Millipore Tylan General FC-2900 User manual

INSTRUCTION

MANUAL

FC-2900

SERIES

Mass

Flow

Controllers

and

Flowmeters

Wan

General

Mass

Flow

Controllers

FC-2900,

FC-29000,

FC-2901,

FC-29010,

FC-2902,

FC-29020

FC-2910,

FC-29100,

FC-2911,

FC-29110,

FC-2912,

FC-29120

FC-2900B,

FC-2900BO,

FC-2910B,

FC-2910BO

FC-2900M,

FC-2900MO,

FC-2901M,

FC-2901MO,

FC-2902M,

FC-2902MO

Mass

Flowmeters

FM-3900,

FM-3901,

FM-3902

FM-3910,

FM-3911,

FM-3912

FM-3900M,

FM-3901M,

FM-3902M

JUNE

1997

ADDENDUM

Instruction

Manual

for

Millipore

FC-2900

Series

Mass

Flow

Controllers

and

Flowmeters

Replaces

content

on

introduction

page

(i)

and

pages

45-48

of

version

908609-001,

Rev.

P

Note

to

Our

Customers

Early

in

1997,

Millipore

Corporation

acquired

Tylan

General,

and

Span

Instruments

to

further

strengthen

and

expand

its

product

and

technology

offer-

ings

to

microelectronics

customers.

Tylan

General

was

a

leader

in

flow

technologies

since

1965,

and

started

developing

products

for

the

semiconductor

applications

in

1985.

Because

Millipore

is

able

to

focus

on

the

gas

filtration,

purification,

process

control

and

delivery

needs

of

the

microelectronics

industry,

customers

can

count

on

sales

and

service

support

from

specialists

who

understand

their

applications

thoroughly,

The

instrument

you

have

just

purchased

is

one

of

the

finest

mass

flow

controllers

available.

It

includes

significant

advantages

on

the

state-of-the-art

as

measured

against

leading

competitive

units.

It

offers

increases

stability

and

inherent

linearity,

tightly

controlled

response

and

maximum

applications

flexi-

bility.

Furthermore,

it

is

backed

by

the

strongest

commitment

fo

quality,

service

and

support

in

the

industry.

Please

review

the

following

page

for

the

Millipore

network

listing

of

manufacturing,

sales

and

service

locations

worldwide.

GENERAL

LIMITED

WARRANTY

FOR

GAS

PRODUCTS

Subject

to

the

limitations

and

disclaimers

set

forth

below,

MILLIPORE

CORPORATION

("Millipore")

warrants

that

for

the

Applicable

Warranty

Period

(as

defined

below)

following

the

date

of

shipment,

the

products

manufactured

by

it

shall

be

free

from

defects

in-materials

and

workmanship

when

installed,

serviced

and

operated

in

accordance

with

the

applicable

product

documentation.

In

the

event

that

a

product

failure

is

caused

by

a

defect

in

mate-

rials

or

workmanship

within

the

Applicable

Warranty

Period,

Millipore

agrees

to

repair

or

replace,

at

its

option,

any

product

or

part

thereof

that

proves

to

have

such

a

defect

at

no

charge

to

the

purchaser,

provided

that

prompt

written

notice

of

any

such

defect

is

given

to

Millipore.

Millipore's

agreement

to

repair

or

replace

any

product

found

to

be

defective

in

materials

or

workmanship

is

the

exclusive

remedy

provided

herein;

this

remedy

shall

not

be

deemed

to

have

failed

of

its

essential

purpose

so

long

as

Millipore

is

willing

and

able

to

repair

or

replace

any

such

defective

Millipore

product

or

part.

Limitations.

The

warranty

set

forth

above

is

LIMITED

and

Does

Not

Cover:

(A)

products

with

the

identification

label

or

serial

number

altered

or

removed;

(B)

products

which

have

been

repaired

by

any

person

other

than

an

authorized

Millipore

service

representative;

(C)

products

which

have

been

subjected

to

misuse,

neglect

or

abuse

(including,

without

limitation,

exposure

to

overpressure,

use

with

excessive

voltage

or

inappropriate

power

source

or

exposure

to

hostile

operating

conditions

unless

the

product

has

been

expressly

specified

by

Millipore

for

use

therein).

In

the

case

of

Millipore

products

which

are

systems

that

include

components

manufactured

by

companies

other

than

Millipore

or

its

affiliates,

the

foregoing

warranty

shall

apply

only

to

those

components

and

subassemblies

manufactured

by

Millipore

or

its

affiliates;

the

non-Millipore

components

and

sub-

assemblies

included

in

such

systems

are

covered

by

the

warranty,

if

any,

extended

by

the

manufacturer

thereof.

Millipore

hereby

assigns

any

such

war-

ranty

to

the

system

purchaser.

Disclaimers.

MILLIPORE

MAKES

NO

OTHER

WARRANTY,

EXPRESSED

OR

IMPLIED.

THERE

I$

NO

WARRANTY

OF

MER-

CHANTABILITY

OR

OF

FITNESS

FOR

A

PARTICULAR

PURPOSE.

