Mid-West

Instrument

Installation and Operating Instructions

Supersedes IM142/02

d r s t e r l i n g h e i g h t s , m i 4 8 3 1 4

Wednesday, October 24, 2018

1. Safety

Before installing verify compatibility to the process

media and temperature in contact with the wetted

parts. Incompatible media and / or operation at

temperature extremes can cause premature

degradation of materials which could result in

safety risk to personnel.

Verify the selected pressure range (differential

pressure and working pressure) and the switch

ratings are within specification for your application.

arning! Remaining media may result in a

risk to personnel, environment etc.

Use sufficient precautionary

measures when removing and

transporting the product.

1.1

Intended use: The indicating / non-indicating

differential pressure s itches are used for

monitoring differential pressures in industrial

applications. The manufacturer shall not be liable for

any claims if the product is used in applications

contrary to the intended use.

1.2

Personnel: Personnel installing and putting this

instrumentation into service shall be suitably trained

and qualified in accordance ith local codes,

practices and regulations.

PRODUCT DESCRIPTION

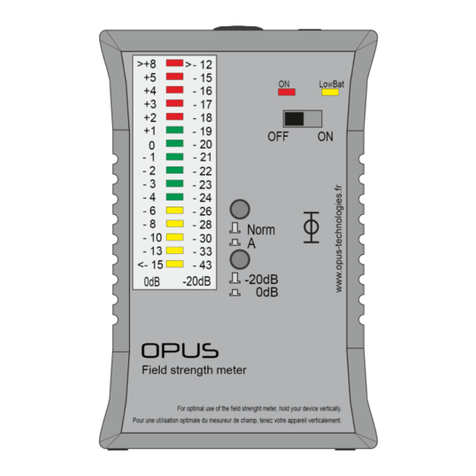

The Model 142 “Delta Meter”® is a differential pressure

instrument available as a s itch, gauge, or both. A

flexible elastomer diaphragm and calibrated range spring

are moved by differential pressure. A magnet, coupled

ith the diaphragm, transmits motion through the all

of the pressure housing to a follo er magnet attached to

an indicating pointer. The rotation of the follo er

magnet causes the pointer to track movement of internal

driver magnet and indicate differential on the dial scale.

When equipped ith s itches, a contact is made or

broken by the magnetic field of the internal magnet. See

Bulletin ELECIM_142 Series/latest for gauges ith

s itches.

The diaphragm is totally supported upon reaching full

travel in either direction, providing full over-range

protection to rated orking pressure.

INSPECTION

Before installation check the product label on each

instrument against the receiving paper ork and the

intended application for correct part number, materials

of construction, orking pressure, dial range, etc. If

equipped ith s itches, check electrical rating, type of

enclosure, etc. Inspect for shipping damage and, if

damaged, report it immediately.

NOTE - Before attem ting re airs contact your local

Mid-West Re resentative or our factory. Failure to do

so will void any warranty.

DRIVER

MAGNET

FOLLOWER

MAGNET

DIAPHRAGM RANGE

SPRING

HIGH LOW