MIDWEST FASTENERS SURE SHOT II User manual

Wld SureShotII Manl_Cvr01.fh1 3/5/13 7:52 PM Page 1

C M Y CM MY CY CMY K

Hand Held – Capacitor Discharge

Welding System

Owner’s Manual

4VSF4IPU**

$%

4UVE8FMEJOH4ZTUFN

0XOFST.BOVBM

t*OTUBMMBUJPO

t0QFSBUJPO

t.BJOUFOBODF

.*%8&45'"45&/&34*/$

3JDIBSE4USFFU

.JBNJTCVSH0)

1IPOF

'BY

ª.JEXFTU'BTUFOFST*OD"MM

SJHIUTSFTFSWFE

1SJOUFEJO

64"

¥

.*%8&45'"45&/&34*/$

4VSF4IPU**4UVE8FMEJOH4ZTUFN

Warranty

...........................................................................................

2

Safety Precautions

............................................................................

3

What is CD Stud Weldin

g

...............................................................

5

Overview

..........................................................................................

7

Installation

........................................................................................

8

Set

up

Setup

Set

................................................................................................

9

Power

-Up and Adjustment

.............................................................

-Up and Adjustment .............................................................

-Up and Adjustment

11

Making Test Welds

.........................................................................

12

Weld Joint Quality

........................................................................

12

Preventive Maintenance

.................................................................

13

Troubleshooting

.............................................................................

13

Controller Specifi cations

................................................................

16

Weld Gun Specifi cations

...............................................................

16

Controller

Exploded View & Parts List

........................................

17

Weld Gun Exploded View & Parts List

.........................................

Weld Gun Exploded View & Parts List .........................................

Weld Gun Exploded View & Parts List

19

Electrical Schematic

.......................................................................

20

Notes

..............................................................................................

21

5"#-&0'$0/5&/54

(&/&3"-

*/530%6$5*0/

4&56101&3"5*0/

."*/5&/"/$&

1"35441&$*'*$"5*0/4

FOREWORD:

Your new stud welding equipment is carefully constructed of the fi nest components and materials available.

Used properly, this equipment will give you years of profi table, effi cient Service. The system incorporates the latest in

engineering advances for completely reliable welding of mild steel, stainless steel

and aluminum

. The electrical and

mechanical components of the stud welder are thoroughly performance inspected prior to assembly in the welder. The

assembled unit is completely performance checked. The welder is delivered to you in functional electromechanical condition.

A careful study of this manual will enable you to understand how the welder operates to insure proper performance unde

r

all operating conditions.

WARRANTY: All parts used in the assembly of your MIDWEST FASTENERS S

ureShot II Welding System are fully

guaranteed for three (3) years from factory shipment date.

Under this warranty, MIDWEST FASTENERS reserves the right to repair or replace, at its option, defects in material or workmanship

which occur during the warranty period. Notice of any claim for warranty repair must be furnished to MIDWEST FASTENERS

within ten (10) days after the defect is discovered. MIDWEST FASTENERS does not assume liability for shipping, or liability for

any labor or material related to use of this system unless such costs are expressly authorized in writing by MIDWEST FASTENERS.

MIDWEST FASTENERS, INC. does not warrant defects in welders, parts or accessories resulting, from abuse, improper

installation, or for reasons beyond its control.

This warranty is valid only when welding pins an

d

/or studs approved by or purchased from MIDWEST FASTENERS.

¥

.*%8&45'"45&/&34*/$

4VSF4IPU**4UVE8FMEJOH4ZTUFN

8&-%*/(4"'&5:13&$"65*0/4

"/%8"3/*/(4

INSTALLATION AND SERVICING SAFETY

Improperly installed or improperly grounded

equipment is a hazard. Always have qualifi ed

personnel perform the installation, trouble-shooting,

and maintenance. Do not perform any electrical

work unless you are qualifi ed to do the work. Be

sure the system is properly grounded.

Maintain this unit according to the manual.

Disconnect input power before servicing this

equipment and use lockout tags. Signifi cant DC

voltage can still exist in this equipment after removal

or shut down of the input power. Turn off all

equipment when not in use.

ELECTRICAL SHOCK HAZARD

Contact with live electrical parts and ground can

cause severe injury or death. DO NOT weld in damp

areas or while equipment or clothing are damp or

wet. Do not touch the stud if you are in contact with

the work, ground, or another electrode from a

different machine. Don’t stand directly on metal or

the earth; stand on dry boards, insulating mats or an

insulating platform.

Before turning on power, be sure you are wearing

appropriate protective clothing:

- high-topped, heavy rubber-soled shoes

- long (gauntlet style), dry, fl ameproof, hole-free

insulated gloves

- heavy, long-sleeve, cuffl ess shirt

- heavy, cuffl ess trousers and

- a welding helmet or cap.

GENERAL WELDING JOB SAFETY

Use this equipment only for its intended purpose.

Use well-maintained equipment. Replace worn or

damaged cables or parts immediately; bare wiring

can kill. Do not drape cables over your body. Keep

all panels and covers securely in place. Do not

overload electrical wiring, be sure power supply

system is properly sized, rated and protected to

handle the unit. Don’t connect multiple guns or work

cables to a single weld output terminal. Follow rated

duty cycle and allow overheated equipment adequate

cooling periods. Do not block or fi lter airfl ow to

unit.

