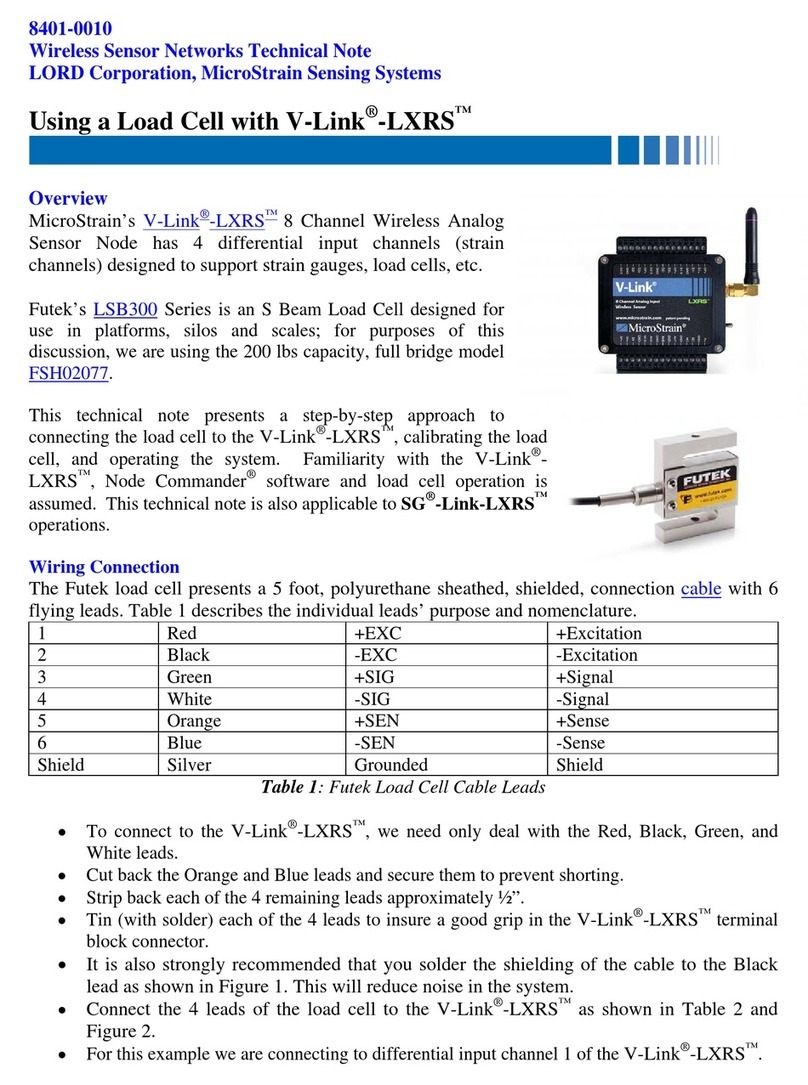

Quick Start Guide

MIP Soft & Hard Iron Calibration

3DM-GX3-25 (fw version 2.0.00 and above)

3DM-GX3-35

3DM-GX3-45

Overview

Most models of the 3DM-GX3®series contain a magnetometer. The magnetometer values are

available as fully calibrated outputs and are also used to correct heading drift in the Orientation

Matrix, Euler Angles and Quaternion outputs. The 3DM-GX3®has been carefully designed to

eliminate as many ferro-magnetic components as possible to prevent distortions in the readings

of the earth’s magnetic field which can cause errors in the magnetometer output. In addition, the

magnetometer is factory calibrated on non-magnetic stages in order to compensate for any

remaining internal sources of error. However, these measures can only compensate for error

sources that are internal to the device; they cannot compensate for errors that may be introduced

externally by mounting structures or adjacent devices. Careful mounting of the 3DM-GX3®can

avoid external magnetic anomalies caused by sources such as coils, magnets, and ferrous metal

structures and mounting components (steel nuts and bolts). Often these sources are hard to avoid

or are hidden and so a field calibration of the magnetometer after final installation is highly

