5

Lower your helmet and press the welding gun trigger

switch to initiate an arc.

As the weld isdeposited,push the

torch from a right to left direction,slowlyalongtheseamat

a constant speed. Using the wire feed speed control,

adjust for a 'crisp' soundingarc.

Spot Welding

MIG spot welding is made fromone side of the sheets

placed one upon another so that the high welding current

penetrates through the upper sheet(max.1.5mm) and

also a part ofthe lower sheet.

A circular spot is produced

each time the torch trigger is pressed. The spotweldtime

't1'canbevaried.

Select'spot'weldingbyturningswitch't1"

only.

Fit a spot-welding nozzle to the torch.

See GUN PARTS LIST.

Set voltage and wire feed speed controls to near max.

settings and carry out test welds on scrap materials as

follows:

Position the legs of spot-welding nozzle over weld

position and depress torch trigger switch. At the

termination of the weld, check for weld penetration (small

dimple showing on underside of weld), and adjust spot

weldtimeforbestresults.

When welding sheets of unequal

thickness, the thinner sheet must be on top. Thicker

sheets can be welded together by drillinga hole inthe top

sheet anddirecting thewireinto hole-thisis knownas'plug

welding'.

Spot welding requires ONLY LIGHT PRESSURE;

the sheets are pressed against each other with the legs of

the welding nozzle.

Switch Welding All Models

The wire feed output is switched on and off repeatedly.

This produces a lower heat input which is particularly

advantageous when welding thin or poor-quality materials

aswellasbridginggaps.

Select 'stitch' welding by turning 't1'and 't2'controls to the

halfway setting. Vary time to obtain best results. Theydo

nothave tobeequal.

't1' controls the welding or working cycle.

't2' controls the

pause cycle between welding.

Note: The trigger on the gun must be kept depressed during

bothcycles.

Welding occurs during the working (ON) cycle. During the

pause cycle, the wire feed STOPS, and the arc will

extinguish.

During the pause cycle the moltenpool will cooldown. The

arc will ignite again automatically at the beginning of the

following working cycle when the filler wire makes contact

with the molten pool.

The welding current is automatically switched on and off

and the shielding gas supply will remain on during the

pause cycle.

Note: Spot welding and stitch welding of aluminium is

not possible.

SETTING UP GUN FOR ALUMINIUM WELDING

The Welding Gun

Remove the liner positioner nut from the adaptor block at the

wire feed end of the gun cable. Remove the gas nozzle,

contact tip holder, gas diffuser/ contact tip from the welding

torch and remove existing liner if fitted.

Carefully push the Teflon liner with brass neck liner attached,

through the gun cable until the end of the liner protrudes from

the swan neck.

Adjust the contact tip holder, gas diffuser/ contact tip and gently

push the liner to seat it into the back of the contact tip holder/

contact tip. Replace the gas nozzle.

At the adaptor block end of the gun cable, slide the brass nipple

and “O” ring over the liner until they are located om the recess

in the adaptor block and replace the liner retaining nut.

DO NOT CUT THE TEFLON LINER YET!!

