Mielta M7 User manual

GLONASS/GPS Tracker

MIELTA M7

(ТНА-1803-01)

User manual

Firmware version2.8.2

Last modified 05.11.2019

Tambov 2019

2

Table of content

Table of content...................................................................................................2

1. Description...................................................................................................4

2. Technical specifications................................................................................5

3. General information.....................................................................................6

3.1 Power supply connection .....................................................................6

3.2 Configuration .......................................................................................6

3.3 Communication....................................................................................6

3.4 Indication .............................................................................................8

3.5 General IO ports...................................................................................9

3.6 Digital interfaces ................................................................................10

4. Functionality ..............................................................................................11

4.1 Communication ....................................................................................11

4.2 Track upload and traffic consumption ..................................................12

4.3 Data upload to multiple servers ...........................................................13

4.4 Time synchronization ...........................................................................13

4.5 Mobile operator selection ....................................................................13

4.6 SIM card selection ................................................................................14

4.7 Track points registration.......................................................................14

4.8 Switch to Parking mode........................................................................15

4.9 Filtering false GPS coordinates .............................................................15

4.10 Power-saving modes ..........................................................................16

4.11 Tracker configuration methods ..........................................................16

4.12 Bluetooth access point .......................................................................18

4.13 Bluetooth headset support.................................................................18

4.14 Digital sensors configuration ..............................................................18

4.15 Working with Mielta system display...................................................19

4.17 Working with CANlog (P145) ..............................................................20

4.18 Working with CANFMS-3 ....................................................................20

4.19 Working with PressurePro APM1 pressure control system.................20

4.20 Working with PressureProPulse pressure control system...................21

3

4.21 Working with external navigation data source ...................................21

4.22 Working with fuel-metering device Eurosens Delta RS100.................21

4.23 Working with ZET7012 pressure sensor..............................................21

4.24 Working with ADM20 RFID reader......................................................22

4.25 Driver identification............................................................................22

4.26 Manual control of discrete output......................................................22

4.27 Discrete input .....................................................................................22

4.28 Alarm button ......................................................................................22

4.29 Odometer...........................................................................................22

4.30 Power saving modes.........................................................................23

4.31 Diagnostics .........................................................................................23

5Firmware update........................................................................................23

6Installation .................................................................................................24

Annex 1................................................................................................................26

General purpose commands ......................................................................26

Set/get commands ....................................................................................29

Diagnostic commands ................................................................................48

Standard parameter data ...........................................................................53

Additional parameter data .........................................................................53

List of supported devices and protocols .....................................................54

4

1. Description

MIELTA M7 is designed for satellite transport monitoring. MIELTA M7 functions are

collecting, processing, saving and transmitting sensor data to server on vehicles and

stationary objects. With additional sensors connected allow to control fuel consumption,

activity of executive devices, vehicle parameters, driver identification and more. The

terminal is adapted to operate in any automotive on-board network, has built-in antennas

for easy installation.

MIELTA M7 has all necessary hardware and software functions with acceptable

price. Terminal is designed to solve your monitoring problem fast and reliable.

5

2. Technical specifications

Power supply

8 –55 V. Power surge protection, reverse polarity

protection, PTC fuse.

Power consumption

1 W average, 3 W max

Battery

800 mAh Li-Po battery, charging from USB cable and

vehicle onboard power

Universal ports

4 ports

Analog input mode: DC 0-36 V, input resistance 30 kOhm,

10 bit ADC;

Discrete input mode: active level - 0V, internal pullup 3.3

V, input resistance 20 kOhm, frequency up to40 kHz,

counter up to 1000000;

Discrete output mode: open collector, DC current up to

200 mA, self-induction protection.

Аccelerometer

Internal, 8G

1-wire

Internal, up to 8 devices

RS232

Internal

RS485

Internal, up to 8 devices

CAN 2.0b

Internal, ISO 15765-4

USB 2.0

Configure, firmware update, data transmission, power

Navigation

GLONASS, GPS, -166 dBm, internal patch antenna 25х25

mm / extrernal active antenna

GSM-antenna

Internal, 900/1800 MHz

Bluetooth

Bluetooth3.0, configuration, firmware update, data

transmission

Memory

16Mb, 60000 track points, additionally Micro-SD up to 32

GB

SIM-card

1pcs, micro-SIM, hot swap, SIM chip option

Server

data transmission

Up to 3 servers

Protocol

Wialon IPS 1.1, IPS 2.0, binary

Protection Rating

IP44

Operation temperature

-40 to+60 °С, humidity up to 98% at a temperature of 25

°С, without dew. Built-in battery charging: 0..+50°С

Averall dimensions

49 х 64 х 17mm

Weight

60 g

6

3. General information

3.1Power supply connection

Tracker is designed for use in automotive on-board system 12/24V, or with USB

adapter 5V 1A. MIELTA M1 also have a vehicle battery discharge control function which is

designed to set Tracker to power-saving mode if predefined conditions occurred (onboard

voltage value etc).

