7

www.roadwidener.com

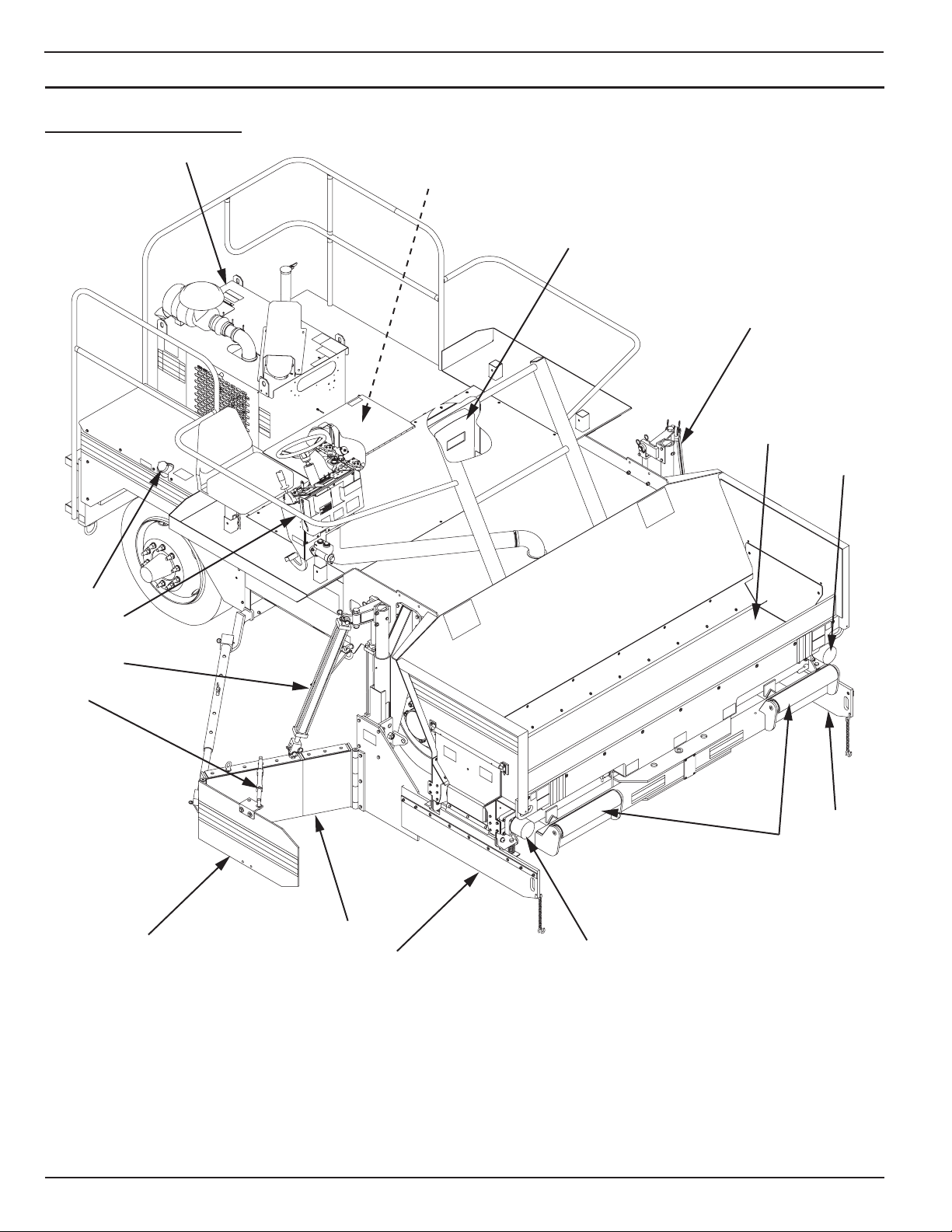

Model SPD-6

1.3 WArrAnty

Midland warrants to the original purchaser only,

that each part of the Road Building Machine, or

components, or the other manufactured items, sold

herein, under normal use and service, shall be free

from defects in workmanship and material for 180 days

or 500 working hours, from initial start-up, whichever

occurs rst, except that this warranty shall not apply

to tires, engines, batteries, manufactured hydraulic

components, which items shall be subject only to the

original manufacturer’s warranty. No adjustment shall

be made for defective items unless notice is given in

writing within ten days after the defect is noted and the

equipment is immediately taken out of service. Use of

equipment thereafter shall constitute acceptance and

waiver of the alleged defects.

This warranty shall be fullled by Midland repairing or

replacing at its factory, products or parts that have been

returned to it with transportation charges prepaid and

that appear to its satisfaction to have been defective in

workmanship or material.

THE FOREGOING SPECIFIC WARRANTY IS IN

LIEU OF ANY OTHER EXPRESSED OR IMPLIED

WARRANTIES INCLUDING ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR USE, AND ANY OTHER OBLIGATION

ON PART OF MIDLAND. MIDLAND SHALL NOT BE

RESPONSIBLE UNDER THIS WARRANTY FOR

ANY LOSS OF USE OF THE VEHICLE, LOSS OF

TIME, INCONVENIENCE, COMMERCIAL LOSS OR

CONSEQUENTIAL DAMAGE.

NO AGENT, EMPLOYEE OR REPRESENTATIVE OF

MIDLAND HAS ANY AUTHORITY TO BIND MIDLAND

TO ANY AFFIRMATION, REPRESENTATION OR

WARRANTY CONCERNING THE MACHINE SOLD

UNDER THIS CONTRACT NOT STATED WITHIN, AND

UNLESS AN AFFIRMATION, REPRESENTATION OR

WARRANTY MADE BY AN AGENT, EMPLOYEE OR

REPRESENTATIVE IS SPECIFICALLY INCLUDED

WITHIN THIS WRITTEN AGREEMENT, IT SHALL

NOT BE ENFORCEABLE AGAINST MIDLAND.

1.4 enGIne WArrAnty

To receive full warranty protection, All John Deere

engines must be registered with John Deere company.

To register your engine with John Deere, please

visit the website: https://jdpswarrantyreg.deere.com/

WarrantyReg/viewRegistration.do.

Warranty Period is normally 2000 engine hours or 2

years from the date of purchase which ever occurs rst.

ALL WARRANTY REPAIR REQUESTS MUST BE

RECEIVED THROUGH AND PROCESSED BY

SUPERIOR DIESEL INC. TO AUTHORIZE LOCAL

JOHN DEERE DEALER REPAIRS, CONTACT

SUPERIOR DIESEL INC AT PHONE NUMBER

1-888-803-9175/SERVICE OR THROUGH E-MAIL AT

UNAUTHORIZED REPAIR MAY VOID ANY ENGINE

WARRANTY.”

ENGINE WARRANTY

To receive Full Warranty Protecon, all JD Diesel engines must be

Registered with John Deere.

Register This Engine with John Deere at:

hps://jdpswarrantyreg.deere.com/WarrantyReg/viewRegistraon.do

Warranty Repairs

(WITHIN WARRANTY PERIOD –normally - 2000 HRS/2 YRS. WHICHEVER OCCURS FIRST)

PM-0159

ALL JOHN DEERE WARRANTY REPAIR REQUESTS MUST BE

RECEIVED THROUGH and PROCESSED by SUPERIOR DIESEL INC.

In order to AUTHORIZE LOCAL John Deere DEALER Repairs.

CONTACT: SUPERIOR DIESEL INC.

(UNAUTHORIZED REPAIR MAY VOID ANY WARRANTY)