SONOPAN RF-100 User manual

RADIOMETER – PHOTOMETER RF-100

USER'S MANUAL

PPUH SONOPAN Sp. z o.o.

Poland, 15-950 Białystok, ul. Ciołkowskiego 2/2

tel./fax:+48 (85) 742 36 62

http://www.sonopan.com.pl

– 2 –

Table of contents

1. INSTRUMENT CHARACTERISTICS .......................................................................................... 4

1.1. Technical data ........................................................................................................................ 4

1.2. Measure probe unit................................................................................................................. 5

1.3. Steer unit................................................................................................................................ 5

2. EQUIPMENT................................................................................................................................. 6

2.1. Basic equipment..................................................................................................................... 6

2.2. Extra equipment ..................................................................................................................... 6

3. BASIC ELEMENTS OF METER................................................................................................... 6

4. RESULTS FIELD (MAIN WINDOW)........................................................................................... 7

4.1. Measure window.................................................................................................................... 7

4.1.1. Measure result format .................................................................................................... 8

4.2. Measured value logarithmic indicator ..................................................................................... 8

4.3. Status bar ............................................................................................................................... 8

4.3.1. Measure range field........................................................................................................ 8

4.3.2. Type of measurement field............................................................................................. 8

4.3.3. Measure range field........................................................................................................ 9

4.3.4. Statistics field ................................................................................................................ 9

4.3.5. Memory field................................................................................................................. 9

4.3.6. Battery supply field........................................................................................................ 9

4.3.7. Alarm field .................................................................................................................... 9

4.3.8. Time / date field............................................................................................................. 9

5. SERVICE ACTIVITY.................................................................................................................... 9

5.1. System MENU ....................................................................................................................... 9

5.1.1. Menu TYPE OF MEASUREMENT............................................................................. 10

5.1.1.1. Single measure .................................................................................................... 10

5.1.1.2. Continuous measure ............................................................................................ 10

5.1.1.3. Relative measure ................................................................................................. 10

5.1.1.4. Integration........................................................................................................... 10

5.1.1.5. Integration-clear .................................................................................................. 11

5.1.1.6. Statistics... ........................................................................................................... 11

5.1.2. Menu SETUP............................................................................................................... 11

5.1.2.1. Autorange............................................................................................................ 11

5.1.2.2. Zero setting ......................................................................................................... 11

5.1.2.3. Calibration........................................................................................................... 12

5.1.2.4. Luminancja ......................................................................................................... 12

5.1.2.5. Backlight............................................................................................................. 13

5.1.2.6. More.................................................................................................................... 13

5.1.3. MEMORY................................................................................................................... 14

5.1.3.1. Save measure....................................................................................................... 14

5.1.3.2. Load measure... ................................................................................................... 15

5.1.3.3. Clear last ............................................................................................................. 15

5.1.3.4. Clear all............................................................................................................... 15

5.1.3.5. Autosave... .......................................................................................................... 15

5.1.3.6. Send to PC........................................................................................................... 16

5.2. Starting instrument (power on sequence) .............................................................................. 16

5.3. Selecting measure range ....................................................................................................... 17

5.4. Measure ............................................................................................................................... 17

5.4.1. Single measure............................................................................................................. 17

5.4.2. Continuous measure..................................................................................................... 17

5.4.3. Relative measure.......................................................................................................... 17

5.4.4. Integrating ................................................................................................................... 17

5.4.5. Statistics ...................................................................................................................... 18

5.5. Measures memory................................................................................................................ 18

5.5.1. Working with external memory.................................................................................... 18

5.6. Working with luminance accessory ...................................................................................... 18

5.7. Working without measure probe........................................................................................... 19

5.8. Switching instrument off ...................................................................................................... 19

– 3 –

6. COMMUNICATION WITH PC................................................................................................... 20

6.1. Transmission protocol .......................................................................................................... 20

6.2. Automatic power on ............................................................................................................. 20

6.3. Controlling computer program ............................................................................................. 20

7. POWERING................................................................................................................................. 20

7.1. Control of battery supply. ..................................................................................................... 21

7.2. Automatyczne wyłączanie. ................................................................................................... 21

8. EXPLOITATION RECOMMENDATION ................................................................................... 21

9. WARRANTY AND REPAIRS..................................................................................................... 21

10. CE MARKING AND EEE DIRECTIVE .................................................................................. 23

11. APPENDIX A: Photometric probe G.L-100............................................................................. 24

12. APPENDIX B: Instrument probe for measure ultraviolet irradiance UV-A G.UVA-100........... 25

13. APPENDIX C: Instrument probe to measure photochemical (blue light) retinal hazard

G.BLH-100 .............................................................................................................................. 26

14. APPENDIX D: Instrument probe to measure photosynthetic active radiation G.PAR-100 ...... 27

15. APPENDIX E: Luminance accessory PL1.-RF100.................................................................. 28

16. APPENDIX F: Accessory PL-68 to measure luminance with luxmeter instrument ................. 29

– 4 –

1. INSTRUMENT CHARACTERISTICS

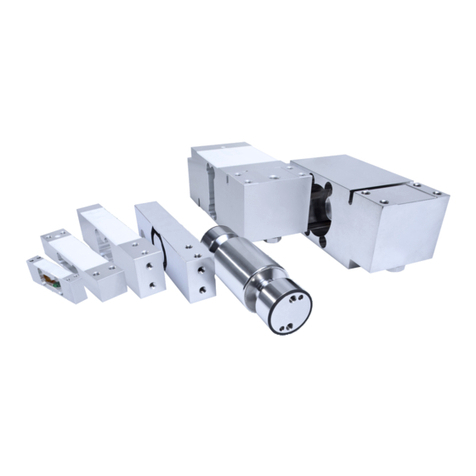

Radiometer-Photometer RF-100 belongs to the family of RF-1xx devices (where xx is numerical

designation). Device structure is based on concept of separation device function onto probe with is com-

plete meter and user steer unit which role is link user steering device with probe. This concept of device

allows operating with many probes with can have different metro-logic function. Under notion of metro-

logic function includes here: frequency characteristics of detector, number of measure ranges, dynamics

of a range, number of sub bands, physical units. Type of measure probe decides about complete meas-

urement device function, so it can be photometer or radiometer with arbitrarily defined spectral optical

radiation relative sensitiveness. Steering unit has saved list of probes together it can operate (named allow

list), and it has predefined maximal firmware version of probe with it can operate. It allows in easy way

to evolve into both device types with backward compatibility into older versions.

