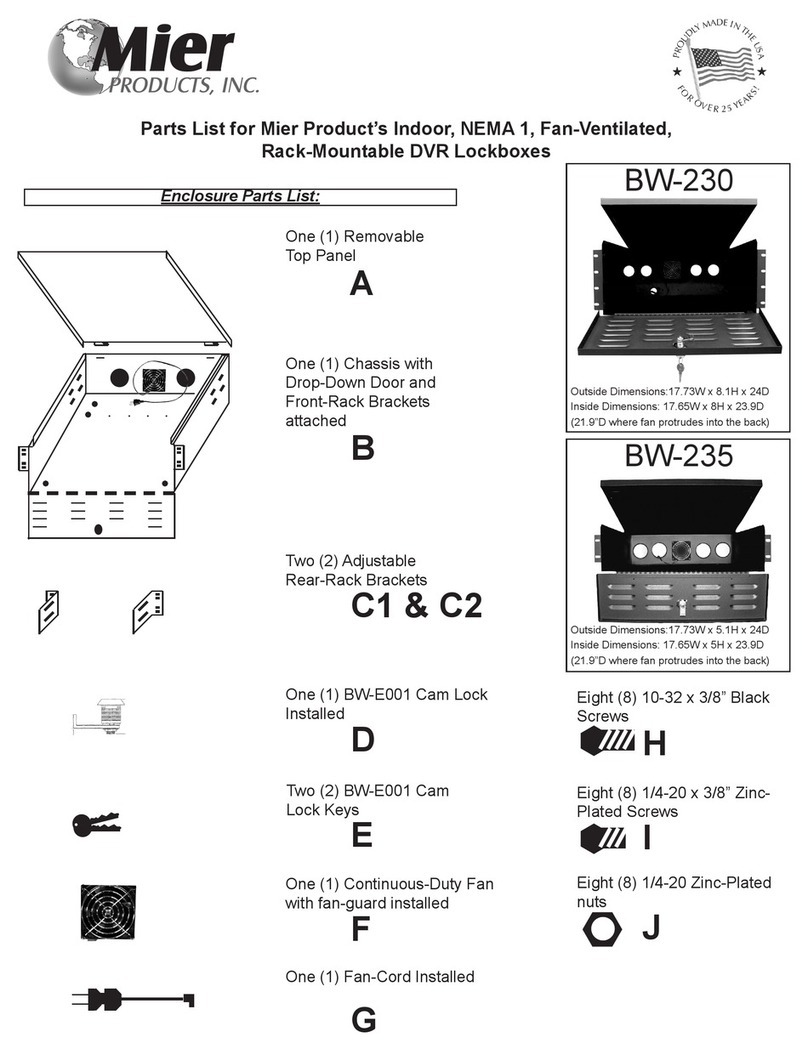

Mier products ACE Series User manual

Temperature Controlled Enclosures

Protect your electronics and control their environment!

BW-124-8-ACE

NEMA 4, 24”W x 24”H x 8”D

with an 800 BTU AC unit

ACE Series

Outdoor enclosures with UL Listed

air-conditioners, lters, and thermostats

BW-242410ACE

NEMA 4X, Polycarbonate,

non-metallic enclosure,

24”W x 24”H x 10”D with an

800 BTU AC unit

BW-124ACE

NEMA 4, 24”W x 24”H x 12”D

with a 2000 BTU AC unit

BW-136ACE

NEMA 4, 24”W x 36”H x 12”D

with a 2000 BTU AC unit

BW-RACKACE

NEMA 4, 22”W x 12RU H x 24”D

with 2000 BTU AC unit and an

internal 19” rack

BW-124-8-ACHT

NEMA 4, 24”W x 24”H x 8”D with an

800 BTU AC unit and 150W heater

BW-136ACHT

NEMA 4, 24”W x 36”H x 12”D with a

2000 BTU AC unit and 500W heater

BW-124ACHT

NEMA 4, 24”W x 24”H x 12”D with a

2000 BTU AC unit and 500W heater

ACHT Series

Outdoor enclosures with UL Listed

air-conditioners, heaters, lters, and thermostats

BW-242410ACHT

NEMA 4X, Polycarbonate,

non-metallic enclosure,

24”W x 24”H x 10”D with an

800 BTU AC unit and a

150W heater

Add a “W” at the end of these

part numbers for an optional

window in the door as shown

above and below.

BW-RACKACHT

NEMA 4, 22”W x 12RU H x 24”D

with 2000 BTU AC unit, 500W

heater, and an internal 19” rack

Don’t see the enclosure you need?

Call or e-mail us and we’ll be happy to help!

Protection from Vandals and Mother Nature!

Indoor & Outdoor Electrical Enclosures | Drive-Alert Vehicle Detection & Asset Protection Systems | Custom Fabrication

BW-124-8-ACESS

Stainless steel NEMA 4X

version

BW-124ACESS

Stainless steel NEMA 4X

version

BW-136ACESS

Stainless steel NEMA 4X

version

BW-RACKACESS

Stainless steel NEMA 4X

version

BW-124-8-ACHTSS

Stainless steel NEMA 4X

version

BW-124ACHTSS

Stainless steel NEMA 4X

version

BW-136ACHTSS

Stainless steel NEMA 4X

version

BW-RACKACHTSS

Stainless steel NEMA 4X

version

P

R

O

U

D

L

Y

M

A

D

E

I

N

T

H

E

U

S

A

F

O

R

O

V

E

R

3

0

Y

E

A

R

S

!