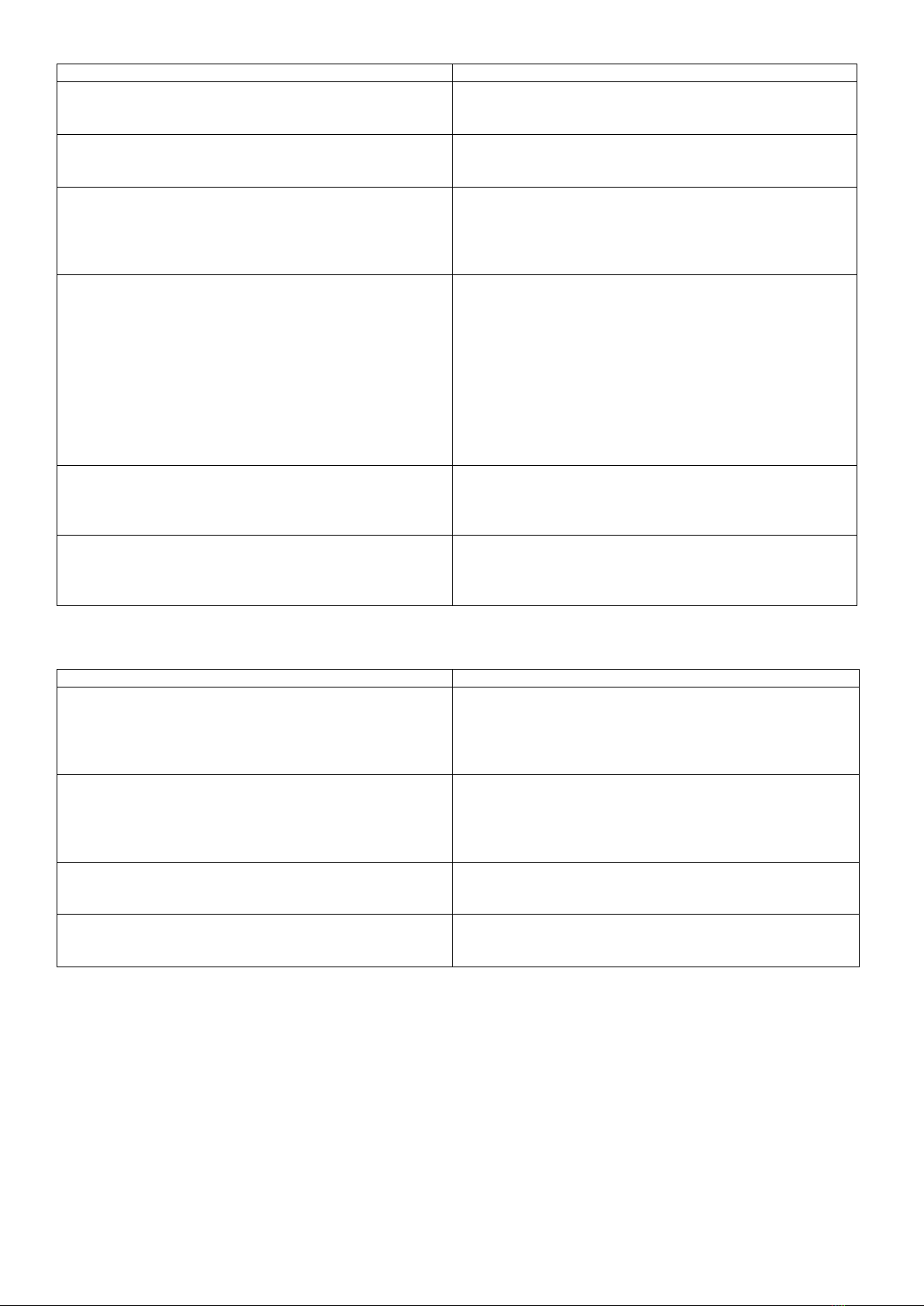

FIGURE 4.

The Welding Machine

With a pair of long-nosed pliers, remove the steel inlet

guide tube from the central adaptor on the front face of the

weldingmachine.

With the Teflon liner still protruding from the adaptor

block

feed the liner through the inlet of the central adaptor until

the adaptor block is butted against the central adaptor.

Fastenintopositionwithadaptorblock locknut.

Cutthelinerintheshape ofa'V',usingasharpknifeso that

it butts up to the feed rollers as pictured. (FIG.4.) Remove

the welding gun from the machine and cut the brass

support tube so that it is 3mm shorter than the protruding

Teflonliner.

Slide the brass support tube over the liner and enter the

Teflonlinerwithbrasssupporttubefittedintotheinletin the

central adaptor. Feed through until the adaptor block is

buttedagainstthecentraladaptorandtightenthelock nut.

Replace the wire hub tension by backing off the nutin the

centre ofthehubuntilthenutispositioned attheendof the

stud.

After confirming the wire feed roll is the correct size for the

aluminium wire being used, and that the wire is fed through

the gun cable, back off the wire feed roll pressure screw until

the feed roll no longer feeds the wire and re-tighten

approximately 2turns. Toomuchpressure willdeform the soft

aluminium wire and cause the wire to jambin thecontacttip.

Note: To help prevent wire deformation

‘U' groove

feed roller is a better alternative than a 'V'

groovefeedroller.

Contact Tip

Aluminium welding requires a contact tip with greater

clearance than that used for steel. Special clearance contact

tips are available for welding aluminium and are designed

withAsuffix.e.g.0.9A,1.2A.

PARTS LIST

Part No. Description

1260005 Teflon Liner 1.0mm

1260021 Teflon Liner 1.2mm

1290461 Brass Support Tube for Teflon Liner

1310001 Nipple for Teflon Liner

86003033 Drive Roll 0.9/1.0-1.2mm AI (195 230 260

300)

86003066 Drive Roll 0.9/1.0-1.2mm AI (350 400)

1410004 Contact Tip 0.9mm Aluminium

1410006 Contact Tip 1.0mm Aluminium

1410010 Contact Tip 1.2mm Aluminium

86007001 Brass Neck Liner