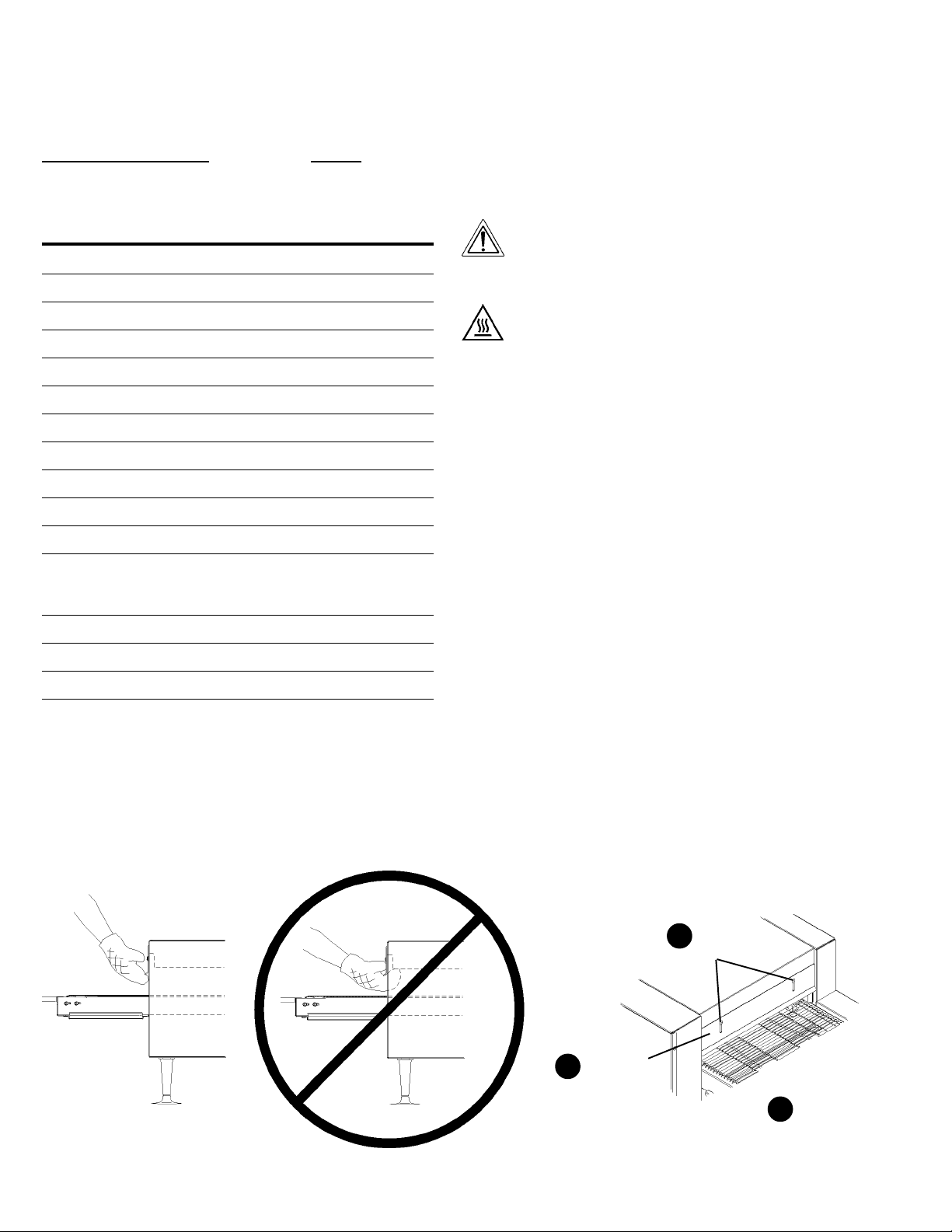

WARNING: IN CASE OF FIRE

Disconnect the oven from its power source

IMMEDIATELY. Shutting down the electrical heating

elements allows the unit to cool, making it easier to

put out the fire.

WARNING: FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE

WARNING

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR

DEATH. READ THE INSTALLATION AND

OPERATING INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

WARNING

DISCONNECT THE OVEN FROM ITS

ELECTRICAL POWER SUPPLY BEFORE

CLEANING OR SERVICING.