Radiometer-Photometer RF-100 is designed to co-operate with measure probes type G.xxx-1xx

(where x is numerical designation of type) manufactured by SONOPAN. Metro-logic parameters of suite

(steer unit plus measure probe) depends on used probe unit, that is used for measurement radiation inten-

sity or illumination intensity. For several kinds of measure probe units luminance mode was proposed

(energetic or depending on relative spectral probe sensitiveness. Measurement of luminance is available

after attaching proper accessory with measure filed angle 1°, 3° or 10°.

For example, instrument RF-100 with measure probe type G.L-100 makes luxmeter that fulfill regula-

tion needs (PN-89/E-04040.00 Measuring optical radiation. Photometric measures. General regulations;

PN-89/E-04040.03 Measure lighting intensity; Enactment number 31 Chairman's of Main Measure Of-

fice from 20.03.1995 regarding introduction of regulation about metro logical luxmeters. Journal of Legal

Measure Nr 6 from 22.03.1995) for device class 5.

This probe and steer unit was approved by Main Measure Office and has got sign: RP T 02 197. Metro-

logical is exactly same as manufactured by SONOPAN luxmeter L-100 instrument.

Radiometer-Photometer RF-100 was designed with integrating measurement function. This option makes

possible irradiation and exposure measurements.

This instrument is basic photometric device directed for all measuring services and employee of optical

radiation laboratory.

In range of electromagnetic compability Radiometer-Photometer RF-100 grants claims of norms:

EN61326 „Electrical equipment for measurement, control and laboratory use. EMC re-

quirements ”.

EN61000-6-2 „Electromagnetic compatibility (EMC). Generic standards. Immunity standard

for industrial environments ”

EN61000-6-3 „Electromagnetic compatibility (EMC). Generic standards. Emission standard for

residential, commercial and light-industrial environments ”

1.1. Technical data

• Precision class: depends on probe unit (look appendix)

• Entire error: depends on probe unit (look appendix)

• Spectral matching: depends on probe unit (look appendix)

• Direction matching: depends on probe unit (look appendix)

• Measuring ranges: depends on probe unit (look appendix)

• Detector: individual for measurement probe unit type

• Display: graphical LCD 128×64 pkt.,

• Supply: battery 9V (6LR61)

• Dimensions: 152 × 83 × 33 mm

• Operation temperature: 0 ÷ 40ºC

• Max environment relative humidity: 80%

Device is provided with several user functions :

• Manual or automatic change of measuring range ,

• Single-time measurement or continuous,

• Relative measurement with optional reference ,

– 5 –

• Integration of measured quantity in respect of time,

• Measurement statistic independently for peek and integrated values:

• counting average value,

• finding minimal value,

• finding maximal value,

• counting ratio min/avg,

• counting ratio min/max,

• Manual or automatic adding measurement to statistics,

• Measure memory: 512 cells with user comment space,

• External memory for measurements (511 cells),

• Browsing and Viewing measures saved in memory,

• Continue measurement record saved in memory,

• Manual or automatic writing measures to memory,

• PAUSE driver – stopping measurement process,

• Zero setting measure probe driver (detector dark current),

• Automatic zero setting driver,

• Steering for calibrating measurement probe,

• Two-way communication with computer through RS232C port,

• Option that allows switching on and off steer unit through RS-232C interface,

• Choice of RS232C port speed,

• Calendar and real time clock,

• Alarm with user comments ( e.g. remind about calibration deadline (date) ) ,

• Supply voltage control,

• Two automatic turn off drivers with changeable inactive time value,

• Two automatic back light LCD screen drivers.

The device user options are available through expandable menu lists visible at graphic display.

Radiometer-Photometer RF-100 consists of two cooperate units: measuring probe and it's steer unit.

1.2. Measure probe unit

Measuring probe type G.xxx-1xx is complete photometer which include :

• radiation detector spectrum and direction corrected,

• analog-digital converter,

• zero setting driver,

• automatic zero setting driver,

• automatic measure range change driver,

• register for calibration value,

• communication interface witch steering unit.

1.3. Steer unit

Steer unit type RF-100 provide :

• communication with measurement probe,

• visualization result of measures witch units,

• handling measure device by user,

• communication witch computer.

– 6 –

2. EQUIPMENT

2.1. Basic equipment

• Steering unit RF-100,

• Measure probe type, order dependent (optional),

• Cable to communicate with PC,

• Supply battery,

• Computer software handling measurement device,

• User's manual,

• Guarantee card .

2.2. Extra equipment

• Attachment for measuring luminance PL1.RF-100 – measure field angle 1°,

• Attachment for measuring luminance PL3.RF-100 – measure field angle 3°,

• Attachment for measuring luminance PL10.RF-100 – measure field angle 10°,

• External memory module MP32.RF-100 – memory 32KB (511 cells),

• Hook for photometric probe,

• Transport suitcase.

Inside transport suitcase there are profiled soft nests assigned for placing all basic and extra equipment

elements. They provide proper storage and transport conditions that don't expose content on mechanical

damages.

3. BASIC ELEMENTS OF METER

–

P

D

Y

M

A

$ +

S V

G J

@

Q

E

Z

N

B

% !

T W

H K

#

R

F

/

O

C

& ?

U X

I L

9

5

1

8

4

0

6 7

2 3

MODE

SETUP

h

i

d

d

e

n

c

a

l

i

b

r

a

t

e

b

u

t

t

o

n

b

a

c

k

l

i

g

h

t

b

u

t

t

o

n

measure probe socket

ext. power supply / PC socket

display

keyboard

alphanumeric keyboard

RADIOMETER

RF-100

ESC

external memory socket

Illustration 1. Radiometer-Photometer RF-100

– 7 –

4. RESULTS FIELD (MAIN WINDOW)

Main window of steering unit was named after content of graphics display, when all bookmarks of

MENU are disabled, when starting winieta is off and when there is no displayed communicate on instru-

ment screen.

Main display window consists from measuring window, logarithmic bar of measured value and strip of

status.

Illustration 2. Main Window view for light intensify , relative measurement, statistics and integration

mode

4.1. Measure window

Measure window includes:

• battery life indicator:

pause,

measure,

• Measure range overflow indicator with is displayed after measure state indicator,

• measure value determination:

illumination

luminance,

luminance exposure (time integral intensity of illumination),

luminance time integrating,

• measured value filed,

• measured value unit field.