ATTENTION: When choosing an enclosure for your application, careful

consideration must be given in determining the heat load and operating

temperature parameters of the electronics mounted within. Also consider

the conditions of the environment where the unit is to be mounted, and the

moisture toleration of the electronics mounted within. Based on these facts,

the need for air-conditioning, humidity control, heat, and/or fans can be

determined as well as the NEMA rating needed. (For example, if the

electronics cannot be exposed to moisture of any kind, a NEMA 3R fan-

ventilated unit would NOT work; you would need at least a NEMA 4 or

NEMA 4X unit.) Mier commonly recommends the highest NEMA rated and

most effective Temperature Controlled units which are the “ACHT” series

enclosures.

Mier’s FC, ACE & ACHT Series enclosures are special order and typically take

2-4 weeks to ship. As they are special order, they are non-returnable/non-

cancellable.

NOTE: To keep NEMA Rating, installers must strictly

follow OEM installation instructions and must properly

install NEMA rated water-tight ttings on all openings.

DO NOT MOUNT enclosures equipped with air-conditioners on walls

of apartments, ofces, condos or homes due to slight vibration from

the AC unit, which might become a nuisance to those who live/work

on the other side of the wall. Mier recommends mounting these units

on concrete pads using vertical struts of angle-iron or poles, or

mounting on walls not common to living/work areas.

Remember: Sealing the outside of pipes and holes made for conduit

is only half the job. Always make the pipe and hole openings inside

the enclosure water/air-tight to prevent condensation, or even mice,

coming up into the enclosure from the ground. It is recommended all

holes be made in the bottom of the enclosure so the entire unit acts as

a moisture shield.

Powder-Coated Steel, Stainless Steel or Polycarbonate: Mier offers all

of these choices in temperature controlled enclosures. ALL of Mier’s

Air-Conditioned and Air-Conditioned with Heater enclosures are

NEMA4 air/dust/water-tight. The Polycarbonate and Stainless models

add the benets of NEMA 4X add even more corrosion protection.

Mier Products’ Temperature Controlled Enclosures

Installation and Warranty Information

Mier’s outdoor enclosures are designed to

provide a degree of protection against rain,

sleet, snow, ice, dirt, and dust.

***** AC/Heater Units Must be kept upright at all times or damage to cooling system may result *****

2000BTU & 800BTU AC Units with compressor coil heater and thermostats with variable controls for both cooling or heating

Power:

Once installed correctly, the power cords for the AC unit and the heater are within the enclosure. Thus, the installer/electrician is responsible for

getting power inside the enclosure. It is up to the installer to cut, and properly install with water-tight ttings, any holes needed to run power within or

run cables out of these enclosures. It is recommended all holes be cut into the bottom of the enclosure so the entire unit acts as a moisture shield.

Both the AC unit and the heater get their power from AC 115V, 60hz. Mier recommends the installer/electrician run power into the box via exible or

rigid conduit, with water-tight ttings both inside and out, to outlet boxes mounted within the enclosure. Note: other voltages available.

Wiring: use #12 AWG standard house wiring to a quad outlet box

Connection: the AC/Heater unit has a standard 3-prong NEMA 5-15P plug and the tamper switch connects to the standard low-voltage alarm circuit.

* Power: 115V, 60hz (other voltages available)

* Amp Draw: 2000 BTU draws 7 amps with initial start-up spike of 17.5 amps.

800 BTU draws 3.8 amps with initial start-up spike of 8.5 amps.

* Dimensions: 2000 BTU unit is 10”W x 20”H x 10”D ---- Weight: 63 lbs

800 BTU unit is 7.5”W x 15.75”H x 7.25”D ---- Weight: 27 lbs

* Mounts: Slips into pre-punched holes on enclosure (Note: install gasket rst)

* Min/Max Temp: -40/131 degrees F (-40/55 degrees C)

500 Watt & 150 Watt Heaters

* Power: 115V, 60hz (other voltages available)

* Amp Draw: 500-watt heater draws 4.5 amps, 150-watt heater draws 1.5 amps

Tamper Switch - Plunger style includes both NC and NO contacts

* Maintenance: ***Clean the air lter every six months minimum*** RP aluminum washable air lters are designed to provide

excellent ltering efciency with a high dust holding capacity and a minimum amount of resistance to air ow. Because they are

constructed entirely of aluminum they are lightweight and easy to service. Optimum lter performance is maintained by recoating

the lters after washing with RP Super Filter Coat adhesive. To achieve maximum performance from your air handling equipment, air

lters should be cleaned on a regular basis. The inlet air lter is located behind the front cover. To access lter, pull ring protruding

from slot in bottom of front cover. The lter may now be cleaned or new lter installed.

