Mikro DPM680 User manual

Please read this instruction manual thoroughly before

installation, operation and maintenance of the DPM680

power meter.

This power meter should NOT be installed or used for primary

protection. Do not use the device in applications where its failure

can cause harm or death. Avoid high re risk applications.

The symbol on the left is used throughout this instruction

manual to alert the user or personnel of the danger or to prompt

caution during the installation and maintenance process.

EMC CoMplianCE

This power meter has been tested and found to comply with the limits of the IEC/EN61000 EMC

standards. These standards are designed to provide reasonable protection against interference

when using this device. Failure to install or use the device in accordance with the instruction may

cause harmful interference. This does not, however, guarantee that interference will not occur in any

installation. In case of interference, the user is encouraged to:

• relocate or reorient the victim/emitting equipment

• change the connection point of the victim/emitting equipment

• increase the distance between the victim/emitting equipment and the power meter

Please consult a qualied technician for assistance.

DisClaiMEr

Mikro shall not be liable for errors contained herein including any incidental and/or consequential

damages arising from the use of this material. Mikro also reserves the right to vary the product from

that described in this material without prior notice.

CopYriGHT

The licensed software contained in the product is proprietary software owned by Mikro or its third party

suppliers and it shall be used solely in connection with the product.

BEforE You BEGin

3

1. INTRODUCTION 5

1.1 How to Use This Manual 5

1.2 Content of Box 8

1.3 Parts of the Power Meter 8

2. INSTALLATION 10

2.1 Precautions 10

2.2 Meter Placement & Connections 10

2.3 Meter Setup 14

2.4 TCP/IP Connection Setup 15

3. METER OPERATIONS 17

3.1 OVERVIEW page & MAIN MENU 17

3.2 Password Authentication 18

3.3 VOLTAGE sub-menu 20

3.3.1 Phase Voltage 21

3.3.2 Line Voltage 21

3.3.3 Maximum Phase Voltage 22

3.3.4 Minimum Phase Voltage 22

3.3.5 Maximum Line Voltage 23

3.3.6 Minimum Line Voltage 24

3.3.7 Sequence Voltages 24

3.3.8 Voltage Harmonics 25

TaBlE of ConTEnT

3.3.9 Voltage Harmonics Table 26

3.3.10 Voltage Waveform 27

3.4 CURRENT sub-menu 28

3.4.1 Phase Current 29

3.4.2 Maximum Current 30

