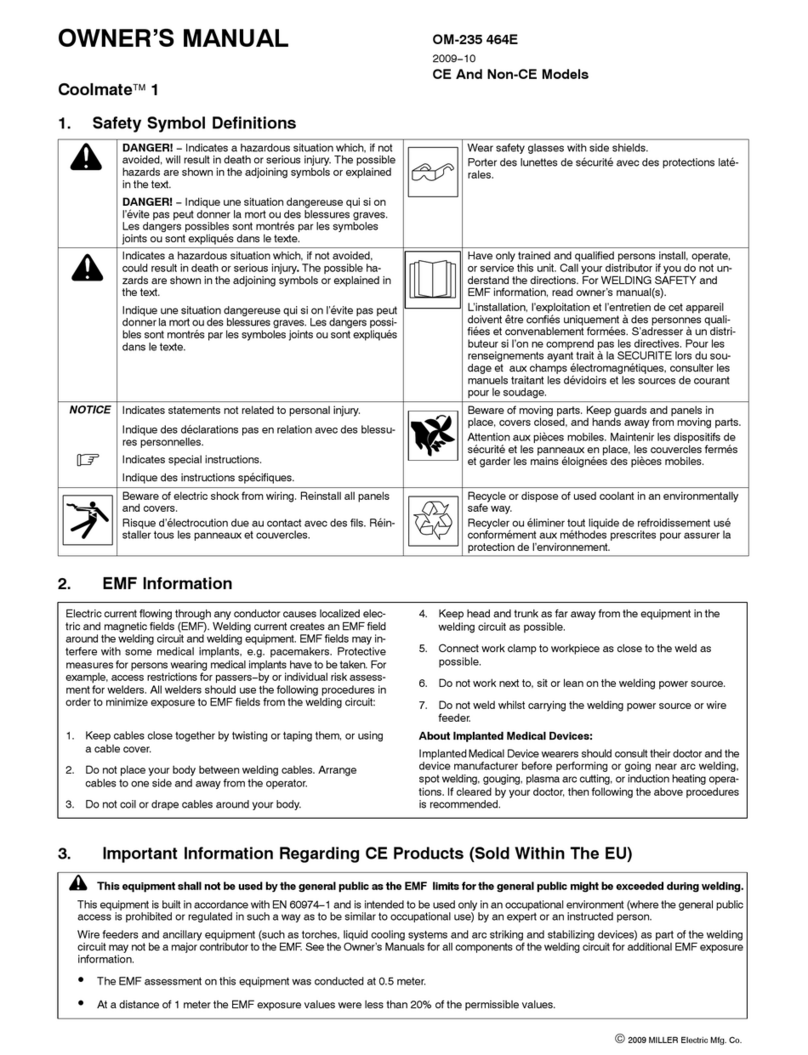

Miller Electric Three-Phase Running Gear User manual

Other Miller Electric Welding System manuals

Miller Electric

Miller Electric SRH-444 User manual

Miller Electric

Miller Electric S-62 User manual

Miller Electric

Miller Electric SQUAREWAVE 1000 User manual

Miller Electric

Miller Electric Millermatic Premium Running Gear 300 416 User manual

Miller Electric

Miller Electric Spoolmate 100 Series User manual

Miller Electric

Miller Electric Big Blue 602P User manual

Miller Electric

Miller Electric Subarc DC 650 User manual

Miller Electric

Miller Electric APT-1000 User manual

Miller Electric

Miller Electric Subarc DC 1250 User manual

Miller Electric

Miller Electric MT-26 Torches User manual

Miller Electric

Miller Electric Millermatic 200 SKP-34 User manual

Miller Electric

Miller Electric GB-10 User manual

Miller Electric