DO NOT weld if movement is confi ned or if there is

danger of falling. Wear a safety harness if working

above fl oor level. Shut unit down and remove weld

stud from the stud weld gun when not in use.

ELECTROMAGNETIC FIELDS AND

EMF

Electric and magnetic fi elds may be dangerous.

Welder operators having pacemakers should consult

their physician before welding. EMF may interfere

with some pacemakers. Exposure to EMF may have

other health effects which are unknown. Connect the

work cable to the work piece as close as possible to

the area being welded. Keep welding power source

and cables as far away from your body as possible.

Electromagnetic energy can interfere with sensitive

electronic equipment such as computers and

computer-driven equipment such as robots.

FUMES HAZARDS

Welding produces fumes and gases. Breathing these

fumes and gases can be hazardous to your health,

particularly in confi ned spaces. Do not breath fumes

and gases. Always ventilate confi ned spaces or use

approved air-supplied respirator. Welding on coated

metals such as galvanized, lead or cadmium plated

steel can be hazardous, in terms of fumes produced,

unless the coating is removed from the weld area.

Don’t weld near degreasing, cleaning or spraying

operations.

FIRE SAFETY AND BURN PREVENTION

(ARC RAYS CAN BURN EYES AND SKIN)

Always wear safety glasses with side shields in any

work area. Even if wearing a welding helmet, face

shields and goggles are also required. Wear goggles

over safety glasses when chipping, wire brushing or

grinding slag. Chipped slag may be hot and can fl y

far. Bystanders should also wear goggles over safety

glasses. Use protective non-fl ammable screens or

barriers to protect others from fl ash and glare.

Warn bystanders not to watch the arc and not to

expose themselves to the rays of the electric-arc or

hot metal.

Welding on closed containers, such as tanks, drums

or pipes, can cause them to blow up. Do not weld

where fl ying sparks can strike fl ammable material.

Remove all combustible materials a minimum of

35-ft. away from the welding arc or cover the

materials with a protective nonfl ammable covering.

¥

.*%8&45'"45&/&34*/$

4VSF4IPU**4UVE8FMEJOH4ZTUFN

Stud welding is a welding process where a “stud” (or similar metal part)

is instantaneously end-joined to a metal workpiece. This process involves

the same basic principles and metallurgical aspects as any other welding

process.

The equipment required to stud weld is composed of a direct current power

supply, a controller, a weld gun and cables to tie the system components

together. In most systems the power supply and controller are combined into

one unit called the “Welder.”

463&

4)05**

456%8&-%*/(4:45&.

1/$%48

The stud welding process is as follows. The stud is placed

in the collet of the

“Weld Gun” and then positioned against the workpiece. The weld gun trigger

is depressed and t

hrough operation of the stud welding controller and the

design of the stud, an arc is drawn which melts the base of the stud and a

proportionate area of the workpiece. The stud is then forced by the weld gun

into the molten pool and held in place until the metals resolidify. This high

quality fusion weld is completed in milliseconds.

There are two different stud welding processes:

•

Capacitor Discharge

(called

“

C

D

” for brevity) and

•

Arc

.

The difference between these two methods involves the power source used

to provide the welding current, the workpiece size, base material and the

stud design.

$

B

$B

$

Q

BQ

B

B

QB

Q

DJUP

S%

DJUPS%

DJUP

JT

S%JT

S%

D

I

DI

D

B

IB

I

SH

BSH

B

F

SHF

SH

8

F8

F

F

8F

8

ME

FME

F

F

MEF

ME

S

FS

F

X

JUI.JDSPQSPDFTTPS

XJUI.JDSPQSPDFTTPS

X

JUI.JDSPQSPDFTTPS

JUI.JDSPQSPDFTTPS

)ZCSJE$POUSP

)ZCSJE$POUSP

M

)ZCSJE$POUSPM

)ZCSJE$POUSP

8)"5*4456%

8&-%*/

(

)08%0&4

$%456%8&-%*/(

%*''&3'30.

"3$456%8&-%*/

(

Controller

CD

SW-002-00

Weld Gun

CDWG-201-20

Ground

Cable

CD

GC-200-15

¥

.*%8&45'"45&/&34*/$

4VSF4IPU**4UVE8FMEJOH4ZTUFN

$%456%8&-%*/(

The CD stud welding process produces weld power through a rapid

discharge of the stored energy in capacitors. This stored energy is usually

derived from a standard 115 volt AC source. CD stud welding, as a general

rule, is used for studs 3/8" and less in diameter, (or where thin base metals

or dissimilar metals are to be joine

d

).

i$%w456%8&-%*/(130$&44

The ARC stud welding process produces weld power through one of three

standard DC welding power sources. These are Transformer-Rectifi er type,

Moto

r

/

Generator type, or Storage Battery type. A ceramic ferrule is re-

quired in ARC stud welding to maintain the proper atmosphere in the weld

area. ARC stud welding is generally used for studs over 1/4" in diameter or

where heavier base metals are involved.