3.4.3 Minimum Current 31

3.4.4 Current Demand 32

3.4.5 Maximum Current Demand 34

3.4.6 Sequence Currents 34

3.4.7 Current Harmonics 35

3.4.8 Current Harmonics Table 36

3.4.9 Current Waveform 37

3.5 PF & FREQUENCY sub-menu 38

3.5.1 PF and Frequency 39

3.5.2 Power Factor (PF) 39

3.5.3 Displacement PF (DPF) 40

3.5.4 Max/Min Inductive PF 40

3.5.5 Max/Min Capacitive PF 41

3.5.6 Max/Min Frequency 42

3.6 POWER sub-menu 43

3.6.1 Active Power 43

3.6.2 Reactive Power 44

3.6.3 Apparent Power 45

Table of content

4

3.6.4 Total Power 45

3.6.5 Power Demand 46

3.6.6 Maximum Power Demand 47

3.6.7 Maximum Active Power 48

3.6.8 Minimum Active Power 49

3.6.9 Maximum Reactive Power 50

3.6.10 Minimum Reactive Power 51

3.6.11 Maximum Apparent Power 52

3.6.12 Minimum Apparent Power 53

3.7 ENERGY sub-menu 54

3.7.1 Active Energy 54

3.7.2 Reactive Energy 55

3.7.3 Apparent Energy 55

3.7.4 Total Energy 56

3.7.5 Reset Energy Counters 57

3.8 SETTING sub-menu 57

3.8.1 CT & VT Ratios 58

3.8.2 Communication Settings

(only for DPM680) 59

3.8.2.1 Ethernet (TCP/IP)

(only for DPM680) 60

3.8.2.2 Modbus 61

3.8.2.3 View Network Details

(only for DPM680) 62

3.8.3 System Settings 63

3.8.3.1 Version 63

3.8.3.2 Date & Time 64

3.8.3.3 Change Device Password 65

3.8.3.4 Factory Settings 66

3.8.3.5 Display Settings 67

3.8.4 For Factory Use Only 68

4. WEBPAGE OPERATIONS

(ONLY FOR DPM680) 68

4.1 Voltage and Current page 68

4.2 Energy and Power page 70

4.3 Parameter Setting page 72

4.3.1 Webpage Password 74

5. MODBUS OPERATIONS 75

6. TROUBLESHOOTING GUIDE 76

Appendix A Specications 77

Appendix B Numerical Methods 81

B.1 Demand Calculation 81

B.2 Total Harmonic Distortion Calculation 82

B.3 Sequence Components Calculation 82

B.4 Power Factor Calculation 83

B.5 Apparent Power Calculation 83

Table of content

5

1

inTroDuCTion

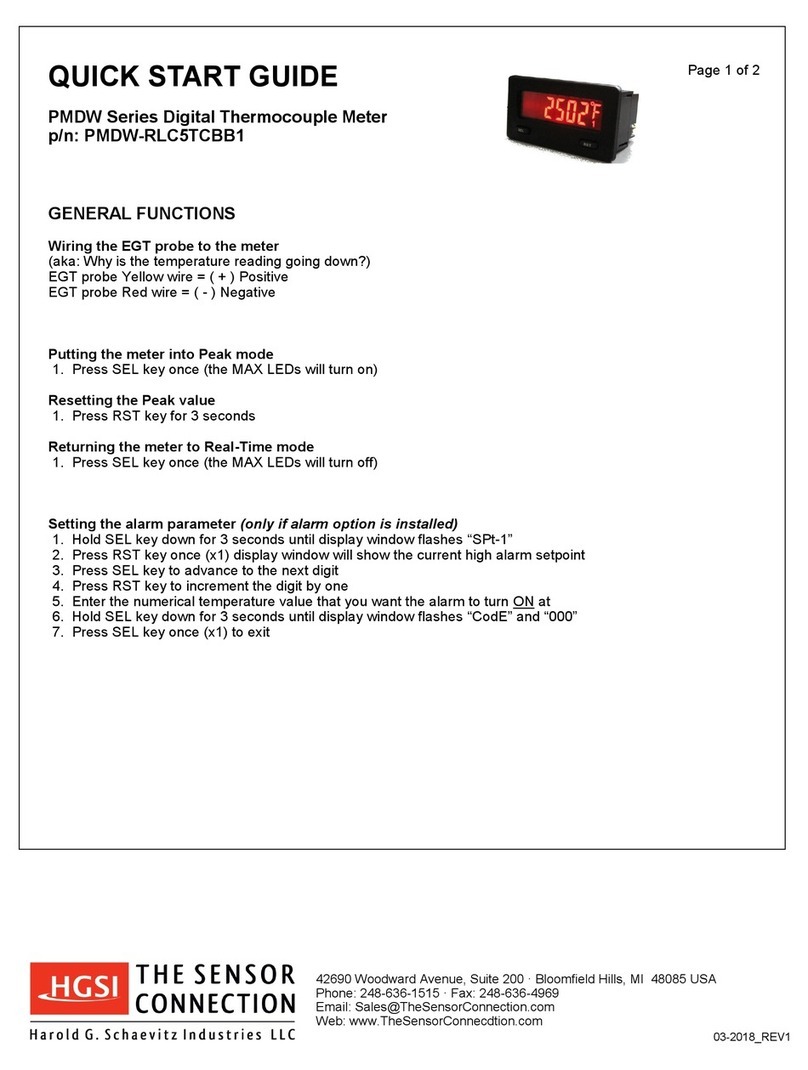

Thank you for purchasing the DPM680 Digital

Power Meter. This multifunction power meter

features a user-friendly colour graphical and

touch button interface. It’s primary function is for

measuring the following parameters:

• True RMS phase (LN) and line (LL) voltage.

• True RMS phase and neutral current.

• Active, reactive and apparent power.

• Active, reactive and apparent energy.

• Total and displacement power factor.

• Frequency.

• Voltage and current harmonics.

•

Voltage and current total harmonic distortion (THD).