Besides:

for relative measurement mode: actual measured value (E) and reference value (E0) ,

for integral measurement mode: actual measured value (E) and integration time (t) in format

hours:minutes:seconds,

for statistics and integration mode: statistics field including: measures count (n), minimal value (min),

maximal value (max), average value (avg), min/avg ratio (mn/a),

min/max ratio (mn/x).

In measure value unit field, before basics unit, instrument prints a symbol of multiple or sub multiple.

Measure values displayed in statistic field do not includes designation of basic unit. They are similar to

computed factors and adjusted to multiplication factor symbols.

Device own proper to show value considerably surpass dynamics of measure probe displaying symbols:

• f (femto) = ×10-15

• p (piko) = ×10-12

• n (nano) = ×10-9

– 8 –

• µ (mikro) = ×10-6

• m (mili) = ×10-3

• k (kilo) = ×103

• M (mega) = ×106

• G (giga) = ×1012

• T (tera) = ×1015

• P (peta) = ×1018

4.1.1. Measure result format

Measure result is reeded from probe and displayed in result field of measure window with setup measure

result resolution. In case when measure value is greater then 9999×LSB (where LSB is weight of less sig-

nify bit), there is a clipping of showed number for four most signify digits. Position of decimal point and

unit fold are pre-selected, in order to present result with best precision.

4.2. Measured value logarithmic indicator

Measured value indicator : is placed in upper part of screen. Indicator

is displayed during illumination measure without relative measure or statistics option selected. It includes

scale fold that covers whole measuring range and strip of fulfillment. Doted part of scale fold covers

lower range. If strip of fulfillment is in this area it signifies, that measurement is possible with greater

resolution on lower range. Indicator is not refreshed during return from option MENU to main window.

4.3. Status bar

In lower part of screen meter signalize actual setup of the device by icons. This field is divided into:

measure range field, measure type filed, measure change range field, statistics field, memory field, power

supply control field, alarm field, time / date field.

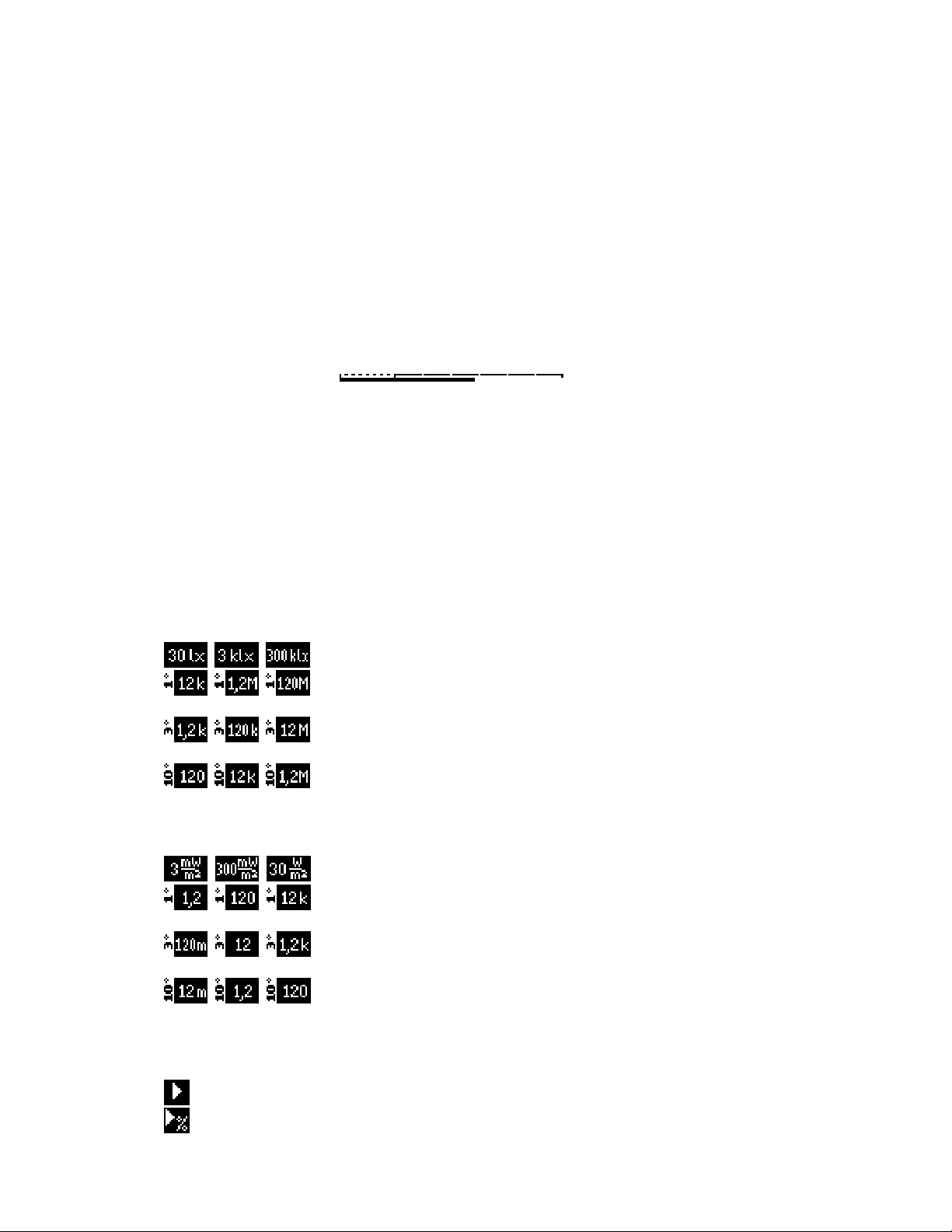

4.3.1. Measure range field

example photometric probe unit:

actual selected illumination measure range,

actual selected luminance measure range for 1° measure field angle

[cd/m2],

actual selected luminance measure range for 3° measure field angle

[cd/m2],

actual selected luminance measure range for 10° measure field angle

[cd/m2],

example radiometric probe unit:

actual selected irradiation measure range,

actual selected luminance measure range for 1° measure field angle [W·m–

2·sr–1],

actual selected luminance measure range for 3° measure field angle [W·m–

2·sr–1],

actual selected luminance measure range for 10° measure field angle

[W·m–2·sr–1].