The

warranty

provided

herein

and

the

data,

specifications

and

descriptions

of

Millipore

products

appearing

in

Millipore's

published

catalogues

and

product

literature

may

not

be

altered

except

by

express

written

agreement

signed

by

an

officer

of

Millipore.

Representations,

oral

or

written,

which

are

inconsistent

with

this

general

limited

warranty

or

such

publications

are

not

authorized

and

if

given,

should

not

be

relied

upon.

Notwithstanding

the

failure

of

any

remedy

provided

herein,

in

no

event

shall

Millipore

be

liable

for

consequential,

incidental,

special

or

any

other

indirect

damages

resulting

from

economic

loss

or

property

damage

sustained

by

any

customer

from

the

use

of

Millipore

products.

Applicable

Warranty

Period.

As

used

in

this

General

Limited

Warranty

the

term

Applicable

Warranty

Period

for

the

indicated

product

groups

shall

be

as

follows:

Product

Group

Duration

of

Applicable

Warranty

Period

Gas

Purifiers

)

Flow

Products

)

Pressure

Products

}

1

Year

Gas

Panels

)

Scoles

and

Gouges

)

Vacuum

Products

2

Years

In

Line

Monitors

6

Months.

To

Place

an

Order

or

Receive

Technical

Assistance

For

additional

information

call

your

nearest

Millipore

office:

In

the

U.S.

and

Canada,

call

tollfree

1-800-MILLIPORE

(1-800-645-5476)

In

the

U.S.,

Canada

and

Puerto

Rico,

fax

orders

to

1-800-MILLIFX

(1-800-645-5439)

Find

the

latest

catalog,

data

sheets

and

technical

briefs

at

www.tmillipore.com

E-mail:

Millipore

Worldwide

AUSTRALIA

Tel.

1

800

222

111

or

(02)

9888

8999

Fax

(02)

9878

0788

AUSTRIA

Tel.

01

50

22

21

237

Fox

01

50

22

21

238

BELGIUM

Tel.

02

64

04

185

Fox

02

64

68

096

BRAZIL

Tel.

(011)

5487011

Fax

|011)

548-7923

CHINA,

PEOPLE’S

REPUBLIC

OF

Beijing:

Tel.

(8610)

6500-8063

Fax

(8610)

65007372

Guangzhou:

Tel.

(8620)

8755-4021

Fax

(8620)

8755-4350

Hong

Kong:

Tel.

(852)

2803-9111

Fox

(852)

2513-0313

Shanghai:

Tel.

(8621)

53069100

Fax

(8621)

53060838

CZECH

REPUBLIC

Tel.

02-205

138

41

02-205

138

42

Fax

02-205

14294

DENMARK

Tel.

3525

0275

Fox

3525

0276

FINLAND

Tel.

09

8171

0010

Fax

09

8171

0011

FRANCE

Tel.

01

30

1271

50

Fax

01

30

12

71

84

GERMANY

Tel.

0816

595

110

Fox

0816

561

399

INDIA

Tel.

91}

80839

46 57

Fax

(91)

80839

63

45

IRELAND

Tel.

01

799

7165

Fax

01

799

7166

ITALY

Tel.

02

21

50

488

Fax

02

26

41

06

79

JAPAN

Tel.

(03)

54429711

Fax

(03)

5442-9738

KOREA

Tel,

(822)

551-0990

Fox

(822)

5510227

MALAYSIA

Tel.

603-757

1322

Fox

603-757

1711

MEXICO

Tel.

(525)

576-9688

Fax

(525)

576-8706

THE

NETHERLANDS

Tel.

020

65

45

226

Fax

020

65

45

227

NORWAY

Tel.

22

59

5888

Fax

22

59

5889

POLAND

Tel.

(49)

816

595

110

Fox

(49)

816

561

399

RUSSIA

Tel.

(49)

816

595

110

Fox

(49)

816

561

399

SINGAPORE

Tel.

(65)

842

1822

Fox

(65)

842

4988

SPAIN

Tel.

091

375

33

81

Fox

091

375

33

82

SWEDEN

Tel.

08

5199

2040

Fox

08

5199

2041

SWITZERLAND

French-speaking:

Tel.

022

82

30

450

Fax

022

82

30

491

German-speaking:

Tel.

01

43 95

356

Fax

01

43 95

355

TAIWAN

Toipei:

Tel.

(886-2)

700-1742

Fox

(886-2)

755-3267

Hsin

Chu

City:

Tel.

(886-3)

571-0178

Fax

[886-3]

572-9520

U.K.

Tel.

0179

361

5808

Fax

0179

361

7442

U.S.A.

AND

CANADA

Tel.

800

645

5476

Fax

800 645

5439

OTHER

COUNTRIES

Millipore

Intertech

(U.S.A.]

