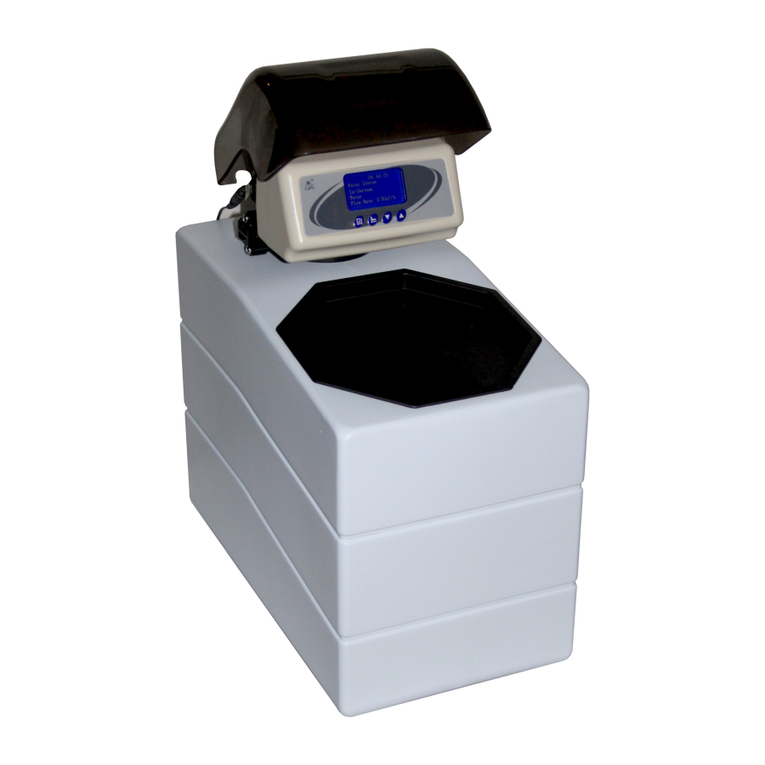

Mijar Smart B65 User manual

USER MANUAL

AUTOMATIC WATER SOFTENER

Smart B65

Smart B65

Water softenening devices, type Smart B65 are ones of high uality and precision. Properly installed and

operated, the Smart B65 devices guarantee infallible operations and increased durability. Please read

this manual carefully before assembly. This manual serves as future reference to system operations.

Water softener, model Boy B65 can be installed everywhere, where the flow rate of water is not higher

that 75l/min** and the water temperature is lower than 40°C. The highest uality of components

installed in Mijar products guarantees their infallible functionality for many years.

Tec nical Parameters:

Tec nical Parameters:

System capacity for 10°dH: [litres] 1500

Sal consumption per regeneration: [kg] 0.7

Flow rate (nom/max): [l/min] 0-20*/75**

Pressure: [bar] 1.5-6.0

Connections: [cal] 3/4”

Maximum temperature of water: [°C] <40

Brine tank capacity: [kg] 10

Amount of resin: [l] 5

Power supply: [V] 230

Heig t: [mm] 620

Widt : [mm] 240

Dept : [mm] 440

*water softened completely

*water softened completely

**water softened partially, only for valves type B65.

Counting t e system's capacity for different water ardness:

The system capacity is counted using formula:

z=1500 x 10/y

where:

z-

z-amount of water softened between regenerations.

amount of water softened between regenerations.

Y-

Y-tested water hardness in °dH (Germann degrees of hardness)

tested water hardness in °dH (Germann degrees of hardness)

EXAMPLE

EXAMPLE of counting the system capacity.

of counting the system capacity.

Data:

Data: tested water hardness: 15 °dH

tested water hardness: 15 °dH

using formula:

→

→→

→z=1500 x 10/15 we receive t e result of

→

→→

→z=1500 x 10/15 we receive t e result of

10

1000 litres.

00 litres.

With a water hardness of 15°dH, the Smart B65 system will soften 1000 liters of water.

TABLE 1: SYSTEM CAPACITIES:

German Degrees(°dH) System Capacity

(litres)

10 1500

11 1363

12 1250

13 1154

14 1071

15 1000

16 938

17 882

18 833

19 789

20 750

21 714

22 681

23 652

24 625

25 600

26 577

27 556

28 536

29 517

30 500

2.SYSTEM OPERATION:

Softening process:

Softening process: (IN SERV)

(IN SERV)

Hard water contains dissolved minerals, among them Calcium and Magnesium ions responsible for

limescale formation on heating parts of e uipment. During the softening process, by mean of ion-

exchange, the Calcium and Magnesium compounds are removed from water. As the water flows

through resin deposits, the Magnesium and Calcium ions are being absorbed on the surface of resin

beads. Over time the softening properties of resin will become depleted and it will have to be

regenerated. The regeneration process proceeds automatically. During the regeneration mode the resin

deposit is flushed with saline solution, thus absorbed minerals are rinsed from resin beads and flushed

off to the sewage system. After the regeneration process the system regains full capacity.

