MIDWEST FASTENERS CD 100 User manual

5/2001

Ownerʼs Manual

450 Richard Street • Miamisburg, OH 45342

Phone: (937) 866-0463 • Fax: (937) 866-4174

(800) 852-8352

CD 100

Solid State

Capacitor Discharge

Stud Welding System

CD50 Stud Welder 0

CD100

Solid State

Capacitor Discharge

Stud Welding System

Owner’s Manual

• Installation

• Operation

• Maintenance

0 C

D

50 Stud Welder

©

2001

MIDWEST FASTENERS, INC.

, all rights reserved.

450 Richard Street

Miamisburg, OH 45342

Phone: (800) 852-8352

Fax: (937) 866-4174

Warranty ......................................................................................... 4

Safety Precautions .......................................................................... 5

What is Stud Welding? ................................................................... 6

How Does CD Stud Welding Differ From ARC Stud Welding? .... 6

CD 100 Overview .......................................................................... 8

CD 100 Installation ........................................................................ 9

CD 100 Setup ............................................................................... 10

Gun Set Ups

Insulation Pins........................................................................ 11

Insulation Pins with Internal Stop.......................................... 11

Weld Studs ............................................................................. 12

Weld Studs with Template Adaptor ........................................ 12

Controller Adjustment .................................................................. 13

Making A Test Weld...................................................................... 13

Weld Quality ................................................................................. 14

Preventive Maintenance................................................................ 15

Troubleshooting ............................................................................ 15

CD 100 Welder Specifications ..................................................... 18

CD 100 Welder Exploded View & Parts List ............................... 19

CD 2P Gun Specifications............................................................ 20

CD 2P Gun Exploded View & Parts List...................................... 21

CD 100 Electrical Schematic........................................................ 22

Notes............................................................................................. 23

TABLE OF CONTENTS

GENERAL

INTRODUCTION

INSTALLATION

SETUP& OPERATION

MAINTENANCE

TROUBLESHOOTING

SPECIFICATIONS

4

©

2001

MIDWEST FASTENERS, INC.

—

C

D

100 Stud Welder

WARRANTY

MODEL NO.

SERIAL NO.

SHIPPING DATE

VOLTAGE REQUIRED

All parts used in the assembly of your MIDWEST FASTENERS

Capacitor Discharge Stud Welding System are fully guaranteed for

one (1) year from factory shipment date.

Under this warranty, MIDWEST FASTENERS reserves the right to

repair or replace, at its option, defects in material or workmanship

which occur during the warranty period. Notice of any claim for war-

ranty repair must be furnished to MIDWEST FASTENERS within ten

(10) days after the defect is discovered. MIDWEST FASTENERS does

not assume liability for shipping, or liability for any labor or material

related to use of this system unless such costs are expressly authorized

in writing by MIDWEST FASTENERS.

MIDWEST FASTENERS, INC. does not warrant defects in welders,

parts or accessories resulting, from abuse, improper installation, or for

reasons beyond its control.

This warranty is valid only when welding pins an

d

/or studs approved

by or purchased from MIDWEST FASTENERS.

©2001

MIDWEST FASTENERS, INC.

—

CD 100 Stud Welder 5

SAFETY

PRECAUTIONS • Comply with all electrical, fire and other applicable codes or ordinances

in the installation and use of stud welding systems.

• Remove all combustible or volatile materials from the weld area.

Although weld splatter resulting from stud welding is normally minimal,

proper precautions should be taken when welding near or through

combustible materials to insure that sparks or weld material do not come

in contact with combustible material.

• Recommend wearing of eye protection at all times when welding.

Spectacle type frames with Shade No. 3 absorptive and filter lens and

side shields are suggested. Never look directly at the weld arc without

wearing eye shields.

• Recommend use of proper ear protection with all CAPACITOR

DISCHARGE stud welding systems. The stud welding operator and

anyone working within five (5) feet of the stud welding operation should

use ear protection devices.

• Use of protective clothing is suggested. Type of clothing will vary as to

application, weld position and stud welding being used; however, in all

cases, it should be fire resistant and sufficient to protect welding

operator from weld splatter and material.