CAUTION

Using any parts other than genuine CTX factory

parts relieves the manufacturer of all liability.

IMPORTANT

Contact your authorized service agent to perform

maintenance and repairs. A service agency

directory is supplied with your oven.

IMPORTANT

CTX (manufacturer) reserves the right to change

specifications and product design without notice.

Such revisions do not entitle the buyer to

corresponding changes, improvements, additions or

replacements for previously purchased equipment.

RETAIN THIS MANUAL FOR FUTURE

REFERENCE

This manual provides detailed information for the

installation and operation of your conveyor oven. It

also contains information to assist the operator in

diagnosing problems in the event of a malfunction.

This manual is an important tool for the operator and

should be kept readily available.

© 1999 CTX, A Middleby Company

CTX 1400 Toastmaster Drive Elgin, IL 60120 USA (847)741-3300 FAX (847)741-4406

Middleby Corp 24-Hour Service Hotline 1-800-238-8444

www.middleby.com

is a registered trademark of CTX, A Middleby Company. All rights reserved.

TABLE OF CONTENTS

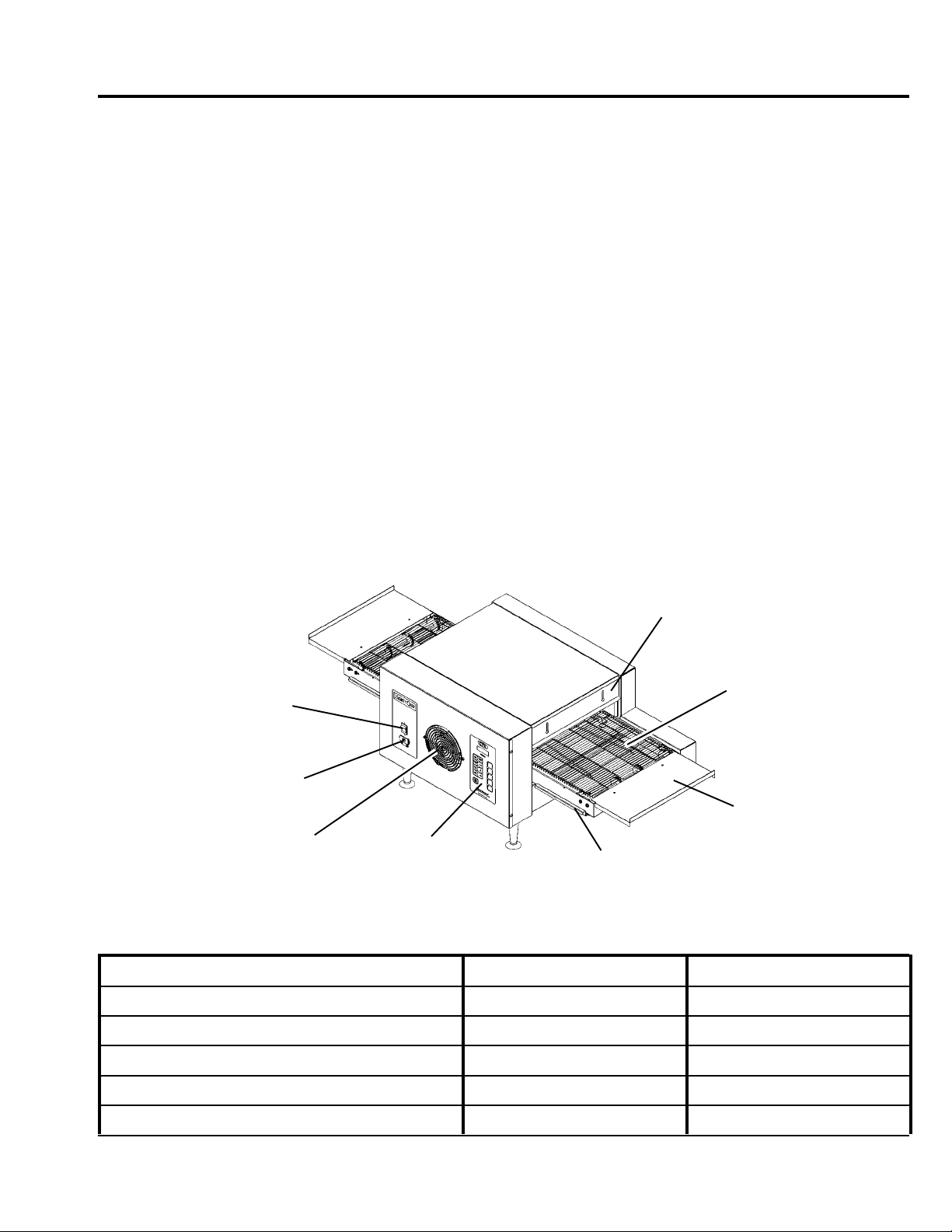

SECTION 1

DESCRIPTION ............................................... 1

A. Features ........................................................... 1

B. Component Location and Function ................... 1

C. Electrical Specifications .................................... 1

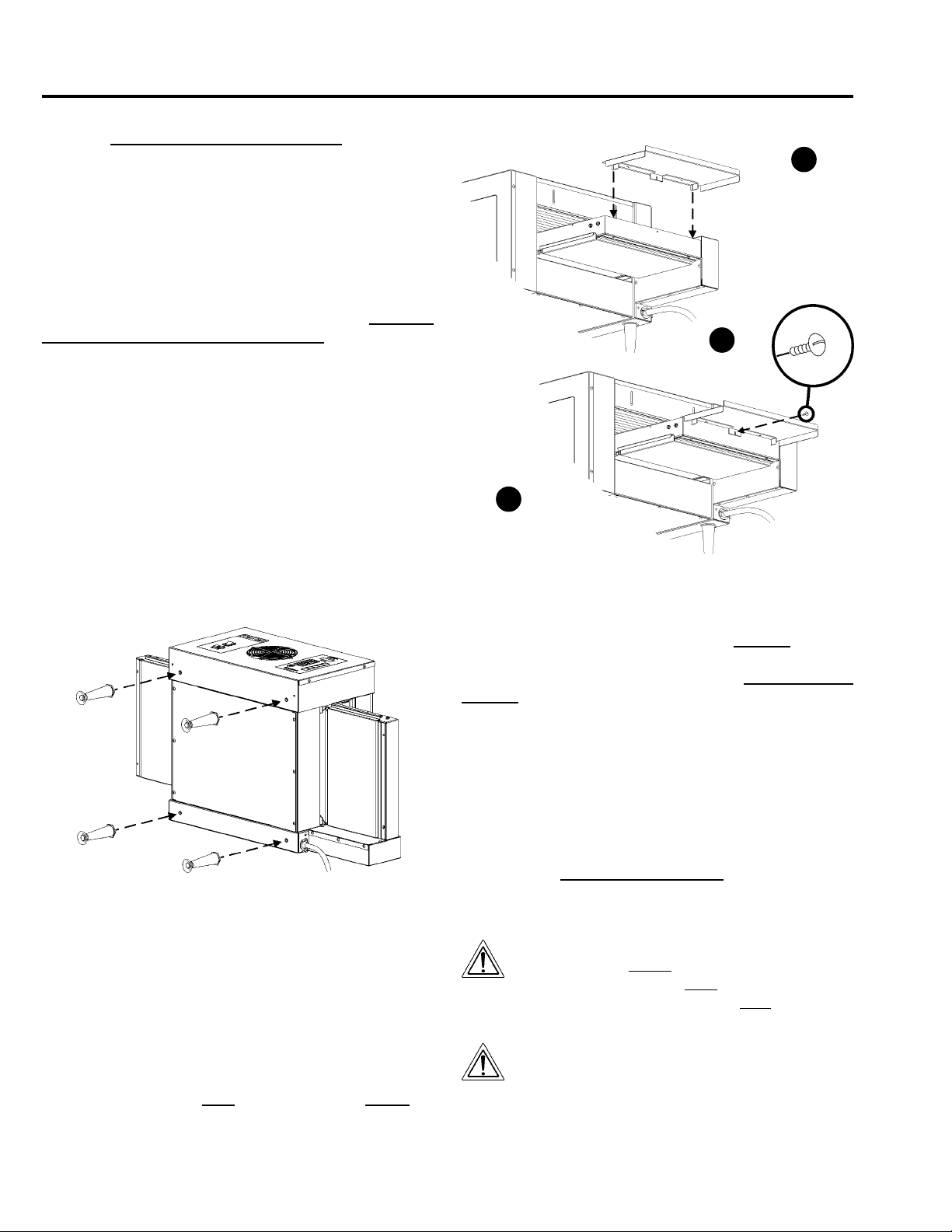

SECTION 2

INSTALLATION ............................................. 2

A. Installation Options and Kit Availability ............. 2

