Microsensor MPM4706 User manual

Other Microsensor Transmitter manuals

Microsensor

Microsensor MPM483DM User manual

Microsensor

Microsensor MPM426W Series User manual

Microsensor

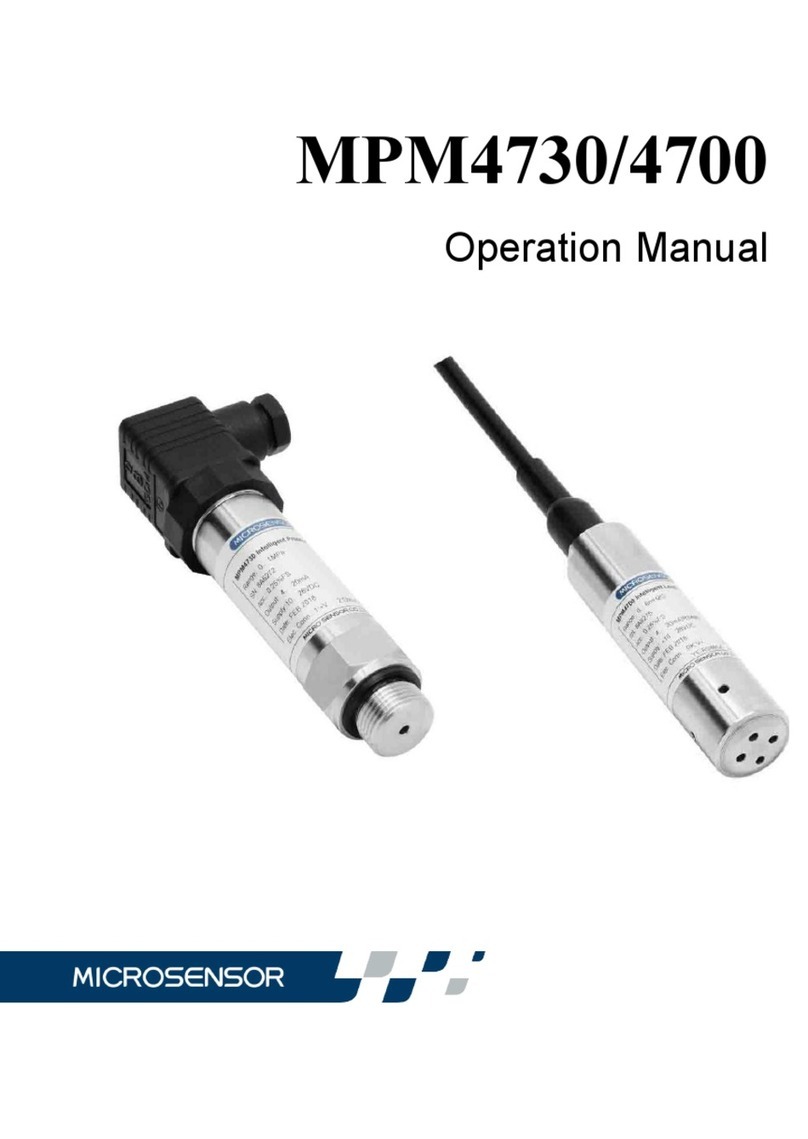

Microsensor MPM4730 User manual

Microsensor

Microsensor MPM489WZ4 User manual

Microsensor

Microsensor MPM489W User manual

Microsensor

Microsensor MPM4841 User manual

Microsensor

Microsensor MPM436W User manual

Microsensor

Microsensor MDM490 User manual

Microsensor

Microsensor MPM480 User manual

Microsensor

Microsensor MPM489WZ3 User manual

Popular Transmitter manuals by other brands

Geo

Geo Web Pack quick start guide

Inovonics

Inovonics EchoStream EN1210W installation instructions

IKONNIK

IKONNIK KA-6 quick start guide

Rohde & Schwarz

Rohde & Schwarz SR8000 Series System manual

Audio Technica

Audio Technica UniPak ATW-T93 Installation and operation

NIVELCO

NIVELCO EasyTREK SCA-300 Series Programming manual