Milky 17597 User manual

1

de BETRIEBSANLEITUNG

OPERATING INSTRUCTION

NOTICE D’UTILISATION

en

fr

MILCHZENTRIFUGE FJ 90, FJ 130 EPR, FJ 130 ERR

CREAM SEPARATOR FJ 90, FJ 130 EPR, FJ 130 ERR

CENTRIFUGEUSE À LAIT FJ 90, FJ 130 EPR, FJ 130 ERR

JANSCHITZ GmbH |Eisenstraße 81 | A-9330 Althofen

T: +43 4262-2251-0 | F: +43 4262-2251-13

230 V - Type 17597

115 V - Type 17597-115

230 V - Type 17602

115 V - Type 17602-115

230 V - Type 17598

115 V - Type 17598-115

12

en CONTENT

General safety recommendations

Technical Specifications

Unpacking and Set Up

Accessories

Assembling Procedure

Top Bowl assembling Procedure

Skimming Procedure

Skimming Regulation

Maintenance and Cleaning

Top Bowl cleaning procedure

List of composing parts

List if composing parts top bowl

Spare parts ordering Procedure

Warranty

Page

13

14

14

14

15

16

16

17

17

18

19

20

21

21

Dear Customer!

We are happy, that you have chosen Milky. We hope, that our device will serve you

as a helpful tool for a long time without any problems. We would be happy, if you

could recommend us to your friends.