• Keep hands, clothing, etc. away from the weld stud, chuck and all other

parts in contact with them during the weld cycle.

• Keep weld cable and connectors in good condition. Inspect periodically

for broken insulation and/or other electrical hazards.

• Do not operate with worn or poorly connected cables. Inspect all cables

often for bare or exposed wires, broken insulation layers and/or loose

connections. Repair all such connections before welding use.

• Do not stand in water or on damp surfaces while welding. Avoid wearing

wet or sweaty clothes. Do not weld in the rain.

WARNING

Use extreme caution when servicing or troubleshooting

any component of this stud welding system.

If possible, turn all power controls “OFF”

and disconnect all electrical cables.

For other suggested precautions, safe practices, etc.

regarding welding, refer to

“Safety in Welding and Cutting”,

ANSI Z49.1, American National Standards Institute.

HIGH VOLTAGE

HEARING

PROTECTION

EYE

PROTECTION

WELDVOLTAGE

CD 100

POWER

OFF

ON

GROUND CABLE

LOW MIN MAX

VOLTAGE

CONTROL

HIGH

WELD

POWER

CDCDCONTROL GUN

+ + –

Stud welding is a welding process where a “stud” (or similar metal part) is

instantaneously end-joined to a metal workpiece. This process involves the

same basic principles and metallurgical aspects as any other welding

process.

The equipment required to stud weld is composed of a direct current power

supply, a controller, a weld gun and cables to tie the system components

together. In most systems the power supply and controller are combined into

one unit called the “Welder.”

CD 100 STUD WELDING SYSTEM (P/N: CDSW-100-01)

The stud welding process is as follows. The stud is placed

in the collet of the

“Weld Gun” and then positioned against the workpiece. The weld gun trigger

is depressed and t

hrough operation of the stud welding controller and the

design of the stud, an arc is drawn which melts the base of the stud and a

proportionate area of the workpiece.The stud is then forced by the weld gun

into the molten pool and held in place until the metals resolidify. This high

quality fusion weld is completed in milliseconds.

There are two different stud welding processes:

• Capacitor Discharge (called “CD” for brevity) and

•Arc.

The difference between these two methods involves the power source used

to provide the welding current, the workpiece size, base material and the

stud design.

6©2001

MIDWEST FASTENERS, INC.

—

CD100 Stud Welder

WHAT IS STUD

WELDING?

HOW DOES

CD STUD WELDING

DIFFER FROM

ARC STUD WELDING?

Controller

CDSW-100-00 Weld Gun

CDPG-200-06

Ground Cable (2 ea.)

CDGC-201-15

Extension

Cable Set

CDES-201-25

©2001

MIDWEST FASTENERS, INC.

—

CD 100 Stud Welder 7

CD STUD WELDING The CD stud welding process produces weld power through a rapid

discharge of the stored energy from a bank of capacitors.This stored

energy is usually derived from a standard 115 volt AC source. CD stud

welding, as a general rule, is used for studs 5/16" and less in diameter,

(or where thin base metals or dissimilar metals are to be joined.)

“CD”STUD WELDING PROCESS

The ARC stud welding process produces weld power through one of three

standard DC welding power sources. These are Transformer-Rectifier type,

Motor/Generator type, or Storage Battery type.A ceramic ferrule is

required in ARC stud welding to maintain the proper atmosphere in the

weld area. ARC stud welding is generally used for studs over 1/4" in

diameter or where heavier base metals are involved.

“ARC”STUD WELDING PROCESS

ARC STUD WELDING

1. Stud is placed against workpiece

and weld gun trigger depressed 2. Stored energy is discharged

through special tip

3. Weld gun forces stud

into molten metal 4. Weld solidifies in

miliseconds

1. Stud is placed against workpiece

and weld gun trigger depressed 2. Stud is lifted by weld gun

and initiating arc is drawn

3. Weld gun forces stud

into molten metal 4. Weld solidifies and

ferrule is removed

8©2001

MIDWEST FASTENERS, INC.

—

CD 100 Stud Welder

OVERVIEW – CD100

CAPACITOR DISCHARGE

STUD WELDER

The CD100 is a capacitor discharge stud welder. The weld energy is stored

in capacitors located inside the control unit. The amount of stored energy

can be controlled by rotating the voltage control knob located on the front

panel.

