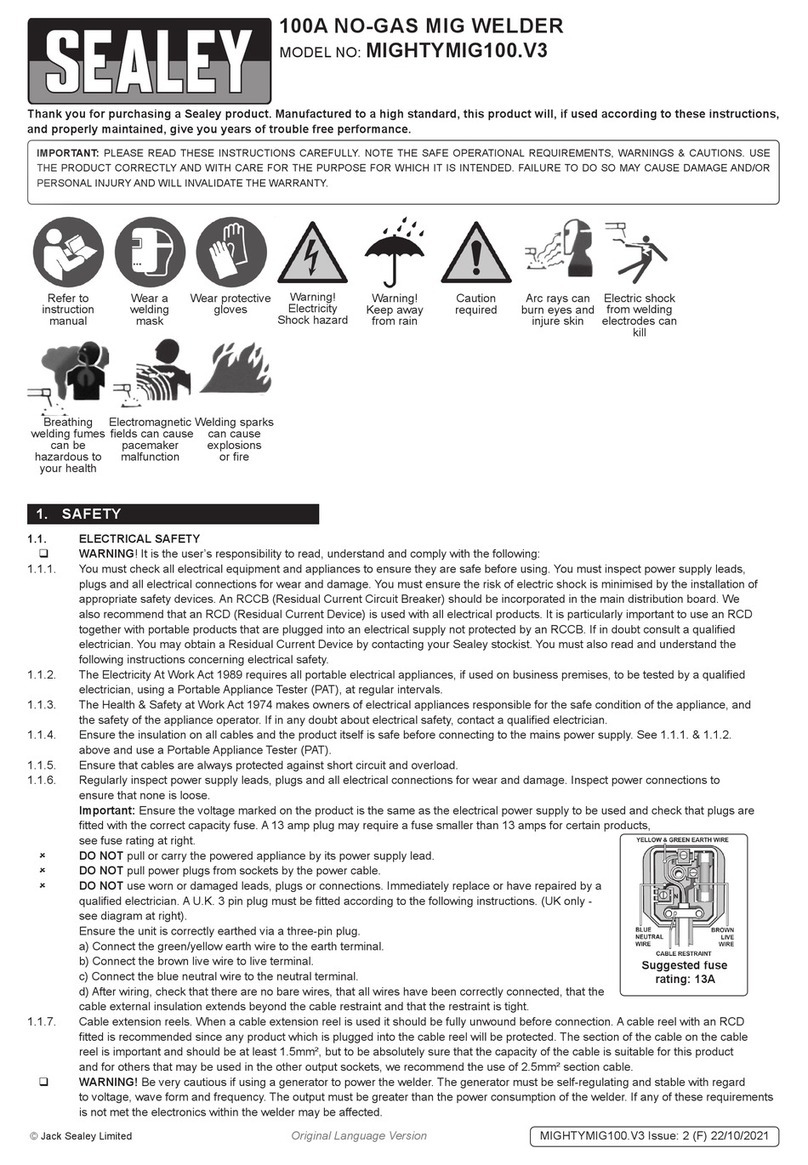

Eagle Gun Setup

INSULATION PINS

WITH COLLET PROTECTOR

Eagle Gun Setup

INSULATION PINS

(Fig. 1) (Fig. 2)

Weld

Pin

1. Seat weld pin firmly against stop.

2. Loosen these adjustment screws.

3. Slide the Leg / Foot assembly until

weld pin flange extends 1/8"- 3/16"

beyond foot (or spark shield.)

4. Retighten adjustment screw.

Adjustable

Leg

Foot

1/8"- 3/16" Protrusion

“B”

Collet

Spark

Shield

(Optional)

“B”

Stop

Weld

Pin

1. If “B” Stop is used, seat weld pin firmly

against stop.

2. Loosen these adjustment screws.

3. Slide the Leg / Foot assembly until

weld pin flange extends 1/8"- 3/16"

beyond foot (or spark shield.)