Tel.+1

(781)

533-8622

Fax

+1

(781)

533-8630

Service

Center

Locations

United

States

Austin

Service

Center

Millipore

Corporation

3017

Alvin

DeVane

Blvd.,

Suite

4230

Austin,

TX

78741

Toll

Free:

800-969-4507

Tel:

512-385-7940

Fax:

512-385-9129

San

Jose

Service

Center

Millipore

Corporation

535

East

Brokaw

Road

San

Jose,

CA

95112

Toll

Free:

800-517-6377

Tel:

408-467-5500

Fax:

408-467-5510

Tempe

Service

Center

Millipore

Corporation

3230

S.

Fair

Lane

Tempe,

AZ

85282

Toll

Free:

—

877-296-7206

Tel:

602-431-1787

Fax:

602-431-0727

JAPAN/ASIA

Kyushu,

Japan

Tel:

81-92-501-8920

Fax

81-92-501-8725

Tokyo,

Japan

Те:

81-03-5442-9711

Fox:

81-03-5442-9730

Yonezawa,

Japan

Те:

81-45-939-7816

Fox:

81-45-939-7817

Gunpo

City,

Korea

Те:

82-331-214-2642

Fax:

82-331-213-7970

Hsin

Chu

City,

Taiwan

Tel:

886-3-571-0178

Fox:

886-3-572-9520

Singapore

Tek

65-842-1822

Fax:

65-842-4988

RETURNING

PRODUCTS

FOR

SERVICE

EUROPE

Dresden,

Germany

Tel:

49-351-8822-645

Fax:

49-351-8822-646

Eching,

Germany

Tek

49-816-595-110

Fox:

49-816-561-399

Dublin,

Ireland

Tel:

353-1-295-9455

fax

353-1-295-9942

Lyon,

France

Те:

33-474-94-45-85

Ғох:

33-474-95-57-50

Livingston,

Scotland

Tel:

44-150-641-2970

Fax:

44-150-641-2980

Swindon,

England

Tel:

44-1793-615-808

Fox:

44-1793-617-442

Washington,

England

Те:

44-191-4192428

Ғох:

44-191-4192429

AUTHORIZED

MILLIPORE

SERVICE

DEALER

ProFlow

9665

Southwest

Allen

Blvd.,

Suite

#113

Beaverton,

OR

97005

Toll

Free:

888-ProFlow

Tel:

503-643-5564

Fax:

503-520-8834

Millipore

and

Tylon

are

registered

trademarks

of

Millipore

Corporation

or

an

affiliated

company.

Copyright

©

1998

Millipore

Corporation,

or

an

affiliated

company.

‘Products

requiring

service

may

be

shipped

to

any

one

of

our

Service

Centers

located

worldwide.

A

complete

listing

of

Millipore

Service

Centers

may

be

found

on

the

Sales

and

Service

Network;

listed

above.

Repaired

products

are

typically

returned

within

5

working

days.

Emergency

service

is

also

available.

For

more

information,

please

contact

the

service

center

nearest

you.

When

returning

mass

flow

products

for

service,

please

be

sure

to

specify

the

type

of

service

required,

the

products

failure

mode,

return

shipment

information,

a

purchase

order

to

cover

non-warronty

charges

and

the

name

and

telephone

number

of

a

person

to

contact

if

questions

should

arise.

In

addition,

you

must

complete

an

appropriate

Certificate

of

Non-Hazardous

Containment

and

attach

it

to

the

outside

of

the

shipping

container

of

the

product

being

returned.

Disclosure

of

all

chemicals

exposed

to

the

equipment

is

required

by

federal

common

carrier

transportation

laws.

This

will

helps

us

to

protect

our

personnel

and

environment,

and

also

helps

us

to

determine

if

special

handling

is

required

to

process

your

repair.

For

example,

California

Hazardous

Communication

Regulation

(general

Industry

Safety

Orders

Sec.

5194

Title

8,

California

Code

CCR

Title

22)

defines

the

regulations

that

must

be

met

for

products

returned

to

California,

U.S.A

for

service.

Certificates

of

Non-Hazardous

Contamination

vary

from

state

to

state,

so

we

recommend

that

you

contact

your

nearest

service

center

to

determine

what

certificates

are

required.

They

can

provide

you

with

the

specific

documents

needed

to

comply

with

state

and

federal

laws.

Omission

of

the

information

or

required

Non-Hazardous

Contamination

form

may

result

in

a

delay

in

processing

your

order

or

return

of

the

material.

This

information

will

help

us

to

avoid

unnecessary

delays

in

processing

your

request

for

service.

!