Version: December 2018

1313

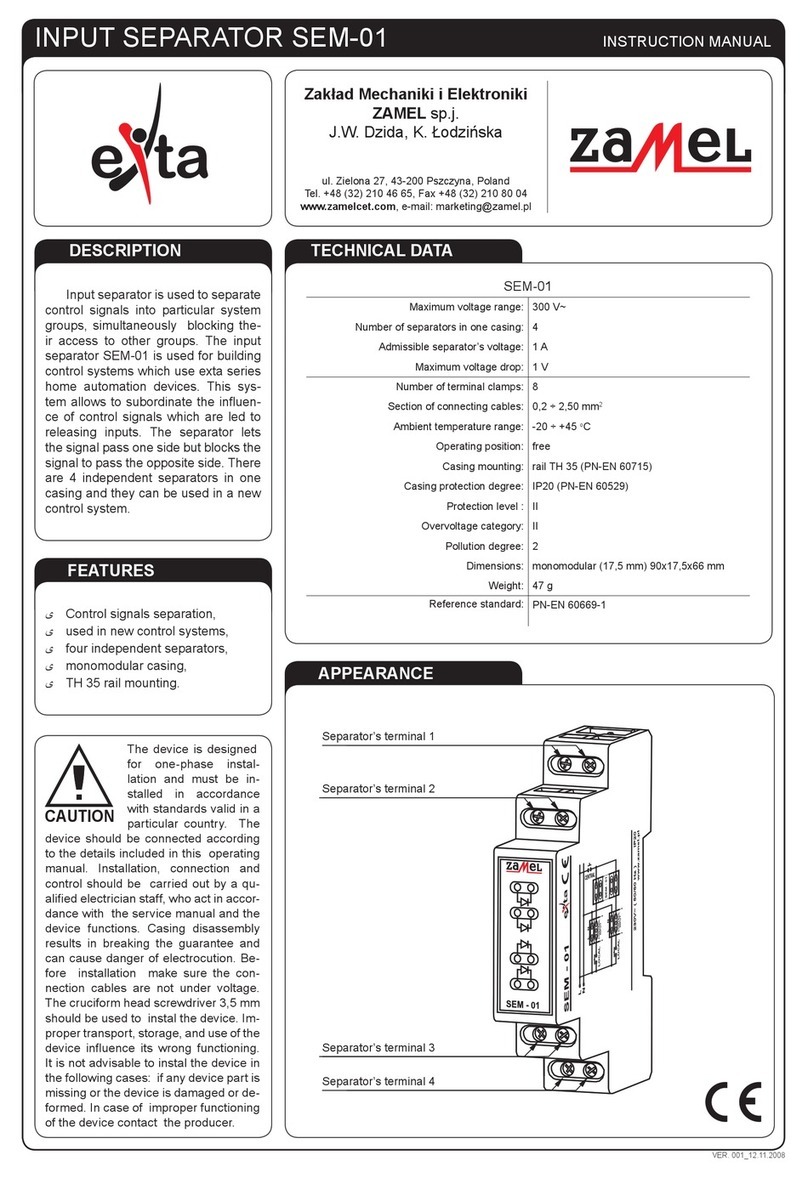

GENERAL SAFETY RECOMMENDATIONS

BEFORE ANY INSTALLATION, READ THIS MANUAL VERY CAREFULLY.

MAKE SURE, THAT YOU HAVE CLOSED TOP BOWL FIXING NUT TIGHTLY.

DISCONNECT DEVICE FROM MAINS BEFORE CLEANING.

DON’T REPAIR THE DEVICE BY YOURSELF, IN CASE OF MALFUNCTION RATHER

CALL AUTHORIZED SERVICE PROVIDED BY YOUR DISTRIBUTOR.

TAKE CARE THAT WATER OR HUMIDITY WILL NOT COME INTO THE DEVICE,

ESPECIALLY BY CLEANING PROCEDURES.

IN CASE OF SERIOUS MALFUNCTIONS, UNPLUG THE DEVICE FROM MAINS AND

CALL AUTHORIZED SERVICE.

IN CASE, THAT THE DEVICE IS NOT FUNCTIONING PROPERLY, EVEN YOU HAVE

EXACTLY FOLLOWED INSTRUCTIONS DESCRIBED IN THIS MANUAL, YOU ARE

ALLOWED TO USE ONLY THOSE PROCEDURES, WHICH ARE ALLOWED BY THE

USER MANUAL. USE OF ANY OTHER PROCEDURES OR ADJUSTMENTS COULD

RESULT IN DEVICE DESTRUCTION OR LONGER SERVICE TIME. INJURIES CON-

NECTED WITH SUCH PROCEDURES CANNOT BE MATTER OF ANY PRODUCT

LIABILITY CLAIMS.

14

Recommended skimming capacity is volume of the milk that can be skimmed within one

skimming cycle. It depends how much solid parts are in the milk. If the flow of the skim-

med milk is reduced than the discs and the bowl must be cleaned.

UNPACKING AND SET UP

Take the device out of the cardboard box and remove packing inserts. Place it on the plain

and stable surface in clear and dry place. Fixing the device on the surface is recommen-

ded. If you want to fix it on the surface, take the screws and fix it on the surface.

ACCESSORIES

In each package you will find also following accessories:

• Operating Manual

• Cleaning brush 371067

• Key for bowl fixing nut and cream screw 3712069

• Spare rubber washer 3711033

• Screws

Please note!

Be careful and do not use the cream separator with damaged mains cord!

Be careful, that the socket is not damaged!

Item MZF FJ 90 MZF FJ 130

Operating Voltage (model 230V) V / Hz 230 / 50 230 / 50

Operating Voltage (model 115V) V / Hz 115 / 60 115 / 60

Motor Power W 70 70

Max. Rotating speed RPM 9500 9500

Max. Capacity l / h 90 130

Max. Container capacity l 12 10

Recommended capacity for skimming l to 60 to 100

Relief disc pcs 7 11

Plain disc pcs 6 10

Net weight kg 3,50 4,70

Protection type IP 23 IP 23

TECHNICAL SPECIFICATION

15

HOW TO ASSAMBLE THE CREAM SEPARATOR

1. Put the housing on a desk or other plain and stable surface.

2. Put assembled top bowl on the conical motor beam and softly press it.

3. Put skimmed milk outlet on the top and then also cream outlet on the top of

the housing

4.

Turn top bowl with hand and check if nothing is touching the outlets. Adjust the outlets to

the desired position for skimming.