Built-in Tracker battery is dedicated for normal device operation in vehicle short

power-down or onboard vehicle power fault conditions. Built-in Tracker battery cyclic

charging / discharging operation is not recommended, early battery failure is possible.

For objects without constant external power (for example, powered from automobile

auxiliary power outlet) it is recommended to set minimal timeout for built-in battery

operation.

For transportation purposes Sleep mode is implemented. All periphery and modules

are powered down. Sleep mode activation is performed by configuration software (by user

interface) or by console command and powering down the Tracker within 10 sec after device

indication turned off.

If built-in battery is discharged during Tracker operation, device automatically goes

to Sleep mode.

To avoid early built-in battery failure long Tracker storing with plugged built-in

battery and no external power is not allowed.

3.2Configuration

The Tracker has a set of commands to configure settings that control the State and

display information (see Annex 1). Tracker can be configured via USB port (configuration

software), via SMS, the TCP commands from the server monitoring (GPRS), as well as

Bluetooth (using Android Configuration software on the mobile device).

Default access password - 12345. If necessary, you can change the password. If

you lose your password regaining access to the device is possible by contacting technical

support.

3.3Communication

The Tracker has a USB connector for connecting to a personal computer and used to

power supply, configure and update software of the device. Micro-Fit 3.0 connector is used

to connect the main power supply and peripherals. On the back side there is a schematic

representation of the plug-in contacts (Figure 2). Before installation of the device, SIM card

must be instaled. For this purpose it is necessary to unscrew the bottom cover of the

7

Tracker, which is attached with four screws. To protect against unauthorized access, the case

is sealed up by a sticker.

Table 1 Peripheral Micro-Fit connector pinout

Number

Notation

Description

1, 2, 8, 9

Port1(2,3,4)

Universal ports 1-4

3, 10

RX, TX

RS-232 interface

4, 11

A, B

RS-485 interface

5, 12

CANH, CANL

CAN 2.0b interface

6

1W

1-Wire interface

7

VCC

Power DC 8 –55 В

Picture 3 Peripheral Micro-Fit connector

Picture 1 M7 exterior

Picture 2 M7 front panel

SMA connector

Micro-SD

Periphery

connector

USB connector

LED indication

8

13,14

GND

Ground

3.4Indication

Tracker Front panel has 4 LEDs: green, yellow, blue, red (see table 2).

Table 2. Normal operation indication

LED

Function

LED switched

on

Blinking slow

Blinking fast

Blinked once

Green

Power on

External power

No External power,

powered from USB

Black box

clearing

Track point

saving

Yellow

GLONASS/

GPS

Coordinates

are fixed

Unstable GLONASS/

GPS signal

Time is not

synchronized

-

Blue

GSM

Registered in

mobile

network

Problems with

registration or SIM

card

Registration in

network

-

Red

Server

Connected to

Server

Problems connecting

to server

Activation of

GPRS-session,

connecting to

the server

Sending data

to server

LEDs indication:

1. All LEDs are switched on–normal operation;

2. Green blinking slow, red switched on –firmware recovery mode;

3. Green led blinks one time in 10 seconds, other switched off –power saving mode;

4. Blue and red LEDs blinks alternately –firmware update process;

5. Green and Red LEDs on first, then Yello and Blue on –go to sleep mode.

LED indication sequence:

1. Successful firmware start:

-Red LED turns on (bootloader startup);

-Red LED turns off, Green LED on (program successfully launched);

-Firmware normal startup: connecting to the GSM and server.

2. Failed firmware start:

-Red LED on;

-Reboot.

3. Failedfirmware startafter update:

-Red LED on for 30 sec;

-Rebooting, several attempts for firmware download;

-Restore previous firmware;

-Regular start of the restored firmware.

9

3.5General IO ports

General IO ports of the MIELTA M1 can operate in the following modes (see table 3).