Proces regeneracji: (REGEN)

During the regeneration process, the resin is rinsed by the saline solution. The regeneration cycle

consists of 4 regeneration stages:

•countercurrent rinse(BACK WASH)

•saline solution rinse (BRINE+WASH)

•rapid rinse (RAPID RINSE)

•settling rinse(SETTLE RINSE)

•brine tank refill (BRINE REFILL)

2. SYSTEM PROGRAMMING: (Rys.1)

The regeneration process has been set to start at 2:00 AM by default. After connecting t e system to

power supply t e user must set t e current time manually first.

•Setting t e current time and t e time of regeneration (pic.1)

To set the current time, the user must press and hold the white button (1), and simultaneously turn the

gearwheel (2) so in the gap (3) the current time is shown* (like on the watch). Nextly, release the white

button (1) so it falls back between the gearwheel pins (2).

*”a”- morning ours (midnight to midday) e.g. 9a=9:00 (AM)

„p”- afternoon ours ( midday to midnight) e.g. 9p=21:00 (PM)

The valve is automatically set to start the regeneration process at 2.00 pm. If the time of regeneration is

to commence earlier, the user should accordingly turn the gearwheel (2) clockwise of counterclockwise

from the current time.

•Setting t e frequency of regeneration (pic.1)

Days of regeneration are set on the 12 day disk (4) by lifting up or lowering the pinions(5). Each pinion

represents 1 day. First the user has to lower all of pinions (5) down (4) and then lift the pinions

representing days, when the regeneration is to be carried out. Red arrow indicated current day.(6)

Example:

✔All of the pinions are lifted up- the regeneration takes place everyday.

✔Every second pinion is lifted up- the regeneration takes place every second day.

✔Every third pinion is lifted up- The regeneration takes place every third day.

✔And so on...

•Manual initiation of regeneration process (rys 1.)

To manually initiate the regeneration process, the user has to turn the knob (7) clockwise until REGEN is

shown in the gap. The know (7) will turn and when the regeneration process is finished, the knob will

reach the (IN SERV) position. T ank to t e built-in water mixer, during t e regeneration mode ard

water is available.

Rys. 1 Control Valve.

3. ASSEMBLY AND INITIATION OF THE SYSTEM:

Before initiating the device, the user must set the current time and the day of regeneration

(see point 2).

The valve is set to carry out the regeneration every 6 days at 2:00 am by default.

Connecting t e device: (pic. 2)

1.Connect inlet (B) and outlet (C ) of the device to the water supply.

1.Connect one side of the draining elastic hose 1/2”, to the fitting (A) and the other to the sewage

system. The sewage system should be unobstructed enough to discard 5 l/min of rinse water. The

elastic hose should be inflexible enough to rule out the possibility of cloggs, which can lead to overflow

of brine tank.

2.Slowly turn on raw water supply valve .

3.Pour approximately. 45kg of tablet salts into the brine tank

4.Deaerate system by turning the knob 7 (rys.1) clockwise to the BACK WASH position. After few

minutes the system will deaerate. Next, turn the knob back to the IN SERV position and the system will

go back to water softening mode

5.Pour about 5 liters to the brine tank .

6.Connect the device to power supply 230V (D) and set the current time (see point 2)

PIC. 2 Device connections.

4.HANDLING THE DEVICE:

The proper handling of the device re uires periodic tablet salt refill.

The brine tank should be fully refilled every time. The minimum amount of salt that must be in the tank

for the device to function properly, is about 1/3 of brine tank capacity.

Refilling the salt tablets:

•Lift the cover of the device,

•Pour the salt tablets.

•Close the lid.

NOTE!:

✗The device must not operate without salt tablets for more than 14 days, otherwise the system may be

damaged.

✗The user must not use the loose salt or salt of unknown origin.

Table of contents

Other Mijar Water Dispenser manuals

Popular Water Dispenser manuals by other brands

IBC Water

IBC Water AST0715MP-960 Installation & operating instructions

Lancaster Water Treatment

Lancaster Water Treatment X FACTOR LX15 Series Installation, operating and service manual

Elkay

Elkay EMABF8 Series Installation & use manual

Oasis

Oasis Osmosis Home installation manual

Monarch Water

Monarch Water ULTIMATE MINI AQUA HE install guide

Haier

Haier HLM-109B instruction manual