Cleaning Instructions:

1. Flush the lter with warm water from the exhaust side to the intake side. DO NOT USE CAUSTICS.

2. After ushing, allow lter to drain. Placing it with a corner down will assure complete drainage.

3. Recoat the lters with RP Super Filter Coat adhesive. When spraying lter do so from both sides for maximum concentration of adhesive.

Depending on the model you purchase, some ACE or ACHT units have less or more cubic volume inside.

• Mier’s “ACHT” and “ACE” models come with a 2000 BTU A/C Unit (aka: T-20s). When installed and functioning properly, it will maintain an

internal preset temperature of (+/- 30F) when the internal heat load is 200 watts. For example the BW-124ACE (enclosure size 24”W x 24”H x

12”D) is capable of maintaining an 800F internal temperature (+/- 30F) up to an outside temperature of 1350F.

• Mier’s “ACHT” models also come with a 500W Heater integrated into the A/C unit. When installed and functioning properly, it will maintain

an internal preset temperature (+/- 30F) when the internal heat load is 200 watts. For example the BW-124ACHT (enclosure size 24”x24”x12”)

maintains a preset temperature (+/- 30F) up to a maximum of up to 600F with an outside temperature of -200F. The BW-136ACHT (enclosure size

24”x36”x12”) maintains a preset temperature (+/- 30F) up to a maximum of up to 600F with an outside temperature of -100F.

• Mier’s “8ACHT” and “8ACE” models, AND Mier’s Polycarbonate enclosure AC models, come with the smaller 800 BTU A/C Unit (aka: T-15).

When installed and functioning properly, it will maintain an internal preset temperature (+/- 30F) when the internal heat load is 100 watts.

For example the BW-1248ACE (enclosure size 24”x24”x8”) is capable of maintaining an 800F internal temperature (+/- 30F) up to an outside

temperature of 1250F.

• Mier’s “8ACHT” models also come with a 150W Heater integrated into the A/C unit. When installed and functioning properly, it will maintain

an internal preset temperature (+/- 30F) when the internal heat load is 100 watts.. For example the BW-1248ACHT (enclosure size 24”x24”x8”)

maintains a preset temperature (+/- 30F) 400F internal temperature down to an outside temperature of -200F.

Mier’s Temperature Controlled Enclosures are completely sealed with no knockouts or holes in the enclosure other than those for mounting the AC

unit. When installed correctly with the AC unit they meet NEMA4 standards and may be used either indoors or outdoors, and provide a degree of

protection to personnel against incidental contact with the enclosed equipment, and they provide a degree of protection for the equipment within

from windblown dust, splashing water, hose-directed water, rain, sleet, snow, ice, and dirt.

• This enclosure is properly installed when the top & bottom mounting ears are ush against the wall or mounting struts, and held securely with

appropriate bolts, and the hinges face to the left after the enclosure has been mounted

• Watertight ttings must be used on all openings created by the installer, including on the inside of the conduit. Mier recommends all conduit entries

and holes be made in the bottom of the enclosures. If the NEMA rating of the ttings are less than the enclosure, the enclosure rating drops to that of

the tting. For instance, an enclosure is NEMA 4, but if an installer uses NEMA 3R ttings the enclosure’s rating must drop to NEMA 3R.

• The door-gasket and AC gasket must remain in place and never be removed.

• The AC/Heater unit must be mounted with the provided gaskets installed between the AC/Heater unit and the enclosure, using the appropriate

pre-cut holes on the enclosure, and strictly following OEM installation guidelines.

• The tamper switch should be mounted on the studs at the top of the enclosure

•If you have ANY questions regarding the installation of these products, call Mier Products at 1-800-473-0213

Mier Products’ Temperature Controlled Enclosures

Installation and Warranty Information

URGENT!

The AC UNIT which

accompanies this enclosure

MUST BE KEPT IN THE

UPRIGHT POSITION

AT ALL TIMES,

and handled with the utmost care

during shipping, storage, installation.

The AC UNIT must be mounted to the

enclosure using the pre-cut holes and

supplied gaskets.

The AC UNIT must be installed in the

upright position, and following OEM

instructions in order to maintain

NEMA rating.

ATTENTION:

WATERTIGHT FITTINGS MUST

BE USED ON ALL OPENINGS!

When installed properly:

* AC Unit is UL/cUL 50 Type 3R, 4, 12,

CE UL le SA6453

* Enclosure meets NEMA4 Standards

* Paint meets NEMA 4, UL-1332

* Gasket meets NEMA 4, UL-50 and

UL-94-HB Flammability Rating

* Tamper Switch is UL Pending

* If your installation is in warmer or cooler exterior environments, of if your internal heat load is greater, or if you are installing in a coastal or

highly corrosive area call Mier Products for advice on special order units

* Mier recommends only installing units with window in shaded areas; as interior temperatures of these units reach 200higher in direct sunlight

than units without windows

* Remember to schedule maintenance of Air-Filters which MUST BE CLEANED PERIODICALLY

* The unit with the MOST COOLING AND HEATING PER CUBIC INCH, and most highly recommended, is the BW-124ACHT

For ON-SITE inspection & repair of A/C units, or A/C Tech Support, call nVent Customer Service at 800-896-2665

AC units needing repair or inspection should be viewed onsite and should not be removed. In the rare case these units would be returned, the

returnee must rst obtain an RMA#, follow the strict shipping and packaging guidelines. The enclosures and AC Units must be shipped on their own

skid, and within the original packaging. REMEMBER: The AC Unit must be kept upright at all times.

