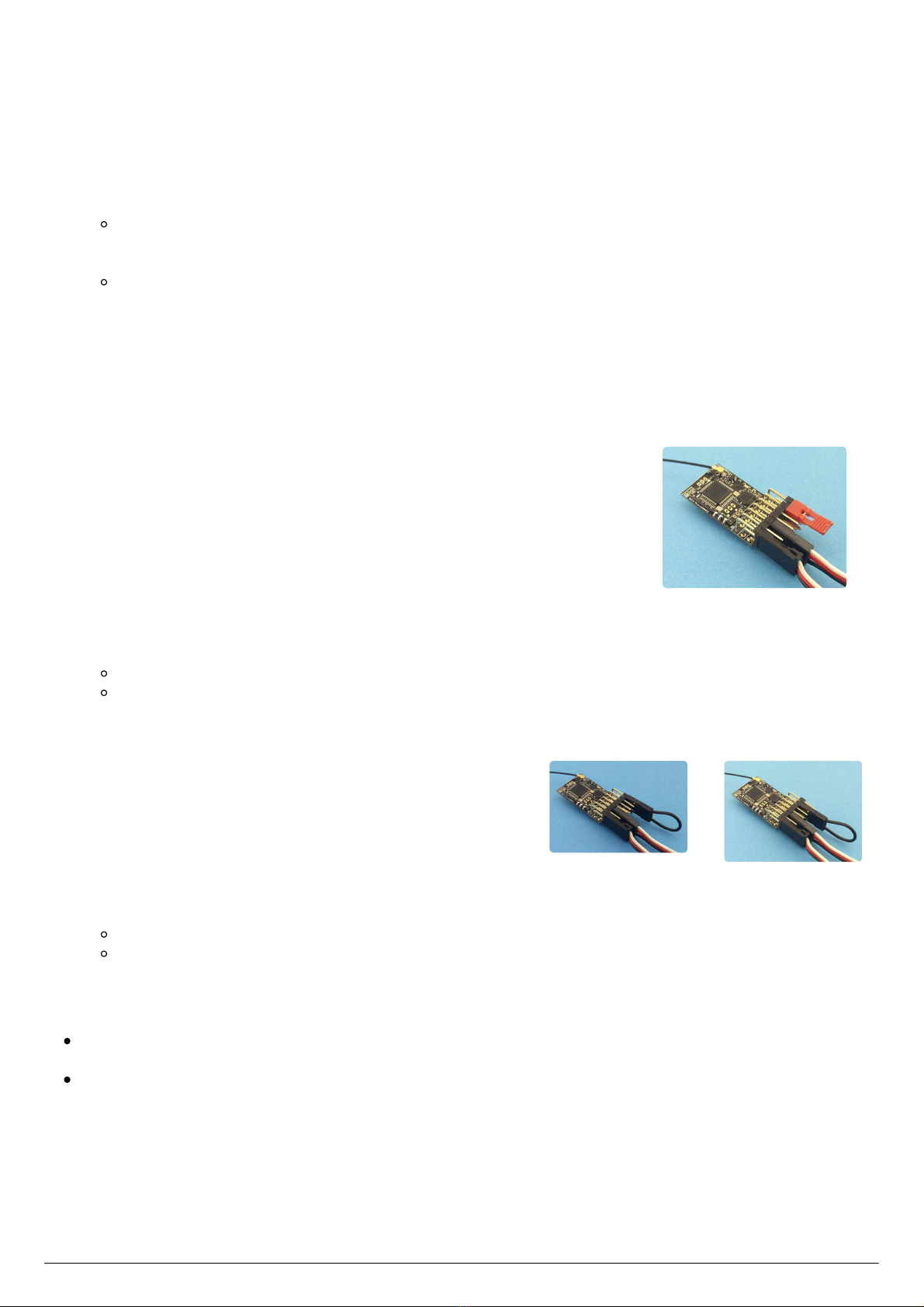

The MR005 free-air range, when used with a Micron low-power transmitter, is 50m-60m and

approximately 200m when used with a full-power (100mW) transmitter. This range will be reduced

indoors due to absorption by furniture / fittings and reflections from metal surfaces. Range is also

reduced if the receiver aerial is in a metal enclosure. Ideally, the aerial should be placed outside an

enclosing box and clear of any metal. The active part of the aerial is the last 30mm and this needs to

'see' the transmitter. The MR005 aerial should not be cut short or made longer as this will affect

operation of the receiver. It is important to perform a range check after installation to ensure you have

full control at all positions around the layout.

Features

Compatible with all DSM2 and DSMX transmitters with up to 10 R/C channels (only 7 used in the

standard MR005 versions, both Micron model rail and aero model stick type transmitters.