4.3.2. Type of measurement field

one time measure,

one time relative measure,

– 9 –

continuous measure,

relative continuous measure,

integration.

4.3.3. Measure range field

manual measure range change (only for one time measurement),

automatic measure range change.

4.3.4. Statistics field

automatic adding measure to statistics..

4.3.5. Memory field

automatic write measure to memory,

memory is empty,

memory is partly full,

memory is full.

4.3.6. Battery supply field

Battery is full,

Battery is partly empty,

Battery is empty,

4.3.7. Alarm field

Alarm is active.

4.3.8. Time / date field

Actual time or date is shown in lower right corner of a display. In case when viewing

measures from memory this field displays time and date of saved measure.

5. SERVICE ACTIVITY

5.1. System MENU

System MENU of Radiometer-Photometer RF-100 contains three basics bookmarks : TYPE OF MEAS-

UREMENT, SETTINGS, MEMORY. Bookmarks are executed through instrument keyboard keys:

. All bookmarks contains list of available choice options. User can change setup options

by changing the position of pointer (option displayed in negative) by keyboard keys and apply the

setup values by key . Sub options menus texts are ended with three dots (expandable menu). Instru-

ment memorize last position of menu pointer.

Canceling setup options is available through keyboard key .

Actual selected options are signalized in list by the checkout .

– 10 –

The info screens that are shown during setup of device can be disabled by keyboard key or .

Changing instrument setup can be only made on pause mode. All setup values and positions of pointers in

menus are memorized in instrument memory and will be available after power on / off sequence.

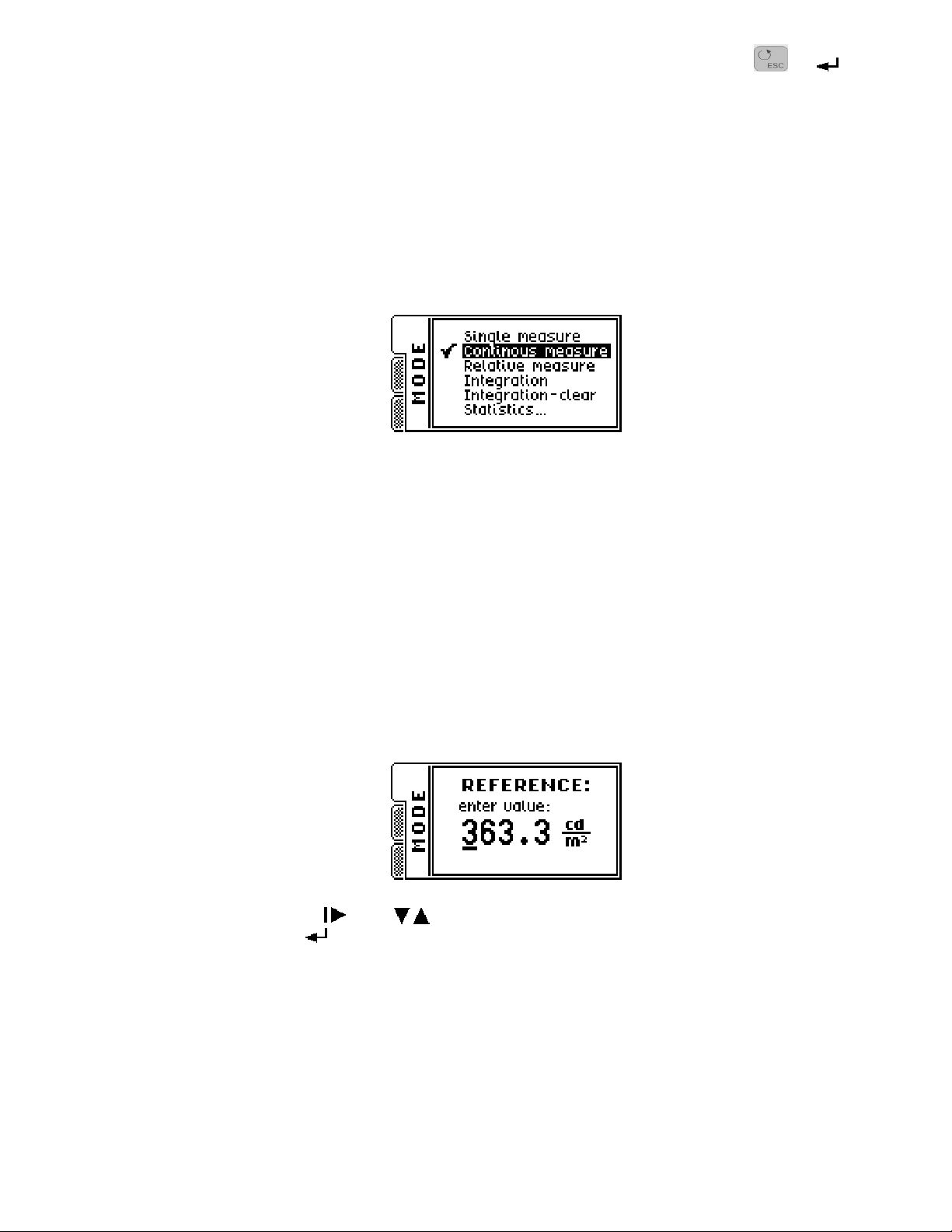

5.1.1. Menu TYPE OF MEASUREMENT

Instrument can operate in three types of measurement (one of three):

• one time measure,

• continuous measure,

• integrating.

Additional, for one time measure or continuous measure provided relative measure option (type on/off).

Illustration 3. Bookmark menu TYPE OF MEASUREMENT with continuous measure option set.

5.1.1.1. Single measure

Function: starting one time measure mode, other setup stay the same.

5.1.1.2. Continuous measure

Function: stating continuous measure mode, automatic measure range option is on after switching to this

mode.

5.1.1.3. Relative measure

Function: Setting relative measure option on/off.

After setting measure option to „on” new window for setup reference value opens. Window contains last

measured default value for reference:

Edit can be made by passing numeric values directly from alphanumerical keyboard. Position of cursor

can be modified by key . Keys change multiplication factor of unit. Approving reference value

can be made by key . After that instrument change operation to automatic measure range change. If

that option was selected during integrating mode, one time measure mode is selected by the instrument.

5.1.1.4. Integration

Function: starting integration measure mode.