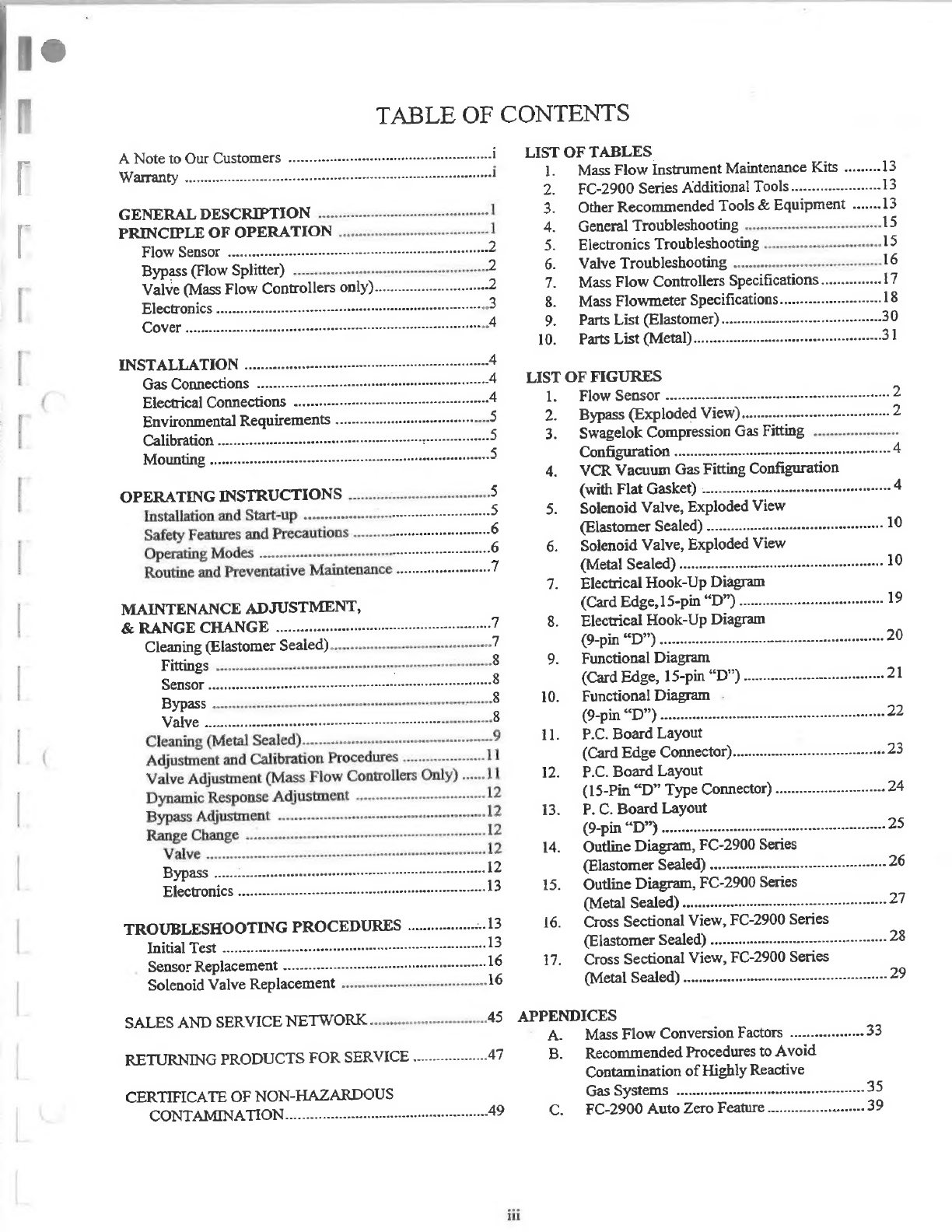

TABLE

ОЕ

CONTENTS

A

Note

to

Our

Customers

.........

а-а...

LIST

OF

TABLES

Warranty

4а

tnnt

nne

enne

1.

Mass

Flow

Instrument

Maintenance

Kits

.........

13

2.

ЕС-2900

Series

Additional

Tools

....................-.

13

GENERAL

DESCRIPTION

............-----.еїєєнөөөөөөөөсєө

3.

Other

Recommended

Tools

&

Equipment

.......

13

PRINCIPLE

OF

OPERATION

4.

General

Troubleshooting

.................................-

Flow

Sensor

................-

ааа.

5.

Electronics

Troubleshooting

.............................

Bypass

(Flow

Splitter)

.......................

6.

Valve

Troubleshooting

.................

n

Valve

(Mass

Flow

Controllers

only).............................

2

7.

Mass

Flow

Controllers

Specifications

Electronics

........................

ennt nnne

nnne ennt

3

8.

Mass

Flowmeter

Specifications.........................

Cover

ДИН

4

9.

Parts

List

(Еізсіютег)...........4.аа

een

10.

Parts

List

(Metal).............................................-

INSTALLATION

......2ә..2............г.м...а.1..2.41!

Gas

Connections

55

Electrical

Connections

.............

eene

4

1.

Flow

Sensor

Дам.

2

Environmental

Requirements

...........ам.4

4

лə

|4...

5

2.

Bypass

(Exploded

View)...

2

Calibration

459

3.

Swagelok

Compression

Gas

Fitting

.....................

Mounting

....42мам12.

М-ы

Configuration

..........

4.4

112...

4

4.

VCR

Vacuum

Gas

Fitting

Configuration

OPERATING

INSTRUCTIONS

...............---.өө

5

(with

Flat

Gasket)

............

eren

4

Installation

and

Start-up

..............-—

5.