i"3$w456%8&-%*/(130$&44

i$%w456%8&-%*/(130$&44

"3$456%8&-%*/(

i"3$w456%8&-%*/(130$&44

4UVEJTQMBDFEBHBJOTUXPSLQJFDF

BOEXFMEHVOUSJHHFSEFQSFTTFE

4UPSFEFOFSHZJTEJTDIBSHFE

UISPVHITQFDJBMUJQ

8FMEHVOGPSDFTTUVE

8FMEHVOGPSDFTTUVE

JOUPNPMUFONFUBM

8FMETPMJEJàFTJO

NJMJTFDPOET

4UVEJTQMBDFEBHBJOTUXPSLQJFDF

BOEXFMEHVOUSJHHFSEFQSFTTFE

4UVEJTMJGUFECZXFMEHVO

BOEJOJUJBUJOHBSDJTESBXO

8FMEHVOGPSDFTTUVE

8FMEHVOGPSDFTTUVE

JOUPNPMUFONFUBM

8FMETPMJEJàFTBOE

8FMETPMJEJàFTBOE

GFSSVMFJTSFNPWFE

¥

.*%8&45'"45&/&34*/$

4VSF4IPU**4UVE8FMEJOH4ZTUFN

463&4)05**

07&37*&8

The

SureShot II

is a capacitor discharge stud welder. The weld energy is

stored in a capacitor located inside the control unit. The amount of stored

energy can be controlled by the UP or Down digital control pushbuttons

located on the front panel as indicated by the digital display.

CD weld studs, or pins, used with the

SureShot II

must have a specially

designed projection at the weld end. When the stud

is inserted into the weld

gun and placed against the workpiece

, and the trigger switch is depressed,

the following occurs:

1. The energy stored in the capacitors travels through the weld cables to

the stud.

2. The rapid rise in current ignites the projection and allows a welding

arc to be established between the stud and the workpiece.

3. The arc melts the base of the stud and a portion of the workpiece.

4. The spring pressure inside the welding gun forces the stud into the

molten metal pool created by the arc.

5. The cycle ends upon contact of the stud to the workpiece.

6. The welding gun is then removed. Upon removal, the controller will

automatically recharge to the set voltage.

$"65*0/

The noise generated by stud welding

may exceed allowable levels

established by O.S.H.A. For this reason

it is recommended that proper ear protection be worn

by the operator and anyone working in the immediate area.

8"3/*/(

Voltages inside the unit can reach 200 volts D.C.

even if the unit is turned off. All repair work

should be handled by factory trained personnel.

¥

.*%8&45'"45&/&34*/$

4VSF4IPU**4UVE8FMEJOH4ZTUFN

463&4)05**

*/45"--"5*0/

Follow the process below to properly install your S

u

reShot II stud welder.

4VSF4IPU**

$BCMF$POOFDUJPOT

1. Carefully remove the controller, cables and weld gun from the ship-

ping packaging.

2. Set the

Controller

on a clean, dry, sturdy surface near an appropriate

voltage supply and the workpiece.

3. Connect the

Ground Cable

male cam-lok connector to the controller

connector marked

“

GROUND

.

”

4. Clamp the

Ground Cable

C-clamp fi rmly to a clean

(free from paint,

rust, scale, grease or oil) area on the workpiece.

5. Connect the

G

un Cable Set

male cam-lok connector to the controller

un Cable Set male cam-lok connector to the controller

un Cable Set

connector marked

“

GU

N

GUN

GU

.”

6. Connect the

Gu

n Cable Set

control connector to the controller con-

n Cable Set control connector to the controller con-

n Cable Set

nector marked

“

CONTROL.”

7. Plug the Controller

Power Cord

into a grounded 110 VAC power

Power Cord into a grounded 110 VAC power

Power Cord

source.

NOTE:

All cables should be

laid out straight or in large loops.

Poor welds may result if

welding cables are closely

coiled or stacked up.

Controller

Weld Gun

Ground

Cable

Power Cord

¥

.*%8&45'"45&/&34*/$

4VSF4IPU**4UVE8FMEJOH4ZTUFN

463&4)05**

4&561

After installation, two setup phases must be completed before welding can

begin. These phases are:

•

Weld Gun Setup

, and

•

Controller Adjustment

.

Your weld gun setup will depend on your application and the particular pin

or stud to be welded. Setting up the gun consists of the following:

1. Locate the pins

(

or studs) that were shipped for your job and load a

pin to the weld gun, with tipped-fl ange out, until stop is reached.

2. Make sure that the gun

“

setu

p

setup

setu

” accessories that came with the Talon

weld gun are adjusted properly and fastened tightly. Illustrations on

the following pages for:

• Cuphead Pins (Fig. 1)

• Insulation Pins (Fig. 2)

• Insulation Pins with Collet Protector (Fig. 3)

• Insulation Pins with Internal Stop (Fig. 4)

NOTE:

These components may need to be readjusted, or changed, as

your job requirements change, or as arcing or wear begins to affect

performance of the accessory.

