Miller Electric SWP-2 Spot Welder Pedestal User manual

Other Miller Electric Welding System manuals

Miller Electric

Miller Electric Millermatic 140 Auto-Set User manual

Miller Electric

Miller Electric Two Fifty AC User manual

Miller Electric

Miller Electric MILLERMATIC 30A CONTROL/FEEDER User manual

Miller Electric

Miller Electric SuitCase X-TREME 12VS User manual

Miller Electric

Miller Electric GENERWELD 130 User manual

Miller Electric

Miller Electric DS-75D16 Swingarc User manual

Miller Electric

Miller Electric Invision 456MP User manual

Miller Electric

Miller Electric AUTO ARC MW 4150 User manual

Miller Electric

Miller Electric Big Blue 602P User manual

Miller Electric

Miller Electric Bobcat 250 User manual

Miller Electric

Miller Electric GL-25 User manual

Miller Electric

Miller Electric Spectrum 125C User manual

Miller Electric

Miller Electric STARFIRE 1 User manual

Miller Electric

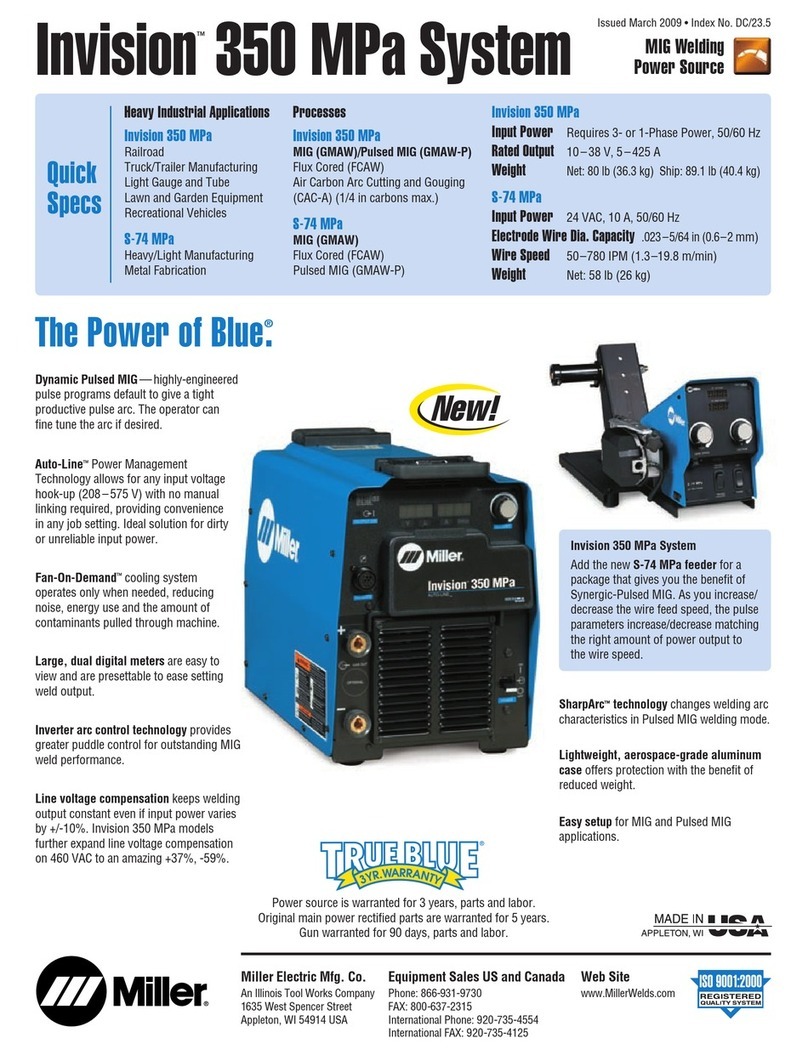

Miller Electric Invision 350MPa User manual

Miller Electric

Miller Electric Summit Arc 1000/1250 User manual

Miller Electric

Miller Electric Spectrum Plus User manual

Miller Electric

Miller Electric MOG-300 User manual

Miller Electric

Miller Electric RCCS-RJ User manual

Miller Electric

Miller Electric SQUAREWAVE 1000 User manual

Miller Electric

Miller Electric Millermatic Vintage M-25 Gun User manual

Popular Welding System manuals by other brands

TAFA

TAFA 30*8B35 owner's manual

Lincoln Electric

Lincoln Electric INVERTEC V350-PRO CE Technical specifications

ESAB

ESAB Buddy Arc 145 instruction manual

CIGWELD

CIGWELD 636804 use instructions

Red-D-Arc

Red-D-Arc DC-400 Operator's manual

Hobart Welding Products

Hobart Welding Products Spool Gun DP 3035-10 owner's manual