NON-MECHANICAL

FLOW EQUALIZATION

The patented design of the Bio-Kinetic system provides

non-mechanicalflowequalizationfortheSingulairModel960

wastewatertreatmentplant. Equalizationreducesincoming

hydraulicsurges(e.g.typicalshowerof10minutesduration,

bathtub discharge of 5 minutes duration, clothes washer

dischargeof 2 minutesduration and dishwasherdischarge

of 2 minutes duration) throughout the system. The flow

equalization provided by the Bio-Kinetic system causes

wastewater to be held upstream of the final outlet during

hydraulic surges, which preserves treatment integrity and

enhancessystemoperation. Theactualrateofequalization

variesand depends uponspecific loadingpatterns and the

duration of each flow surge. At the design loading pattern

like the one used during the NSF/ANSI Standard 40

performance evaluation, the Model 960-500 GPD system

equalizesallflow anaverageof 48%. As aresult,hydraulic

surgesandperiodsofhighwastewaterflowareautomatically

reduced to protect the environment and all treatment plant

processes on a demand use, as needed, basis.

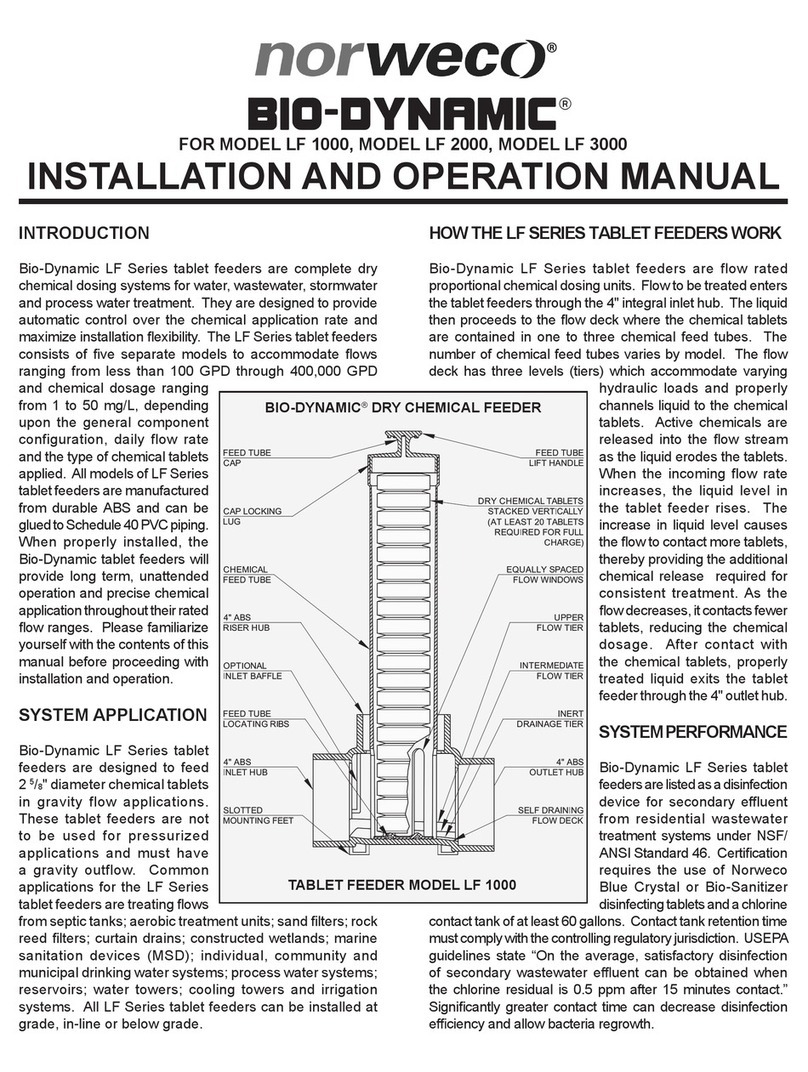

BLUE CRYSTAL®RESIDENTIAL

DISINFECTING TABLETS

If local regulations require, an initial supply of Blue Crystal

disinfecting tablets will be placed in the Bio-Kinetic system

chlorine feed tube(s) at system start-up. Specifically

formulated for use in the Singulair system, Blue Crystal

disinfectingtabletsprovideefficientand reliable disinfection

wheneffluent chlorination isdesirable. Manufactured from

calcium hypochlorite, Blue Crystal disinfecting tablets

provideeffective,economicalbacteria killing power. Liquid

enteringthe Bio-Kineticsystem contacts the installed Blue

Crystal disinfecting tablets, just downstream of the

equalization ports. A fully charged feed tube will last an

averageofsixmonths. During eachsemi-annualinspection,

yourlocal distributor’s servicetechnician will checksystem

operation,the rate oftablet consumptionandinstall tablets

duringroutineservice inspections.

NOTE: USEPAguidelinesstate“Ontheaverage,satisfactory

disinfectionofsecondarywastewatereffluentcanbeobtained

when the chlorine residual is 0.5 ppm after 15 minutes

contact.” Retention time must comply with the controlling

regulatoryjurisdiction.

CAUTION: Theimproper handlingofBlueCrystaltablets

may cause personal injury or property damage. Keep

out of the reach of children and do not allow the tablets

or feed tube to contact skin, eyes, or clothing. Tablets

may be fatal if swallowed and tablet dust is irritating to

the eyes, nose and throat. Do not handle the tablets or

feed tubes without first carefully reading the product

container label, MSDS information and the handling

andstorageinstructions. Mixingof chemicalsmaycause

a violent reaction leading to fire or explosion. For

additionalinformationabout BlueCrystaltablets contact

your local distributor.