8&-%(6/

4&561

¥

.*%8&45'"45&/&34*/$

4VSF4IPU**4UVE8FMEJOH4ZTUFN

8FME

1JO

4FBUXFMEQJOGJSNMZBHBJOTUTUPQ

-PPTFOUIFTFBEKVTUNFOUTDSFXT

4MJEFUIF-FH

'PPUBTTFNCMZVOUJM

XFMEQJOGMBOHFFYUFOET

CFZPOEGPPUPSTQBSLTIJFME

CFZPOEGPPUPSTQBSLTIJFME

CFZPOEGPPUPSTQBSLTIJFME

3FUJHIUFOBEKVTUNFOUTDSFX

"EKVTUBCMF

-FH

'PPU

1SPUSVTJPO

#$PMMFU

4QBSL

4IJFME

0QUJPOBM

#4UPQ

8FME

1JO

0QUJPOBM8FME(VO4FUVQGPS*OTVMBUJPO1JOT-POHFS5IBO

/05&TIPXOXJUI*OUFSOBM4UPQBOE4UPQ"EKVTUFS

VTFEGPSMPOHQJOTSBUIFSUIBO#4UPQ

1/8 - 3/16"

Protrusion

4FBUXFMEQJOGJSNMZBHBJOTUJOUFSOBMTUPQ

-PPTFOUIFTFBEKVTUNFOUTDSFXT

4MJEFUIF-FH

'PPUBTTFNCMZVOUJMXFME

QJOGMBOHFFYUFOET

CFZPOE

GPPUPSTQBSLTIJFME

GPPUPSTQBSLTIJFMEGPPUPSTQBSLTIJFME

3FUJHIUFOBEKVTUNFOUTDSFX

8FME

1JO

*GB#4UPQJTVTFETFBUXFMEQJO

GJSNMZBHBJOTUTUPQ

-PPTFOUIFTFBEKVTUNFOUTDSFXT

4MJEFUIF-FH

'PPUBTTFNCMZVOUJM

XFMEQJOGMBOHFFYUFOET

CFZPOEGPPUPSTQBSLTIJFME

CFZPOEGPPUPSTQBSLTIJFME

CFZPOEGPPUPSTQBSLTIJFME

3FUJHIUFOBEKVTUNFOUTDSFX

"EKVTUBCMF

-FH

'PPU

1SPUSVTJPO

#4UPQ

PQUJPOBM

#$PMMFU

JOTJEF

1SPUFDUPS

$PMMFU

1SPUFDUPS

$PMMFU

1SPUFDUPS

*OTFSU

$VQIFBE

1JO

1MBDFNBHOFUJDDIVDLJOHVOTIBGU

BOESFUJHIUFOTFUTDSFX/PPUIFS

BDDFTTPSJFTBSFSFRVJSFE

1MBDF

$VQ

)FBE

1JO

PO

NBHOFUJD

DIVDL

'PSGPJMGBDFE'4,NBUFSJBM0/-:

VTFDVQIFBEQJOTXJUIQBQFSXBTIFST

/05&

8IFO

XFMEJOH

NBJOUBJO

DPSSFDU

QSFTTVSFPOHVOBQQSPYJNBUFMZ

PGHVOTQSJOH

.BHOFUJD

$IVDL

'JH

'JH

'JH

'JH

463&4)05

**5"-0/(6/4&561

$61)&"%1*/4

463&4)05

**5"-0/(6/4&561

*/46-"5*0/1*/4

463&4)05

**5"-0/(6/4&561

*/46-"5*0/41*/4

8*5)$0--&51305&$503

463&4)05

**5"-0/(6/4&561

*/46-"5*0/41*/4

8*5)*/5&3/"-4501

¥

.*%8&45'"45&/&34*/$

4VSF4IPU**4UVE8FMEJOH4ZTUFN

After verifying that the welding system is installed and your weld gun is

setup properly for your application, the fi nal step is to adjust your stud

welding controller to the proper settings.

1.

Turn the controller

O

N

/

OFF

switch to

“

ON

.” Verify by observing

“

READY

” lamp.

2. Using the chart below, adjust the

weld voltage

using the UP or

DOWN pushbuttons until the

LEDs reads the desired value.

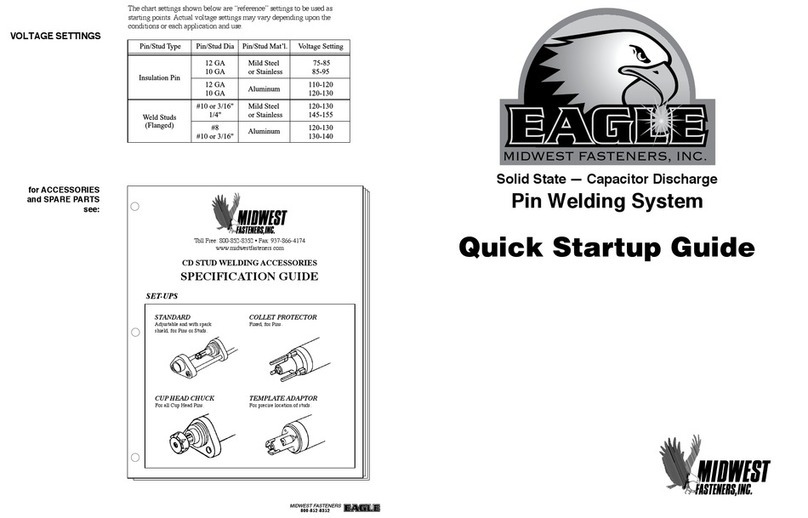

The chart settings shown below are "reference" settings to be used as start-

ing points. Actual voltage settings may vary depending upon the conditions

or each application and use. The voltages shown also assume that the fol-

lowing are in use (as described in previous Installation and Setup sections

of this manual.)

