Milky FJ 45 User manual

Page 1

Operating Instruction

PASTEURIZER, CHEESE AND

YOUGHURT KETTLE FJ 45 & FJ 90

Franz Janschitz Ges.m.b.H, Eisenstraße 81, A-9330 Althofen

T: +43 4262-2251-0, F: +43 4262-2251-13, E: of[email protected], W: www.janschitz-gmbh.at

Page 2

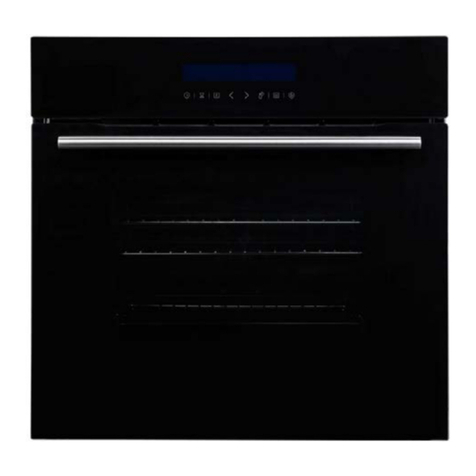

Pasteurizer FJ 45/90 is used for thermal treatment of milk by larger quantities of 20/30l milk. For the production of dairy products

like cheese, curd etc. Pasteurizer is an open type, heated water must not be under pressure. The milk is heated with an electric

heating. Water is used from the water supply or the water tank for cooling. Required temperature is set with an electronic

controller. The motor can be switched on or off. The three-layer container is heat insulated. It is made out of stainless steel

W.Nr.1.4301 (AISI 304). Excellent surface treatment makes the cleaning easy. The Pasteurizer FJ 45/90 is easy to use and

eco-friendly.

IMPORTANT NOTES

TECHNICAL DATA

BEFORE SWITCHING ON THE HEATING MAKE SURE THAT THE PASTEURIZER IS FILLED WITH COOLING

WATER, OTHERWISE THE HEATING WILL BURN!

Item FJ 45 FJ 90

Maximum capacity 45 liter 90 liter

Minimum capacity 20 liter 30 liter

Heating type electric electric

Heating performance 6kW 6kW

Maximum temperature up to 90°C up to 80°C

Rpm of the mixer 104 rpm 104 rpm

Outlet DN 40 DN 25

Connection power max. 6.200W max. 6.200W

Electric connection 400V 3N 50Hz 400V 3N 50Hz

Water IN connection 8mm diameter 8mm diameter

Water OUT connection 25mm diameter 30mm diameter

Dimensions

Length 700mm 740mm

Width 560mm 800mm

Height 730mm 820mm

Net weight 21kg 31kg

CHILDREN AND UNAUTHORIZED PEOPLE ARE NOT PERMITTED TO WORK WITH THE PASTEURIZER!

SAFETY-EXHAUST OUTLET MUST ALWAYS BE FREE, DO NOT COVER OR CONNECT SOMETHING!

Page 3

The machine will serve you for a long time, if you use and clean it according to the description in the operating instruction.

1. In case of difculties call your dealer or the authorized service of the distributor.

3. Warranty is given for a period of 12 months. Our obligation under this warranty is limited to the repair or exchange of the

device or a part (due to our evaluation) in the time of 12 months after the purchase.

4. Defects or damage on the machine, which are lead back to improper installation, operation, connection or treatment are

excluded from this warranty

5. The guarantee also does not include:

• Heating

• Engine - destroyed by water intake

• Parts of the control device - destroyed by water intake

• Main supply line/wire

6. The denoted technical specications are only valid when all conditions in this operation manual are fullled.

Dear customer,

we are convinced that you will be satised with our Pasteurizer and that this device will serve you for a long time. We

hope that you also will recommend it to your friends.

Thanks for the purchase and your condence!

SERVICE CONDITIONS

A quick and correct delivery of spare parts is only possible, if you tell us the following specications:

• Type of the device

• Number of the device (on the nameplate)

SPARE PARTS

2. Warranty is only given for defects which evidently result from wrong fabrication or materials.

7. Other rights, which are not mentioned in the upper obligations of the manufacturer, especially the responsibility for personal

injuries, are excluded.