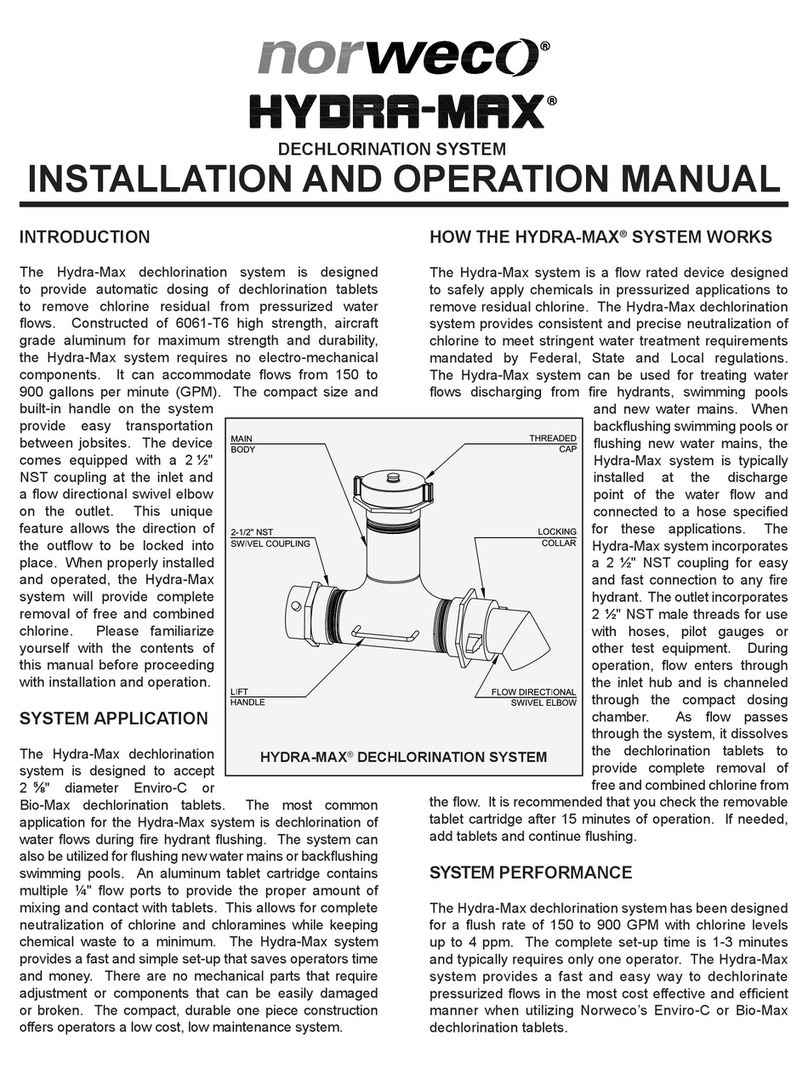

BIO-NEUTRALIZER®DECHLORINATION

TABLETS

Inenvironmentallysensitiveareas,environmentalregulations

mayrequiretheuseofBio-Neutralizerdechlorinationtablets.

Manufactured as an efficient and dependable means to

chemically neutralize both free and combined chlorine,

Bio-Neutralizer dechlorination tablets provide consistent

reduction or elimination of chlorine residual without

unnecessarilyreducing the levelofdissolved oxygeninthe

treatment system effluent. Bio-Neutralizer dechlorination

tablets utilize a unique chemical mixture for chlorine

reduction and environmental protection. As liquid passes

throughthe finaldischarge zone ofthe Bio-Kineticsystem,

the flow contacts the installed Bio-Neutralizer tablets and

residual chlorine is removed from the system effluent. A

fullycharged Bio-Neutralizerfeed tube willlast anaverage

of six months. During each semi-annual inspection, your

local distributor’s service technician will check system

operation,the rate oftablet consumptionandinstall tablets

duringroutineservice inspections.

CAUTION: Bio-Neutralizer tablets or feed tubes should

not be mixed with Blue Crystal tablets. Do not handle

the tablets or feed tubes without first carefully reading

the product container label, MSDS information and the

handling and storage instructions. For additional

information about Bio-Neutralizer tablets contact your

local distributor.

NO OWNER MAINTENANCE

The Singulair system is inspected and serviced by a local

licensed, factory-trained distributor, therefore, no owner

maintenance is required during the warranty period. The

Singulair system does not require pumping as often as a

septic tank. Under normal use only the pretreatment

chamber should be pumped. How often pumping is

necessary depends on system use. The local Singulair

distributor will inspect the aeration chamber contents and

plant effluent at six month intervals to determine if the

pretreatmentchamberisdischargingexcessivesolids. Every

threeyears,thepretreatmentchambershouldbeinspected.

Thepretreatmentchamberwill normally requirepumpingat

three to five year intervals. Contact your local distributor

priortotankpumpingforcompleteinformationonremoval of

equipment,access toindividual chambers, coordinationof

services and proper disposal of tank contents. A tank

pumping service licensed by the local regulatory agency

must be used for removal and disposal of tank contents.

The tank pumper should consult with local authorities to

determinetheproper disposalmethod.

If a period of intermittent use, or an extended period of

non-use of the Singulair system is anticipated, contact the

local distributor for instructions. Your local licensed

distributorhascomprehensiveSingulairserviceinstructions

andhasbeenfactory-trainedintroubleshootingprocedures.

Contact your local distributor if you require service or

informationregardingtankpumping.