5. Put the container holder on the cream funnel (outlet). The floater is placed in the con-

tainer holder. The container is placed on the container holder (please see picture below)

Fixing hooks are only available in FJ 130

6.

Place closing cork in the hole situated in the middle of milk container. The narrow side of

the closing cork handle must be turned away from the cut in the container (see picture). The

milk outflow will be closed.

WHEN FILLING THE CONTAINER WITH MILK, THE CLOSING CORK MUST BE

CLOSED! THE THIN PART OF THE CLOSING CORK MUST POINT TO THE NOTCH IN

THE CONTAINER.

Fixing parts with rubber holder (detail). Only on FJ 130

16

SKIMMING PROCEDURE

Best skimming results are achieved, when starting to skim immediately after milking. If

milk is cooled, warm it up to a temperature between 30 to 35 ºC. Milk cannot be skimmed

with temperature lower 30 °C. When the milk is properly warmed up, pour it in the

container.

• Switch on cream separator with switcher 0 / I and wait 30 seconds. The top bowl will

by then have reached the right speed. Cream separator FJ 130 has above the switcher a

signal lamp which, by switching on the separator, shines red, and when machine reaches

working speed starts to shine green.

• Only when the LED shines green, open the closing cork by turning it into the opening

position. The end of the closing cork is turned to the cut (tooth) in the container and flow

is opened.

If milk is coming out of the housing holes, it means:

• You have opened the closing cork before the motor has reached working speed.

• Top bowl nut was not fixed enough.

• Rubber washer is placed badly, or it is destroyed.

When this is the case, close the closing cork, turn the milk separator OFF and correct the

problem.

CLOSING CORK MUST ALWAYS BE CLOSED BEFORE TURNING OFF THE DEVICE!

AFTER FINISHING THE PROCESS, CLEAN AND DRY THE DEVICE CAREFULLY!

TOP BOWL ASSEMBLING PROCEDURES

1. Put the rubber washer into the notch of top bowl bottom part.

2. Place the metal discs in the top bowl. Take care with the placement of the

discs - device uses two different types of disks - plain and relief discs. First,

insert relief disc, then plain disc and repeat the procedure until all discs are

placed. Avoid any use of strength while placing the discs. With gently shaking

and turning of the top bowl bottom part all the discs will find their place very

easily.

3. Put plastic partition in the top bowl cover part.

4. Place the two parts (top and bottom part) of the top bowl together. Take

care that top bowl top part marked with ˝0˝ and top bowl bottom part ˝0˝

are in the same place and direction.

5. Screw the top bowl fixing nut with hand and fix it strongly with the fixing

key. The mark ˝0˝ must stay in the same direction.

The fixing nut must be strongly fixed, because it is

exposed to high forces.

