www.roadwidener.com

2

Model SP-8 &10

1. IntroduCtIon And WArrAnty

1.1 IntroduCtIon

Congratulations on your purchase of the Midland

Machinery SP machine. This SP machine has

been designed and manufactured to the strictest

specications. It is our utmost desire that you achieve

success and are rewarded years of service from your

equipment purchase.

Carefully examine your machine upon receipt. Report

any damage immediately to the freight carrier and

register any claim. Should any material or manufacturing

defects be discovered, report your ndings to our

service department along with the model, serial number

and date of purchase. We want to know that you are

satised with the machine. As always, we welcome

input on how our products can be improved to serve

you better.

Read and understand this manual before using your

machine and follow all of the safety instructions. Keep

this manual with your machine at all times.

Some components may have separate operation and

maintenance manuals. Where this manual indicates

that you should read another manual, and you do

not have that manual, contact Midland Machinery for

assistance.

This manual explains the operation and routine

maintenance of the SP machine. It does not instruct

you how to transport, travel and/or operate on specic

roadways or terrain.

Information furnished in this manual does not include

all of the details of design, production, or variations

of the equipment. It does not cover all the possible

contingencies, which may arise during operation,

setup, or maintenance. Should special problems

arise, or further information be desired, please contact

Midland Machinery. This manual is provided to the SP

owner to assist in the safe operation and maintenance

of the equipment.

The text contained in this manual is for current

production models. Some instructions and maintenance

procedures may not apply to your specic unit.

Equipment modications from original design and

specications are strictly prohibited. Modications may

compromise safe operation of the machine, subjecting

users to serious injury or death and may void any

remaining warranty.

Midland Machinery reserves the right to change,

improve, modify or expand features of this equipment

at any time. Specications, models, or equipment are

subject to change without notice, and without incurring

any obligations to change, improve or expand features

of previously delivered equipment. Because of

variations in optional equipment and continued design

improvement, certain information contained within this

manual may not apply.

This Operator’s Manual does not replace, nor does its

use release the operator from observing all safety or

operating limitations as well as any applicable federal,

state, provincial or local regulations.

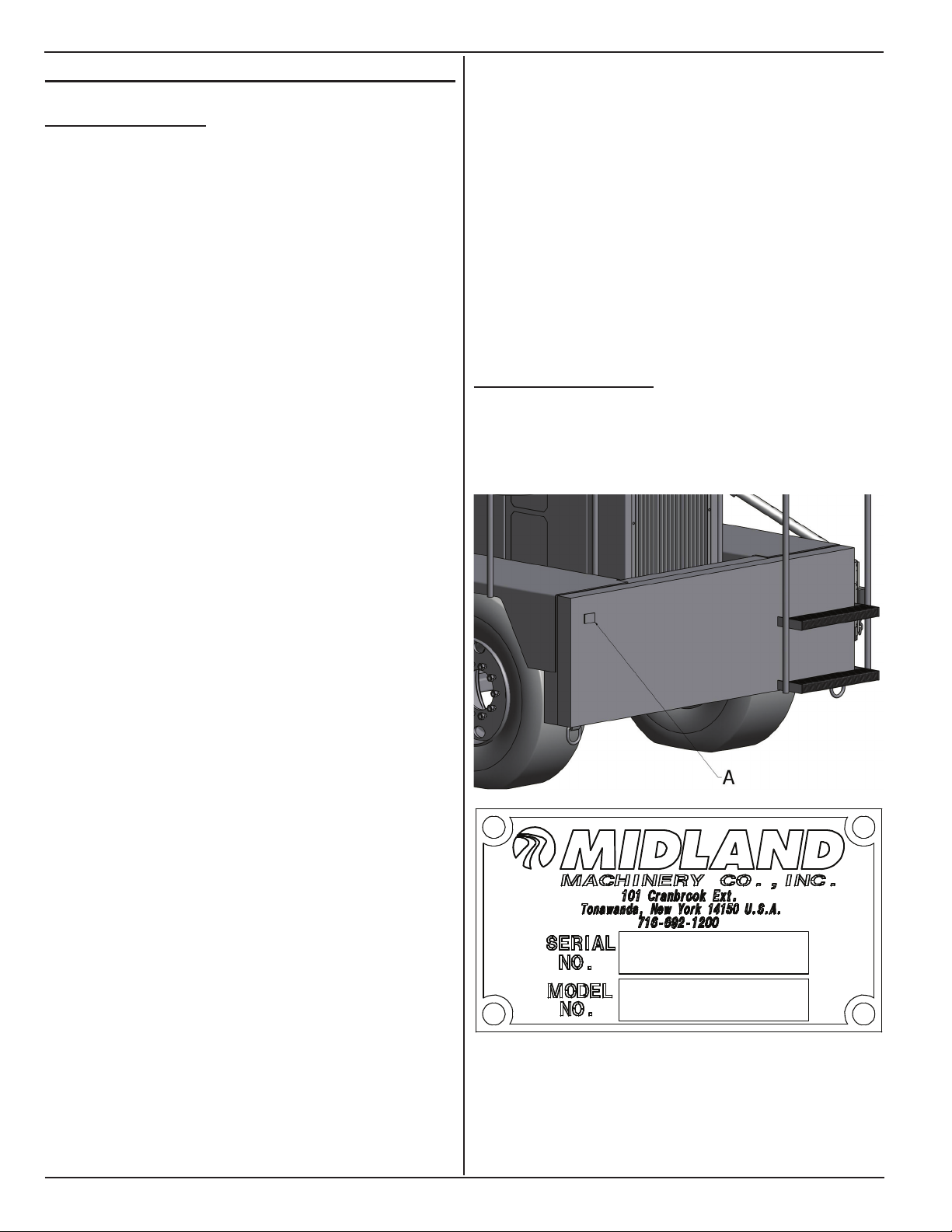

1.2 serIAl numBer

The serial number plate (A) is located on left rear

corner of the machine.