Table3.Unversalports modes

1

Analog input

Voltage measurement, 0 –36 V

Ignition signal control

2

Discrete input

Frequency measurement, 1Hz –40 kHz

Low frequency measurement, 0.1Hz –40.0 Hz

Counter,frontedge, 0 –999999

Counter, backedge, 0 –999999

Discrete signal, 0/1

Encoder (Port1 + Port2), 0 - 999999, increment, decrement

Alarm button, 0/1, track point saving

3

Discrete output

0/1, i-button key activation, odometer impulse generator

The analog input is designed for voltage measurement and registration of slowly

changing signals. Measurement of signal level occurs 20 times per second. The data

smoothing algorithm is applied.

When you activate the ignition control function, you can select the signal source is

one of universal ports either power network. In this mode, the Tracker monitors voltage and

modifies the Boolean value of the "IGN" when passing through the established threshold

voltages.

Binary input, designed to work with sensors and signal sources open collector type.

High signal level limited voltage 36 V, low level should be no more than 1 V from GND. The

Tracker has an internal pull-up to + 3.3 v.

In some cases, to improve anti-jamming and ensure a minimum load current of

a frequency output of the external appliance, you must be connected pullup

resistors with nominal 4.7-10 kOhm between the signal wire and power plus (no

more than 36 V).

Tracker has two modes of frequency measurement - high and low, two modes of

counting pulses with synchronization on the front and the recession signal, as well as logical

status mode entry (entry by the mass closure gives «1»).

Encoder mode uses two ports simultaneously and can keep counting pulses from 0 to

999999 in two directions (increment, decrement). Used, for example, for compensation of

oscillating movements of flow sensors.

Digital output is built according to the scheme "open collector" and is intended for

actuating devices control. The following operating modes:

manual mode (switch output status by the command);

identification mode (change status to detect the iButton keys/RFID cards out

of the allowed range);

10

odometer impulse generator.

Before activating discrete output mode of the Tracker’s universal port,

disconnect all external circuits connected to this port.

Before connecting the external circuit, make sure that the current universal

port in discrete mode will not exceed the maximum value of 200 mA.

3.6Digital interfaces

Algorithm of working with digital sensors is built on traditional trackers MIELTA

scheme with virtual slots. In Tracker defined slots for each digital interface (eight for RS485

and eight for 1-Wire), each of them can be configured on any sensor supported by tracker.

The main advantage of this approach is flexibility, ease of configuration and the ability to

simultaneously support various protocols on a single interface. Configuring sensors can be

made during operation, do not interrupt the flow of data and does not require restarting.

Data can be obtained immediately after correct setting up the sensor (using Configuration

software, all changes can be tracked in real time).

Featured network settings for peripheral devices 1-Wire and RS-485 are given in

tables 4, 5 and 6.

Table 4.Featured 1-Wire networksettings

Length of the line

The number of

devices on the bus

Ttype of cable used

Topology

Up to 5 m

Up to8pcs

Any

Free

Up to 20 m

Up to8pcs

2x22(20) AWG

UTPCat. 3-5e

Bus with patches

up to 0,5 m

Up to 50 m

Up to 8 pcs

OnlyUTP, FTPCat. 3-5e

Bus only

Table 5.Recommended settings for the RS-485 network

Length of the line

The number of

devices on the bus

Type of cable used

Topology

Up to 20 m

Up to8pcs

2x22(20) AWG

UTPCat. 3-5e

Bus with patches

up to 5 m

Up to 100 m

Up to8pcs

Only FTP, STP, S/FTPCat. 5-7

Bus with patches

up to 2m

With a wire length more than 20 meters, you must use a 120 Ohm terminating

resistor on the opposite end of the line from Tracker.

11

To ensure correct and safe operation of digital interfaces, ground potentials of

Tracker and the attached devices must be connected, otherwise signal can be

matched using an optical isolator.

Table 6. Recommended CAN network parameters

Length of the line

Type of cable used

Termination

Up to 0,5 m

CAN-BUS 1x2x0,34

Not obligatory.

Depends from bus

topology

From 0,5 to 5 m

CAN-BUS 1x2x0,34

Not obligatory.

Depends from bus

topology

For operation with CAN bus vehicle wiring is often used with length not more than 5

meters. In this case need for termination resistors is defined by experimental way.

More detailed instruction for CAN operation see in configuration software help.

4. Functionality

4.1 Communication

Tracker has communication module SIM868. Micro-SIM card holder is installed on

PCB. For installation it is necessary to open the case. MIELTA M1 supports SIM card hot

swapping without shutting down the power supply.