Page 4

1. Placement

Put pasteurizer on a table or suitable at surface. Do not put pasteurizer on the oor. It is recommended that source of water

(water pipe, water collector) is not more than 2 meters away.

It is also recommended that outlet is not more then 3 meters away. Pasteurizer must be placed at least 0,5m from the walls.

The room has to have adequate electrical supply. Temperature in the room where pasteurizer is placed must never be lower

than 5°C and it is not recommend to be higher than 24°C.

2. Fixing the outlet

Page 5

3. Closing the outlet

Make sure that the outlet is closed (OFF).

4. Fixing tube on „COOLING WATER OUT“

On WATER OUTLET x exible plastic tube till sink. Length of the tube must not be longer than 3m.

OFF

ON

Page 6

5. Fixing tube on „COOLING WATER IN“

On WATER IN connection x the tube with standard rubber connector.

6. Connecting on electric supply

Pasteurizer must be connected with three-phase power plug on electrical supply 380V 50Hz . Before connecting pasteurizer

on power supply it must be checked that power supply in the room corresponds to the power voltage indicated on nameplate

and to power of connection on power supply.

Page 7

7. Connecting tube with water pipe

Before every SWITCH ON pasteurizer must be connected on water pipe, water collector or cooling system. For connetion

has to be used tube with universal rubber connector.

8. Turn on the water to ll the kettle with cooling water

Open the water valve that much that water connection stays on the valve.

ATTENTION

Open slowly the valve for cold water and only that much that rubber connector stays on the pipe – such water ow is

sufcient and economical. If we increase water ow then rubber connector falls from the pipe. Higher water ow will not

shorten time of cooling, it will only enlarge use of water which is not economical.

Page 8

9. Water comes out from the water outlet

Pasteurizer lls with water and when water comes out from WATER OUTLET then the pasteurizer is lled with water.

Pasteurizer is prepared for working.

10. Turn off the water pipe

Page 9

11. Switching on the main switch

OFF

ON

12. Review of last set temperature

Press key SET on short - on display shows last set value.

Page 10

13. Show momentary temperature in the kettle

Press key SET on short an it will show momentary temperature in the kettle.

14. Change of set temperature

Press key SET and hold on at least 2 seconds - the last set temperature will be shown, sign °C will start to pulse.

Page 11

15. Changing the value

For changing the value press key ↑ (enlargement) or ↓ (reduction).

Enlargement ↑

Reduction ↓

16. Remembering the new set value

So that machine remembers new set value press on short key SET or wait 10 seconds.

Page 12

18. Filling the kettle with milk

Then ll the kettle with milk. Minimal capacity of milk is 20/30 liter.

17. Checking

First check if you lled pasteurizer with water, adequate connection on the power supply and set temperature on temperature

control unit.

Page 13

20. Swich on the heating

Press key START and the heaters will start to work.

19. Cover the kettle with cover

OFF

ON

Page 14

22. Automatic regulation of the heating

The heater is switch off when milk in the kettle reaches set point temperature and switch on again when milk temperature

drops 2°C below set point temperature. This procedure control unit repeats without limit.

21. Starting the mixer

Push switch MIXER in position 1 and mixer will start to work.

OFF

ON

Page 15

24. Switching off the mixer

The mixer can be also switched off.

ATTENTION

For reaching constant temperature of the milk the mixer has to be switched on.

23. Switch off the heating

Pressing key START the heating is switched off.

OFF

ON

OFF

ON

Page 16

25. Turn on the water for cooling

Rubber connector must be on the pipe of the valve. Slowly open the valve till water ow where rubber washer still stays on

the pipe. That water ow is sufcient and economical.

OFF

ON

26. Starting the mixer

For constant and quick cooling the mixer has to work.

Page 17

28. Turn off the water

When milk cools down on wanted temperature close the valve and consequently also water ow.

27. Check dropping of temperature

Page 18

OFF

ON

29. Switching off the mixer

30. Cleaning

First switch off the Pasteurizer, the main switch has to be in position “0“ (OFF). After use clean the kettle with warm water,

add some washing-up liquid. After cleaning the kettle has to be washed out well with hot water. The use of aggressive clea-

ning agents is not recommended.

ATTENTION

The Pasteurizer has to be disconnected from the power supply before cleaning.

This manual suits for next models

1

Table of contents