Instrument loads last parameters and values after switching to this mode. This leave option for user to

continue last integral measurement. Result value of actual illumination is rewritten from last one time

measure or continuous measure. After leaving integrating mode (switching one time measure mode, con-

tinuous or relative measure), in the result field instrument displays last measured value of illumination

during integral operation mode.

– 11 –

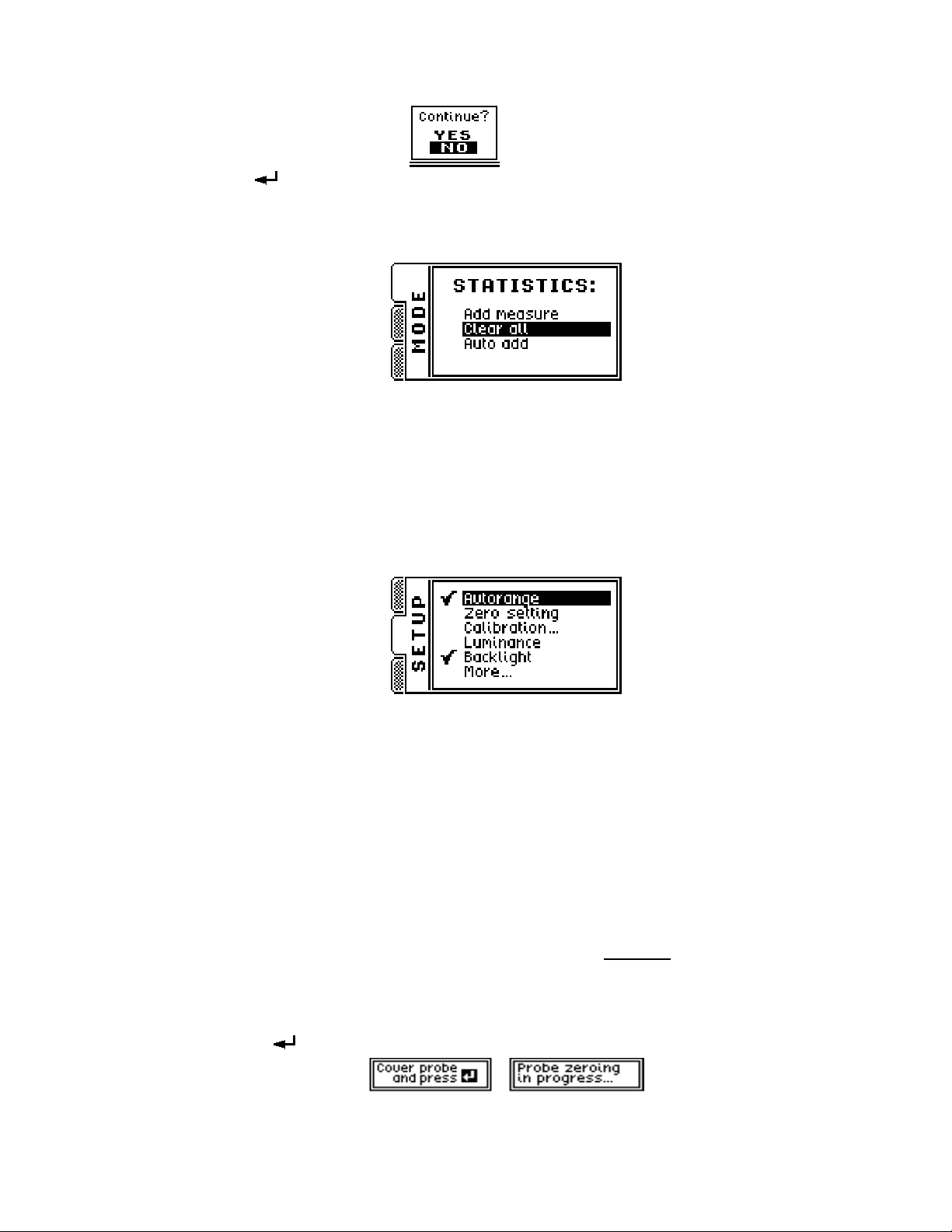

5.1.1.5. Integration-clear

Function: Deleting measured integrated value and it's related statistics.

Instrument displays notice window: . After selecting true response and approving it by

keyboard key meter delete measured integrated value and it's related statistic values.

5.1.1.6. Statistics...

Function: statistics sub menu:

• Add measure - adding last measure to statistics.

• Clear all - delete (after approving the notice window) statistics .

• Auto add - on/off appending data to statistics after every measure.

Statistic option only concern one time measure and continuous measure. In integrating mode instrument

make independent statistical calculation.

5.1.2. Menu SETUP

Illustration 4. Bookmark menu SETTINGS with setup options : automatic measure range change and

display back light on.

5.1.2.1. Autorange

Function: on/off automatic measure range.

Setting this value to off is equal to setting manual measure range change. In this case one time measure

will be set automatically.

5.1.2.2. Zero setting

Function: compensating photo detector probe dark current.

WARNING! Zero setting the instrument probe can be made only after covering measure probe.

If measure probe at zero setting process is not covered, instrument may work im-

properly.

On display screen instrument will remind about covering measure probe, and after approving wish to zero

set probe by key instrument display communicate about status of process.

Zero setting measure probe process on all measuring ranges. Values of zero setting are saved in internal

registers of measure head.

– 12 –

5.1.2.3. Calibration...

Function: Calibration of measure probe.

WARNING! Calibration is made by proper Main Measure Office or Laboratory during in

strument calibration process. In other case instrument indications will not ap

prove standard pattern.

In order to perform calibration process correctly it is necessary to have proper photometric pattern (light

direct pattern) and conditions for correct illumination model restoring on surface of receipt field of meas-

ure probe.

Calibration must be done on any range for intensify level about 3/4 measure range.

Before calibrating instrument probe, pre-calibration measure witch photometric pattern is required.

After selecting Calibration from menu OPTIONS new edit window for measured calibration value will

open. :

Value editing is allowed by inputing values from alphanumerical keyboard. Position of cursor can be

changed by key . Keys change multiplication factor of unit. Approving reference value can be

made by key „Calibration” available through hole in left lateral of steer unit (Illustration 1.). If inputed

value does not fit instrument criteria, meter will generate one of following error communicates:

New proper calibration ratio calculated based on measured one is saved in internal register of measure

probe. From main window of instrument last and actual calibration factor can be viewed only in the same

form that is saved in internal probe register:

The value of calibration ratio may include in range: 0.5÷1.0. In internal memory probe format that value

equals range: 4194304÷8388607.