CD weld studs, or pins, used with the CD100 must have a specially

designed projection at the weld end. When the stud

is inserted into the weld

gun and placed against the workpiece

, and the trigger switch is depressed,

the following occurs:

1. The energy stored in the capacitors travels through the weld cables to

the stud.

2. The rapid rise in current ignites the projection and allows a welding

arc to be established between the stud and the workpiece.

3. The arc melts the base of the stud and a portion of the workpiece.

4. The spring pressure inside the welding gun forces the stud into the

molten metal pool created by the arc.

5. The cycle ends upon contact of the stud to the workpiece.

6. The welding gun is then removed. Upon removal, the controller will

automatically recharge to the set voltage.

CAUTION

The noise generated by stud welding

may exceed allowable levels

established by O.S.H.A. For this reason

it is recommended that proper ear protection be worn

by the operator and anyone working in the immediate area.

WARNING

Voltages inside the unit can reach 200 volts D.C.

even if the unit is turned off. All repair work

should be handled by factory trained personnel.

HIGH VOLTAGE

HEARING

PROTECTION

©2001

MIDWEST FASTENERS, INC.

—

CD 100 Stud Welder 9

CD100 INSTALLATION Follow the process below to properly install your CD100 stud welder.

CD100 Cable Connections (straight polarity shown)

1. Carefully remove the controller, cables and weld gun from the

shipping packaging.

2. Set the Controller on a clean, dry, sturdy surface near an appropriate

voltage supply and the workpiece.

3. Connect the Ground Cable male cam-lok connector to the controller

connector marked “CD / GROUND CABLE” for each of two (2)

recommended ground cables.

4. Clamp the Ground Cable C-clamp firmly to a clean

(free from paint,

rust, scale, grease or oil) area on the workpiece. Using the two (2)

recommended ground cables, surround the area to be welded.

5. Connect the Extension Cable Set male cam-lok connector to the

controller connector marked “GUN.”

6. Connect the Extension Cable Set control connector to the controller

connector marked “CONTROL.”

7. Connect the Gun Cable male cam-lok connector to the Extension

Cable Set female cam-lok connector.

8. Connect the Gun Cable control connector to the Extemsion Cable Set

control connector.

9. Plug the Controller Power Cord to appropriate power source.

NOTE: All cables should be

laid out straight or in large loops.

Poor welds may result if

welding cables are closely

coiled or stacked up.

Ground Cable

(2 recommended)

Weld

Gun

Controller

CD CD CONTROL GUN

Extension

Cable Set

10 ©2001

MIDWEST FASTENERS, INC.

—

CD100 Stud Welder

CD100 SETUP After installation, two setup phases must be completed before welding can

begin. These phases are:

• Weld Gun Setup, and

• ControllerAdjustment.

Your weld gun setup will depend on your application and the particular

stud to be welded. Setting up the gun consists of the following:

1. Locate the pins (or studs) that were shipped for your job and place a

pin into the weld gun Collet with the “weld tip” protruding. Push this

pin in until it seats firmly, assuring that the flange (or collar) of the

weld end does not come into contact with the collet.

2. Make sure that the gun “setup” accessories that came with the CD 2P

weld gun are adjusted properly and fastened tightly. Illustrations on

the following pages for:

• Insulation Pins (Figure 1)

• Insulation Pins with Internal Stop (Figure 2)

• Weld Studs (Figure 3)

• Weld Studs with Template Adaptor (Figure 4)

NOTE: These components may need to be readjusted, or changed, as

your job requirements change.

WELD GUN SETUP

Weld

Pin

Optional Weld Gun Setup for Insulation Pins Longer Than 4"

(NOTE: shown with Internal Stop and StopAdjuster

used for long pins, rather than “B”-Stop.)

1/8 - 3/16"

Protrusion

1. Seat weld pin firmly against internal stop.

2. Loosen these adjustment screws.

3. Slide the Leg/Foot assembly until weld

pin flange extends 1/8"- 3/16" beyond

foot (or spark shield.)

4. Retighten adjustment screw.

©2001

MIDWEST FASTENERS, INC.