• Positive, negative and zero sequence voltage

and current.

• Current (thermal) demand for phase current.

•

Power demand for active, reactive and apparent power.

• Time stamped maximum and minimum voltage,

current, power factor, frequency and power.

• Time stamped maximum current and power

demands.

It’s large colour graphics LCD also displays:

• Scalable voltage and current waveforms

• Voltage and current harmonic spectrums up to

the 32nd order

Introduction 1 1.1

For SCADA and remote monitoring, this power

meter also comes with:

• Modbus RTU connectivity

• Modbus TCP/IP connectivity (only for DPM680)

• Built-in webserver (only for DPM680)

1.1

How To usE THis Manual

For installation instruction, the Installation chapter

2 should be read carefully.

The OVERVIEW page & MAIN MENU and

Password Authentication sections of the Meter

Operations chapter 3 cover the common steps

before jumping to any parameter page. The tree

diagram shown in Fig 1 shows the menus, sub

menus, pages and sub pages to navigate through

before reaching the page of interest.

Please refer to the Table of Content to jump to

the operation details in the Meter Operations

chapter 3. Chapter 6 on Troubleshooting

Guide can be used stand-alone. For DPM680,

chapter 4 deals with the Webpage Operations.

Finally, chapter 5 on the Modbus Operations

should be used in conjunction with the DPM680

Modbus Communication Manual that can be

downloaded from the www.itmikro.com website.

Information on calculation methods are given in

Appendix B.

6

Phase Voltage

Overview Main Menu

Voltage

Current

PF / Freq

Power

Energy

Setting

Line Voltage

Maximum Phase Voltage

Minimum Phase Voltage

Maximum Line Voltage

Voltage THD

Minimum Line Voltage

Sequence Voltages

Voltage Harmonics

Voltage Waveform

Current Demand

Minimum Current

Maximum Current

Phase Current

Maximum Current Demand

Sequence Currents

Current Harmonics Current THD

Current Waveform

Current Harmonics Table

PF and Frequency

Power Factor (PF)

Displacement PF (DPF)

Max/Min Inductive PF

Max/Min Capacitive PF

Max/Min Frequency

Active Power

Reactive Power

Apparent Power

Total Power

Power Demand

Maximum Power Demand

Maximum Active Power

Minimum Active Power

Maximum Reactive Power

Minimum Reactive Power

Maximum Apparent Power

Minimum Apparent Power

Active Energy

Reactive Energy

Apparent Energy

Total Energy

Reset Energy Counters

CT & VT Ratios

Ethernet (TCP/IP)

Modbus

View Network Details

Version

Date & Time

Change Dev Password

Factory Settings

Display Settings

Comm Settings

System Settings

For Factory Use Only

Voltage Harmonics Table

Fig 1 : Operation tree diagram

Introduction 1.1

Detailed technical specications and parametric

limits are listed in Appendix A.

7

Phase Voltage

Overview Main Menu

Voltage

Current

PF / Freq

Power

Energy

Setting

Line Voltage

Maximum Phase Voltage

Minimum Phase Voltage

Maximum Line Voltage

Voltage THD

Minimum Line Voltage

Sequence Voltages

Voltage Harmonics

Voltage Waveform

Current Demand

Minimum Current

Maximum Current

Phase Current

Maximum Current Demand

Sequence Currents

Current Harmonics Current THD

Current Waveform

Current Harmonics Table

PF and Frequency

Power Factor (PF)

Displacement PF (DPF)

Max/Min Inductive PF

Max/Min Capacitive PF

Max/Min Frequency

Active Power

Reactive Power

Apparent Power

Total Power

Power Demand

Maximum Power Demand

Maximum Active Power

Minimum Active Power

Maximum Reactive Power

Minimum Reactive Power

Maximum Apparent Power

Minimum Apparent Power

Active Energy

Reactive Energy

Apparent Energy

Total Energy

Reset Energy Counters

CT & VT Ratios

Ethernet (TCP/IP)