4. Retighten adjustment screw.

Adjustable

Leg / Foot

1/8"- 3/16" Protrusion

“B”

Stop

(optional)

“B”

Collet

(inside

Protector)

Collet

Protector

Collet

Protector

Insert

11 ©2005 MIDWEST FASTENERS, INC. — Eagle Pin Welding System

Continues, next page. >

3. Circuit Breaker trips when

weld is made.

4. Welder turns on, but

does not operate.

A. Shorted charge SCR.

B. Faulty printed circuit (PC) board.

A. Open circuit in weld or ground

cables.

B. Open circuit in trigger cable or

defective trigger switch.

C. Capacitors not charging.

replace transformer.

Check with ohmmeter. (Should not

show continuity in either direction.)

Replace if defective.

Repair or replace PC board.

With cables plugged into welder, touch

collet or chuck to grounded surface.

Check for “Contact” (yellow) light.

If light does not come on, repair or

replace defective cables. (NOTE:

DO NOT trigger gun while in

contact with grounded surface.)

With cables plugged into welder, hold

gun away from grounded surface

and depress trigger button. Check

for “Trigger” (green) light. If light

does not come on, repair or replace

defective trigger switch or control

cable assembly.

Check for indication of capacitor charge

on voltmeter. Replace PC board if

no charge is actually occurring.

