Operating instructions

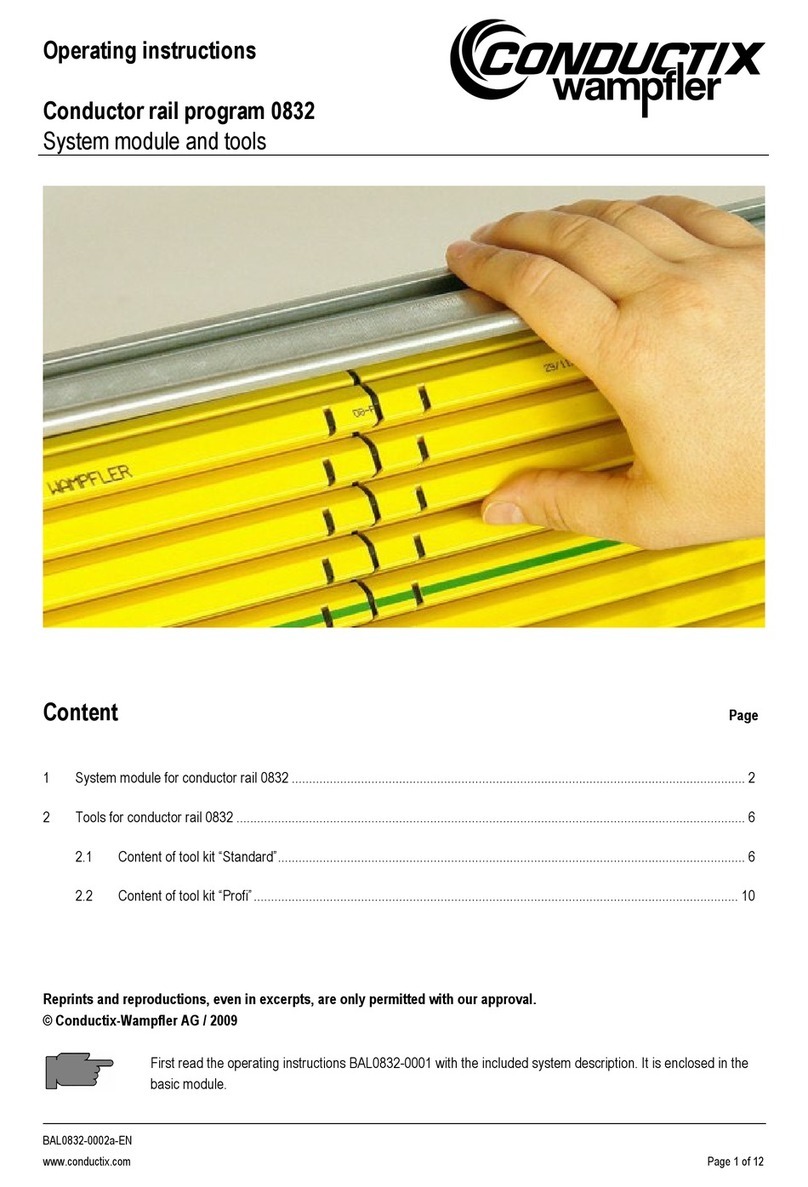

Conductor rail program 0832

System description

BAL0832-0001a-EN

www.conductix.com Page 10 of 27

5Start-up and operation

CAUTION! Machine/property damages!

Only trained personnel may perform the start-up!

The following items must be checked prior to start-up:

•Is the conductor rail system completely assembled?

•Are damaged components installed?

•Are all components clean?

•Max. hang-up distance of 3.2 m on the rack consoles or consoles

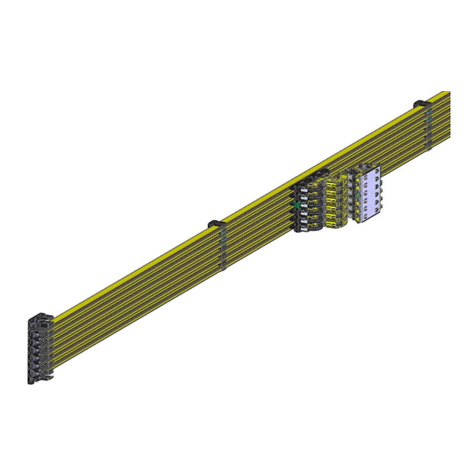

•Proper fit of the support profiles with the adapters and system hangers

•Are all insulating profiles snapped into the support profiles?

•Are the connecting elements, insulating connectors, clamping sheets and connector pins available on all change overs?

•Are the clamping sheets centered on all support profile change overs and are the nuts tightened?

•Proper electrical connection of the power feed

•Proper electrical connection of the current collectors (including the strain relief to be attached by the customer)

•Are conductor strips inaccessible with fingers

•Are end caps available

•No scattered parts in the operating area (all assembly tools removed)

•Proper fit of the current collector or change support, if available, on the stacker crane

•Securing the change support – if available – with the cable tie

•No conflict of the current collector lines during all operating conditions

•Insulation test in correspondence with local technical standards, regulations and laws

The movement of the individual current collectors must be evaluated over the entire travel section in manual or “slow travel”

(compare chapter 1 for installation tolerances) and potential conflicts must be eliminated.

Conductor rail system 0832 (EcoClickLine) can be operated at the following parameters after a successful start-up:

•Rated voltage: max. 690 V / USA/Canada --> 500 V

•Approved ambient temperatures are system related (from -30 to +55°C)

•The difference of the usage temperature is system related (max. 50 K)

•Max. travel speed on the track: 600 m/min

•Max. travel speed in the pick-up guide area: 80 m/min

It must be verified during the operation that no personnel is located in the aisle.

CAUTION! Machine/property damages!

Damages of the conductor rail system due to improper assembly!