3 Plain disc

4 Relief disc

17

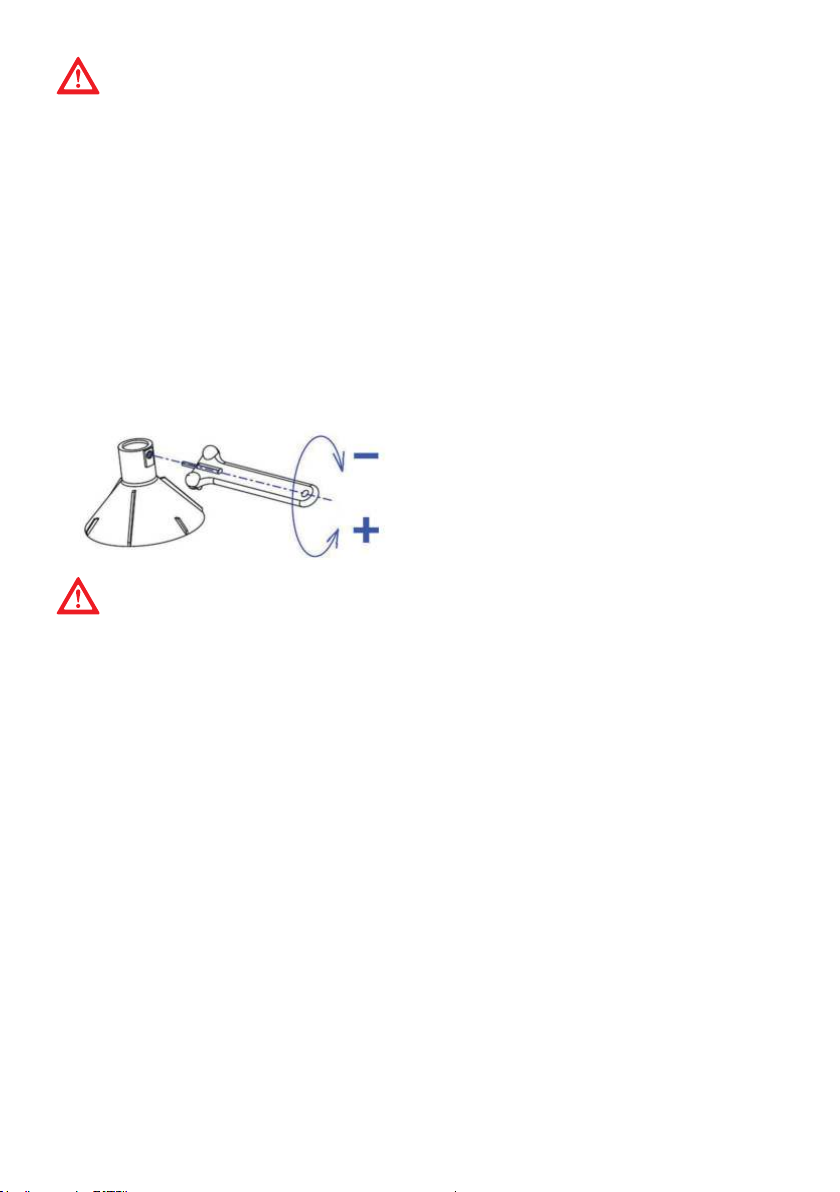

SKIMMING REGULATION

The cream separator is factory adjusted with around 10 % of cream from whole milk volume

at milk temperature 35 °C. It is possible to adjust this percentage due to different conditi-

ons like density or volume of cream. Adjust hexagonal adjusting cream screw by turning it

(placed in the plastic partition in top bowl upper part).

• For more density cream – less volume, turn it towards right (clockwise)

• For less density cream – higher volume, turn it towards left (counter clockwise). In most

cases it is enough to turn the adjusting screw for ¼ of the rotation.

Cream adjusting screw details and function

TAKE CARE, NOT TO FIX THE ADJUSTING CREAM SCREW TOO DEEP. THIS CAN

CAUSE HARM TO THE SCREW COIL. DON’T UNSCREW THE REGULATION SCREW

TOO MUCH. THIS CAN CAUSE PROBLEMS WITH DISASSEMBLING THE PLASTIC

PARTITION AND THE TOP BOWL UPPER PART.

PLEASE NOTE! After you have finished skimming, pour approximately 1/2 l of skim-

med milk back into milk container. This will clean the rest of cream in the top bowl.

After all procedures are finished, simply turn OFF the device and wait until motor

stops. Always check, whether the rubber washer is damaged or too much exten-

ded. In such cases please replace it with a new one.

- less cream volume and higher cream density

+ higher cream volume and less cream density

MAINTENANCE AND CLEANING

• All parts of the top bowl should be cleaned with hot water with some detergent.

• Rests of milk, cream or other impairs should be cleaned with soft duster or cleaning

brush. Especially take care to clean very precisely all the holes in top bowl upper part,

top bowl bottom part and in adjusting screw. For cleaning these parts, a cleaning brush

is strongly recommended! Other parts of the separator, which come in touch with milk,

should also be cleaned with hot water in which a detergent is added. Then rinse parts in

clean water.