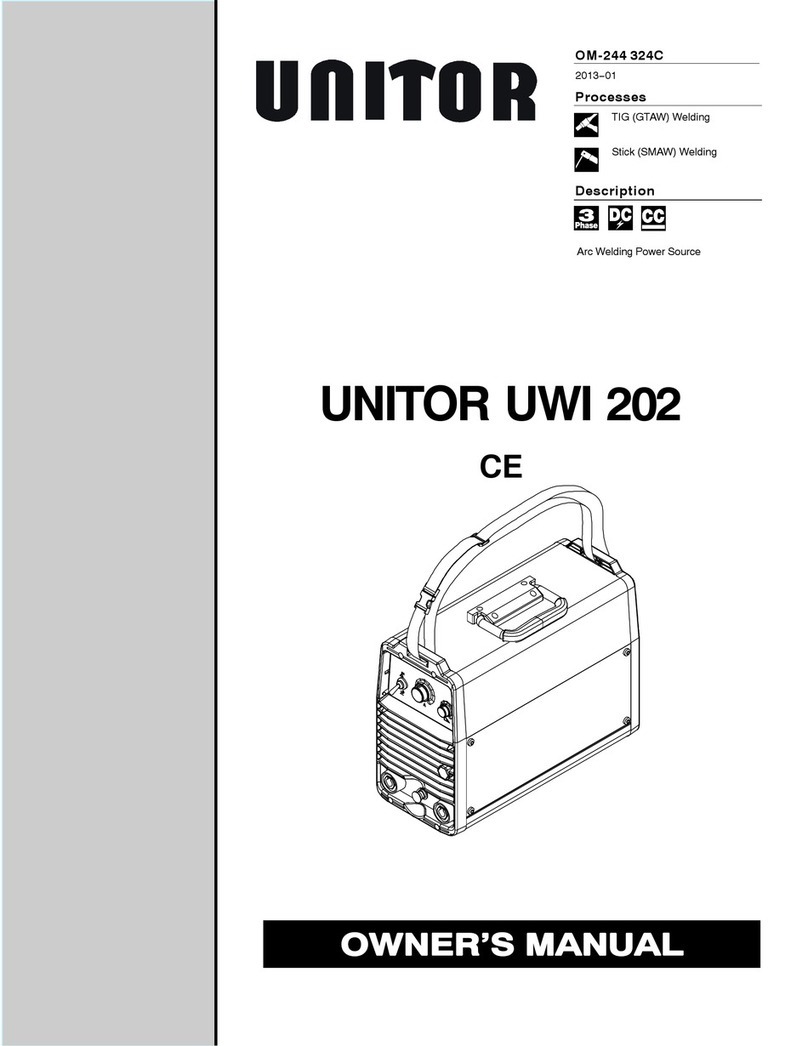

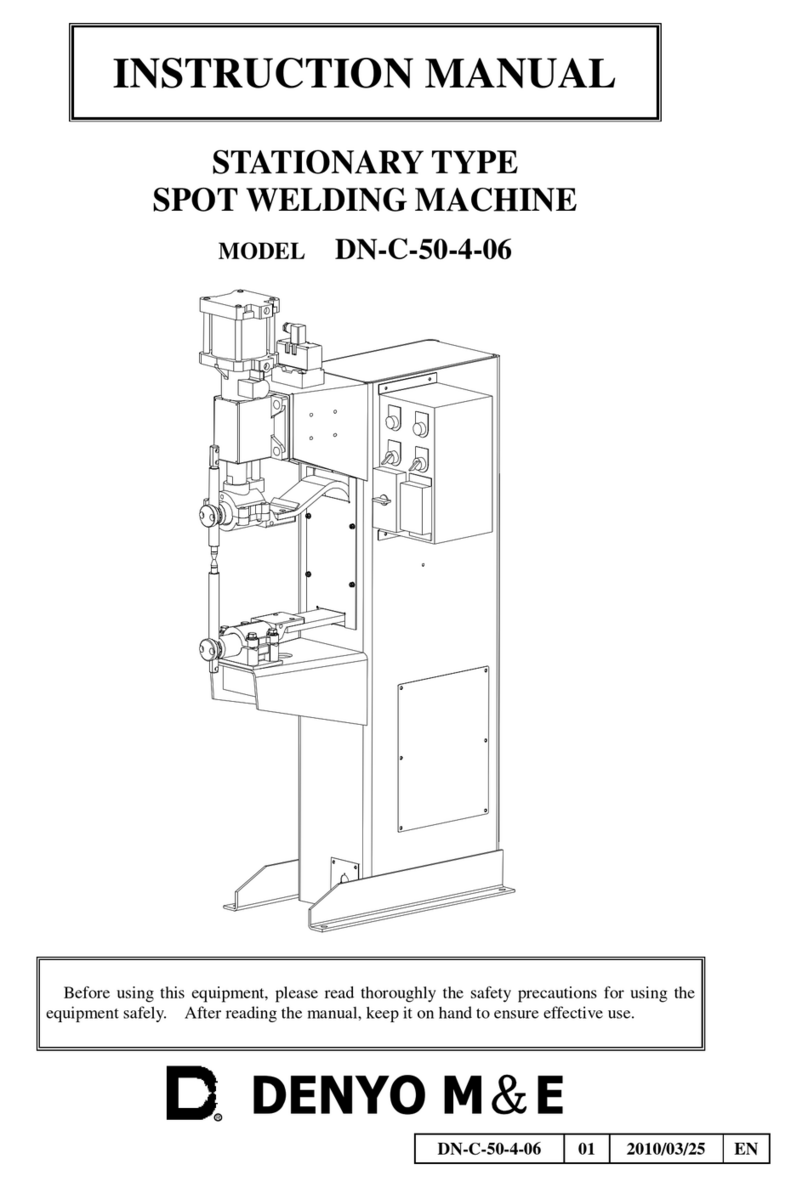

EAGLE INSTALLATION

Eagle Components

Controller

CDSW-005-00

Weld Gun

CDWG-201-06T

Ground Cable

CDGC-200-15

WELDVOLTAGE

MINMAX

VOLTAGE

CONTACT

TRIGGER

CONTROLGUN

GROUND

READY

13 ©2005 MIDWEST FASTENERS, INC. — Eagle Pin Welding System

EAGLE GUN

SPECIFICATIONS

Weight...............................1.6 pounds

(not including cables)

Pin/Stud Range .................14 ga. – 1/ 4" dia.

Weldable Materials ...........Mild Steel, Stainless,

and Aluminum

Material ............................High strength, impact

resistant, polycarbonate

Dual Cable Length............35'

5

"

4

"

2

"

Follow the process below to properly install your Eagle pin welder.

1. Carefully remove the controller, cables and weld gun from the shipping

packaging.

2. Set the Controller on a clean, dry, sturdy surface near an appropriate

voltage supply and the workpiece.