Built-in GSM modem works in the ranges 900/1800 Mhz, supports GPRS class B, multi

slot 12/10. To activate the GPRS following options are provided:

access point name;

login;

password.

If GPRS-session is active, MIELTA M1 starts the process of connecting to the

monitoring server. Simultaneous work with three different servers is supported. To

configure the connection, use the following options:

Server address (possibly set up as an IP address, for example 193.193.165.165,

and the DNS name of the server, for example hosting.wialon.com, the

maximum length of the name is 63 characters for the main server and 47

characters for two additional servers);

the connection port, depending on the Protocol (for example, 21204);

the access password to the server, the maximum length is 15 characters;

communication protocol (Wialon IPS 1.1, 2.0 and Wialon IPS binary protocol

supported).

12

4.2 Track upload and traffic consumption

After successfully connecting to the servers Tracker starts to upload collected track

data from built-in "black box". MIELTA M1 internal memory stores up to 10000 track

records, which can be sent to server or uploaded by configuration software. Number of

stored records to be sent to each server enabled by device configuration does not depend

on the number of configured connections. The order of "black box" track points and

messages upload is following: from newest to oldest. Tracker allow to upload up to 10 points

in the packet.

Following data upload modes are provided:

Fast. This type of uploading has maximal traffic consumption, however, allow

you to track the object on the server with minimal delay. If the connection to

the server is active, the track point to the server is uploaded immediately after

registered by MIELTA M7.

Batch. This type of track upload is a compromise between traffic consumption

and delay between track point generated and received by server. This mode is

specified by setting the maximum allowed delay for data uploading. That is, a

packet is prepared for sending to server when a maximum delay after previous

packet sent is occurred, or if the number of records in the “black box”is greater

than the maximum possible number of points in the packet. In other words, if

the black box is empty, the Tracker is waiting for the timeout to allow sending

the next packet, and if the black box records accumulated, then the Tracker

sends data packets without delays until it unloads all the records from the black

mailbox.

Scheduled. This mode is designed for reduced traffic consumption during track

upload. Period for track data accumulation must be specified for this mode.

Server connections in scheduled mode are inactive all the time except

scheduled time when GPRS activates for all accumulated track data upload.

After sending all track data Tracker close all the connections and returns to

track data accumulation mode for given period of time. In data accumulation

mode MIELTA M7 is available only by SMS commands.

Uploading track mode should be adjusted separately for home network and roaming.

It should be noted that the more track points are packed in the packet, the lower overhead

of packet headers and less traffic consumption. TCP connection is used for track data

upload.

When track upload and track point registration settings are configured it should be

noted that terminal supports keep-alive connection function to avoid connection closing by

timeout. Ping packets are sent to server every 3 minutes if no track point is generated during

this time. Keep-alive reduces traffic consumption related to connection closing and re-login.

Roaming track upload disable function is also implemented to reduce vehicle

monitoring cost.

13

4.3 Data upload to multiple servers

MIELTA M7 is able to work with multiple monitoring servers simultaneously. For each

server, you can separately specify any Protocol supported by firmware. To configure the

connection enable option must be set. Also Server IP address (or domain name), Port and

Protocol must be set. Password for server authorization and track upload mode are defined

globally for all connections. Number of Track points stored in Black Box does not depends on

number of Servers for sending and all the Track points are uploaded to all configured

servers.

4.4 Time synchronization

After powered-up, MIELTA M7 must synchronize the system time with a source of

accurate time. It can be done in two ways: request the exact time from mobile operator

base station or receive from GPS / GLONASS satellites. It should be noted that time

synchronization by base stations signal is not supported by all operators. From the moment

power is applied and until the system clock is synchronized with the time source, the

terminal stores track points in temporary memory. After synchronization, the terminal

updates the time at previously saved points. If you turn off the power of the terminal until

the clock is synchronized, then all track points from the moment of power-up will be lost.

Every minute the system time is compared with the time received from the satellites.

If the vehicle is parked for a long time with a poor signal level of the satellites (garage,

carport), then the system clock error may accumulate. If there is no satellite signal within 24

hours, the synchronization of the system time by base stations is allowed. The maximum

error of the system clock in the absence of a source of accurate time usually does not exceed

1-2 seconds per day. If system clock error exceeds 15 minutes during time synchronization

procedure, the message “WARN: RTC CLOCK” will be sent to the statistics server. With

normal terminal operation, this situation is possible if the system time synchronization has

not been performed for several years (long-term parking of the vehicle in a garage with a

weak GSM signal and satellites).