Solenoid

Valve,

Exploded

View

Safety

Features

and

Precautions

(Elastomer

Sealed)

......................................

ние

10

Operating

Modes

...............

ener

6.

Solenoid

Valve,

Exploded

View

Routine

and

Preventative

Maintenance

........................

7

(Metal

Sealed)

................

eerte

10

7.

Electrical

Hook-Up

Diagram

MAINTENANCE

ADJUSTMENT,

(Card

Edge,

15-pin

*D")

...................

sse

19

&

RANGE

CHANGE

.........

1

ente

entem

$.

Electrical

Hook-Up

Diagram

Cleaning

(Elastomer

Sealed)

(9-pin

D”)

мама.

ааа

а

аа

ы

20

Fittings

............

n

9.

Functional

Diagram

Sensor

eniin

(Card

Edge,

15-pin

^D")

..............——

21

Bypass

....................

nn

10.

Functional

Diagram

MET

(9-pin

D”)

ЛД

Ды

22

Cleaning

(Metal

Sealed)

11.

Р.С.

Board

Layout

Adjustment

and

Calibration

Procedures

.....................

11

(Сага

Edge

Connector)..............—.—..

1.44.аа

а

а

23

Valve

Adjustment

(Mass

Flow

Controllers

Only)

......

1

12.

P.C.

Board

Layout

Dynamic

Response

Adjustment

....................-.....-....

12

(15-Pin

“D”

Type

Connector)

.............----.--------

24

Bypass

Adjustment

.............

ene

12

13.

P.C.

Board

Layout

Range

Change

............

nennen

12

(9-ріп

“Ю”)

......

eese

tern

teen

25

Valve

3

55

....12

14.

Outline

Diagram,

FC-2900

Series

Bypass

(Elastomer

Sealed)

.................———

A

26

Electronics

15.

Outline

Diagram,

FC-2900

Series

(Metal

Sealed)

.................

eene

27

TROUBLESHOOTING

PROCEDURES

16.

Cross

Sectional

View,

FC-2900

Series

Initial

Тез...

а...

(Elastomer

Sealed)

..............—

A

28

Sensor

Replacement

..................

ЯГ

17.

Cross

Sectional

View,

FC-2900

Series

Solenoid

Valve

Replacement

...............—..

1

421

2Д

2

(Metal

Sealed)

................—

eee

29

SALES

AND

SERVICE

МЕТУУОК..............--өө

45

APPENDICES

A.

Mass

Flow

Conversion

Factors

..................

33

RETURNING

PRODUCTS

FOR

SERVICE

..................

47

B.

Recommended

Procedures

to

Avoid

CERTIFICATE

OF

NON-HAZARDOUS

СОМТАМПШЧАТТОМ................---««є«.енөөөөчлгүөє

49

ili

Contamination

of

Highly

Reactive

Gas

Systems

C.

FC-2900

Auto

Zero

Ееайиге.........................

39

This

page

was

intentionally

left

blank.

"

Wan

Genera

GENERAL

DESCRIPTION

Tylan

General

Model

FC-2900

series

Flow

Controllers

accurately

and

reliably

measure

and

control

the

mass

flow

rate

of

gases.

They

have

been

specifically

designed

to

allow

operation

on

any

gas

having

a

known

molar

specific

heat

(pCp).

The

FC-2900

series

has

a

user-adjustable

range

from

10

sccm

to

30

sim

full-scale

flow

rate.

This

is

accomplished

in

the

flowmeter

section

by

replacing

the

bypass.

In

the

controller

section,

many

changes

in

flow

range

can

be

accomplished

by

an

external

adjustment

of

the

control

valve

alone.

Very

large

range

changes

may

involve

resizing

of

the

valve

orifice.

The

instrument

operates

on

+15

VDC

power,

provides

a

0

to

5.0

VDC

indicated

output

signal

linearly

proportional

to

the

flow

rate,

is

RFI

protected

and

is

both

mechanically

and

electrically

interchangeable

with

most

Tylan

General

mass

flow

controllers.

The

FC-2901/FC-2911

is

equipped

with

a

15-pin

“D”

connector

and

the

FC-2902/FC-2912

is

equipped

with

a

9-pin

“D”

connector.

Either

can

have

0-5

VDC

or

4-20mA

input/output

signals.

For

simplicity,

references

in

this

manual

are

to

a

card

edge

style

P.C.

Board,

+15

VDC

power

source

and

0-5

VDC

input/output

signals.

The

FC-2900B/2910B

operates

from

a

+12

VDC

battery

source.

Other

inherent

design

features

include:

е

Balanced

Power

Load

e

Enhanced

stability

of

both

zero

and

span

e

Auto

Zero

Function

(except

FC-2900B/2910B

and

flowmeters)

e

Metal

seals

with

ultra-high

leak

integrity

of

1

x

10-10

atm-cc/sec.

He

(FC-2900M/2901M/2902M/3900M/3901M/3902M)

Fast

response

with

minimal

overshoot

Battery

Powered

(FC-2900B/2910B)

Normally

closed

or

normaily

open

solenoid

valve

with

both

mechanical

and

electrical

“purge”

capability.