Miller Electric Spectrum 875 Auto-Line User manual

Miller Electric

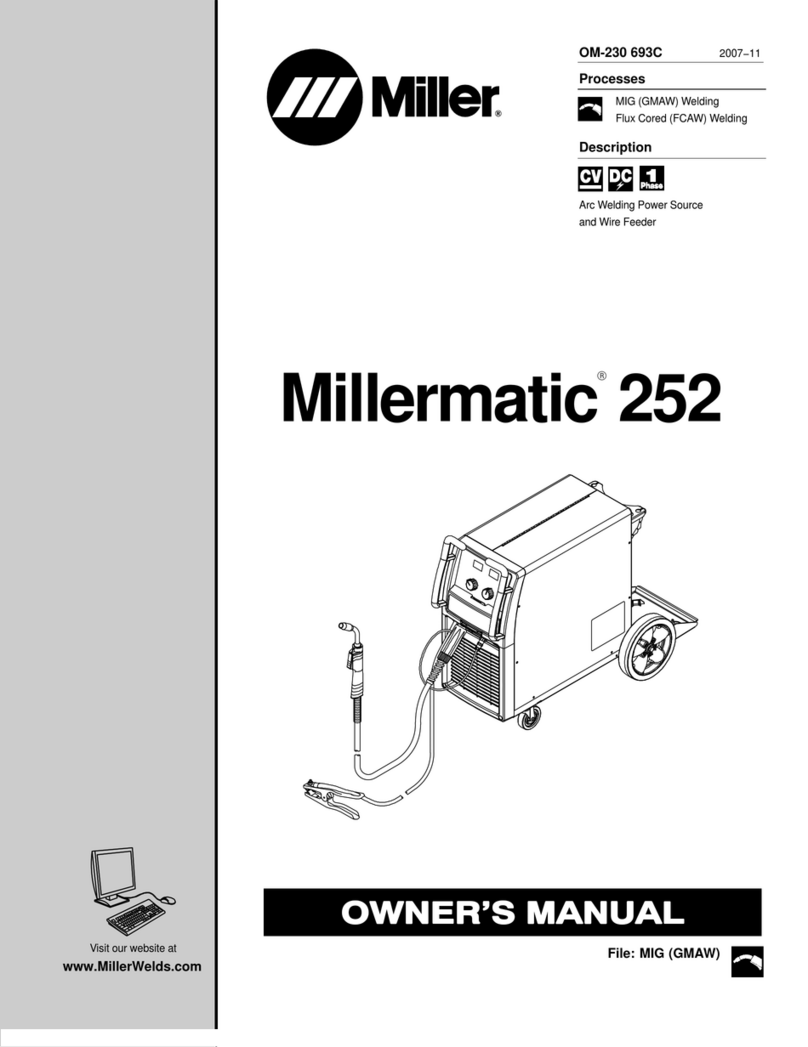

Miller Electric OM-230 User manual

Miller Electric

Miller Electric GENERWELD 130 User manual

Miller Electric

Miller Electric SRH-503 User manual

Miller Electric

Miller Electric 145 User manual

Miller Electric

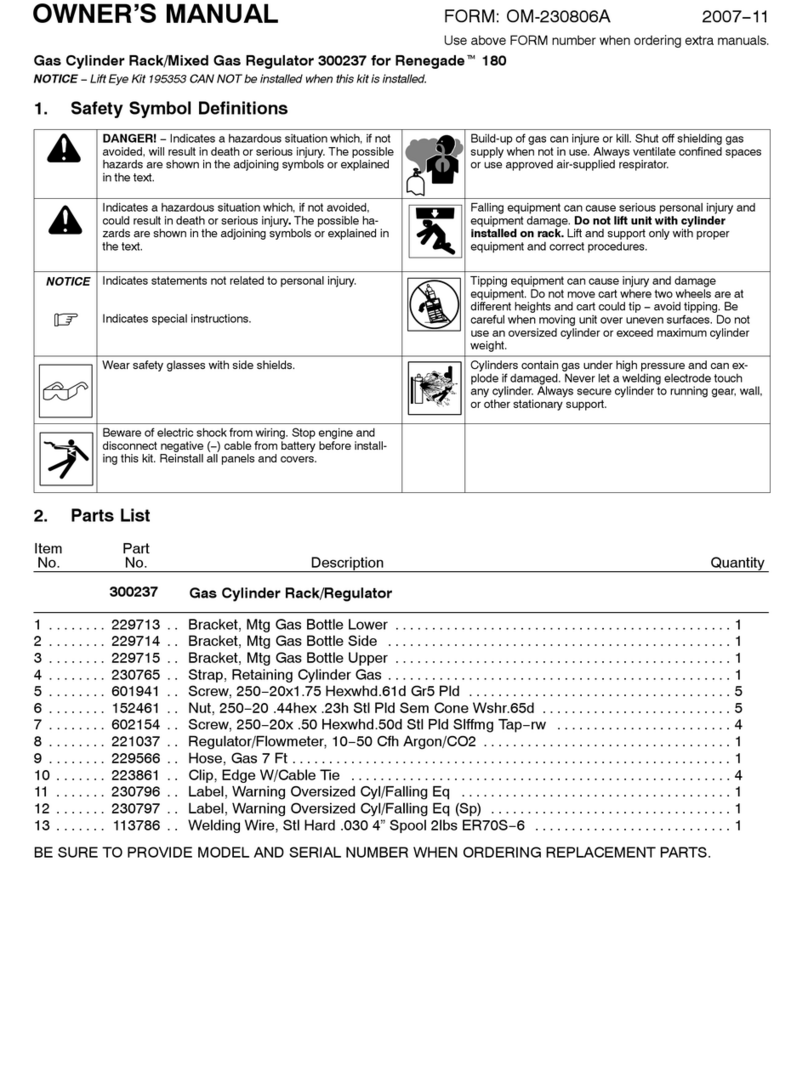

Miller Electric Gas Cylinder Rack User manual

Miller Electric

Miller Electric Big Blue 500D User manual

Miller Electric

Miller Electric Sidekick GA-16C Gun User manual

Popular Welding System manuals by other brands

TAFA

TAFA 30*8B35 owner's manual

Lincoln Electric

Lincoln Electric INVERTEC V350-PRO CE Technical specifications

ESAB

ESAB Buddy Arc 145 instruction manual

CIGWELD

CIGWELD 636804 use instructions

Red-D-Arc

Red-D-Arc DC-400 Operator's manual

Hobart Welding Products

Hobart Welding Products Spool Gun DP 3035-10 owner's manual