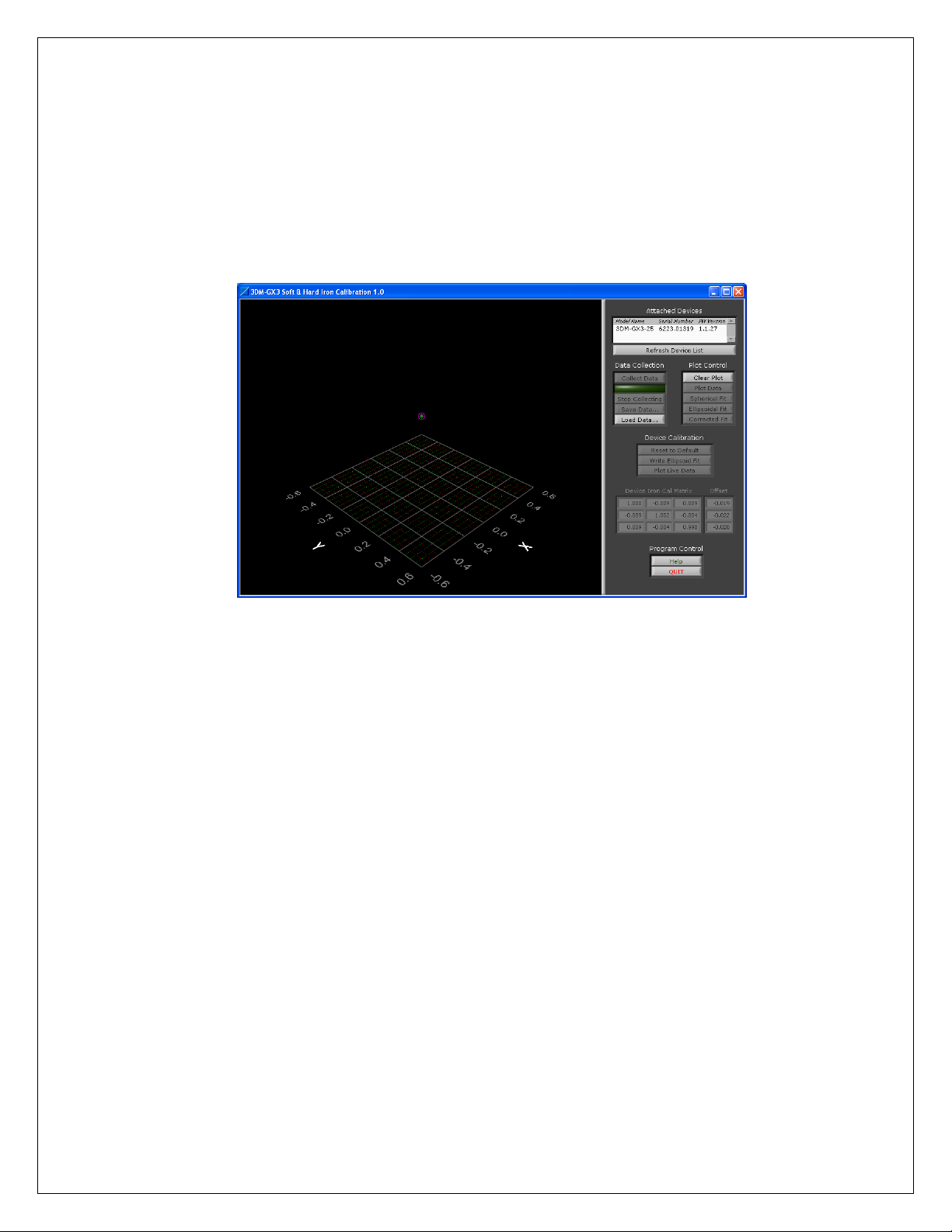

recommended. This can be accomplished using MicroStrain’s MIP Soft & Hard Iron

Calibration software.

Important

If you have a 3DM-GX3®-25 with a firmware version that is lower than 2.0.00, you need to use

the 3DM-GX3®Soft & Hard Iron Calibration. If you have version 2.0.00 or above, you may use

either 3DM-GX3®Soft & Hard Iron Calibration or the MIP Soft & Hard Iron Calibration

software.

Caution

Starting with 3DM-GX3®firmware version 1.1.27, the user has the option of turning off the

heading correction and/or the magnetometer. The default setting is to have both turned on.

Please make sure the magnetometer is turned ON before calibrating.

Instructions

Before starting, make sure you have installed the MIP Soft & Hard Iron Calibration software

from the installation CD or from the installer downloadable at www.microstrain.com.

1) Connect the 3DM-GX3®to your computer using either the RS-232 communication cable

and power supply or the USB communication cable. If you have not already done so,

follow the instructions in the 3DM-GX3®Quick Start Guide on the installation CD to

make sure the device is properly installed and communicating with your computer.