4.5 Mobile operator selection

Two methods of mobile operator selection are implemented in MIELTA M1 for GPRS

session activation:

-Mode 1: list of high priority operators (up to 150) + list of disabled operators (up

to 50);

-Mode 2: list of enabled operators (up to 200).

Mode 1. MIELTA M1 starts to search available operators after power applied. If

MIELTA M1 found high priority operator among available and if current operator is not in

high priority list, terminal starts to register with in priority mobile network. If registering or

GPRS connection activation failed then tracker tries to connect to the next high priority

operator. If all high priority operators failed then tracker try to connect to any available

operator. Disabled operators are ignored in this case. If all enabled operators are failed

14

registering then terminal try to register in disabled network, GPRS connection is disabled. In

this case terminal is available only by SMS commands. Scanning for available operators

executed every 15 minutes in roaming, every 2 hours in home network. If GPRS status

sending to server option is enabled then text message is generated during operator switch.

Mode 2. In this mode MIELTA M1 activates GPRS connection only for operator within

list of enabled. For other operators GPRS connection is disabled.

4.6 SIM card selection

When 2 SIM cards are inserted SIM selection is performed after mobile operator

selection procedure. SIM card for operation is selected by several criteria listed below by

priority reducing:

- SIM card presence;

- SIM card lock status (binding to Tracker);

- GPRS session activation ability;

- Cell network registration status;

- SIM card slot status (priority / disabled);

- Cell network signal level.

First, Terminal checks SIM insertion to slot. Then high priority is given to first SIM

with successfully activated GPRS context even if that SIM is in roaming. If both SIM cards are

able to activate GPRS context then high priority is given to SIM registered in home network.

If both SIMs has same network registration status then SIM priority is selected from

configuration. If one of SIM slots is disabled by configuration, terminal will operate only with

card inserted in enabled SIM slot. In this case SIM card in disabled SIM slot is available only

by SMS. A last criterion is cell network signal level. Note: if SIM card installed during SIM lock

procedure war changed by another, it also will be disabled.

4.7 Track points registration

Three modes are provided for track points registering:

Stop;

Parking;

Movement.

After power-up and time synchronization Tracker allows track points registration and

switches to "stop" mode. Following settings are available for this mode:

Registration period. Option for time interval for track point registration.

Switch to "Parking” mode time. Sets the maximum time spent in "Stop"

mode, after which the Tracker goes “Parking”. The main difference between

these modes is that “Parking” mode has option for reduced power

consumption, which will be described in the following sections.

Track point registration period is provided for "Parking" mode.

When Tracker registered that vehicle started to move it changes its state from

“Parking” or “Stop” to "Movement". Two modes are provided for flexible track point

15

registration adjustment: “low speed” profile and “High speed” profile. First you need to

specify boundary for velocity ranges, separating low and high speed. Such partitioning

enables you to, for example, to specify different settings for traffic in the city and on the

highway. Each profile has following settings:

Distance. Sets the maximum distance relative to previously registered track

point.

Angle. Sets the maximum change of direction relative to previously registered

track point.

Time. Sets the maximum time between track points registration.

For the "Movement" mode track point registration options for speed limit exceed are

provided:

Speed limit. Sets the maximal allowed speed of an object, by exceeding which

track point is generated.

Speed limit increment. Sets the speed limit increment for which track point is

registered.

Acceleration threshold. Track point is generated during sharp acceleration or

braking the vehicle. Threshold can be set in range [1.1..8.0]

Ignition state change. Track point is generated during ignition state changing.

Input and voltage threshold level can be adjusted.

4.8 Switch to Parking mode

It is possible to set one or several conditions for switching to Parking mode from Stop

mode:

-By GPS zero-speed timeout (default condition);

-By ignition status;

-By accelerometer sensor (waits for accelerometer “Stop” status).

If multiple conditions are selected switching to Parking mode is performed when all the

selected conditions are obtained (logical AND). If no conditions selected then Parking mode

is disabled. For every type of condition Track point registration options are provided.

4.9 Filtering false GPS coordinates

MIELTA M7 provides “GPS Filter” which is designed to prevent Track point

registration with low accuracy coordinates. This filter has following settings:

Maximal HDOP value;

Minimal number of satellites.