Modbus

View Network Details

Version

Date & Time

Change Dev Password

Factory Settings

Display Settings

Comm Settings

System Settings

For Factory Use Only

Voltage Harmonics Table

Introduction 1.1

8

Front

Rear

Side

96 mm

83 mm

17 mm

100 mm

96 mm

90 mm

86 mm

86 mm

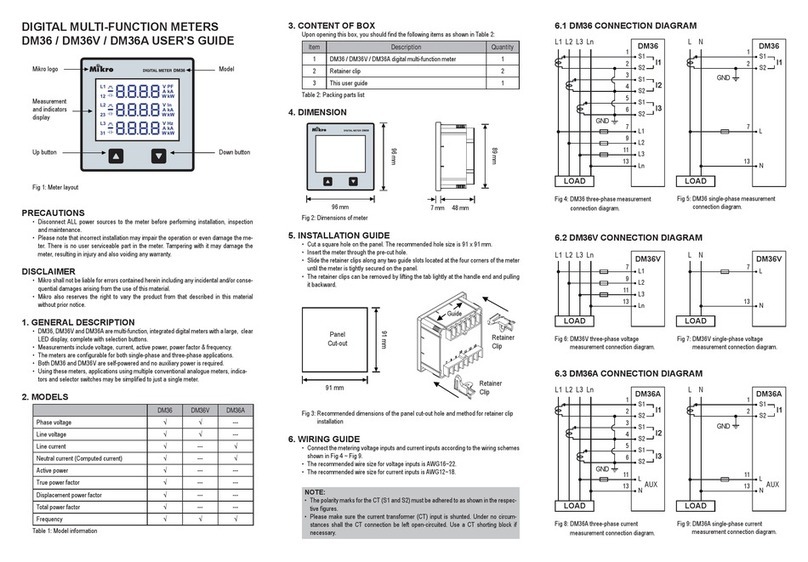

Fig 2 : Dimension of meter

1.2

ConTEnT of Box

Upon opening this box, you should nd the following items shown in Table 1:

1.3

parTs of THE powEr METEr

Fig 2 shows the outline dimension of the power meter.

Table 1 : Parts list

1

2

3

4

5

6

DPM680/B power meter

Retainer clip

Control power plug

RS-485 plug

Voltage input plug

This instruction manual

1

2

1

1

1

1

No Description Quantity

Introduction 1.2 1.3

9

The parts and locations in the meter where connections and

fastening are made is shown in Fig 3 and Table 2:

Fig 3 : Parts location

Table 2 : Location and parts labels

Label

A

B

C

D

E

F

G

H

I

J

Part / Location Description

Control power input Meter control power supply

Voltage input Metering voltage connection

Current input Metering current connection

RS-485 port RS-485 connection for Modbus RTU

RJ45 port LAN connection for Modbus TCP/IP & webserver

(only for DPM680)

Retainer clip

Retainer clip slot

Control power plug

RS-485 plug

Voltage input plug

Clip to hold meter in cut out hole

Location to slide the retainer clips

Meter control power detachable terminal block

RS-485 detachable terminal block

Metering voltage detachable terminal block

Introduction 1.3

10

Please note that incorrect installation may impair

the operation or even damage the meter.

There is no user servicable part in the meter.

Tampering with the meter may damage the

meter, resulting in injury or even death and also

voiding any warranty.

2.2

METEr plaCEMEnT &

ConnECTions

Before installing the power meter, please

check that the environment meets the following

conditions:

• Operating temperature: -10˚C to +55˚C

• Humidity: 5% to 95%, non condensing.

• Dust free environment with sufcient ventilation

away from electrical noise and radiation.

All wiring must be in accordance with local codes

and regulations.

2

insTallaTion

2.1

prECauTions

Please observe the following safety precautions

before and during the installation of the power

meter:

• Only competent and trained personnel should

install this device.

• Use appropriate personal protective gloves,

glasses and clothing.

• Never work alone.

• Disconnect ALL (metering, control power and

communication) power sources to the meter

before performing installation, inspection, test

and maintenance.

• Do not perform megger, hi-pot or any high voltage

stress test with the meter connected to the system.

• Use a shorting block to short circuit the CTs

before disconnecting from the meter.

• Install in a suitable enclosure where meter

connections are inaccessible with suffcient

clearance from other live parts.

• Do not bypass any fuse.

• Follow safe electrical work practices.

• Use only dry cloth to wipe the meter.