• If milk or cream rests get dry, do not remove them with sharp objects or sharp duster. It

can easily happen, that the galvanic protection cover or plastic parts are damaged.

• Before cleaning cream separators housing, disconnect device from mains. Clean it first

with wet duster and then try it with dry duster. Take care, that water doesn’t come into

the device.

Ensure, that no water comes in contact with the motor and other electric parts.

The device is protected against direct water access, please take care and avoid, that

water comes into the device.

Before cleaning, always disconnect the Cream Separator from the mains supply.

18

IF IT IS NOT POSSIBLE TO MOUNT OFF THE TOP BOWL FROM THE MOTOR AFTER

SKIMMING, PLEASE SHAKE IT GENTLY.

PLEASE AVOID TO USE FORCE – IT CAN CAUSE HARM TO THE DEVICE AND MOST

OF THE PARTS.

TOP BOWL CLEANING PROCEDURE

With the key, which is packed with the cream separator, unscrew the top bowl fixing nut

as it is shown on the picture below.

The easiest way to perform this procedure is:

1. Fix key into the holes, which are on the top bowl fixing nut.

2. Press the key down and turn it until the fixing nut is released. It is

now possible to unscrew the fixing nut by hand.

3. Dismount the top bowl cover with the help of the key and separate

all different pieces, which are found under the cover - plastic partition,

metal discs and rubber washer. Clean them with hot water. To achieve

better results, cleaning detergent can be added to the hot water.

4. Wash all the parts with hot water and dry them with dry and

soft duster.