Filters by acceleration sensor and by ignition status are provided to prevent "false

travel" and "track stars" during parking. Filters can be independently enabled and disabled. If

both filters are active, coordinates freeze at parking is most reliable. But for unforeseen

cases (for example, vehicle evacuation) GPS distance control is provided and Tracker will

register the track in any case. One of General IO Ports or onboard voltage value can be used

to control the ignition status. Hysteresis is provided for voltage value. For parking in areas

16

with weak satellite signal it is recommended to disable coordinates transmission to filter the

"track stars" by disabling coordinates transmission in Parking mode. If only acceleration filter

is used then following restriction for Track point registration in parking mode is used: if

number of visible satellites is less than 12 and HDOP is less than 0.8, Track points are

generated without coordinates.

4.10 Power-saving modes

Three energy modes are implemented in Terminal:

Main mode. In this mode Track points registration and sending to server are

performed according to Tracker settings.

Power saving mode. Dedicated for battery saving during parking, excluding

data loss. That is, data registration from sensors and GPS-receiver does not

stops but GSM module is powered off. Powering on is performed once per

hour for 15 minutes for accumulating Track data upload. If Tracker in roaming

and track upload is disabled in roaming then GPRS session is not activated.

GSM module is turned on in this case for checking inbound SMS commands.

Power saving mode is activated automatically in Parking mode.

Sleep mode. Dedicated for long-term parking. In Sleep mode Tracker

periodically controls the value of the supply voltage, other functions are not

available. If Tracker is powered directly from the battery of the vehicle and if

assumed long parking between vehicle rides, it is recommended that option

"Enable sleep mode on parking" is checked. Two thresholds are available for

setup: “Enter sleep mode" voltage and “Exit sleep mode” voltage. That is,

onboard voltage is higher when vehicle engine is turned on than for stopped

engine.

4.11 Tracker configuration methods

Tracker configuration is done using the text console commands. To access the

Tracker you must enter a password. In cases of password loss, you can enter the master

password. Ask for it from MIELTA technical support. Master password has a limited validity

period.

Several ways to configure the Tracker are provided:

•TCP commands;

•SMS commands;

•PC configurer utility (by USB);

•Android configurer utility (by Bluetooth).

Configuring by TCP or SMS commands is performed by sending text console

commands to Tracker. It is possible to send multiple commands in a single message, with

commands written in execution order. Commands are delimited by a semicolon. A full list of

commands is given in Annex 1.

17

Working with Mielta Tracker in console mode starts with user authorization pwd

command. All commands except for pwd and logout returns OK or ERR after command

processed. OK indicates that the command completed successfully, ERR means that an error

occurred while executing the command or command is entered incorrectly. In the Tracker,

there are several users, for each independent authorization is required: 1. Phone (SMS) 1; 2.

Phone 2 (SMS); 3.Phone (SMS) 3; 4. Phone (SMS) 4; 5. USB (command line); 6.Bluetooth;

7.TCP (monitoring server). Simultaneous work with multiple Tracker users is allowed. A list of

phone numbers enabled for authorization can be requested by get phone command, set

new phone number - set phone command.

After entering correct password, access granted to execute commands. After 30

minutes of inactivity session automatically closes. Session can be also closed manually by

corresponding command (logout).

Table 6. Configure monitoring server connection parameters example:

Command

Ansver

pwd 12345

Welcome! User logged in

set server 0 on 193.193.165.165 20332 IPS_2_0

OK

set pwdservermielta

OK

rebootall

Table 7. Sensor configuring example:

Command

Ansver

pwd 12345

Welcome! User logged in

set sensor R4.1 LLS Fuel 1 1 3

ok

set sensor OW1 DS1820 Temp 1 1 987654321

ok

logout

Good-bye! User logged out

To configure by USB or Bluetooth corresponding desktop Windows and mobile

Android configurers are designed. Configurer also displays real-time sensor data.

Work with Android configure starts with Bluetooth access points search. If necessary

devise selected program requested to enter Bluetooth connection PIN code, after that you

should enter access to terminal password. After entering the correct password Configurer

has access to Tracker.

Tracker in the Windows operating system is defined as a virtual COM port. By clicking

the "device selection" in the Configurer displays the search window, where you can view all

found trackers. After necessary device selected and correct device access password entered

software starts to request data from Tracker and display on user interface. Windows

software has following additional functions:

•Tracker firmware update from file;

•Uploading the track records from Black box to file;

•Tracker settings import/export to file.