The

FC-2900

series

of

mass

flow

instruments

include:

Mass

Flow

Controllers

FC-2900(O)*

10

sccm

to

10

slm

with

card

edge

connector

FC-2901(0)*

10

sccm

to

10

slm

with

15-pin

“D”

connector

FC-2902(O)*

10

sccm

to

10

slm

with

9-pin

"D"

connector

FC-2910(O)*

100

sccm

to

30

slm

with

card

edge

connector

ЕС-2911(0)*

100

sccm

to

30

sim

with

15-pin

“р”

Connector

100

sccm

to

30

slm

with

9-pin

^D"

connector

FC-2900B(O)*

10

sccm

to

10

slm,

Battery

Powered

FC-2912(O)*

*“Q”

designates

normally

open

valve

option.

FC-2910B(O)*

100

sccm

to

30

slm,

Battery

Powered

FC-2900M(O)*

(EP)**10

sccm

to

30

slm

with

Metal

Seals

and

card

edge

connector

FC-2901M(O)*

(EP)**10

sccm

to

30

sim

with

Metal

Seals

and

15-pin

“D”

connector

коор

(EP)**10

sccm

to

30

sim

with

Metal

Seals

and

9-pin

“D”

connector.

Mass

Flowmeters

FM-3900

10

sccm

to

10

slm

with

card

edge

connector

FM-3901

10

sccm

to

10

sim

with

15-pin

“D”

connector

FM-3902

10

sccm

to

10

slm

with

9-pin

“D”

connector

FM-3910

100

sccm

to

30

sim

with

card

edge

connector

FM-3911

100

sccm

to

30

slm

with

15-pin

"D^

connector

FM-3912

100

sccm

to

30

slm

with

9-pin

“D”

connector

FM-3900M(EP)**

10

sccm

to

30

slm

with

Metal

Seals

and

card

edge

connector

10

sccm

to

30

slm

with

Metal

Seals

and

15-pin

“D”

connector

10

sccm

to

30

slm

with

Metal

Seals

and

9-pin

“D”

connector.

FM-3901M(EP)**

FM-3902M(EP)**

4-20

mA

input/output

signals

(available

with

instruments

that

have

a

*D"

connector).

“J”

option

NOTE:

This

manual

describes

the

operation

and

adjustment

procedures

for

flow

controllers.

All

sections

pertaining

to

the

flowmetering

portion

of

the

controller

also

pertain

to

flowmeters,

while

sections

pertaining

to

the

valve

do

not.

It

should

also

be

noted

that

the

autozero

function

is

not

available

on

any

of

the

flowmeter

models.

`

PRINCIPLE

OF

OPERATION

The

flow

controller

is

a

self-contained,

closed-loop

control

system

which

measures

the

mass

rate

of

gaseous

flow

through

the

instrument,

compares

this

with

an

externally

commanded

flow

rate,

and

adjusts

the

valve

to

control

the

flow

to

the

commanded

level.

The

flow

controller

consists

of

four

basic

elements

which

accomplish

this

function.

°

The

flow

sensor

°

Тһе

bypass,

ог

flow-splitter,

which

determines

the

full-

scale

flow

range

of

the

measuring

section

The

control

valve

The

electronics

which

condition

the

flow

signal

and

drive

the

control

valve.

**“EP”

designates

Electro-polished

option.