5. Never wash the discs in the dishwasher!

19

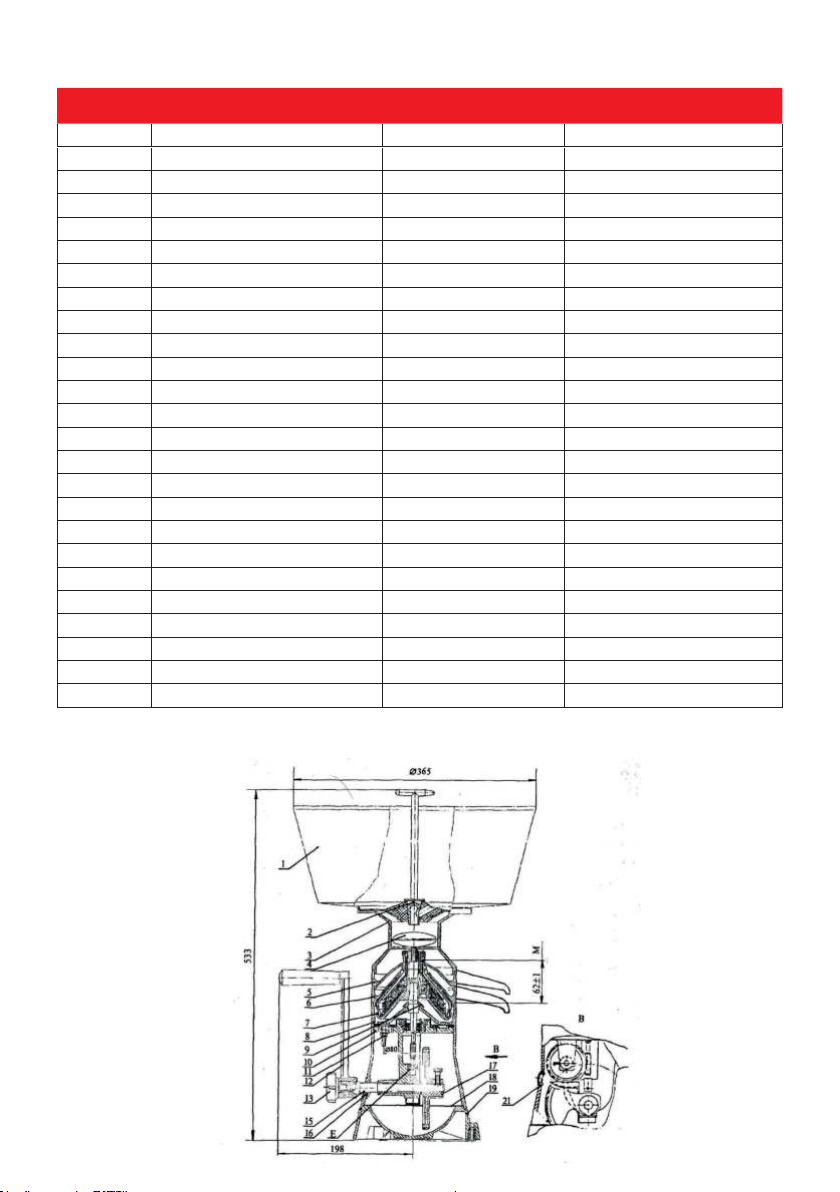

PART LIST

Name Part. no. MZF FJ 90 Part. no. MZF FJ 130

1 Foot 3711019 3711019

2 Bottom cover 3171017 3171017

3 Motor 230 V 17595 26000

3 Motor 115 V 17596 26001

4 Main switch 371151 371151

5 Cover of main switch 371153 371153

6 Housing - green 3712005-G 375005-G

6 Housing - blue 3712005-B 375005-B

6 Housing - silver 3712005-S 375005-S

7 Mains cord assembly 230 V 26002 26002

7 Mains cord assembly 115 V 26003 26003

8 Holder assembly / 375069

9 Bearing cover 3711013 3711013

10 Top bowl assembly 3712021-A 375021-A

11 Outlet for milk 3711037 375037

12 Outlet for cream 3711039 375045

13 Container holder inox / 35051

13 Container holder - green 3711041-G /

13 Container holder - blue 3711041-B /

13 Container holder - silver 3711041-S /

14 Floater inox / 375059

14 Floater plastic 3712045 /

15 Container 371051 375063

16 Container washer / 371055

17 Closing cork 3711061 3711061

DRAWING OF THE CREAM SEPARATOR

20

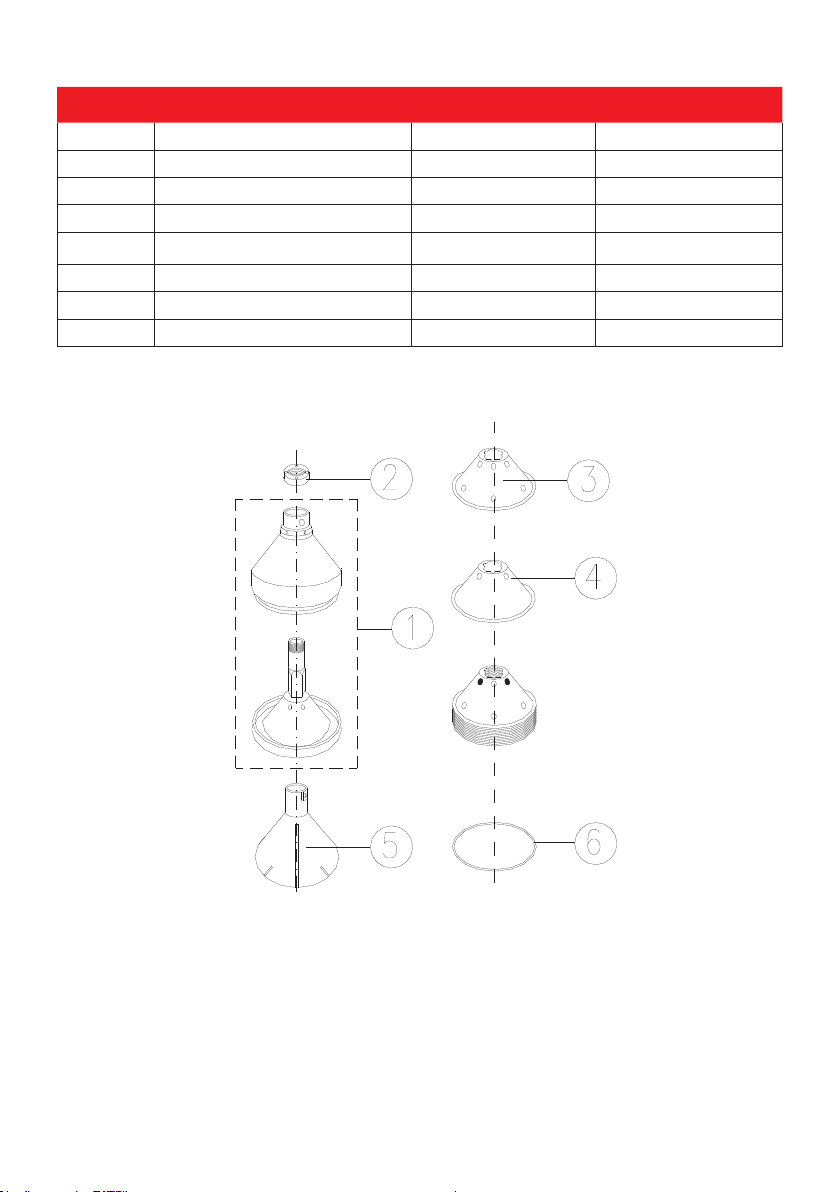

PART LIST TOP BOWL

Name Part. no. MZF FJ 90 Part. No. MZF FJ 130

1 Top bowl balanced 3712021-B 375021-B

2 Rubber washer 3711033 3711033

3 Metal disc relief 3711025 3711025

4 Metal disc plain 3711026 3711026

5 Plastic partition 3711029 3711029

6 Cream regulation screw 103444 103444

7 Fixing key 3712069 3712069

8 Cleaning brush 371067 371067

21

Changes and misprints reserved.

SPARE PARTS ORDERING PROCEDURE

Fast and reliable shipment of spare parts is only possible, if the description is clear

enough. At the time of ordering please state clearly:

• Type of cream separator.

• Serial number printed on the label plate at the bottom side of the device.

• Part name and code number of wished spare part.

WARRANTY

1. In case of troubles consult your distributer or call authorized service.