18

4.12 Bluetooth access point

Bluetooth connection configuration has following options:

PIN. You need to initialize the connection via Bluetooth.

Access point name. Should be set to identify the Tracker during devise search.

By default, the name is defined as a device IMEI.

Multiple modes of operation are implemented:

Disabled. Bluetooth access point is unavailable.

Enabled until restart. Activates the access point until you restart Tracker.

External power on. The access point is activated every time when you

disconnect and external supply voltage (even if you are reconnecting Tracker

continues to work from the built-in battery). Access point after reconnecting

the power active 15 minutes, and if during that time was not Bluetooth

connection after this time is disabled.

Always on. Bluetooth access point always available.

Speakerphone. Bluetooth is used to connect to the headset for voice

communication (see section 4.10).

Bluetooth access points work on the Tracker practically does not affect the unloading

track and the rest of the functional GSM-module that allows you to connect your Android

device and use it as a monitor sensors in real time.

4.13 Bluetooth headset support

To receive voice calls, you can connect a wireless headset. To do this, in the

“Communication” menu of the configuration software in the “Bluetooth Settings” section,

select necessary mode and click the “Write settings”. To pair with a wireless headset, click

the Configure button, search for available devices, and select the desired device. After

clicking the “Write settings” button, the MAC-address of the selected device will be stored in

the terminal memory. The terminal will automatically connect to the selected device, if

available. An incoming call is answered automatically. If the headset is not used, hands-free

mode should be turned off.

4.14 Digital sensors configuration

Each of RS-485 and 1-Wire interfaces have eight slots and supports up to 8 digital

sensors. One slot on RS-232 interface.

To work with the sensor, you must select the corresponding slot of the interface,

choose sensor type, specify the required settings (bus address, data type, etc.). One sensor

can be selected within the slots. For example, the fuel level sensor produces 3 parameter

(fuel level, frequency and temperature) by adjusting the three slots on the fuel level sensor

for each data type, we get all three measurement parameters and send them to the server

monitoring.

19

A packet of data sent to the server is created automatically, depending on the

availability of active slots. On the server slots are denoted as follows: R2.1 for RS-232, R4.1,

..., R4.8 for RS-485 and OW.1, ..., OW.8 for 1-Wire. For example, the first slot RS-485 and 5-

th slot 1-Wire bus on the server is as follows: R4.1 = 4096, OW.5 = 123456. For some types of

sensors available possibility to receive 2 parameter with a single slot, in this case, the slots

on the server will have the following designations: R4.1.1, 4.1.2,..., R4.8.1, R4.8.2.

4.15 Working with Mielta system display

The Tracker supports display MIELTA connected by RS-485 bus. The system display is

used to display the overall Tracker status, connection parameters, data from different

interfaces, specially adapted for work on stationary and mobile gas stations. Tracker

supports up to 8 displays on bus system, each of them can display different data. The display

is connected to one of the RS-485 port slots with the address, similar the sensors.

4.16 Working with “ATOL” tachograph

Terminal supports *.ddd file upload from ATOL Drive 5 tachograph by “Penal”

protocol. Tachograph device type can be selected in the list of peripheral devices on RS-232

interface. *.ddd files upload supports Wialon hosting and Wialon Local servers. Tacho

manager app should be installed on server. File can be uploaded from tacho on server by

request. Request format is defined by Wialon IPS 2.0 protocol. In the request in field “Driver

ID” should be specified FirstName SecondName of the driver equal to specified driver’s card.

If TCP connection lost during file upload server returns error and upload should be started

again by request.

Terminal has tacho upload problem diagnostics. Messages with errors are saved to

Black box and uploaded to server. Full list is in following table.

Table 9. ddd file upload error list:

N

Message

Description

1

MSG: 'ddd' file upload: OK

File successfully uploaded

2

ERR: 'ddd' file upload: tacho not

found in sensor slots

No slot assigned to tacho

3

ERR: 'ddd' file upload: driver not

found in card slots

“FirstName SecondName” was not found in tacho card slots

4

ERR: 'ddd' file upload: driver card

ejected

Driver card was ejected from slot during file upload

5

ERR: 'ddd' file upload: server

connection lost

Wialon server connection error

6

ERR: 'ddd' file upload: serial port

connection problem

Tacho stopped responding during terminal requests

8

ERR: 'ddd' file upload: operation

cancelled by user

Tacho restricted terminal access to driver card during

upload by user by tacho front panel

9

ERR: 'ddd' file upload: tracker not

Tracker is not ready to download *.ddd file (for example,

20

ready

time is not syncronized on terminal)

10

ERR: 'ddd' file upload: unknown

error

Unknown error

4.17 Working with CANlog (P145)

M7 supports CANlog (P145) connected by RS-232 port. In this case R2.1 slot returns

CANlog connection status. If status equal to zero, then CANlog connected normally. If status

is less than zero then CANlog has connection problems (= -1) or setup problems (= -2).