101.6±0.5mm

91±0.5mm

91±0.5mm

Fig 4 : Cut-out hole

Installation 2 2.1 2.2

11

a) provide a cut out hole on the switchgear and

control panel according to DIN43700/ANSI

C39.1 as shown in Fig 4.

b) insert the meter through the hole and slide in the

retainer clip along the slots on both sides of the

power meter until the device is tightly secured on

the switchgear and control panel. The direction

and orientation of the retainer clips is shown in

Fig 3. The retainer clip can be removed by lifting

the tab lightly at the handle end.

c) remove the detachable terminal block from

the voltage input connection and connect the

metering voltage inputs to the detachable

terminal block as shown in Fig 5 according

to the wiring schemes shown in Figs 6 to

9 below. The recommended wire size is

AWG16~22.

Please make sure the power to

the voltage metering input is totally

removed.

Shunt any unused metering voltage

input to the N input connection

Fig 5 :

Metering voltage input detachable terminal block

connections

Upon completing this step, please insert the

detachable terminal block securely into the

voltage input connector housing.

The terminal block must be inserted

securely into the connector housing

on the meter to prevent improper

operation.

d) connect the metering current input to the current

input terminal block as shown in Fig 10 at page

12. The recommended wire size is AWG12~18.

Please make sure the power to the

current metering input is always

shunted. Under no circumstances

can the CT connections be left open

circuit. Use a CT shorting block if

necessary.

Never connect the metering current

input to the measured circuits

without using CTs.

Only use CTs complying with

IEC 61869 - 2

Installation 2.2

12

Fig 6 :

3-phase star plus neutral,

4CTs with direct voltage input connection

Fig 8 :

3-phase delta without neutral 3CTs with 3VTs connection

Fig 7 :

3-phase star plus neutral,

3CTs with direct voltage input connection

Fig 9 :

3-phase delta without neutral 3CTs with direct

voltage input connection

L3

L2

L1

S

2

S

1

S2

S1

S2

S1

l3

GND

l2

l1

S2

S1 ln

Ln

L3

L2

L1 Ln

90~415 V AC /

100~300 V DC

AUX

RS 485

Modbus-RTU

LOAD

Ethernet

(Only for DPM 680)

L3

L2

L1 RS 485

Modbus-RTU

Ethernet

(Only for DPM 680)

S

2

S

1

S2

S1

S2

S1

l3

GND

l2

l1

S2

S1 ln

Ln

L3

L2

L1

90~415 V AC /

100~300 V DC

AUX

LOAD GND

L3

L2

L1

S

2

S

1

S2

S1

S2

S1

l3

GND

l2

l1

S2

S1 ln

Ln

L3

L2

L1 Ln

90~415 V AC /

100~300 V DC

AUX

LOAD

RS 485

Modbus-RTU

Ethernet

(Only for DPM 680)

L3

L2

L1 RS 485

Modbus-RTU

Ethernet

(Only for DPM 680)

S

2

S

1

S2

S1

S2

S1

l3

l2

l1

S2

S1 ln

Ln

L3

L2

L1

90~415 V AC /

100~300 V DC

AUX

LOAD

GND

Installation 2.2

13

Upon completing this step, please insert the

detachable terminal block into the meter control

power supply connector housing.

An isolation transformer or EMC lter may need

to be installed before feeding into the power

meter in case of power quality problems in the

control power supply.

e) remove the detachable terminal block from the

meter control power supply connection and

connect the control power supply via a fuse

to the terminal block as shown in Fig 11. The

recommended wire size is AWG 16 ~ 20.

The recommended fuse part no is LVSP5 from

Littelfuse. Please note that without this fuse, the

meter installation is only rated at CAT II. For CAT

II installations, an adequate circuit breaker or fuse

according to local regulations should be installed.

Please make sure the power to the

meter control is totally removed.

The meter control power supply

MUST be connected via an external

circuit breaker and be protected by a

CAT IV fuse.

Fig 10 :

3-phase and neutral CT connections

Fig 11 :

Control power connections

Installation 2.2

The terminal block must be inserted

securely into the connector housing

on the meter to prevent improper

operation.

Installation 2.2

14

Up to 32 devices can be connected in a daisy

chain fashion and the total cable length should

not be more than 1000m.