Calibration can be done also in luminance mode. The Calibration factor is only one and it equal concerns

illumination and luminance measurements. This can be done because steer unit allows only proper dis-

play and calculation of various physical values.

5.1.2.4. Luminancja

Function: on/off luminance measurement mode.

It is necessary to connect (or disconnect) proper measure probe accessory. Type of connected accessory

can be chosen from expandable luminance menu:

Luminance mode can be set only for probes that are compatible witch luminance operation mode. In other

case instrument does not allow setup that option.

For luminance option all types of instrument operations are available. Besides all setup option, integral

values and statistics are memorized. That option allow to continue measures when switching from illumi-

nation to luminance mode and vice versa.

– 13 –

5.1.2.5. Backlight

Function: on/off back light of display.

Display back light increase contrast of lcd, through that increase reading capabilities of lcd screen, but

when it's on it decrease battery life time. Back light increase brightness of display, when measure is sup-

plied from battery that option allow reading display at dark rooms and is not noticeable at normal illumi-

nation. When back light driver is on it increase battery power consumption for about 25%. Instrument by

default increase battery life time by switching back light driver of when instrument is powering on. Lcd

back light can be on for a moment by specific key placed on left side of lateral steer unit (Illustration 1.).

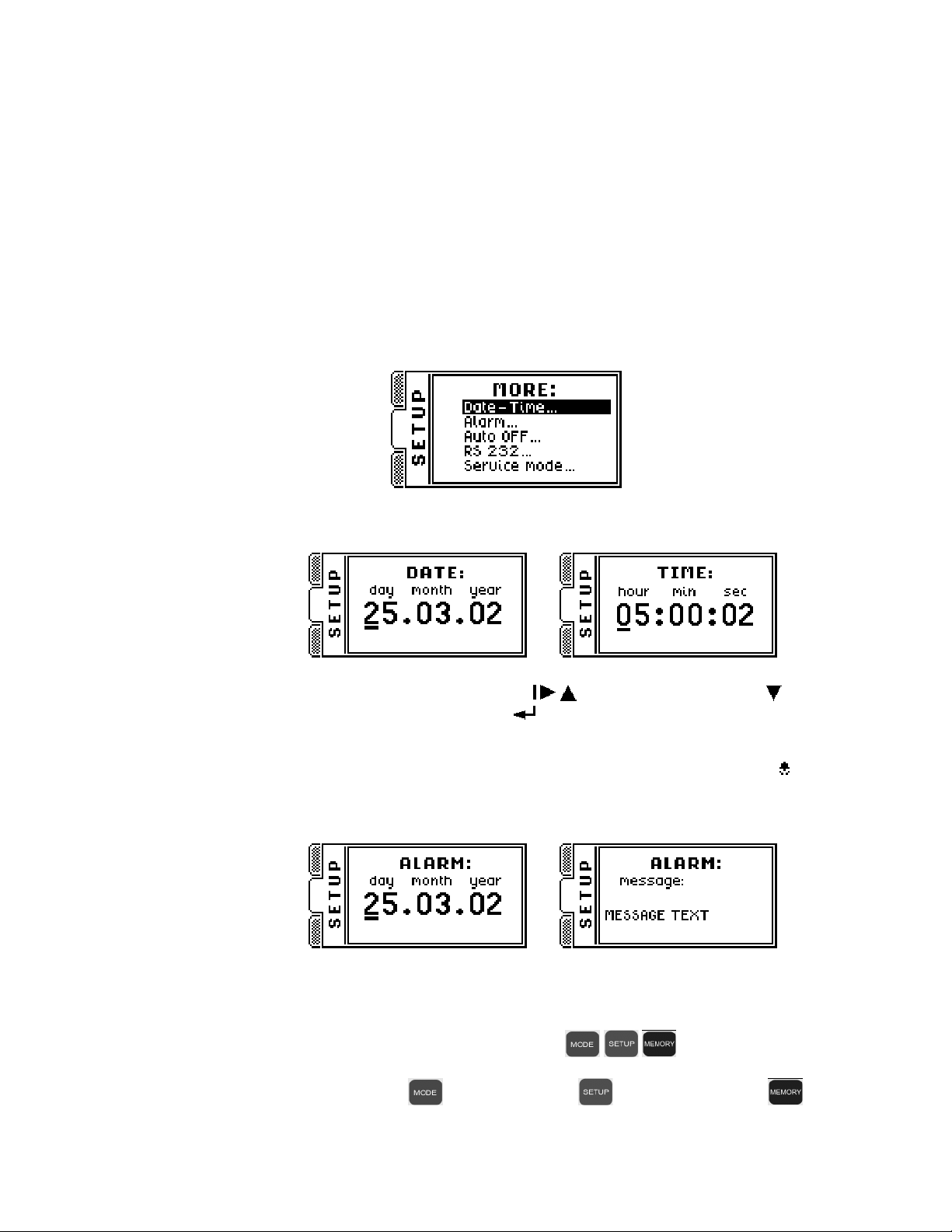

5.1.2.6. More...

Function: sub menu for calendar setup, alarm, automatic power off, parameters of PC data transmission :

Date-Time... - real time clock setup. New windows will open sequentially:

Setup values is done by the alphanumeric keyboard keys. Position of cursor can be

changed in right direction by keys , and in left direction by key . Approv-

ing setup values is done by key .

Alarm... - on/off alarm. This option can be used for example to remind about date of certify

(calibration). When alarm is active (signalized by icon in status stripe: ), during

startup of instrument window with alarm communicate will appear if date will be

equal or greater then setup alarm date value. After switching alarm option on new

windows will open sequentially:

Editing date value is done like edit process of real time clock setup. During alarm

communicate edit process, directly from keyboard alphanumeric keys are available

base chars (digits, dot and space). With all keys additionally user can input three

different chars that are placed at left part of key. Switching through different key

functions take here menu choice keys: , that background color is

same as input special chars. So to enter char from upper level of special chars user

must push key , from middle level and from bottom level before

pressing keyboard alphanumeric key.

If menu choice key was used again it cause switch to entering base chars mode.

– 14 –

Shape of cursor decides about selected sort of input char : - base char, - upper

level characters, - middle level characters, - bottom level characters. Cursor

position can be shift right by key's , and shift left by key . Approving

setup values can be done by key .