Wan

General

Flow

Sensor

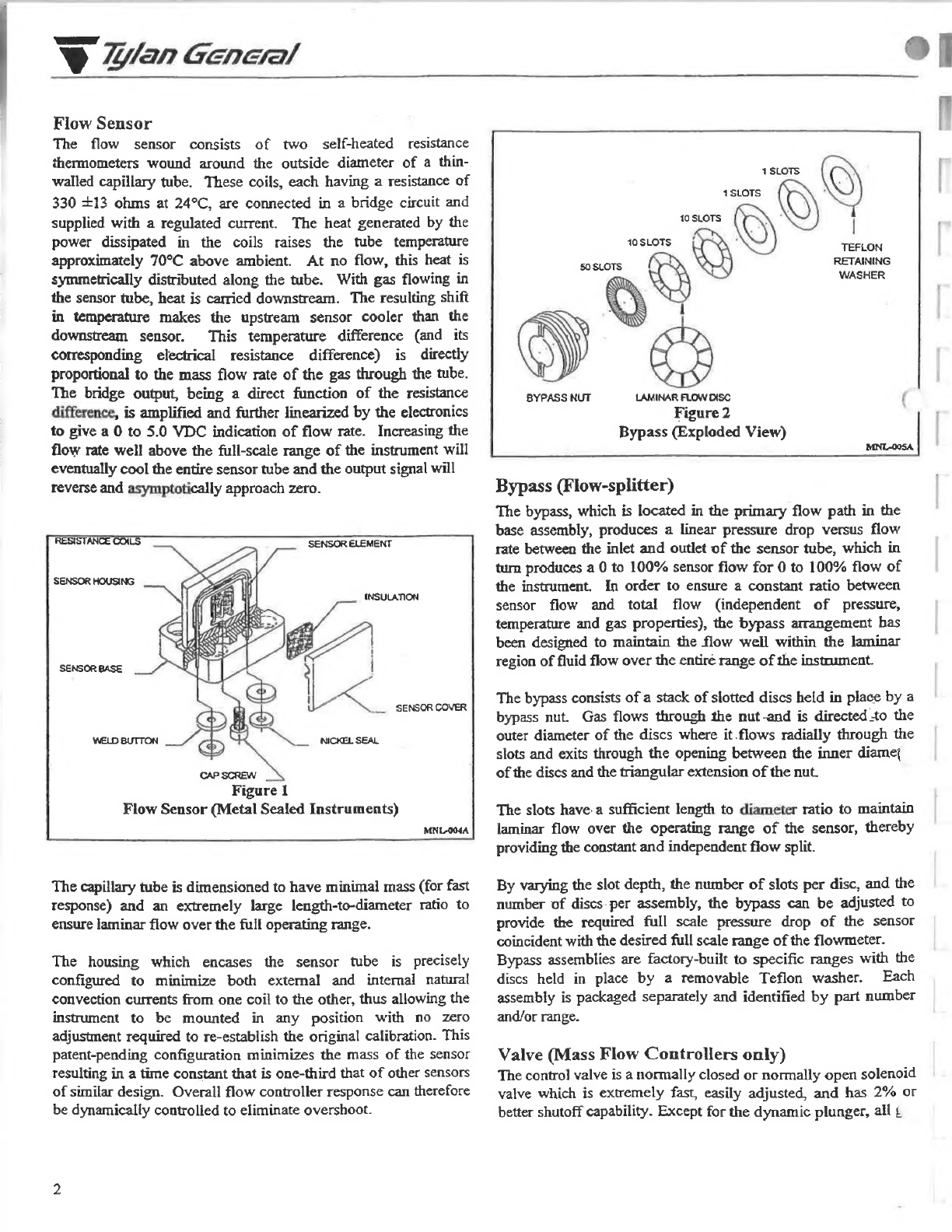

The

flow

sensor

consists

of

two

self-heated

resistance

thermometers

wound

around

the

outside

diameter

of

a

thin-

walled

capillary

tube.

These

coils,

each

having

a

resistance

of

330

+13

ohms

at

24°C,

are

connected

in

a

bridge

circuit

and

supplied

with

a

regulated

current.

The

heat

generated

by

the

power

dissipated

in

the

coils

raises

the

tube

temperature

approximately

70°C

above

ambient.

At

no

flow,

this

heat

is

symmetrically

distributed

along

the

tube.

With

gas

flowing

in

the

sensor

tube,

heat

is

carried

downstream.

The

resulting

shift

in

temperature

makes

the

upstream

sensor

cooler

than

the

downstream

sensor.

This

temperature

difference

(and

its

corresponding

electrical

resistance

difference)

is

directly

proportional

to

the

mass

flow

rate

of

the gas

through

the

tube.

The

bridge

output,

being

a

direct

function

of

the

resistance

difference,

is

amplified

and

further

linearized

by

the

electronics

to

give

a

0

to

5.0

VDC

indication

of

flow

rate.

Increasing

the

flow

rate

well

above

the

full-scale

range

of

the

instrument

will

eventually

cool

the

entire

sensor

tube

and

the

output

signal

will

reverse

and

asymptotically

approach

zero.

INSULATION

Р

|

.

SENSOR

COVER

Figure

1

Flow

Sensor

(Metal

Sealed

Instruments)

The

capillary

tube

is

dimensioned

to

have

minimal

mass

(for

fast

response)

and

an

extremely

large

length-to-diameter

ratio

to

ensure

laminar

flow

over

the

full

operating

range.

The

housing

which

encases

the

sensor

tube

is

precisely

configured

to

minimize

both

extemal

and

internal

natural

convection

currents

from

one

coil

to

the

other,

thus

allowing

the

instrument

to

be

mounted

in

any

position

with

no

zero

adjustment

required

to

re-establish

the

original

calibration.

This

patent-pending

configuration

minimizes

the

mass

of

the

sensor

resulting

in

a

time

constant

that

is

one-third

that

of

other

sensors

of

similar

design.

Overall

flow

controller

response

can

therefore

be

dynamically

controlled

to

eliminate

overshoot.