Upon completing this step, please insert the

detachable terminal block into the RS-485 port

connector housing.

f) if Modbus RTU is used, remove the

detachable terminal block from the RS-485

port and connect the Modbus communication

cable to the terminal block as shown in Fig

12. The recommended wire size is AWG22 or

thicker, shielded twisted pair.

g) for DPM680, if Modbus TCP/IP or the web-

server is used, simply connect the LAN cable’s

RJ45 connector to the RJ45 port shown in Fig 3.

Please make sure the polarity is

correctly aligned.

Please make sure the connector

snaps into the port to ensure proper

connection is made.

Avoid running the cable near

sources of electrical noise. The

network cable shield should be

grounded at only ONE end.

Fig 12 :

Modbus RTU connections

2.3

METEr sETup

Before commencing operation, the meter has to

be set up. To do this, the meter must be powered

up by the meter control power supply.

Under section 3.8, the following parameters

should be reviewed against the default value and

modied if necessary:

• CT ratio and VT ratio, see section 3.8.1

• IP address and subnet mask, see sections

3.8.2.1 and 3.8.2.3 (only for DPM680)

• RS-485 serial data format and baud rate,

see section 3.8.2.2

• Modbus RTU device address,

see section 3.8.2.2

• Modbus remote read enable,

see section 3.8.2.2

• Date and time, see section 3.8.3.2

• Device password, see section 3.8.3.3

The terminal block must be inserted

securely into the connector housing

on the meter to prevent improper

operation.

Installation 2.2 2.3

15

To reset the energy register values, please see

section 3.7.5

The following parameters should also be

reviewed against the default value and modied

if necessary:

• demand interval and sub interval block for

thermal current demand, see section 3.4.4

• demand interval and sub interval block for

power demand, see section 3.6.5

The following registers should be reviewed and

reset if necessary:

• maximum and minimum phase voltages, see

sections 3.3.3 & 3.3.4

• maximum and minimum line voltages, see

sections 3.3.5 & 3.3.6

• maximum and minimum current, see sections

3.4.2 & 3.4.3

• maximum current demand, see section 3.4.5

• maximum and minimum inductive power factor,

see section 3.5.4

• maximum and minimum capacitive power factor,

see section 3.5.5

• maximum and minimum frequency, see section

3.5.6

• maximum power demand, see section 3.6.6

• maximum and minimum active power, see

sections 3.6.7 & 3.6.8

• maximum and minimum reactive power, see

sections 3.6.9 & 3.6.10

• maximum and minimum apparent power, see

sections 3.6.11 & 3.6.12

2.4

TCp/ip ConnECTion sETup

The meter runs on IPv4 and its TCP/IP settings

can either be xed by the user or assigned

via DHCP. By default, the TCP/IP settings are

assigned via DHCP and the alternate default

xed TCP/IP settings are as follow:

IPv4 address: 192.168.28.28

Subnet mask: 255.255.255.0

Gateway address: 192.168.28.1

These values can be changed at the meter as

explained in section 3.8.2.1.

Installation 2.3 2.4

16

e) Single click to highlight the Internet Protocol

Version 4 (TCP/IPv4) bar and click on the

Properties button. The Internet Protocol

Version 4 (TCP/IPv4) Properties window will

appear as shown in Fig 14.

f) check on the Use the following IP address

button and set the IP address to 192.168.28.1

and the subnet mask to 255.255.255.0 as

shown below.

Fig 13 :

Local Area Connection Properties window

Only devices within the sub-network as dened

by the subnet mask can communicate with the

meter. In the instance of the above default subnet

mask, only devices (e.g. PC or router, etc.) with

IP addresses that begin with 192.168.28 can

communicate with the meter.

For direct PC connection, the IP address of the

PC can be changed as follows:

a) go to the START menu and click on the

Control Panel label.

b) under the Network and Internet heading,

click on the View network status and tasks

link.

c) under the Tasks sidebar, click on the Manage

network connections link.

d) double click on the LAN port that is connected

to the meter. You may be asked by Windows

for access permission. Upon conrmation,

you will see the Local Area Connection

Properties window as shown in Fig 13.

Installation 2.4

17

Fig 14 :

Internet Protocol Version 4 (TCP/IPv4) Properties window

noTE:

The last digit of the IP address may be varied

from 1 up to 255 but care must be taken to

use only a vacant IP address.

