Installation and Service Instructions

Midco®International Inc.

4140 West Victoria Street

Chicago, Illinois 60646

toll free 866.705.0514

tel 773.604.8700

fax 773.604.4070

web www.midcointernational.com

8471 34

HMA 2 &

HMA 2A

DIRECT FIRED MAKE-UP AIR BURNERS are used in

industrial and commercial applications to maintain the

desired environmental temperatures required by critical

processes i.e. health purposes, production systems,

quality control, comfort and loss prevention where it

is necessary or required to exhaust large amounts of

conditioned air.

Make-up Air Systems used as stand alone heating

systems or operating in combination with central heating

plants systems can be cost effective in three ways: 1)

reducing the initial expenditures, 2) tempering incoming

air which may extend the life of expensive central heating

plants and 3) reducing excessive equipment cycling or

premature component failures due to increased heating

demands.

Our innovative two stage combustion burner is not just a

modification or improvement of the old, but a completely

new approach to direct-fired combustion. The two-stage

combustion improves control of the flame process, meets

or exceeds the new ANSI Standards while outperforming

the competition. By incorporating two separate flames

within the burner combustion zone, the flame is more

stable, shorter and cleaner, permitting the reduction of

emissions levels and allowing for higher temperature rise

and higher tolerance to varying conditions when placed in

the profile opening.

The Blue Flame Series Features and Benefits

Reduced NO2and CO Emissions: Lower emissions

levels that pass the ANSI Z83.4, Z83.18 and Z83.25 standards.

Higher Temperature Rise: The two stage combustion

process lowers NO2emissions which is the limiting factor in

temperature rise.

Increased Capacity: Up to 750,000 BTU’S per foot. (Higher

BTU levels can be achieved if ANSI Z83 Standards for CO and

NO2emissions are not of a concern. Process heaters can fire

up to 1,000,000 BTU’S a foot or more.)

Increased Differential Pressure Drop and Higher Velocities:

HMA 2 & 2A burners can operate as low as 0.05″to 1.4″W.C.

differential pressure range or in air velocity as low as 800 fpm to

4000 fpm.

Flame Stability: Two stage combustion provides better flame

stability and emission control, allowing for a shorter flame and

easier profile configuration.

Reduced Inventory Costs - HMA 2A: Single burner casting

can be fired with natural, propane or butane gas 1, reducing

burner inventory.

Reduced Shipping Costs: A smaller, lighter casting than the

competition’s, can lower your freight costs.

Turndown: 30-1 turndown can be achieved with proper

modulating controls and valves. (Higher turndown possible

depending on equipment design.)

Emission performance is application specific and may vary.