CANlog data is sent to server by separate data fields with prefixes, according to CANlog

documentation. Tracker has restriction for number of prefixes sent to server. That is why

just necessary prefixes should be selected during CANlog setup. It can be done by

configuration software or by TCP / SMS text commands. Additionally, terminal can set

CANlog program to select vehicle type or send command to restart CANlog.

Set of parameters for sending is configured by configuration software. To increase

number of allowed parameters to send Black box record size must also be increased, see

set/get bbcfg command description.

4.18 Working with CANFMS-3

M7 supports CANFMS-3 CAN logger. Operation with CANFMS is similar to CANlog

except logger reboot function and vehicle type selection. Vehicle type is selected by logger

configuration utility. R2.1 slot returns connection status (0 –normal operation, -1 -

connection problems, -2 -setup problems).

Set of parameters for sending is configured by configuration software. To increase

number of allowed parameters to send Black box record size must also be increased, see

set/get bbcfg command description.

4.19 Working with PressurePro APM1 pressure control system

M7 supports PressurePro wireless pressure sensors. Value reading from wireless

sensors is processed by PressurePro AMP1 monitor which is connected by RS-232 to the

terminal. RS-232 must be configured for the PressurePro. R2.1 slot returns number of

connected wireless PressurePro sensors. Terminal supports up to 34 sensor values sending

to server. Values are sent in psi (1 atmosphere = 17.7 psi) for pressure (P). Temperature zone

values (T) are also sent to server, each temperature zone is 20°C wide. Server notation for

measured values is: P1=15,T1=3. For temperature estimation following formula is used:

T=(n-2)*20°C (i.e. T1=3 means tire temperature is estimated in 20..40°C range). Only active

sensor data is sent to server, that is why after R2.1 slot setup for PressurePro no other

options are required.

This manual suits for next models

1

Table of contents

Other Mielta GPS manuals

Popular GPS manuals by other brands

NCSNAVI

NCSNAVI R120 user manual

Kirsch

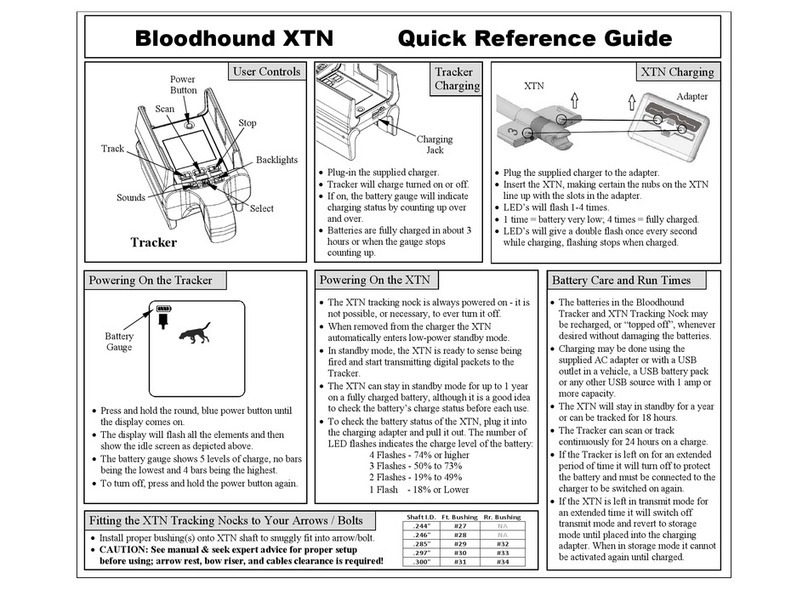

Kirsch BLOODHOUND XTN Quick reference guide

Garmin

Garmin GPS 12XL - Hiking Receiver Owner's manual & reference

Navilock

Navilock NL-464US user manual

AMG-Sicherheitstechnik

AMG-Sicherheitstechnik AMGoTrack Long Term GPS Tracker v2 manual

Raven

Raven RPR 110 Installation and service manual