P

R

O

U

D

L

Y

M

A

D

E

I

N

T

H

E

U

S

A

F

O

R

O

V

E

R

3

0

Y

E

A

R

S

!

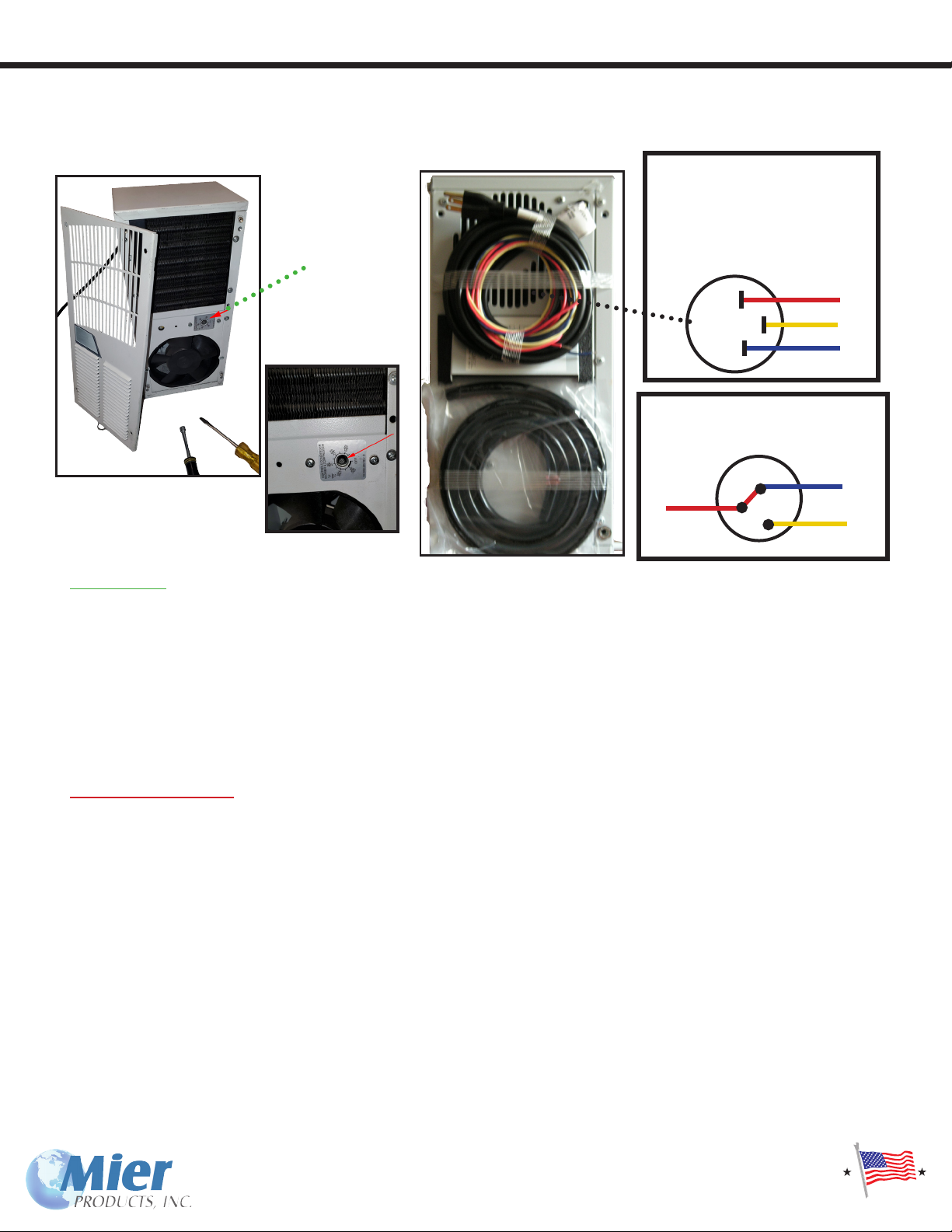

Many of the air-conditioners and combination air-conditioner/heater units have optional Malfunction Switches in them, that are

controlled by the red, yellow, and blue wires that exit the AC unit with the power-cord.

2000 BTU AC Unit Thermostat Instruction and Malfunction-Switch Wiring Information

2

1 3

Malfunction Switch Wiring

Red = Common

Yellow = Normally OpenYellow = Normally Open

Blue = Normally Closed

Internal facing surface

External facing surface

Thermostat:

The “ACHT” Series enclosures are both heated and air-conditioned, so there are two dials for the thermostat on these

units. The “ACE” Series enclosures are air-conditioned, without heaters, so there is only one dial for the thermostat.