1 Consult Midco for applications using butane fuels.

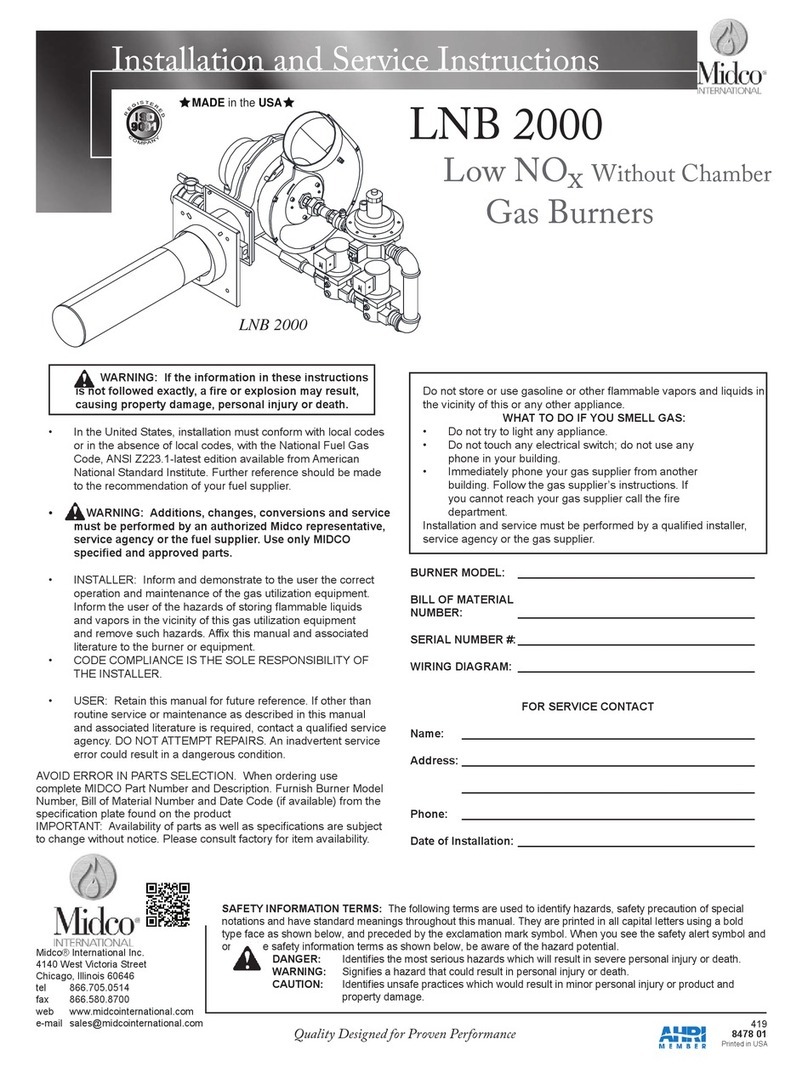

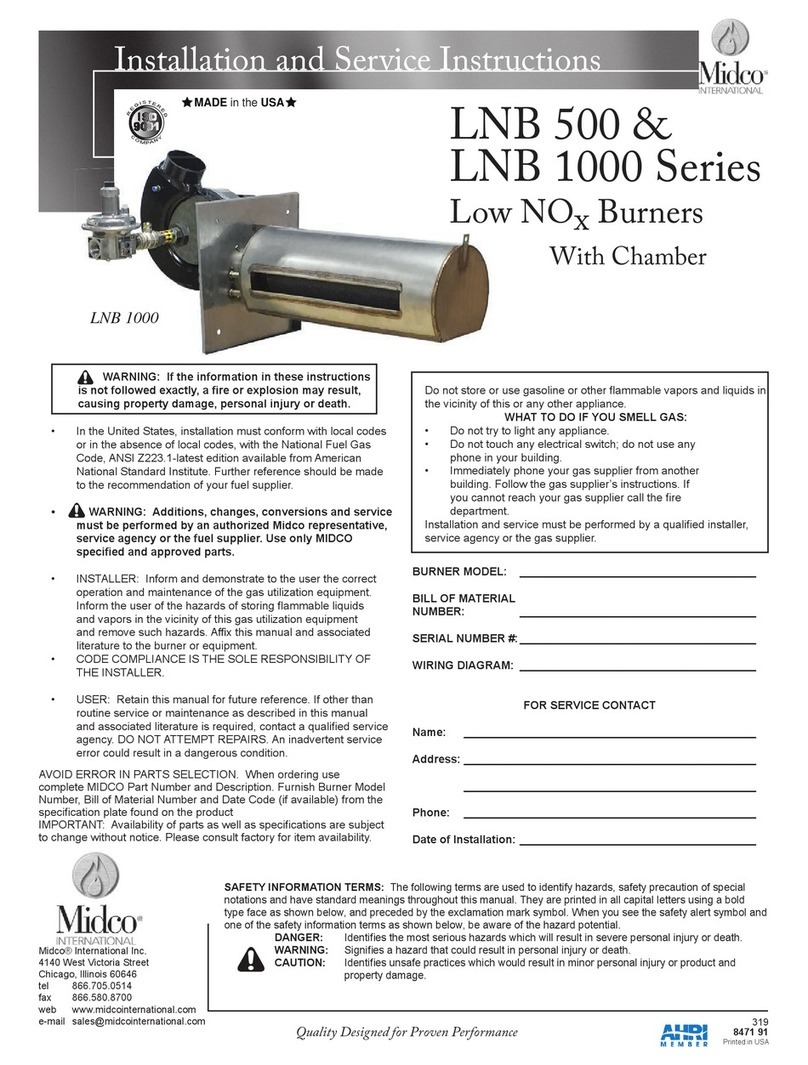

Direct-Fired Gas Burners

MADE in the USA

1219