A)

Straight polarity cable set ups in use (Gun = Negative, Ground = Positive.)

B) Ground connection directly to the part to be welded and connected in

a clean, solid manner.

C) 1/8" protrusion of pi

n

/

stud onto work (

3

/16" for Aluminum) causing

an equal amount of spring pressure in the gun - or - cup of cuphead

pins centered on a magnetic chuck.

D)

S

ILVER

gun spring for Mild Steel or Stainless Steel pins or studs.

ILVER gun spring for Mild Steel or Stainless Steel pins or studs.

ILVER

BLACK gun spring for Aluminum pins or studs.

S

ILVER

gun spring

ILVER gun spring

ILVER

for cuphead pins.

E)

Good, clean accessories and work surface to be welded, with proper setup

of all accessories.

Pi

n

/

Stud Type Pi

n

/

Stud Dia Pi

n

/

Stud Mat’l. Voltage Setting

12 GA Mild Steel 80-90

12 GA Mild Steel

65-75

10 GA or Stainless

80-90

12 GA

75-85

10 GA

80-90

#8 85-95

#10 or 3/16"

90-100

1/4" 1

25-135

#

8

80-9

0

#10 or 3/16" 120-130

NOTE:

Be sure that proper observation of all safety precautions

are in place before performing the next step.

8&-%108&3

"%+645.&/5

Pi

Pi

/

/

Pi

12 GA Mild Steel

10 GA or Stainless

10 GA

#8 85-95

1/4" 1

#10 or 3/16" 120-130

Pi

Pi

Stud Type Pi

12 GA Mild Steel 80-90

12 GA Mild Steel

10 GA or Stainless

10 GA

#8 85-95

1/4" 1

#10 or 3/16" 120-130

Stud Dia Pi

12 GA Mild Steel 80-90

12 GA Mild Steel

10 GA or Stainless

12 GA

10 GA

#8 85-95

#10 or 3/16"

1/4" 1

8

#10 or 3/16" 120-130

Stud Mat’l. Voltage Setting

12 GA Mild Steel 80-90

#8 85-95

1/4" 1

#10 or 3/16" 120-130

Insulation Pin

Weld Studs

(

1/4" 1

(

1/4" 1

Flange

1/4" 1

Flange

1/4" 1

d

1/4" 1

d

1/4" 1

)

1/4" 1

)

1/4" 1

Mild Steel

#8 85-95

Mild Steel

#8 85-95

or Stainless

#10 or 3/16"

or Stainless

#10 or 3/16"

1/4" 1

or Stainless

1/4" 1

Cuphead Pin

12 GA Mild Steel 80-90

Cuphead Pin

12 GA Mild Steel 80-90

Aluminum

Aluminum

#10 or 3/16" 120-130

Aluminum

#10 or 3/16" 120-130

$POUSPM1BOFM

¥

.*%8&45'"45&/&34*/$

4VSF4IPU**4UVE8FMEJOH4ZTUFN

3. Pick up the weld gun and place the stud fi rmly against the workpiece

(The test workpiece should be a material that is similar to the

workpiece to be welded to in actual production.)

4. Depress the weld gun trigger, wait momentarily, and then pull the gun

straight back off the stud.

5. Test the weld integrity (see below.)

7&3*':*/(8&-%

+0*/526"-*5:

4UVE8FMEFE+PJOU2VBMJUZ

• A

GOOD

weld is determined by bending the stud back and forth.

Failure should occur in the stud shank or workpiece, not in the weld.

•

HOT

weld shows excessive splatter — adjust voltage downward

•

COLD

weld shows little or no splatter and may have a void

between the stud and workpiece — adjust voltage upwards.

6. Adjust the weld voltage up or down until a satisfactory weld is

consistently achieved, using the UP and DOWN pushbuttons.

When weld quality is consistently satisfactory, the SureShot II is properly

installed and setup.

If you need assistance

with setup, or operation, call

MIDWEST FASTENERS

Technical Support at

(800) 852-8352

Monday through Friday

between

8

am and

5

pm

Eastern time.

4UVE8FMEFE+PJOU2VBMJUZ

Even weld

fi llet

all around

Excessive splatter

and

thin weld fi llet

Little or

no weld

fi llet

GOOD

HOT

COLD

.",*/(5&458&-%4

¥

.*%8&45'"45&/&34*/$

4VSF4IPU**4UVE8FMEJOH4ZTUFN

13&7&/5*7&

."*/5&/"/$&

5306#-&4)005*/(

Your MIDWEST FASTENERS welder is designed for long service with

minimal care. Ordinary common sense maintenance will keep it operating

effi ciently. The following are a few tips on preventive maintenance.

1. Treat the cables with respect. Avoid sharp bends or kinks which may

break the cables. DO NOT use the cables as a

“

towlin

e

” to drag or

lift the controller. Avoid damaging or straining the cables where they

enter the gun or controller.