Malfunction Switch:

Units with the optional Malfunction Switch have a normally open connection between the red and yellowyellow wires, and a

normally closed connection between the red and blue wires. If a malfunction would occur, the red and yellowyellow wires

will be closed and the blue and red wires will be open.

Maximum electrical ratings for this switch are 13 amps for 120V AC models and 10 amps for the 240V AC models.

The malfunction switch on the air conditioner is a pressure switch. It is plumbed into the high pressure side of the

hermetic system. In a typical application, the malfunction switch is not wired to control any component of the air

conditioner, rather it is an independent switch designed to actuate a customer supplied alarm of some type. There is no

power supplied to the malfunction switch, it requires both a power source and an alarm (light, buzzer, bell, etc.) to be of

any use.

The pressure and temperature are relative in refrigeration circuits. Therefore when the temperature goes up then the

system pressure will go up also. Typically the temperature in the system will go up when the lter is clogged, the

condenser blower is not operating, or the condenser coil is obstructed. The malfunction switch will close the contact

which can then send a signal to the customer supplied alarm device.

The overload on the air conditioner is a bi-metal klixon switch through which the power to the compressor ows. If the

compressor gets too hot, the overload opens the circuit, shutting off the compressor. When the switch cools down again,

it closes the contact and allows the compressor to run again.

Pressure Switch Diagram

Red

Common

Blue - NC

Yellow - NOYellow - NO

P

Thermostat

Location

Thermostat location inside

enclosure after installation

P

R

O

U

D

L

Y

M

A

D

E

I

N

T

H

E

U

S

A

F

O

R

O

V

E

R

3

0

Y

E

A

R

S

!

800 BTU AC Unit Thermostat Instruction and Malfunction-Switch Wiring Information

Many of the air-conditioners and combination air-conditioner/heater units have optional Malfunction Switches in them, that are

controlled by the red, yellow, and blue wires that exit the AC unit with the power-cord.

2

1 3

Malfunction Switch Wiring

Red = Common

Yellow = Normally OpenYellow = Normally Open

Blue = Normally Closed

Internal facing surface

Remove FRONT Cover

Thermostat:

The “ACHT” Series enclosures are both heated and air-conditioned, so there are two dials for the thermostat on these

units. The “ACE” Series enclosures are air-conditioned, without heaters, so there is only one dial for the thermostat. The

800 BTU AC unit’s thermostat is set to 75 F/23 C. To change the temperature setting, remove the front face of the unit.

Use a standard screwdriver to adjust thermostat. For cooler temperatures turn clockwise, for warmer temperatures turn

counterclockwise. Setpoint differential is 6 F.

UNITS WITH HEAT

With a dial setting of 75 F, heat will turn on @ 70 F and turn off @ 75 F. Cooling will turn on @ 85 F and turn off at80 F.

There is a 10 F difference between the heater off setpoint and cooling on setpoint to prevent both from operating at the

same time. The dial range of the thermostat is 50-95 F.

Malfunction Switch:

Units with the optional Malfunction Switch have a normally open connection between the red and yellowyellow wires, and a

normally closed connection between the red and blue wires. If a malfunction would occur, the red and yellowyellow wires

will be closed and the blue and red wires will be open.

Maximum electrical ratings for this switch are 13 amps for 120V AC models and 10 amps for the 240V AC models.

The malfunction switch on the air conditioner is a pressure switch. It is plumbed into the high pressure side of the

hermetic system. In a typical application, the malfunction switch is not wired to control any component of the air

conditioner, rather it is an independent switch designed to actuate a customer supplied alarm of some type. There is no

power supplied to the malfunction switch, it requires both a power source and an alarm (light, buzzer, bell, etc.) to be of

any use.

The pressure and temperature are relative in refrigeration circuits. Therefore when the temperature goes up then the

system pressure will go up also. Typically the temperature in the system will go up when the lter is clogged, the

condenser blower is not operating, or the condenser coil is obstructed. The malfunction switch will close the contact

which can then send a signal to the customer supplied alarm device.

The overload on the air conditioner is a bi-metal klixon switch through which the power to the compressor ows. If the

compressor gets too hot, the overload opens the circuit, shutting off the compressor. When the switch cools down again,

it closes the contact and allows the compressor to run again.

Pressure Switch Diagram

Red

Common

Blue - NC

Yellow - NOYellow - NO

P

Thermostat

Location

Thermostat Close Up

Pole Mount Kits

for 2 inch to 5 inch poles (see next page for larger poles)

ATTENTION: THERE IS NO NEED TO DRILL HOLES INTO THE ENCLOSURES TO MOUNT THE

POLE-MOUNT KITS. PLEASE SEE INSTRUCTIONS BELOW.

• For poles that are 2” in diameter up to 5”, our Pole-Mount Kits use two (2) rails

across the top and bottom of the enclosure and t between the enclosure and the pole,

and four (4) pole-brackets that go around the pole (two on bottom and two on top)

which are tightened down for a secure t. (see next page for 6” to 12” poles)

Part numbers for these kits are the BW-24PM2 (2” pole), BW-24PM3 (3” pole)

and BW-24PM4 (4” - 5” poles)

Example of a

Pole-Mount Kits for

2” to 5”

diameter poles

Mier Recommends using at least two people to pole-mount

heavy enclosures, and preforming steps 1-2 PRIOR to going to

job site.