3.45V to 8.4V working voltage range - 5 NiMH cells is ideal.

All outputs have a 220 ohm series resistor which allows direct connection of a low-current LED.

Servo outputs are reversible and end-points may be adjusted.

Outputs maintain current setting on signal loss and are saved every minute so that they can be

restored next time the receiver is switched on.

The CPU LED is repeated to P8 (rear JST-ZH socket or solder pads, depending on the MR005

version).

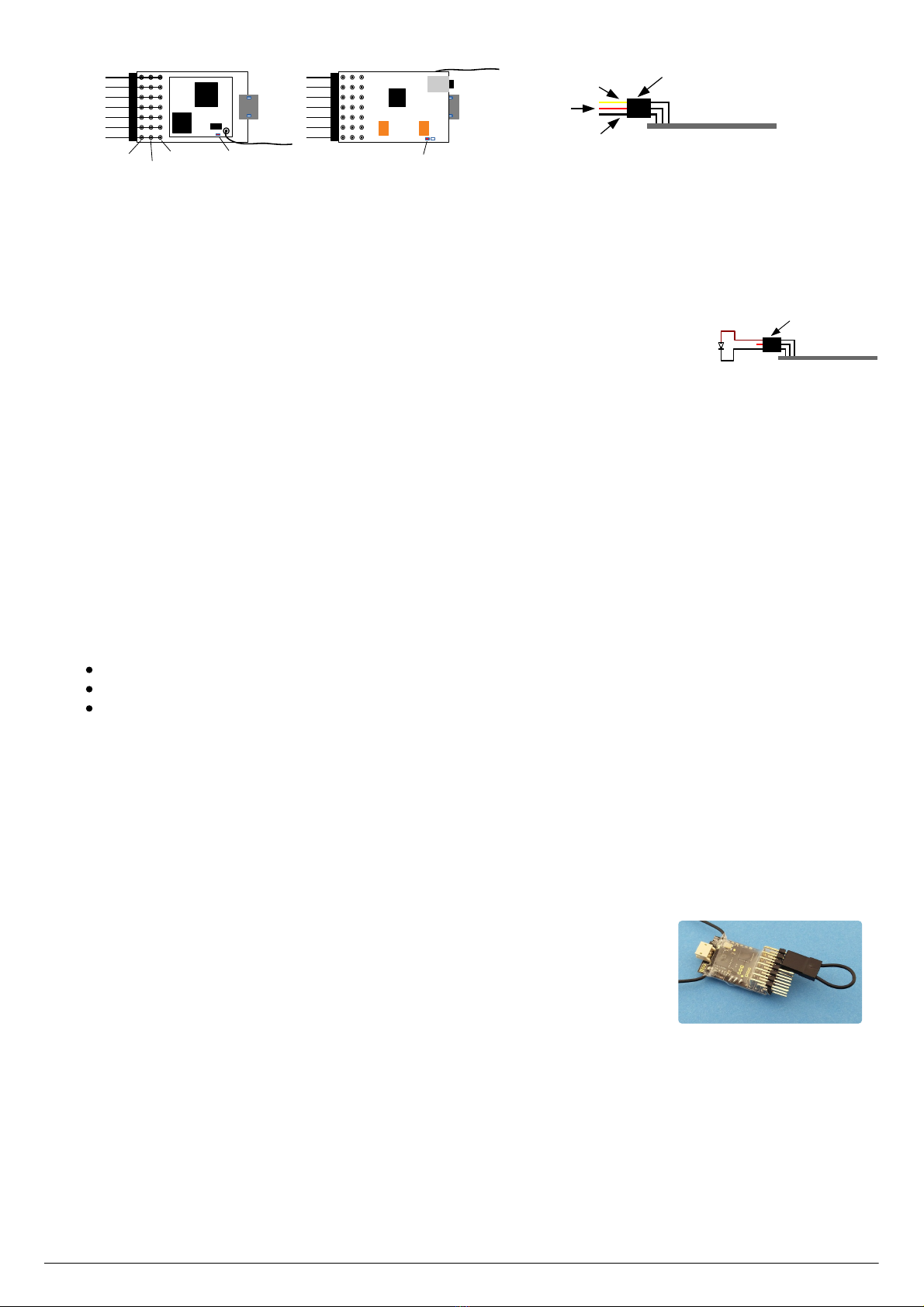

Connections and Indicators

MR005 has 7 sets of output pins which can be used for servos (MR005-7S) or LEDs for colour light

signals or trackside lighting (MR005-7X). The pin sets, numbered from the top of the diagram below, are

0.1" pitch to take standard R/C plugs.