2. Louvers on the sides of the controller should be free from obstruc-

tions at all times to prevent overheating.

3. Keep the controller and gun clean and dry, free of grease, water, dust

and dirt. Do not lubricate any part of your CD

2 weld gun.

4. The weld gun is for welding studs only. Do not use the weld gun as

a multipurpose tool (i.e., Hammer—banging studs to test welds or

break ferrules, Scraper—removing rust, scale or weld splatter, etc.)

When troubleshooting the sureShot II, the following precautions must be

observed.

1. Controller power must be

TURNED OF

F

!

NOTE:

Dangerous voltage levels can still be present in the control-

ler—even after power is disconnected.

2. The use of a vol

t

/

ohmmeter is recommended to verify where any

voltage may, or may not, be present.

3. The use of a continuity tester (or trouble shooting light) can be used

for continuity checking (disconnected) cables only.

The troubleshooting chart on the following pages can assist in locating and

fi xing problems with the SureShot II.

HIGH VO

LT

AGE

¥

.*%8&45'"45&/&34*/$

4VSF4IPU**4UVE8FMEJOH4ZTUFN

130#-&. 1044*#-&$"64&

$033&$5*7&"$5*0/

5306#-&4)005*/(

$)"35

130#-&. 1044*#-&$"64&

1. Welder does not turn on

and will not weld.

2. Circuit breaker on

welder trips each time

the welder is turned on.

3. Circuit breaker welder

trips after weld is made.

4. Welder turns on and

display does show revi-

sion level and diagnostic

LED’s do not fl ash.

5. Welder turns on and dis-

plays revision level and

diagnostics, but does not

charge capacitor.

A. Power cable connection at welder

or power source not complete.

B. Power cables/connectors

damaged.

C. Wrong power cord.

D. Open circuit breaker or damaged

wall outlet.

A. Faulty circuit breaker.

B. Shorted transformer.

C. Shorted rectifi er.

D. Shorted weld capacitor.

E. Wrong power cord.

A. Faulty printed circuit board.

B. Shorted fl yback diode.

A. Faulty printed circuit board.

B. Fuse blown on printed circuit

board.

A. “Contact” between gun and work.

B. Voltage set at minimum.

C. Trigger is depressed.

Inspect power cable connections.

Repair if loose.

Inspect for damage. Repair or replace

power cord as needed.

E

nsure that correct power cord for

incoming voltage is being used.

SureShot II offers 110V and 220V

power cords. Ensure power cord in

use matches electrical service.

Reset breaker, replace outlet or

relocate connection to available

power. Contact qualifi ed Electrician

if power is still not available.

Check with ohmmeter and replace if

defective.

Replace if defective.

Replace if defective.

Check with ohmmeter and replace if

defective.

E

nsure that correct power cord for

incoming voltage is being used.

SureShot II offers 110V and 220V

power cords. Ensure power cord in

use matches electrical service.

Repair or replace if defective.

Repair or replace if defective.

Repair or replace if defective.

Check with ohmmeter and replace if

defective.

Ensure that no contact is made

between gun and workpiece for

charging to occur.

Adjust for proper welding.

Release trigger to allow charging.

Inspect gun microswitch. Check with

ohmmeter. Replace if defective.

¥

.*%8&45'"45&/&34*/$

4VSF4IPU**4UVE8FMEJOH4ZTUFN

5306#-&4)005*/(

$)"35

5. (continued).

6. Welder turns on, dis-

plays revision level and

diagnostics, but will not

weld.

7. Welder does not retain

the voltage setting when

powered off and back

on.

8. Weld voltage cannot be

increased and/or low-

ered.

D. Faulty printed circuit board.

E. Faulty charge triac (open).

F. Faulty discharge relay.

A. Open circuit in weld or ground

cables.

B. Damaged control cable/trigger

switch.

C. Faulty weld SCR.

D. Faulty printed circuit board.

A. Weld not performed after voltage

adjustment was made.

B. Voltage reverts to minimum

setting when the welder is turned

on.

A. “Trigger” or “Contact” made .

B. Faulty printed circuit board.

Replace if defective.

Repair or replace if defective.

Repair or replace if defective.

Check for “Contact” (yellow) light

while stud is held against work.

If light does not come on, check

the weld cable and ground cable.

Repair or replace defective cables as

needed. Check for clean, solid ground

connection and correct if necessary.

While holding the gun away from the

workpiece, depress the trigger switch.

The “Trigger” (green) light should

come on. If not, repair/replace trigger

switch and or control cable.

Repair or replace if defective.

Replace if defective.

The unit will remember the voltage

of the last weld made. If the voltage

setting is changed, a weld must be

made in order to store the setting in

memory. Alternatively, the trigger

can be depressed, while holding the

gun away from the workpiece to store

a new setting without performing a

weld.

The voltage will automatically revert

to the minimum setting, if the welder

is shut down while operating at the

maximum voltage setting for safety.

Ensure that contact between the stud

and the workpiece is not being made

and that the trigger switch is not

depressed while adjusting the voltage.

Inspect gun microswitch. Check with

ohmmeter. Replace if defective.

Replace if defective.