1) Attach the two (2) rails to the enclosure by placing them at

against the Mounting Brackets on top and bottom of the

enclosure, corresponding to the mounting holes. Then place the

3/8 x 16 Bolts through the Rails and the holes in the

enclosure Mounting Brackets. Secure with the 3/8” Washers on

the outside and 3/8 x 16 Flange-Nuts on the inside.

2) Twist and insert the four (4) pole-brackets into the two rails.

Two of these brackets go in the top rail, and two go in the

bottom rail with the curved sections facing inwards towards

each other to wrap around the pole (see photo):

3) Wrap the pole-brackets around the pole, insert the

attachment bolts, secure and tighten with the lock-nuts.

12

2

1

3

3

These pole-mount kits are used with the following Mier Products Enclosures:

BW-1248BP, BW-1248FC, BW-1248ACE, BW-1248ACHT, BW-124BP, BW-124FC,

BW-124ACE, BW-124ACHT, BW-136BP, BW-136FC, BW-136ACE, BW-136ACHT,

BW-RACKACE and BW-RACKACHT

Pole Mount Kits

for 6 inch to 12 inch poles (see previous page for smaller poles)

P

R

O

U

D

L

Y

M

A

D

E

I

N

T

H

E

U

S

A

F

O

R

O

V

E

R

3

0

Y

E

A

R

S

!

ATTENTION: THERE IS NO NEED TO DRILL HOLES INTO THE ENCLOSURES TO MOUNT THE

POLE-MOUNT KITS. PLEASE SEE INSTRUCTIONS BELOW.

• For poles that are 6” in diameter to 12”, our Pole-Mount Kits use two (2) heavy-duty

adjustable bands which t inside the rails across the top and bottom of the enclosure

and t between the enclosure and the pole as pictured on the left and below.

Part numbers for these kits are the BW-24PM6 (6” to 8” poles), BW-24PM8 (8” to 10”

poles) and BW-24PM12 (10” to 12” poles)

Example of a

Pole-Mount Kits for

6” to 12”

diameter poles

Mier Recommends using at least two people to pole-mount

heavy enclosures, and performing steps 1-4 PRIOR to going to

job site.

1) Mark the center point of each Mounting Rails (A).

2) Slide the Adjustable Band Guides inside both Mounting

Rails, and center them to the point marked on step 1 (B).

3) Place the 1/4” x 20 Screws and 1/4” Washers on the outside

of the Mounting Rails, run the bolts through the Mounting Rails

and Adjustable Band Guides, and secure with the 1/4” x 20

locknuts on the inside (C and B).

4) Insert the two (2) Heavy-Duty Adjustable Bands into the

two (2) Adjustable Band Guides inside the Mounting Rails.

The bands should curve outwards, away from the inside of the

Mounting Rails. One (1) of these Heavy-Duty Adjustable Bands

goes in each of the Adjustable Band Guides assembled inside

each of the Mounting Rails (D).

5) Attach the two (2) assembled Pole-Mount Rails onto the two

(2) Mounting Lips of the Enclosure using the four 3/8” x 16

Carriage Bolts entering through the inside of the Mounting Rail,

use TWO (2) of the eight 3/8” EXTRA THICK Washers ON EACH

bolt between the rail and the enclosure lip for proper spacing,

then use the 3/8” Standard Washers on the outside of the Enclo-

sure Lip with the 3/8” ange-nuts (E).

6) Wrap the bands around the pole and use a power driver with

a straight blade screw-driver, or a 3/8” socket tting, to tighten

the bands securely around the pole (F). F

C

D

A

E

B

These pole-mount kits are used with the following Mier Products Enclosures:

BW-1248BP, BW-1248FC, BW-1248ACE, BW-1248ACHT, BW-124BP, BW-124FC,

BW-124ACE, BW-124ACHT, BW-136BP, BW-136FC, BW-136ACE, BW-136ACHT,

BW-RACKACE and BW-RACKACHT

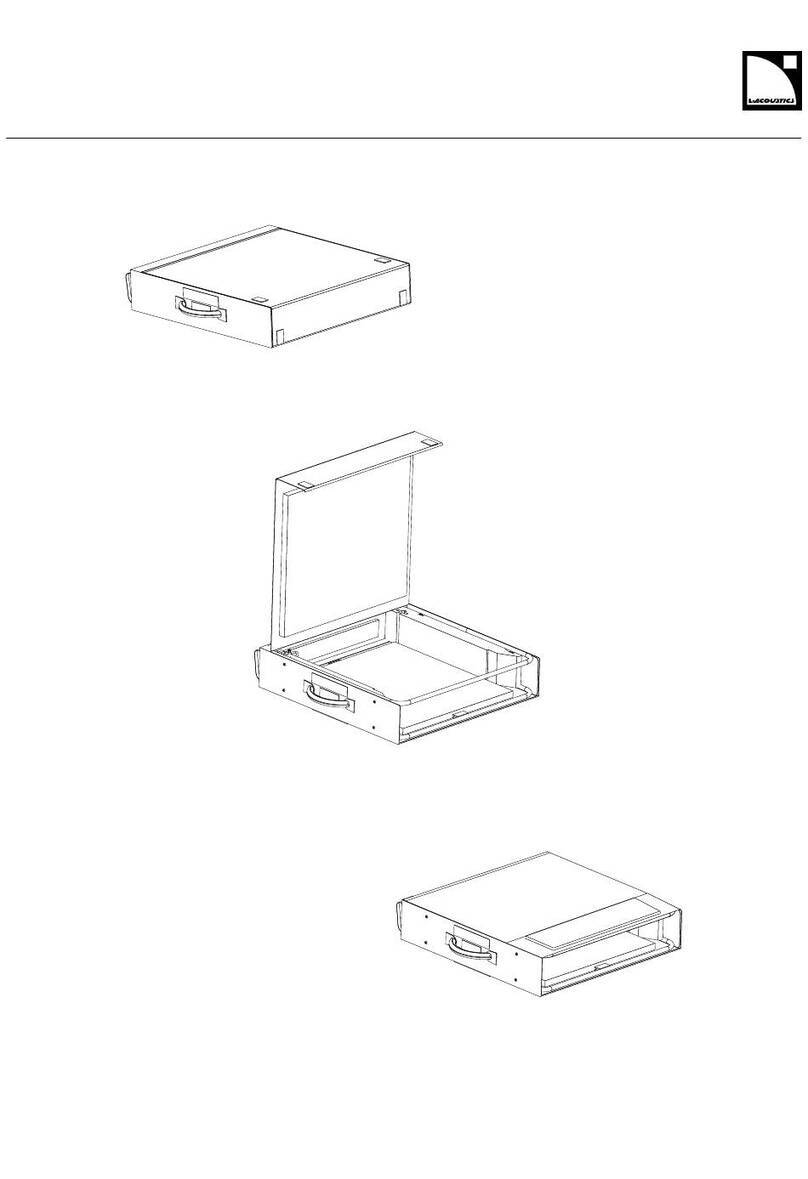

Mounted inside the gate-

house at a gated community

Using metal tubing or angle-

iron and a concrete slab

Along a gate using metal

tubing to run wiring from

one enclosure to another

Wall-mount

Using conduit and

angle-iron

Rack Enclosure mounted

on a wall

Installer made mounting

surface

Pole-Mount Kits

available for enclosures

to be mounted on 4” to

14” poles. Call Mier and

specify the enclosure you

want to use, and the pole

size, for help choosing the

correct pole-mount kit.

NOTE: Do Not Mount On Apartment/Condo/Ofce Walls

Home and ofce AC units are mounted a few feet away from a home or on

the roof of an ofce building in order to avoid vibration noise from

becoming a nuisance to those who live/work within. For that same reason,

Mier recommends installers mount our temperature-controlled enclosures

on concrete slabs with angle-iron or poles as pictured, or on walls that are

not common to living or ofce space.

Our engineers recommend the following options around RGS ttings in holes installers might cut into the enclosures, in order to keep NEMA ratings:

• If not using conduit or ex-cable, and running your cords directly into the enclosure, we recommend drilling your holes in the bottom of the

enclosure and using a Heyco tting appropriate for your specic cord size, and able to t in our 3/16” enclosure wall thickness.

• If you are using conduit or ex-cable, we recommend drilling your holes in the bottom of the enclosure and using an appropriate tting such as:

• SealCon DS21AA-BK = ¾” Liquid-Tight Conduit Fitting with DOUBLE Lock - http://www.sealconusa.com/conduit/product/double-seal.html

• SealCon ST21NA-BK = ¾” Liquid-Tight Conduit Fitting with SINGLE Lock - http://www.sealconusa.com/conduit/product/condsttwist-npt.html

• McMaster Carr 7119K13 = ¾” Liquid-Tight Conduit Fitting/Heavy-Duty - http://www.mcmaster.com/#7119k13/=vg864m

Remember: sealing the outside

of holes used for conduit

coming up from the ground is

only half of the job. You must

also make the inside of the

opening from the

conudit water/air-tight to

prevent ground condensation

and even mice from coming up

into the enclosure!

Customer Shared Mounting Examples and Notes

Make sure you properly ground the enclosure, especially if mounting to a wall or wooden posts. If you’re not sure how to do this,

consult a certied electrician or contact the manufacturer.

NOTE: all conduit and holes

are in the bottom of the

enclosure. This allows the

entire unit to act as a shield

against rain, sleet, snow,

moisture, etc.

ENCLOSURE WARRANTY:

Mier Products, Inc.’s Limited Warranty Program, for Standard Line or Custom Enclosures and Parts, protects the original owner for 30 days from the

date of purchase against defects in original parts or workmanship. Mier Products, Inc. agrees to repair or replace parts (Mier’s option) that are deemed

defective by our Quality Control Team, without charge for parts or labor, if the defective unit is returned prepaid to Mier Products, Inc., Kokomo, IN,

within the 30-day period.