—

CD 100 Stud Welder 11

CD-2P WELD GUN

SETUP

INSULATION PINS .

Weld

Pin

1. Seat weld pin firmly against stop.

2. Loosen these adjustment screws.

3. Slide the Leg/Foot assembly until

weld pin flange extends 1/8"- 3/16"

beyond foot (or spark shield.)

4. Retighten adjustment screw.

Adjustable

Leg Foot

1/8"- 3/16" Protrusion

“B”

Collet Spark

Shield

(Optional)

“B”

Stop

CD-2P WELD GUN

SETUP

INSULATION PINS .

WITH .

INTERNAL STOP .

(Fig.1)

(Fig.2)

1. Seat weld pin firmly against “B” stop.

2. Loosen these adjustment screws.

3. Slide the Leg/Foot assembly until

weld stud flange extends 1/8"- 3/16"

beyond foot.

4. Retighten adjustment screw.

1/8"- 3/16" Protrusion

Weld

Stud

Adjustable

Leg Foot“B”

Collet

“B”

Stop

12 ©2001

MIDWEST FASTENERS, INC.

—

CD100 Stud Welder

CD-2P WELD GUN

SETUP

WELD STUDS .

(Fig.3)

CD-2P WELD GUN

SETUP

WELD STUDS .

WITH .

TEMPLATE ADAPTOR .

(Fig.4)

1/8"- 3/16"

Protrusion

Weld

Stud

“B”

Collet

“B”

Stop Template

Adaptor

Faceplate

Work- Positioning Weld Gun with

Piece Template Template

Adaptor

Faceplate

Template Adaptors are used

when precise positioning of the

stud is required. (Observe correct

material and design guidelines for

all positioning templates).

After verifying that the welding system is installed and your weld gun is

setup properly for your application, the final step is to adjust your stud

welding controller to the proper settings.

1. (Before turning on power) turn the controller VOLTAGE selector

switch to “MIN” (fully counterclockwise.)

2. Turn the controller ON/OFF switch to “ON.” Verify by observing

“POWER” lamp.

3. Using the chart below, adjust the “VOLTAGE” control until the

“WELDVOLTAGE” meter reads the desired value.

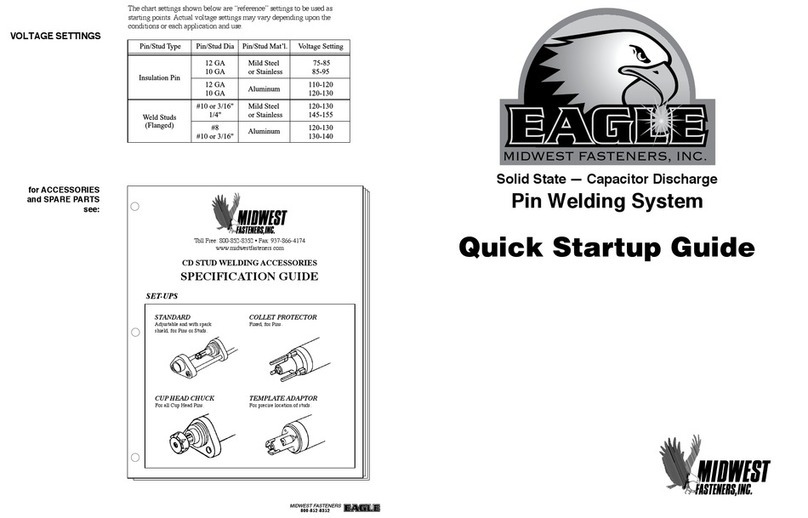

The chart settings shown below are "reference" settings to be used as

starting points. Actual voltage settings may vary depending upon the

conditions or each application and use. The voltages shown also assume

that the following are in use (as described in previous Installation and

Setup sections of this manual.)

A)

Straight polarity cable set ups in use (Gun = Negative, Ground = Positive.)

B) Ground connection directly to the part to be welded and connected in

a clean, solid manner.

C) 1/8" protrusion of pin/stud onto work (3/16" for Aluminum) causing

an equal amount of spring pressure in the gun.