Meter Operations 2.4 3 3.1

3

METEr opEraTions

The power meter front panel user interface comes

with a large colour LCD display and 4 touch buttons,

labelled F1, F2, F3 and F4 as shown in Fig 15.

To touch the button, simply place a nger on the

square below the labels corresponding to the menu

item at the bottom of the display.

3.1

oVErViEw paGE & Main

MEnu

Upon power up, the power meter will display an

OVERVIEW page, listing a summary of basic

parameters for all phases as shown in Fig 15:

g) click on the OK button to exit. Repeat pressing

the OK button in the Local Area Connection

Properties window.

Fig 15 : OVERVIEW page

F1 F2 F3 F4

18

TouCH BuTTon funCTions:

• when any button is touched, the MAIN

MENU will be displayed as shown in Fig 16

below.

• to go to the sub-menu of interest, touch the

SELECT (F2) button in multiple times until

the corresponding icon is highlighted (within

a dashed rectangular box) as shown in

Fig 16. To conrm this selection, touch the

ENTER (F4) button.

• to return to the OVERVIEW page, touch the

HOME (F1) button in the MAIN MENU.

When the power meter is left idle for more than 5

minutes, the display will default to the OVERVIEW

page.

Fig 16 : MAIN MENU

Meter Operations 3.1 3.2

3.2

passworD

auTHEnTiCaTion

For authentication in the parameter setting

operations, the user may be prompted for a valid

password. In this mode, the Enter Password

window as shown in Fig 17 below will appear.

TouCH BuTTon funCTions:

• to abort the operation and return to the

previous page, touch the ABORT (F4) button.

• otherwise, touch the SET (F1) button to enter

the input password mode.

In the input password mode, the UP (F2) and

DOWN (F3) buttons will become active and

the background colour of the active eld will be

changed to white.

Fig 17 : Enter Password window

19

noTE:

The device password will be used for all

authentication purposes except in the

Factory Settings sub page.

The default device password is 9999. The user

is advised to set their own password for security

reasons.

On the other hand, the factory setting password

is xed at 6256 and it cannot be changed.

Meter Operations 3.2

TouCH BuTTon funCTions:

• to increase the number, touch the UP (F2)

button.

• to decrease the number, touch the DOWN

(F3) button.

• to select the next active eld to change, touch

the NEXT (F1) button and repeat the above 2

steps.

• to abort the operation and return to the

previous page, touch the ABORT (F4) button.

• to conrm the password, touch the ENTER

(F4) button. If the password is wrong, an

error message will appear and the above

process has to be repeated unless aborted

by touching the ABORT (F4) button.

20

TouCH BuTTon funCTions:

• to select the parameter page of interest,

touch either the UP (F2) or DOWN (F3)

button until the item of interest is highlighted

(within a dashed rectangular box and a RED

dot to its left).

• to conrm this selection, touch the ENTER

(F4) button.

• to return to the MAIN MENU, touch the

BACK (F1) button.

3.3

VolTaGE suB-MEnu

The VOLTAGE sub-menu allows the selection of

voltage parameter pages as shown in Fig 18 and

its continuation in Fig 19:

Fig 18 : VOLTAGE sub-menu

Fig 19 : VOLTAGE sub-menu (cont’d)

noTE:

In a delta system without any neutral as shown

in Figs 8 and 9, the phase quantities are

measured with respect to a virtual neutral point.

