4

The MultiFeeder can be used together with a SIGMA2

Compact in robot installations and other cases, where

1 or 2 extra wirefeeders are required. The MultiFeeder

can be configured with various torches, remote

interface and Mig Manager® interface.

1. The MultiFeeder communicates with the SIGMA2

via a CAN-interface and is connected on the rear

panel of the SIGMA2 via a cable, which can be up

to 15 meters.

2. The documentations for the MultiFeeder consists

of the following:

Functional description incl. configuration.

Mechanical drawing

Functional description

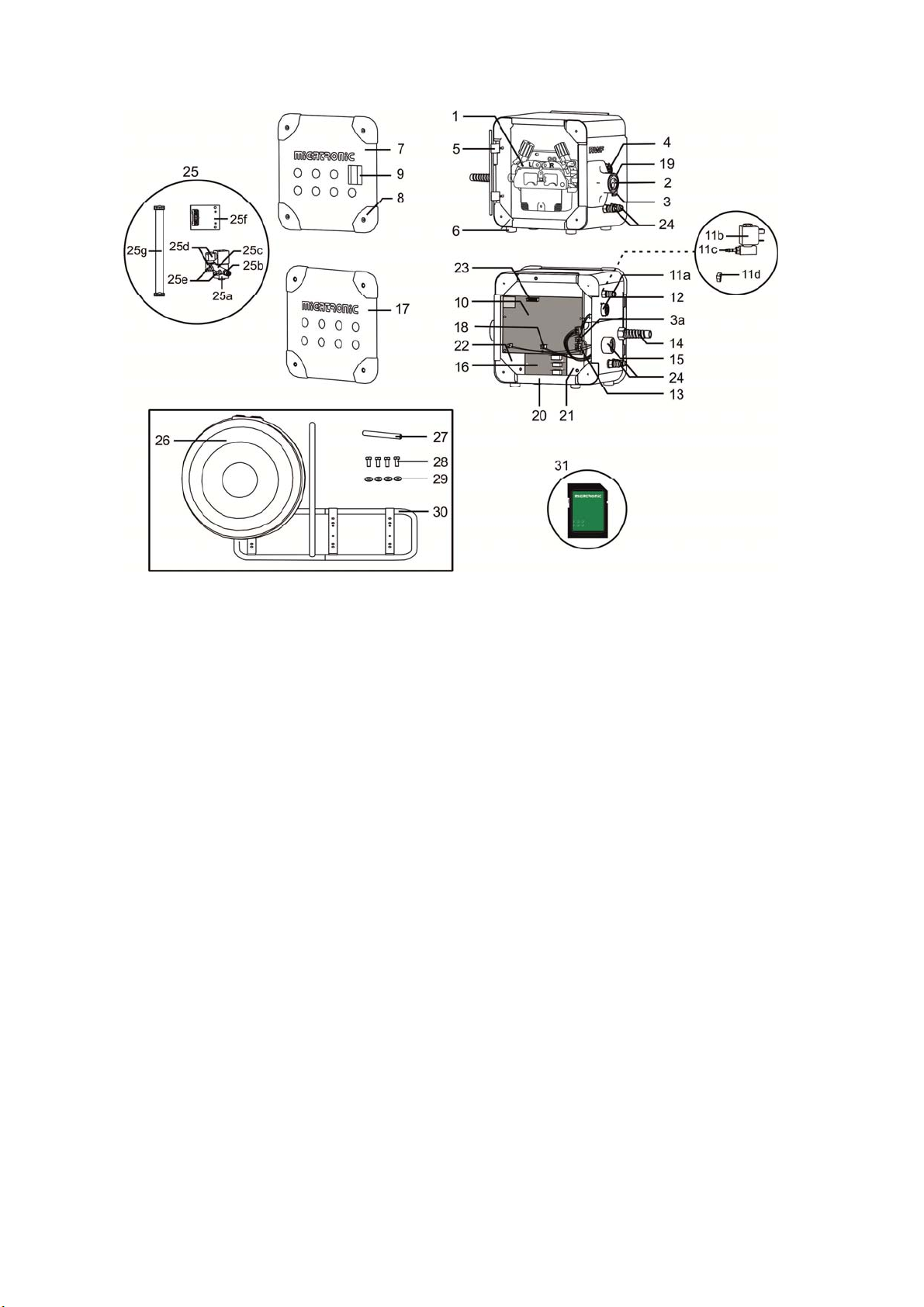

When using 2 MultiFeeders on the same SIGMA2, the

MultiFeeders must be configured as no. 1 and no. 2.

This is done by placing a jumper on the PCB

71613658 as shown in fig. 1.

Functions

The main functions of MultiFeeder is like a standard

SIGMA2 wirefeeder without any userinterface/panel

and can be used with or without robotinterface

connected to the SIGMA2 Compact. The internal

wirefeeder in the SIGMA2 Compact is still available,

when MultiFeeders are connected to the SIGMA2.

Using the MultiFeeders without robotinterface:

The MultiFeeder as well as the internal wirefeeder can

be triggered from the connected torch. When the

MultiFeeder is active (LED-lamp on front is ON),

welding is started immediately. When the MultiFeeder

is not active (LED-lamp on front is OFF), the trigger

will make a programshift and activate the MultiFeeder

without starting welding. Welding is started when the

trigger is activated. The internal wirefeeder in the

SIGMA2 is active, when none of the MultiFeeders is

active.

Pressing the wire inching-button (on front) will start

wire inching immediately, if welding is not started or in

progress. The wire speed can be adjusted on the

SIGMA2 userinterface.

The gastest function is performed only on the active

Multifeeder/wirefeeder by pressing the Gastest-button

on the SIGMA2.

Using the MultiFeeders with robotinterface

The active MultiFeeder (indicated by LED-lamp on

front) is selected from the robotinterface. If the robot-

interface is configured for internal program select,

selecting/activating a MultiFeeder/wirefeeder will

perform a programshift to the program last used with

the specific MultiFeeder/wirefeeder. If the robot-

interface is configured for external program select,

selecting/activating a MultiFeeder/wirefeeder will not

result in a programshift. The SIGMA2 remembers the

welding program last used for each MultiFeeder/

wirefeeder on power-down.

The MultiFeeder can be triggered only from the

robotinterface, and welding is started immediately.

Pressing the wire inching-button (on front) will start

wire inching immediately, if welding is not started or in

progress. Wire inching can also be performed on the

active MultiFeeder/wirefeeder by activating the wire

inching-input on the robotinterface. The wire inching

speed can be adjusted from the robotinterface, but if

this wire inching speed is set to a value below

0.5 m/min, the default value for wire inching speed

8.0 m/min is used.

The gastest function is performed only on the active

Multifeeder/wirefeeder by either activating Gastest-

input on the robotinterface or by pressing the Gastest-

button on the SIGMA2.

The LED-lamp on the front of the MultiFeeder is ON,

when this Multi-Feeder is activated. When none of the

MultiFeeders is active, the internal wirefeeder in the

SIGMA2 is active.

Configuration

MIGATRONIC disclaims all responsibility for damaged

cables and other damages related to welding with

under sized welding torch and welding cables

measured by welding specifications e.g. in relation to

permissible load.

Important!

In order to avoid destruction of plugs

and cables, good electric contact is

required when connecting earth

cables and intermediary cables to the

machine.

Accessories

The MultiFeeder can be equipped with various

standard torches, Mig Manager® and SIGMA2 remote

control

Intermediary cables

Intermediary cables is delivered in lengths of 8m (size

70mm² or 95mm²)

Order no. Length Size

74325964 8m 70mm²

74325965 8m 95mm²