4

MICRONAIR MICROMISER 12 & 16 ATOMISERS FOR USE ON UAVs

3. INSTALLATION

3.1. Atomiser

Many different configurations of UAV (multi-rotor, fixed-wing etc) can be used for

aerial spraying. The following points provide general guidance on the installation of

Micromiser atomisers but are not intended to make specific recommendations. It is

the responsibility of the installer to establish the optimum placement of atomisers

and to carry out trials to assess the spray distribution on the target.

Atomisers are normally mounted on booms extending laterally from the structure

of a multi-rotor UAV or below and slightly behind the trailing edge of a fixed-wing

UAV.

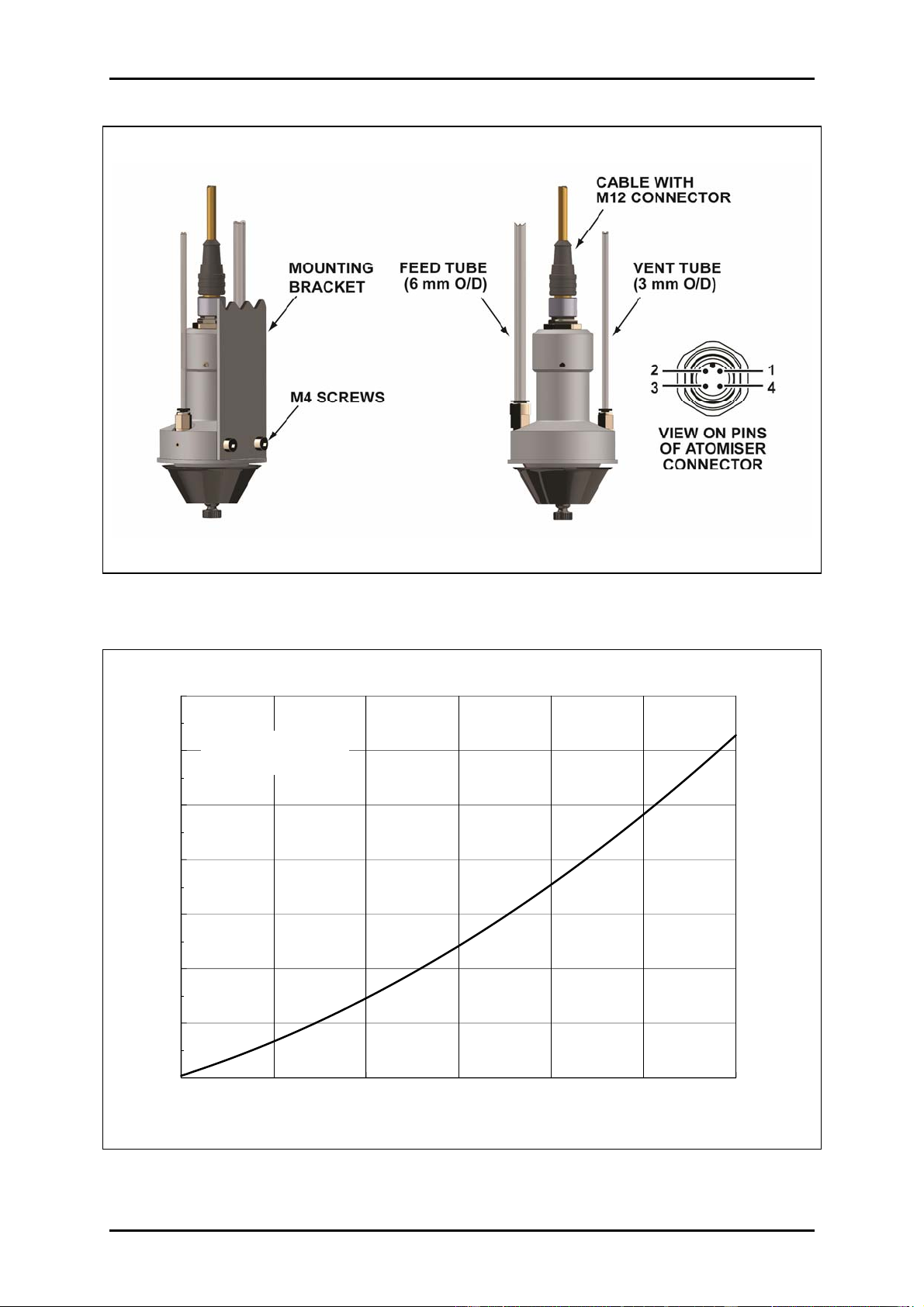

Each atomiser should be attached to a mounting bracket on the boom with two

M4 screws in the tapped holes in the side of the atomiser housing (25 mm

between hole centres) as shown in Fig. 3. M4 x 12 mm stainless steel cap head

screws are supplied with the atomiser and these are suitable for a bracket with a

thickness of 2 – 6 mm. If alternative screws are used these should also be

stainless steel.

The boom structure and bracket must be sufficiently rigid to avoid excessive

vibration in flight.

The booms must be positioned to provide adequate clearance under the

atomisers whilst the UAV is resting on the ground or manoeuvring during take-off

or landing. If necessary, the booms should have sufficient dihedral angle to

maintain ground clearance.

The orientation of the atomisers depends upon the direction and speed of flight of

the UAV. In the case of a fixed-wing UAV or a multi-rotor UAV that flies in only

one direction and sprays at a relatively high airspeed (>10 km/hr) the atomisers

should be mounted with the axis of the motor horizontal with the disc at the rear.

This is similar to the installation of rotary atomisers on conventional agricultural

aircraft and helicopters. In the case of a UAV that reverses its direction of flight

(relative to the airframe) at the end of each spray run or a UAV that will spray at

low airspeeds the atomisers should be mounted with the axis of the motor vertical

with the disc downwards.

3.2. Liquid Feed

The liquid feed to the atomiser is by a tube connected to the inlet fitting on the face

of the housing as shown in Fig. 3. The standard fitting supplied with the atomiser is

a push-fit type that accepts a 6 mm outside diameter flexible tube. If required, this

fitting can be replaced with an alternative type with a M5 male thread to screw into

the atomiser housing.

Spray liquid is fed to the atomiser by means of a pump provided by the installer.

This can either be a positive displacement type (eg a gear pump) with a speed

controller to adjust the output to provide the required total flow rate or a centrifugal or

diaphragm type with a flow control valve. It is recommended that the flow control

valve should be fitted in a by-pass line to return excess flow from the pump to the

tank.