Table of Contents i

Table of Contents

Introduction. . . . . . . . . . . . . . . . . . . . . . . . .1

ERn External Processing Rack. . . . . . . . . . . . . . . . . . . . .1

ERn2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

ERn4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

ERn Modules and Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Contacting ETC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Prepare for Installation . . . . . . . . . . . . . . . .6

Unpack and Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Main Circuit Breaker Protection . . . . . . . . . . . . . . . . . .6

Maximum Current Input . . . . . . . . . . . . . . . . . . . . . . . .6

Where to Install the Enclosure. . . . . . . . . . . . . . . . . . . .6

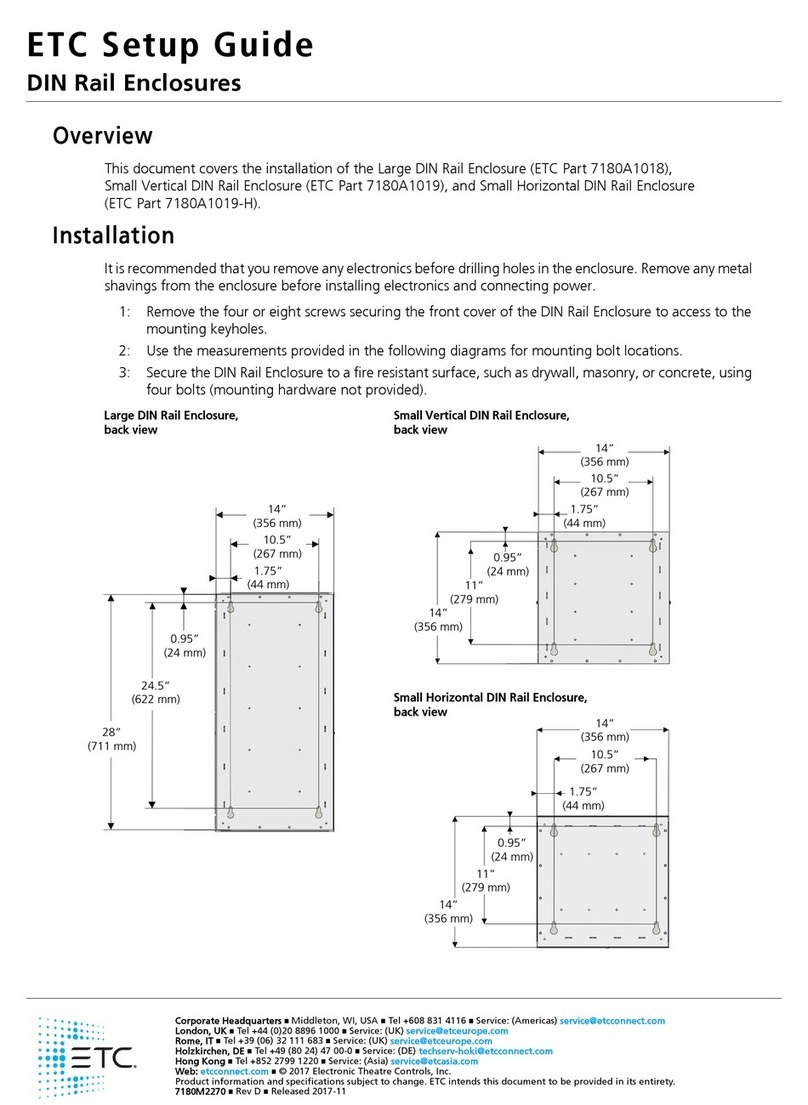

Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Rack Dimensions and Weights. . . . . . . . . . . . . . . . . . . . . . . . . .7

Installation Environment Requirements . . . . . . . . . . . . . . . . . .7

Wire Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Wire Routing and Specification. . . . . . . . . . . . . . . . . . . . . . . . .8

Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Control Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Data Types and Topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Install Rack Enclosures. . . . . . . . . . . . . . . .10

Install the Rack Enclosure. . . . . . . . . . . . . . . . . . . . . . .10

Rough-in Conduit and Wiring . . . . . . . . . . . . . . . . . . .11

Remove Option Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Rough-in Line and Control Conduit and Wiring . . . . . . . . . .12

Terminate Wiring . . . . . . . . . . . . . . . . . . .13

Connect Line Power Wiring . . . . . . . . . . . . . . . . . . . . .13

Connect Control Wiring . . . . . . . . . . . . . . . . . . . . . . . .14

Connect ERn Right I/O Data Terminations . . . . . . . . . . . . . . .15

Connect ERn Left I/O Data Terminations . . . . . . . . . . . . . . . .18

Final Installation and Power Up . . . . . . . .21

Check Main Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Check Line Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Final Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Install Rack Options. . . . . . . . . . . . . . . . . .24

Rack Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24