B. Assembly .......................................................... 2

C. Electrical Connection ........................................ 2

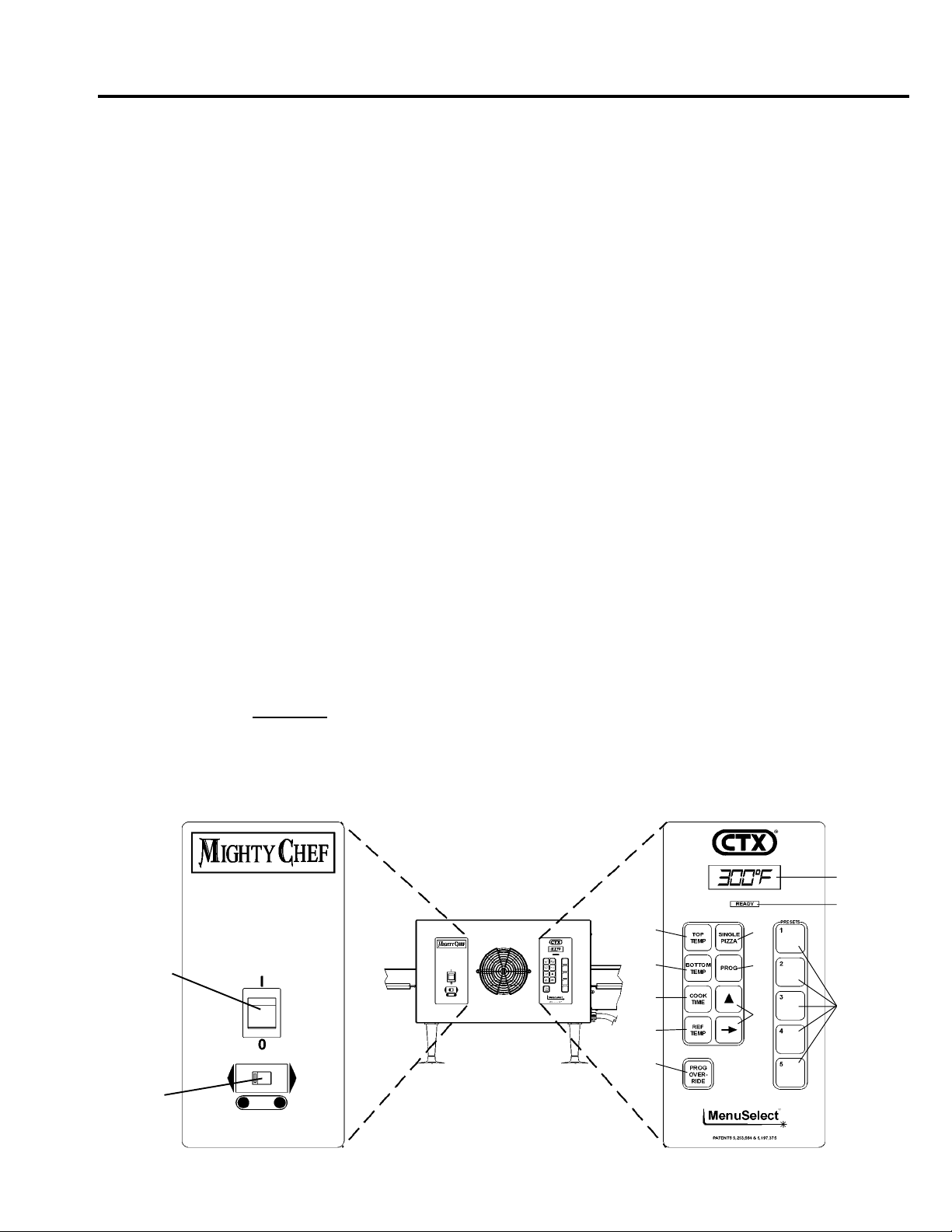

SECTION 3

OPERATION .................................................. 3

A. Location and Function of Controls .................... 3

B. Daily Startup Procedure ................................... 3

C. Operation .......................................................... 4

D. Shutdown Procedure ........................................ 4