Auto off... - inactive time setup for auto off mode. After selecting new window will open :

Keyboard key shift pointer to previous position, to next position, and

shift among columns. Approving setup values can be done by key . This setup

window set's time interval that must elapse from last key press to automatic power

off instrument. This time is counted only if instrument is on PAUSE mode.

Automatic power off is used for increase battery life time.

RS 232... - RS 232 data transfer parameters setup. After select new window will open:

Menu contain in sequence : baud rate speed, parity control, amount of data bit's and

amount of stop bit's. As can be seen user can only change baud rate data speed. Se-

lection can be done by key's and approving setup values can be done by key

.

Service mode... - This option is used in preinitialize process of instrument by manufacturer. It

shouldn't be turn on by user.

5.1.3. MEMORY

Illustration 5. Bookmark MEMORY with auto save option selected .

5.1.3.1. Save measure...

Function: Saving last measure into first free memory cell.

After selecting, new window with save cell number and comment will appear (max 512 save cells for in-

ternal memory and 511 for external memory):

– 15 –

Editing Comment can be done just like editing Alarm comment in menu SETUP. Approving setup values

can be done by key .

5.1.3.2. Load measure...

Function: Browsing memory content.

After selecting, new window with measure saved in cell will appear:

Illustration 6. Window with measure saved in cell.

In window instrument prints: number of actual printed cell, number of occupied cell, measure physical

unit, value of measure, user comment, shortened status that signs instrument setup during measure, date

and time of measure and in case of luminance measurement type of external accessory used during meas-

ure (measure field angle accessory).

By default instrument prints last saved cell. Editing number of browsing cell is done by keyboard alpha-

numeric keys by entering suitable cell number or by keys increasing or decreasing number of actual

selected cell. Cursor position change is done by key .

After pushing key new window with memory cell data explorer will appear:

Illustration 7. Memory cell explorer.

User can return to cell list window by pushing key , pushing key will rewrite content of printed

cell to measure window of instrument. Measure options and saved instrument setup during rewriting will

be programed into instrument. This option allow in easy way to continue saved measure. However meter

forbids rewriting luminance measure when instrument is not in that measure mode. Also meter forbids

rewriting illumination measure when instrument is in luminance mode. Steer unit forbids rewriting saved

measure that was made with different probes that actually is connected to the instrument ( concerns

RF-100).

5.1.3.3. Clear last

Function: deleting after approving content of last memory cell.

5.1.3.4. Clear all

Function: deleting all cells after approving content of whole memory.

5.1.3.5. Autosave...

Function: on/off automatic save measures into memory.

After selecting, new window with auto save time will appear :

– 16 –

Time values change is done by key's and approve by key , after that new window with al-

low user to edit comment will appear. In this window user make default comment that instrument will

give for all cell's during auto save option enabled :

Process of editing comment is the same as in case of editing Alarm comment.

With auto save option enabled, instrument will switch in continuous measure mode. Instrument firmware

does not allow switching to single measure mode or switching from auto range mode during auto save

option enabled. After running measure, instrument will save result in setup delta time. During measure

instrument signalize auto save by blinking working state icon and by icon for memory auto save on

status stripe. After fill of all available memory cells, new window will appear witch communicate about

no free memory cell available and measure process will stop.

5.1.3.6. Send to PC...

Function: sending memory measure content to PC.

After selecting, new window will appear:

Transmission will start after pressing keyboard key . In lcd display user may see overall progress of

memory transmission. Transmission process can be broken through keyboard key .

5.2. Starting instrument (power on sequence)

To power on instrument user must press key . After pressing the power button screen displays start-

ing winieta with manufacturer data and actual firmware version of meter, and after initializing

probe unit – version of measure probe firmware:

Illustration 8. Starting winieta of Radiometer-Photometer RF-100

At lower part of lcd display instrument prints progress bar of initialization task. After task is finished me-

ter generate short sound signal that indicates it is ready to work. First screen can be closed by pressing

any keyboard key. If alarm was set and if alarm date condition is fulfill instrument will print communi-

cate with date and text of communicate:

– 17 –

Alarm screen can be closed by key or . All instrument setups are initialized from saved values

generated during last power off sequence. Last statistics and integrals for illumination and luminance

measures also reinitialized. It also refers to entered comments values and positions of MENU pointer.

Instrument is in PAUSE mode.

5.3. Selecting measure range

Change of measure range can be made from main menu window (Illustration 2.) using key: - changing

to range grater then actual selected, - changing to range less then actual selected. Naturally when auto

range option is selected at measure process instrument will select optimal range automatically. In most

case scenarios automatic measure range is advised. Manual range switching was expected mainly for con-

trol goals.

5.4. Measure

Running measures is only allowed from main window (Illustration 2.). Measure is started through push

key . In display instrument prints MEASURE icon . Meter measures average value from one sec-

ond period of measure. Result is printed on display with four digits precision. After measure finished in-

strument change it's operation mode to PAUSE ( icon: ). If during measure instrument detect range

overflow it will print overflow icon before result value.

In case of selected measure mode, instrument run single or continuous measure .

5.4.1. Single measure

For that measure mode manual or automatic measure range change was expected. In single measure mode

instrument triggers only one measure period. In case when automatic range change option is selected,

measure stands from point when optimal measure range was selected.

Holding key cause continuous measure to point when key is released.

5.4.2. Continuous measure

Continuous measure always take place at automatic measure range change. This setup is controlled and

possibly corrected after switching instrument into continuous measure mode. Measure will continue until

keyboard key or key is pressed.

5.4.3. Relative measure

This option was expected mainly for visualize measured values in percents of any reference values (com-

pare measures). At relative measure mode user may manually add illumination values to statistics also

statistics can be deleted.

5.4.4. Integrating

Integral illumination in respect of time called exposition hasn't got any main value on photometric

measurs. This option is expected for probes that measure radiation hazard, where time of exposure and

absorbed dose is fundamental. But yet, in case when variable illumination conditions and when user can't

exactly determine illumination value, user can use integral mode. Measure will be made until average

value of measure is stable and determined. Result of integrating measure is illumination value.

In case when in any measure period value of measured value is grater then highest measure range, before

integral value instrument will print range overflow icon: .