130#-&. 1044*#-&$"64&

130#-&. 1044*#-&$"64&

$033&$5*7&"$5*0/

¥

.*%8&45'"45&/&34*/$

4VSF4IPU**4UVE8FMEJOH4ZTUFN

5306#-&4)005*/(

$)"35

130#-&. 1044*#-&$"64&

130#-&. 1044*#-&$"64&

$033&$5*7&"$5*0/

9. Consistently poor welds

or erratic welds.

A. Improper gun setup.

B. Improper grounding, cable

installation or incorrect polarity.

C. Weld cables coiled.

D. Incorrect weld voltage.

E. Stud (or Pins) not perpendicular

to workpiece.

Check gun for proper setup (Pg. 10).

Check ground and gun cables for

proper installation and setup (Pg. 8).

Do not coil cables at, or near, weld

area. Loose, or random, loops

are acceptable. Straighten out or

rearrange cables as necessary.

Adjust as necessary (Pg. 11)

Adjust gun setup as necessary. Repair

or replace worn or damaged legs and

feet as needed (Pg. 10).

For safety and security, your SureShot II weld Controller was "factory sealed" at manufacture. T

o maintain warranty,

For safety and security, your SureShot II weld Controller was "factory sealed" at manufacture. To maintain warranty,

For safety and security, your SureShot II weld Controller was "factory sealed" at manufacture. T

and ensure proper servicing, your SureShot II may be returned to

MIDWEST FASTENERS, Ohio, USA, for service

or repair. Call

(800) 852-8352

Monday through Friday between

8

am and

5

pm Eastern time.

¥

.*%8&45'"45&/&34*/$

4VSF4IPU**4UVE8FMEJOH4ZTUFN

463&4)0

5**

456%8&-%*/(4:45&.

41&$*'*$"5*0/4

8FJHIU

QPVOET

1PXFS3FRVJSFNFOU

7"$

)["NQ

1J

O

4UVE3BOHF

HBm

EJB

XFME

CBTF

8FMEBCMF.BUFSJBMT

.JME4UFFM4UBJOMFTT

"MVNJOVN

8FME.PEF

$

BQBDJUPS%JTDIBSHF

$POUBDU

8FME3BUF

NJOVUFNBYJNVN

%FQFOEFOUPOTUVETJ[F

8FME7PMUBHF

m7%$

$BQBDJUBODF

NGE

8FJHIU

QPVOET

OPUJODMVEJOHDBCMFT

1J

O

4UVE3BOHF

HBm

EJB

8FMEBCMF.BUFSJBMT

.JME4UFFM4UBJOMFTT

"MVNJOVN

.BUFSJBM

)JHITUSFOHUIJNQBDU

SFTJTUBOUQPMZDBSCPOBUF

(

VO$BCMF-FOHUI

hEVBM

$BCMFT

h(SPVOE$BCMF

$%

5"-0

/

463&4)05**

456%8&-%*/((6/

41&$*'*$"5*0/4

$

B

$B

$

Q

BQ

B

B

QB

Q

D

JUP

DJUP

D

S%

JUPS%

JUP

JT

S%JT

S%

D

I

DI

D

B

IB

I

SH

BSH

B

F

SHF

SH

8

F8

F

F

8F

8

ME

FME

F

F

MEF

ME

S

FS

F

X

JU

XJU

X

I

JUI

JU

.

I.

I

JD

.JD

.

S

JDS

JD

P

SP

S

Q

PQ

P

SP

QSP

Q

D

F

DF

D

T

FT

F

T

TT

T

P

S

PS

P

S

S

)

)

Z

)Z

)

C

ZC

Z

SJE

CSJE

C

$

SJE$

SJE

P

$P

$

O

PO

P

USP

M

USPM

USP

"

"

"

"

"

¥

.*%8&45'"45&/&34*/$

4VSF4IPU**4UVE8FMEJOH4ZTUFN

463&4)05**

456%8&-%*/(4:45&.

&91-0%&%7*&8%*"(3".

"

#

"

#

$

$

$

$

¥

.*%8&45'"45&/&34*/$

4VSF4IPU**4UVE8FMEJOH4ZTUFN

463&4)05**

1"354-*45

Item Qt

Item Qt

’

y. Part No. Description

Item Qt

y. Part No. Description

1 2 050-3005-01 Ty-Rap

1 2 050-3005-01 Ty-Rap

1 2 050-3005-01 Ty-Rap

1 2 050-3005-01 Ty-Rap

2 1 050-

2 1 050-

2 1 050-

3005-02

Weld Capacitor

Weld Capacitor

3 1 050-

3 1 050-

3 1 050-

3005-03

Rubber Capacitor Pad

Rubber Capacitor Pad

4 1 050-

4 1 050-

4 1 050-

3005-04

Flyback Diode

Flyback Diode

5 1 050-

5 1 050-

5 1 050-

3005-05

Discharge Relay

Discharge Relay

6 1 050-

6 1 050-

6 1 050-

3005-06

Chassis Plate

Chassis Plate

7 1 050-

7 1 050-

7 1 050-

3005-07

Nylon Chassis Mount - Rear

Nylon Chassis Mount - Rear

8 2 050-

8 2 050-

8 2 050-

3005-08

Control Pushbutton

Control Pushbutton

9 1

9 1

9 1

050-

3005-09

Wiring Harness

Wiring Harness

10 1 050-

10 1 050-

10 1 050-

3005-10

Cooling Fan

Cooling Fan

11 5 050-

11 5 050-

11 5 050-

3005-11

S/A Wire-Tie Retainer

S/A Wire-Tie Retainer

12 1 050-

12 1 050-

12 1 050-

3005-12

SureShot II Case

SureShot II Case

13 1 050-

13 1 050-

13 1 050-

3005-13

Ground Buss bar

Ground Buss bar

14

14

1 060-3086-00 Cam-lok Receptacle, Ground (+)