D) “Silver” gun spring for Mild or Stainless Steel, “Black” for

Aluminum applications.

E)

Good, clean accessories and work surface to be welded, with proper setup of

all accessories.

Pin/Stud Type Pin/Stud Dia Pin/Stud Mat’l. Tap Voltage Setting

12 GA Low 90-100

10 GA Low 100-110

12 GA Low 120-130

10 GA Low 135-145

#10 or 3/16" Low 125-135

1/4" Low 135-145

5/16" High 145-155

3/8" High 155-165

#8 Low 120-130

#10 or 3/16" Low 130-140

1/4" High 140-150

5/16" High 150-160

NOTE: Be sure that proper observation of all safety precautions

are in place before performing the next step.

©2001

MIDWEST FASTENERS, INC.

—

CD 100 Stud Welder 13

CD 100 SETUP -

CONTROLLER

ADJUSTMENT

&

MAKING A TEST WELD

Insulation Pin

Weld Studs

(Flanged)

Mild Steel

or Stainless

Aluminum

Mild Steel

or Stainless

Aluminum

4. Pick up the weld gun and place the stud firmly against the workpiece

(The test workpiece should be a material that is similar to the

workpiece to be welded to in actual production.)

5. Depress the weld gun trigger, wait momentarily, and then pull the gun

straight back off the stud.

6. Test the weld integrity (see below.)

14 ©2001

MIDWEST FASTENERS, INC.

—

CD 100 Stud Welder

WELD QUALITY Stud Welded Joint Quality

•AGOOD weld is determined by bending the stud back and forth.

Failure should occur in the stud shank or workpiece, not in the weld.

•HOT weld shows excessive splatter — adjust voltage downward

(see 7. A. below).

•COLD weld shows little or no splatter and may have a void

between the stud and workpiece — adjust voltage upwards.

(see 7. B. below).

7. Adjust the weld voltage up or down until a satisfactory weld is

consistently achieved.

A. When adjusting voltage downward, (e.g. from 100 V to 80 V) it

is necessary to turn the power off. Then turn the voltage selector

knob counterclockwise, turn the power back on, and increase to

the required voltage.

B. To adjust the voltage upwards (increase weld heat), turn the

voltage selector knob clockwise in small increments to a higher

setting.

When weld quality is consistently satisfactory, the CD 100 is properly

installed and setup.

If you need assistance

with setup, or operation, call

MIDWEST FASTENERS

Technical Support at

(800) 852-8352

Monday through Friday

between 8am and 5pm

Eastern time.

Even weld

fillet

all around

Excessive splatter

and

thin weld fillet

Little or

no weld

fillet

GOOD HOT COLD

©2001

MIDWEST FASTENERS, INC.

—

CD 100 Stud Welder 15

PREVENTIVE

MAINTENANCE

TROUBLESHOOTING

Your MIDWEST FASTENERS welder is designed for long service with

minimal care. Ordinary common sense maintenance will keep it operating

efficiently. The following are a few tips on preventive maintenance.

1. Treat the cables with respect. Avoid sharp bends or kinks which may

break the cables. DO NOT use the cables as a “towline” to drag or lift

the controller. Avoid damaging or straining the cables where they

enter the gun or controller.

2. Louvers on the sides of the controller should be free from

obstructions at all times to prevent overheating.

3. Keep the controller and gun clean and dry, free of grease, water, dust

and dirt. Do not lubricate any part of your CD2P weld gun.

4. The weld gun is for welding studs only. Do not use the weld gun as a

multipurpose tool (i.e., Hammer—banging studs to test welds or

break ferrules, Scraper—removing rust, scale or weld splatter, etc.)

When troubleshooting the CD100, the following precautions must be

observed.

1. Controller power must be TURNED OFF!

NOTE: Dangerous voltage levels can still be present in the

controller—even after power is disconnected.

2. The use of a volt/ohmmeter is recommended to verify where any

voltage may, or may not, be present.

3. The use of a continuity tester (or trouble shooting light) can be used

for continuity checking (disconnected) cables only.

The troubleshooting chart on the following pages can assist in locating and

fixing problems with the CD100.

HIGH VOLTAGE

16 ©2001

MIDWEST FASTENERS, INC.