2. Equipment is warranted to be free from defects in material and workmanship for a period

of 12 months against faulty components and assembly. Our obligation under this warranty is

limited to the repair or replacement of the instrument or part thereof, which shall within 12

months after date of shipment prove to be defective after our examination.

3. Defects or injuries of the device, which are result of improper assembly, use, connect or

maintenance are not covered by this warranty.

4. The warranty also doesn´t cover:

a. Motor, destroyed by water or milk inflow,

b. Mains cord.

5. The given technical specifications are valid only when all conditions in this user`s manuals

are fulfilled.

6. Other rights, that are not mentioned in upper obligations of the manufacturer, especially

responsibility for personal injury, are excluded.

32

Janschitz GmbH

Eisenstrasse 81

9330 Althofen

AUSTRIA

Tel.: +43 4262 2251-0

Fax: +43 4262 2251-13

Email: office@janschitz-gmbh.at

www.janschitz-gmbh.at

This manual suits for next models

9

Table of contents

Popular Water Filtration System manuals by other brands

Philips

Philips AWP1808 user manual

amiad

amiad Filtomat MG-110P Installation, operation and maintenance instructions

Pentair

Pentair OMNIFILTER IN-FF-500-SG-QC-4 Installation and operation manual

LifeSource

LifeSource Premier Series owner's guide

norweco

norweco SINGULAIR BIO-KINETIC 960 owner's manual

Whirlpool

Whirlpool WHAROS5 user manual

Dover

Dover HYDRO AquaBlend Xtreme user manual

Pentair

Pentair EVERPURE EZ-RO 200/2G Installation & operation guide

Antunes

Antunes TAC-02 quick start guide

Watts

Watts E-Treat ETREATWCS Installation, operation and maintenance manual

GE

GE GNSV70RBL Owner's manual and installation instructions

Astral Pool

Astral Pool Combo 27413 Instruction and operation manual