Enclosures and fabricated parts are not products containing complicated technology or electronics, so close inspection at the time of receipt by the

customer will quickly determine product quality. Thus, Mier Products, Inc. recommends inspection of enclosures/parts immediately upon receipt and

contacting Mier Products, Inc. if quality issues arise.

Mier Products, Inc. does not assume responsibility for claims or damages caused by improper installation or use of these products, accessories, and/

or products connected to or stored within them. Mier Products, Inc. does not assume responsibility for damages to these products or their accessories

due to shipping damage or damage occurring while in a customer’s warehouse and/or possession. These products and any accessories (including but

not limited to air conditioning units, heaters, fans, lters, locks, latches, tamper switches, removable panels) must be shipped, handled, stored, and

installed with strict adherence to OEM installation instructions.

This warranty constitutes the entire warranty with respect to Mier’s Drive-Alert Models and Accessories and IS IN LIEU OF ALL

OTHERS, EXPRESSED OR IMPLIED, INCLUDING ANY WARRANTY OR MERCHANTABILITY AND WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE AND IN NO EVENT IS MIER PRODUCTS, INC., OR IT’S DISTRIBUTOR, DEALER, OR OEM PARTNERS, RESPONSIBLE FOR ANY CONSE-

QUENTIAL DAMAGES OF ANY NATURE WHATSOEVER.

Any warranty OR sales questions should be directed to Mier Products at 800-473-0213, or via e-mail to [email protected]

Any repair work not covered by this Warranty is available for a nominal charge.

AIR-CONDITIONER, HEAT EXCHANGER, AND FILTER WARRANTY

Mier Products exclusively uses nVent (Mier’s business partner for the heating and cooling systems used in Mier’s Temperature Controlled Enclosures)

air-conditioners and air-conditioners with integrated heating units. The following warranty information was taken from nVent’s warranty policy (10-1008-196

rev 5) for your information. All AC and Heater units come with a nVent instruction manual with warranty infomation included. That information, shipped

with each nVent Thermal unit, supercedes what is written here:

Synopsis of nVent Thermal Warranty

Please note: Warranty effective at time of shipment.

nVent warrants that all material and workmanship are free of defects in quality which impair the usefulness of the air conditioner or heat exchanger for a

period of ve (5) years for non-operating parts, except for the lter; and for one (1) year for everything else when installed and operated under the following

conditions:

A. Maximum voltage variation no greater than plus or minus 10% of nameplate nominal rating.

B. Maximum frequency variation no greater than plus or minus 3 Hz. of nameplate nominal rating.

C. Must not exceed minimum and maximum stated temperatures on the nameplate.

D. Not to exceed (BTU/Hr.) rating, including any heat sink, as indicated on the nameplate.

E. The unit must not be restarted for a period of one (1) minute after intentional or accidental shut-off.

(This does not apply to heat exchanger or lter fan.)

nVent warrants that all material and workmanship are free of defects in quality which impair the usefulness of the lter fan package and all custom air condi-

tioners and heat exchangers for a period of one (1) year, except for the lter, when installed and operated under conditions A, B, C and D above.

Not covered in this warranty is damage to the air conditioner or heat exchanger due to the introduction of other than the nameplate-designated refrigerant.

Operation of any nVent product that has not been designed with proper protective coatings and/or options and is in an abnormal or corrosive environment

voids the warranty.

***Prolonged operation with dirty lters also voids the warranty***

Should any part prove defective within the above warranty period, the customer may choose to return the defective product that is under warranty to nVent

for repair at no charge or the customer has the option to repair the defective products at his own expense and nVent will supply repair parts at no charge

providing the defective part is returned and found to have failed under warranty. Parts supplied as warranty replacement parts will assume the balance of the

warranty on the part returned for warranty consideration.

Please be advised: According to the Federal Register, no person maintaining, servicing, repairing, or disposing of appliances may knowingly vent or otherwise

release into the environment any class I or class II substance used as refrigerant.

nVent assumes no liability beyond the repair or replacement of its own product. Customer modication of nVent products voids the warranty.

The purchaser assumes the responsibility of grounding the unit and installing it in accordance with local electrical and safety codes, as well as the National

Electric Code (NEC) and OSHA.

Warranty Information

P

R

O

U

D

L

Y

M

A

D

E

I

N

T

H

E

U

S

A

F

O

R

O

V

E

R

3

0

Y

E

A

R

S

!

This manual suits for next models

19

Table of contents

Other Mier products Enclosure manuals

Popular Enclosure manuals by other brands

Natec

Natec OYSTER PRO user manual

Thermaltake

Thermaltake Versa Series user manual

Akasa

Akasa integral HDD external enclosure for data-storage mobility with LAN... user manual

StarTech.com

StarTech.com SAT3510BU3 instruction manual

Apollo Enclosures

Apollo Enclosures ELITE Series installation guide

AudioBahn

AudioBahn ABASS10 operating instructions