E. Programming Preset Menu Selections ............. 5

F. Cooking Time and Temperature Guidelines ..... 6

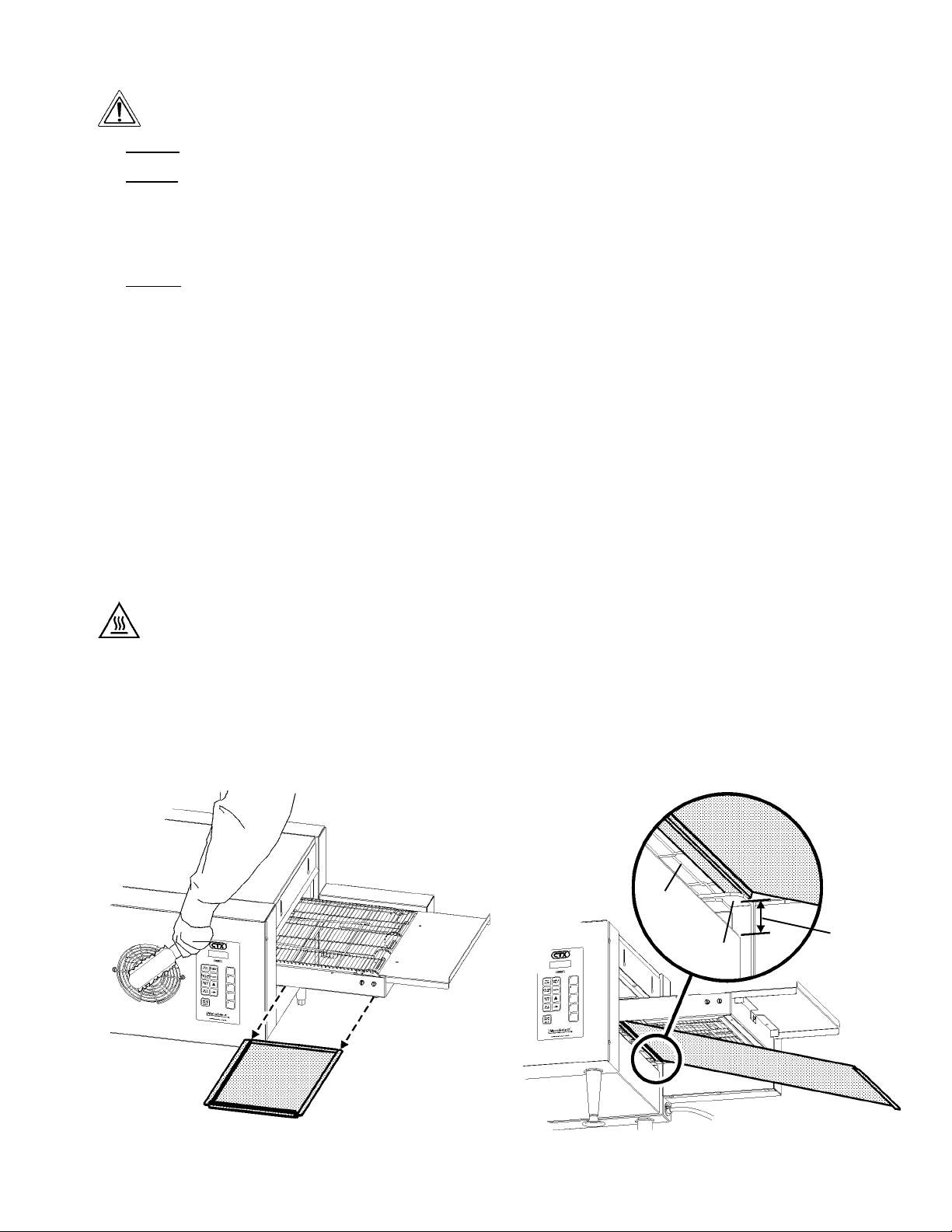

G. Draft Curtain Adjustment .................................. 6

H. Daily Cleaning .................................................. 7

I. Display Messages and Error Codes ................. 8

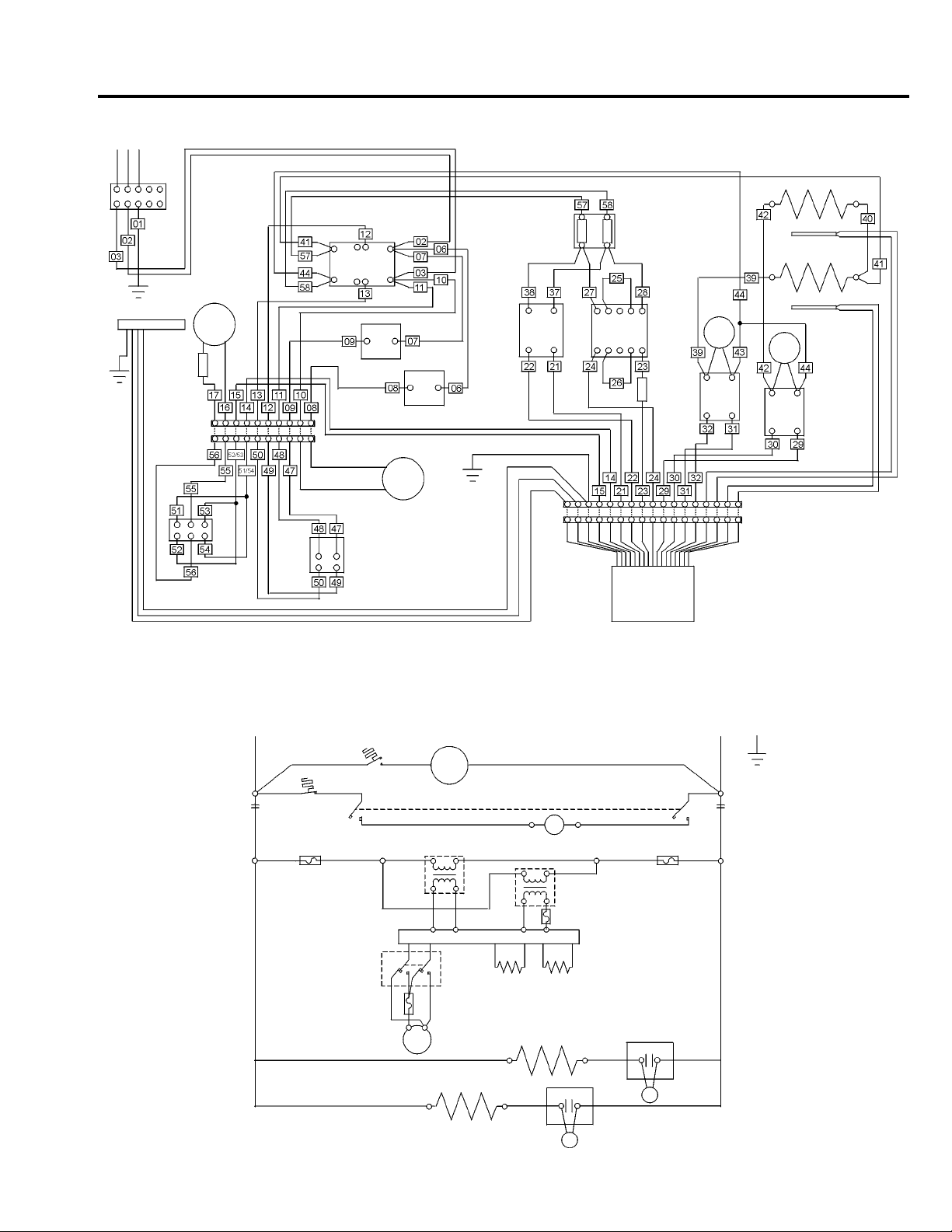

SECTION 4

ELECTRICAL WIRING DIAGRAMS .............. 9

Wiring Diagram and Schematic, Models

TCO21140063 (208V) and

TCO21140066 (240V), 1-Phase.............................. 9