MM1520,1521and1524

STRAINGAUGEINPUT

DUALLIMITALARMS

DESCRIPTION

TheMM1520SeriesStrainGaugeinputalarms

monitoraDCinputsignalfromastraingauge

or bridge and provide dual setpoint alarm

outputs when the input exceeds the alarm

values. EachunitcanbesuppliedasaHI/HI,

HI/LO orLO/LOalarm. Theoutputrelaysare

normallyde-energized, and energize for an

alarmcondition. Twosetsofred/greenLED

indicate alarm status to make setup easier.

Deadband on both alarms is fixed at 0.25%

of span.

MODELNUMBERS

These instructions cover the following

setpoint styles:

MM1520 Strain Gauge Input Dual Alarm

(25-turn screwdriver adj)

MM1521 Strain Gauge Input Dual Alarm

(Single turn dial)

MM1524 Strain Gauge Input Dual Alarm

(10-turn precision dial)

OPTIONS

These instructions cover the following op-

tions on the MM1520. Options installed are

listed on the label attached to the side of the

module.

H/H, H/L, L/L

H=Highalarm.

Alarm occurs on an increasing signal.

L= Low alarm.

Alarm occurs on a decreasing signal.

NO/NC

Normally open or normally closed

relay contacts: (see specifications)

RThe Normal condition for the relays is

de-energized. They energize for alarm

conditions. Option R (Reverse sense)

reverses this logic (Failsafe).

UAll circuit boards conformal coated for

protection against moisture.

CONTROLS

The MM1520, MM1521 and MM1524 mod-

ules contain two setpoint controls, zero and

span adjustments, plus a bridge excitation

voltage adjustment. The setpoint control in

the MM1520 is a 25-turn blind trimpot.

MM1521andMM1524 contain1-turnand25-

turn respectively.

CALIBRATION

Modulesareshipped with ZERO,SPANand

excitation voltage precalibrated. The user

needs only adjust the SETPOINT and

DEADBAND for the desired response.

Refer to the instrument's label to determine

your instrument's supply voltage and input

and output ranges. Refer to the "BLOCK

DIAGRAMANDPINCONNECTIONS"forpin

connections.

Connect the alarm input to its mating input

device, or to a precision resistance bridge

capable of simulating the input device.

(If it is necessary to recalibrate using

electronicinputs,refer to the ELECTRONIC

CALIBRATIONsection.)

To calibrate the alarm setpoints, adjust the

input to the desired alarm 1 setpoint. Adjust

theSETPOINT1controluntilitsLEDswitches

to red (ccw for a high alarm, cw for low).

Change the input to the desired alarm 2

setpointandsimilarlyadjusttheSETPOINT2

control.

Ifthere isaneed torecalibrateZERO,SPAN

and excitation voltage, proceed as follows:

Measurethevoltagebetween+EXC & -EXC

VOLT ADJ control for the desired excitation

voltage. The voltage is adjustable from 4 to

12 VDC.

Settheinputtothelowendoftheinputrange.

Turn the SETPOINT 1 control fully ccw.

AdjusttheZEROcontroluntiltheSETPOINT

1 LED color switches.

Changethe input to the high end of theinput

range. TurntheSETPOINT2 controlfullycw.

AdjusttheSPANcontroluntiltheSETPOINT

2 LED color switches.

RepeatuntiltheZEROandSPANsettingsare

both correct.

AfteradjustingtheZEROandSPANcontrols,

the SETPOINT controls should be reset as

described above.

ELECTRONICCALIBRATION

Ifitisnecessarytorecalibrateusingelectronic

inputs, proceed as follows:

Measure the voltage between +EXC and

-EXC using a precision digital voltmeter.

Connect a calibrated millivolt signal source

betweenthe+SIGand-SIGinputs. Determine

theinput voltage required at each calibration

point. Therequiredvoltageequalsthebridge

sensitivity in millivolts per volt, multiplied by

the excitation voltage. For example, a

sensitivity of 2 mV/V multiplied by 10 V

excitation results in a 20 mV input signal.

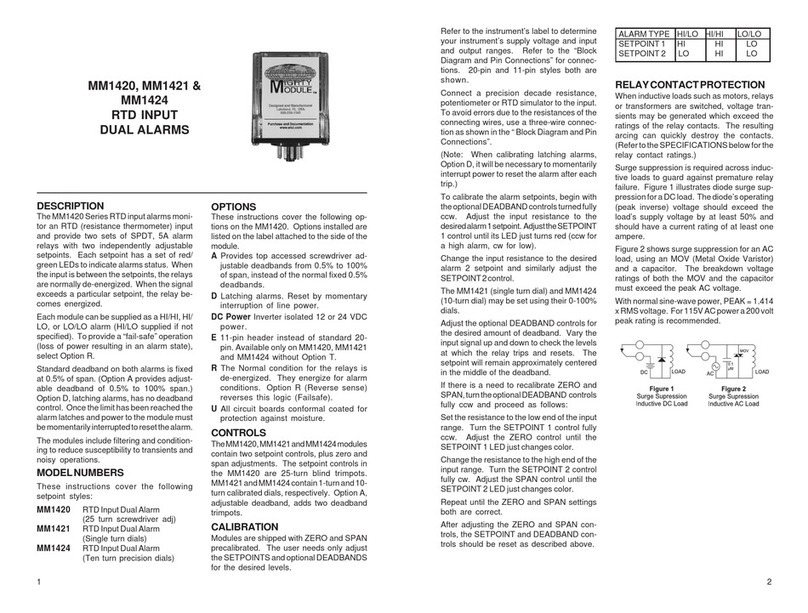

RELAYCONTACTPROTECTION

Wheninductive loads suchasmotors,relays

or transformers are switched, voltage tran-

sients may be generated which exceed the

ratings of the relay contacts. The resulting

arcing can quickly destroy the contacts.

(RefertotheSPECIFICATIONSfortherelay

contact ratings.)

Surge supression is required across induc-

tive loads to guard against premature relay

failure. FIGURE 1 illustrates diode surge

supression for a DC load. The diode's oper-

ating (peak inverse) voltage should exceed

theload's supplyvoltagebyat least50%and

should have a current rating of at least one

ampere.

FIGURE 2 shows surge suppression for an

AC load, using an MOV (Metal Oxide Varis-

tor) and a capacitor. The breakdown voltage

ratings of both the MOV and the capacitor

must exceed the peak AC voltage.

Withnormalsine-wavepower,PEAK=1.414

x RMS voltage. For 115 VAC power a 200

volt peak rating is recommended.

1 2