Setting integrating mode “on”, cause reinitializing earlier computed integral value and result connected

statistics. Also reseting device mode to measuring peek values (single, continuous measure mode) cause

reinitializing earlier saved statistic and give possibility to continue measure from last saved point. The

measure data that upper text is referring is independently memorized for luminance and illumination

modes, also after switching instrument off.

– 18 –

During integrating mode it is possible to manually add measured peek values to illumination statistics and

deleting it's value is also possible.

5.4.5. Statistics

Statistics function operates on chosen measure values and make possible :

computing average value,

finding minimal value,

finding maximal value,

computing min/avg ratio,

computing min/max ratio.

Above-mentioned operations will be executed on measure values that user may manually or automatically

add to statistics (p. 5.1.1.6. ...).

5.5. Measures memory

Radiometer-Photometer RF-100 is provided with internal 32kB memory. Memory is used to storage re-

sults of measurement. Memory is divided into 512 cells. One cell can hold one measure. At writing proc-

ess user may add comment to cell. Maximal comment size is 16 chars (it can be for example identifier of

measuring position ).

Every cell store:

• date and time of measured,

• comment,

• measured values,

• sort of measure type (illumination, integral, luminance),

• measurement physical unit,

• all setup values of instrument from measure time,

• measure probe identifier.

Firmware available memory exploring option, also it enable rewriting saved cell value into measure win-

dow of steer unit. All measure data and setup of device are then rewritten. After that, device setup and

measure data are the same as data and setup during measure save operation. This give possibility to con-

tinue measure from last saved point.

Writing data is only allowed to first free memory cell. When memory is full and at attempt of writing in-

strument prints new window with communicate: . Deleting is only allowed for last cell

and for whole memory (all cells at once).

Measure data memory may by transfered to PC by RS-232C for storage or analysis purposes.

Besides that, instrument allows external memory connection. External memory have 511 storage cells.

Measure memory handling was described in paragraph 5.5.1. Błąd! Nie można odnaleźć źródła odsyła-

cza.. Błąd! Nie można odnaleźć źródła odsyłacza..

5.5.1. Working with external memory

External measure memory handling procedure is very easy. It only consider connection memory module

to proper steer unit socket (Illustration 1). From that moment all operations that will be selected from

menu MEMORY refer to connected external memory. Proper instrument operation is only provided with

SONOPAN external memory module type MP32.RF-100.

In order to connect or disconnect external memory it is necessary to switch off the instrument.

WARNING! It is forbidden to connect or disconnect external memory during data transmission

from meter to computer.

Data stored in internal and external memory do not need power supply.

5.6. Working with luminance accessory

In order to connect luminance accessory it's necessary to unscrew ring from measure probe receipt field

and then on it's place screw luminance accessory (Illustration 9):

– 19 –

Illustration 9. Connecting luminance accessory.

In next step user must change instrument mode to luminance measure. (p. 5.1.2.4. Luminancja). It is

necessary to pay special attention to proper select measure field angle value in meter equal to adopted

accessory. This has fundamental meaning when computing luminance signal measured through probe.

Proper instrument results are only provided with SONOPAN accessory's, since accessory is structurally

fitted to the algorithm of the program that recast luminance signal at probe receipt filed to luminance

units.

When returning from luminance to illumination measure typed, it is necessary to screw earlier discon-

nected ring. This warrants proper probe direction characteristic.

5.7. Working without measure probe

During initiation process steer unit checks up the presence of probe unit. Instrument initialize probe unit

and read it's parameters (type of head, probe firmware version, count and values of measure ranges, type

of measure unit value, compatibility witch luminance mode) and then check up it's authorization to work

with probe. When measure probe unit is not present or instrument is not authorized to work with it, after

closing starting winieta new window witch statement will appear : and at status bar,

meter will do not display range of measure. Starting new measure is forbidden, but options : memory

exploring, transmission memory data to computer also options that are not related witch measure and

reading parameters from measure probe are available. Measure probe unit must by connected only af-

ter switching instrument off.

5.8. Switching instrument off

Instrument can be switched off only by key . During power off sequence device will save setup val-

ues, computed integral and statistic values, comments, positions of menu pointers, external memory

pointer and luminance mode status on internal static memory. Save procedure will not execute when de-

vice will be switched off by battery extraction. Data maintenance in earlier described memory doesn't

require powering the source.

– 20 –

6. COMMUNICATION WITH PC

Connecting meter RF-100 to computer is realized through RS-232C and cable provided together with the

device. Placement of data socket reveal Illustration 1.

6.1. Transmission protocol

Serial data line transmission parameters:

• 1200÷9600bds,

• 8 data bits,

• 1 start bit,

• 1 stop bit,

• no parity bit.

Communication between computer and instrument is bidirectional, i.e. meter sends data and also can be

controlled by PC.

6.2. Automatic power on

With connected meter RF-100 to computer automatic power on will take place at first occurrence of data

frame send by computer through RS-232C port. It allow for full attendance of outlying meter from posi-

tion of steering. When automatic power off after programed idle time occurred. It's recommended to de-

tach transmission cable when functioning with the computer isn't expected. It will help avoid uncontrolled

instrument activations.

6.3. Controlling computer program

Manufacturer to purchased meter RF-100 supply computer program RF.exe. After connecting instrument

to computer and starting meter, it's necessary to proper configure serial transmission port (setup number

of serial port corresponded with meter connection socket and setup data line speed, same as setup in in-

strument). Program permits fully control of instrument and reception of measure data content. Besides

that history option is available user may search measure in history of stored measures with different mask

(15 different search criteria). meter data, history and results can be saved on hard disk in text format (hu-

man-friendly) approbate by any spreadsheet application. Hear separate chars are tabulation chars. It al-

lows for optional processing measured data into prepared spreadsheet template.

Besides that, SONOPAN offer for interested customers that require independent computer software pro-

gramming of instrument Delphi components in the form of compiled software :

• for handling serial port transmission and conversion of transfered data,

• for controling instrument (like upper plus user interface).

Important assistance in work over own application can be bookmark „BuforCOM” in program RF.exe (it

prints received and sent chars and make possible their interpretation).

For further information please contact manufacturer.

7. POWERING

Radiometer-Photometer RF-100 is powered through single 9V battery. It is recommend to use so-called

alkaline batteries witch big capacity of the 6LR61 type or similar. They assure 20 hours of non-

interrupted instrument work. Container for battery is placed on back side of instrument unit.

Table of contents

Other SONOPAN Measuring Instrument manuals