Meter Operations 3.3

This manual suits for next models

1

Table of contents

Other Mikro Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

ATTOLLO ENGINEERING

ATTOLLO ENGINEERING WASP-200 LRF quick start guide

Eputec

Eputec 7905 Installation & maintenance

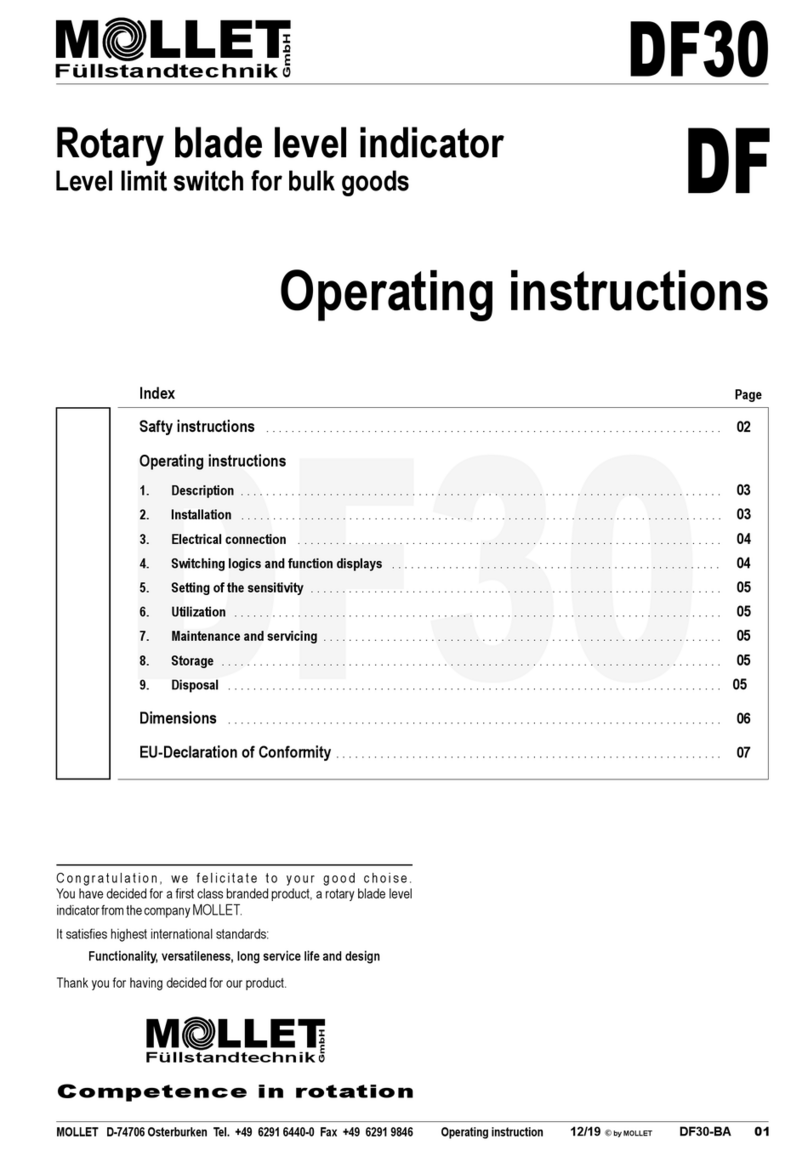

Mollet

Mollet DF Series operating instructions

Envertech

Envertech EnverBridge EVB202 User's operating manual

TR-Electronic

TR-Electronic LE-25 Assembly instructions

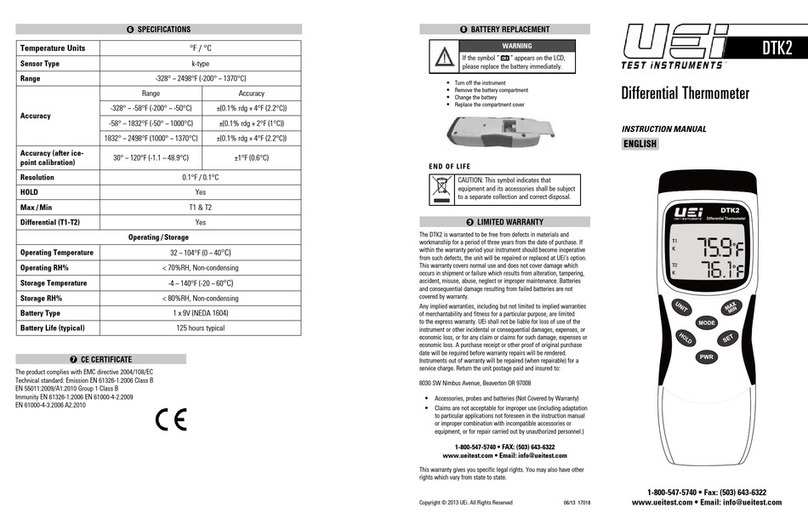

UEi

UEi DTK2 instruction manual