1 060-3086-00 Cam-lok Receptacle, Ground (+)

1 060-3086-00 Cam-lok Receptacle, Ground (+)

15 1 060-3115-00 Control Receptacle

15 1 060-3115-00 Control Receptacle

15 1 060-3115-00 Control Receptacle

15 1 060-3115-00 Control Receptacle

16 1

16 1

16 1

060-3086-00

Cam-lok Receptacle, Gun (–)

Cam-lok Receptacle, Gun (–)

17 1 050-

17 1 050-

17 1 050-

3005-17

Connections Decals Kit

Connections Decals Kit

18 1 050-

18 1 050-

3005-18

Gun

Buss bar

19 2 050-

19 2 050-

19 2 050-

3005-19

Inlet Filter Mesh

20 1 050-

20 1 050-

20 1 050-

3005-20

Power Switch/Breaker

21 1 050-

21 1 050-

21 1 050-

3005-21

PC Board

22 1 050-

22 1 050-

3005-22

Fan Guard

23 1 050-

23 1 050-

3005-23

Power Cord Connector

24 1 050-

24 1 050-

3005-24

Nylon Chassis Mount -

Front

25 1 050-

25 1 050-

3005-25

Weld SCR

26 1 050-

26 1 050-

3005-26

SCR Mount Box-Clamp

27 1 050-

27 1 050-

3005-27

Rubber Transformer Pad

28 1 050-

28 1 050-

3005-28

Transformer

29 1 050-

29 1 050-

3005-29

Bridge Rectifi er

3

0 1 050-

3005-30

Jumper

31

31

1 050-

3005-31

Transformer Mounting Hardware

32 1 050-

32 1 050-

3005-32

Transformer Shield

33 1 050-

3005-33

Triac Switch

34 1 050-

3005-34

Reduction

Relay

35 1 050-

35 1 050-

3005-35

Capacitor Warning Decal

36 1 050-

36 1 050-

3005-36

Discharge Resistor

37 1 050-

37 1 050-

3005-37

Reduction

Resistor

~~ 1 050-

~~ 1 050-

3005-38

Padded Shoulder Strap

~~ 1 050-

~~ 1 050-

3005-39

Control Panel decal Kit

~~ 1

102-0100-02

Security Key

y. Part No. Description

1 2 050-3005-01 Ty-Rap

2 1 050-

3 1 050-

4 1 050-

5 1 050-

6 1 050-

7 1 050-

8 2 050-

10 1 050-

11 5 050-

12 1 050-

13 1 050-

1 060-3086-00 Cam-lok Receptacle, Ground (+)

15 1 060-3115-00 Control Receptacle

17 1 050-

18 1 050-

19 2 050-

20 1 050-

21 1 050-

Item Qt

Item Qt

’

y. Part No. Description

22 1 050-

23 1 050-

24 1 050-

25 1 050-

26 1 050-

27 1 050-

28 1 050-

29 1 050-

0 1 050-

1 050-

32 1 050-

33 1 050-

34 1 050-

35 1 050-

36 1 050-

37 1 050-

~~ 1 050-

~~ 1 050-

~~ 1

Item Qt

y. Part No. Description

Fan Guard

Power Cord Connector

Bridge Rectifi er

Jumper

Transformer Mounting Hardware

Transformer Shield

Triac Switch

Capacitor Warning Decal

Discharge Resistor

Padded Shoulder Strap

Control Panel decal Kit

y. Part No. Description

22 1 050-

23 1 050-

24 1 050-

25 1 050-

26 1 050-

27 1 050-

28 1 050-

29 1 050-

0 1 050-

1 050-

32 1 050-

33 1 050-

34 1 050-

35 1 050-

36 1 050-

37 1 050-

~~ 1 050-

~~ 1 050-

This manual suits for next models

6

Table of contents

Other MIDWEST FASTENERS Welding System manuals

MIDWEST FASTENERS

MIDWEST FASTENERS EAGLE Troubleshooting guide

MIDWEST FASTENERS

MIDWEST FASTENERS CD50 User manual

MIDWEST FASTENERS

MIDWEST FASTENERS TALON User manual

MIDWEST FASTENERS

MIDWEST FASTENERS EAGLE User manual

MIDWEST FASTENERS

MIDWEST FASTENERS CD80 User manual

MIDWEST FASTENERS

MIDWEST FASTENERS UA500 User manual

MIDWEST FASTENERS

MIDWEST FASTENERS sureshot User manual

MIDWEST FASTENERS

MIDWEST FASTENERS CD 100 User manual