—

CD 100 Stud Welder

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

TROUBLESHOOTING CHART

1. Welder does not turn on

and will not weld.

2. Circuit Breaker trips or

fuse blows each time the

controller is turned on.

3. Circuit Breaker trips or

fuse blows when weld is

made.

4. Welder powers on, but

does not operate.

A. Power cable connection at

controller or 115 VAC outlet not

complete.

B. Power cable/connector

damaged.

C. Open circuit breaker, fuse or

damaged wall outlet.

A. Shorted weld capacitor.

B. Shorted rectifier.

C. Faulty circuit breaker.

D. Shorted transformer.

A. Shorted charge SCR.

B.

Faulty printed circuit (PC) board.

A. Ground cable or gun cable

connections not complete.

B. Broken gun control cable or

loose wire connection in plug.

C. Shorted gun control wires at the

gun trigger switch.

D. Faulty printed circuit board.

Inspect power cable

connection.

Repair if loose.

Check for continuity. Repair break

or replace connector.

Check with ohmmeter. Replace

defective part (Fuse = BUSS

MDA30, or equivalent.)

Check capacitors safety vent seal for

rupture hole. Replace defective

capacitor.

Check with ohmmeter. Replace

rectifier if defective.

Check with ohmmeter. Replace

rectifier if defective.

Remove two orange wires from

charge rectifier. If fuse continues to

blow, r

eplace transformer.

Check with ohmmeter. (Should

not

show continuity in either direction.)

Replace if defective.

Replace with new PC board if defective.

Check for continuity and proper

connection of ground to workpiece.

Check continuity between pins “+”

and “Z” of plug while depressing

gun trigger. Should read continuity

only when depressed.

Check continuity between pins “+”

and “Z” of plug. No reading should

be observed while gun trigger is in

the released position.

Replace with new PC board if defective.

©2001

MIDWEST FASTENERS, INC.

—

CD 100 Stud Welder 17

TROUBLESHOOTING CHART

4. Welder powers on, but

does not operate.

5. Weld is excessively hot

regardless of voltage

setting.

6. Consistently poor or

erratic welds.

E. Shorted weld SCR.

A. Shorted charge SCR.

B. Faulty printed circuit board.

C. Open voltage potentiometer.

A. Improper gun setup.

B. Improper grounding, cable

installation or incorrect polarity.

C. Weld cables coiled.

D. Incorrect weld voltage setting.

E. Studs (or Pins) not

perpendicular to workpiece.

F. Faulty printed circuit board.

Unplug PC Board and check

continuity between SCR heat sink

and negative (–) buss bar. No reading

should be observed. Replace SCR if

continuity exists.

Check continuity across SCR. No

reading should be observed in either

direction. Replace charge SCR if

continuity exists.

Replace with new PC board if defective.

Replace defective voltage

potentiometer.

Check gun for proper setup (see page 10).

Check grounding and cable instal-

lation for proper setup (see page 9).

Straighten out cables or place in

random loops.

Adjust as necessary (see page 13).

Adjust gun set up as necessary. Replace

bent or defective legs (see page 10).

Replace with new PC board if defective.

(continued)

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

If you need assistance

with setup, or operation, call

MIDWEST FASTENERS

Technical Support at

(800) 852-8352

Monday through Friday

between 8am and 5pm

Eastern time.

21"

9"

13 "

WELD VOLTAGE

CD 10

0

POWER

OFF

ON

GROUND CABLE

LOW MIN MAX

VOLTAGE

CONTROL

HIGH

WELD

POWER

CD

CD

CONTROL GUN

+

+ –

18 ©2001

MIDWEST FASTENERS, INC.

—

CD100 Stud Welder

CD 100

STUD WELDING SYSTEM

SPECIFICATIONS

Weight..............................66 pounds

Power Requirement..........115 VAC, 60 Hz, 30 Amp

Pin/Stud Range................14 ga. – 3/8" dia.

Weldable Materials ..........Mild Steel, Stainless,

& Aluminum

Weld Modes .....................Contact

Weld Rate.........................14/minute (maximum)*

(* Dependent on stud size.)

Weld Voltage ....................34–175 VDC

Capacitance - Low ...........84,000 mfd

High ..........168,000 mfd

Cables ..............................15' Ground Cable (2 supplied/recommended)

25' Extension Set (recommended minimum)

CD 100

STUD WELDING SYSTEM

EXPLODED VIEW DIAGRAM

& PARTS LIST

©2001

MIDWEST FASTENERS, INC.

—

CD 100 Stud Welder 19

Item Qt’y. Part No. Description

1 2 050-1004-93 Cabinet Handle

2 1 050-1002-54 Sheet Metal Cover

3 1 050-1003-16 Voltage Control Potentiometer

1 050-1002-87 Voltage Control Knob

4 1 050-1004-78 Power Indicator Light

5 1 050-1005-06 Voltmeter LED

6 1 050-1001-06 Fuse Holder

1 050-1001-03 30A Fuse

7 1 050-1004-01 Power Circuit Breaker Switch

8 1 050-1004-03 Hi/Lo Switch

9 1 050-1003-54 Bleed-Off Resistor

10 1 050-1001-15 Safety Switch Bracket

11 1 050-1003-55 Current Limiting Resistor

12 1 050-1003-53 Ballast Resistor

13 1 050-1004-02 Cabinet Safety Switch

14 1 060-3081-01 PC Board Assembly

15 1 050-1002-80

Wiring Harness Assembly

16 1 050-1004-74 Power Cord

17 1 050-1001-05 Fuse Holder

1 050-1001-01 Fuse 1A

18 1 050-1004-16 Terminal Strip

19 1 050-1002-66 Main Transformer

20 1 050-1004-95 Fan Guard

21 1 050-1004-85 Fan

22 1 050-1002-24 Sheet Metal Base

23 1 050-1003-32 Bleed-Off Relay

24 1 050-1002-02 Snubber Capacitor

25 1 050-1004-83 Cable Grommet - AC

26 6 181-1100-58 Hold Down Rod

27 1 050-1005-05 Capacitor Insulator 100/700

28 12 050-1002-01 Weld Capacitor

29 2 050-1001-80 Buss Bar - B

30 1 050-1001-85 Buss Bar - G

31 24 181-3029-01 10-32 x 5/8 Pan Head Screw

24 181-1260-01 #10 Split Lock Washer

32 1 050-1001-33 Steering Diode

33 1 050-1001-80 Buss Bar - B

34 1 050-1001-25 Diode Buss Bar

35 2 050-1001-84 Buss Bar - F

36 1 050-1004-41 Terminal Strip - Gate

37 2 050-1001-82 Buss Bar - D

38 1 060-1009-01 Charge Bridge Rectifier

39 1 050-1003-72 Charge SCR

40 1 050-1001-32 Welding Diode

41 1 050-1004-98 Internal Weld Cable

42 1 050-1005-01 Jumper Bar

43 3 060-3068-00

Camlok Connector Receptacle

44 1 060-3115-00

R&S Connector Receptacle

45 1 050-1001-16 SCR Heat Sink Bracket

46 1 050-1003-73 Main SCR

1 050-1001-62 Data Plate (Not shown)

6 050-1004-80 Resistor Mounting Bracket

(Not shown)

11

24 26

3

4

5

6

8

9

10

14

15

16

17

18

19

22

2

1

40

39

38

37

36

33

32

31

30

29

28

25

13

12

27

7

23

35

42

41

44

43

46

45

34

20

21

Table of contents

Other MIDWEST FASTENERS Welding System manuals

MIDWEST FASTENERS

MIDWEST FASTENERS TALON User manual

MIDWEST FASTENERS

MIDWEST FASTENERS SURE SHOT II User manual

MIDWEST FASTENERS

MIDWEST FASTENERS CD80 User manual

MIDWEST FASTENERS

MIDWEST FASTENERS CD50 User manual

MIDWEST FASTENERS

MIDWEST FASTENERS sureshot User manual

MIDWEST FASTENERS

MIDWEST FASTENERS UA500 User manual

MIDWEST FASTENERS

MIDWEST FASTENERS EAGLE User manual

MIDWEST FASTENERS

MIDWEST FASTENERS EAGLE Troubleshooting guide