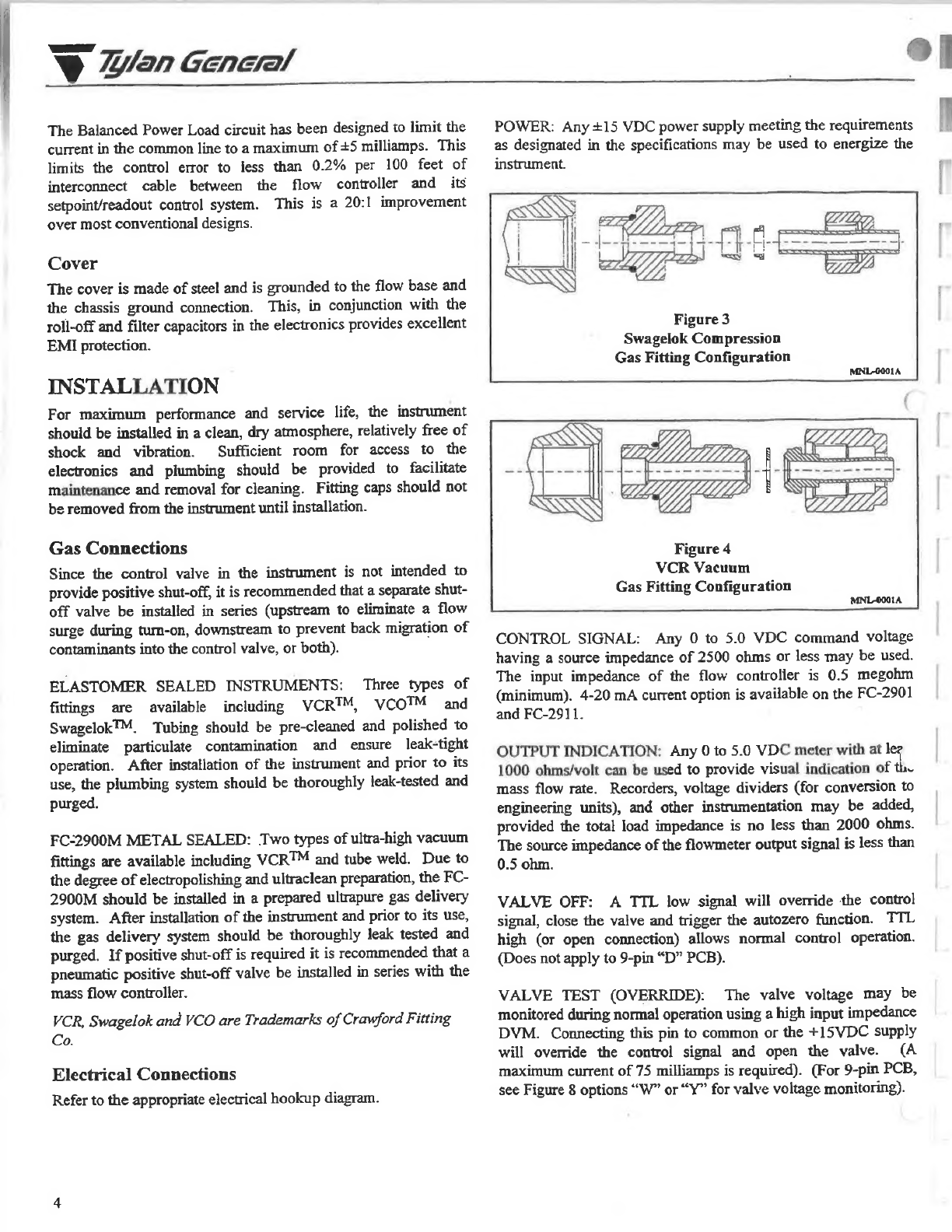

1SLOTS

10

SLOTS

10

SLOTS

WASHER

BYPASS

NUT

LAMINAR

FLOW

DISC

Figure

2

Bypass

(Exploded

View)

Bypass

(Flow-splitter)

The

bypass,

which

is

located

in

the

primary

flow

path

in

the

base

assembly,

produces

a

linear

pressure

drop

versus

flow

rate

between

the

inlet

and

outlet

of

the

sensor

tube,

which

in

turn

produces

a

0

to

100%

sensor

flow

for

0

to

100%

flow

of

the

instrument.

In

order

to

ensure

a

constant

ratio

between

sensor

flow

and

total

flow

(independent

of

pressure,

temperature

and

gas

properties),

the

bypass

arrangement

has

been

designed

to

maintain

the

flow

well

within

the

laminar

region

of

fluid

flow

over

the

entiré

range

of

the

instrument.

The

bypass

consists

of

a

stack

of

slotted

discs

held

in

place

by

a

bypass

nut.

Gas

flows

through

the

nut-and

is

directed

40

the

outer

diameter

of

the

discs

where

it.flows

radially

through

the

slots

and

exits

through

the

opening

between

the

inner

diame;

of

the

discs

and

the

triangular

extension

of

the

nut.

The

slots

have.

а

sufficient

length

to

diameter

ratio

to

maintain

laminar

flow

over

the

operating

range

of

the

sensor,

thereby

providing

the

constant

and

independent

flow

split.

By

varying

the

slot

depth,

the

number

of

slots

per

disc,

and

the

number

of

discs

per

assembly,

the

bypass

can

be

adjusted

to

provide

the

required

full

scale

pressure

drop

of

the

sensor

coincident

with

the

desired

full

scale

range

of

the

flowmeter.

Bypass

assemblies

are

factory-built

to

specific

ranges

with

the

discs

held

in

place

by

a

removable

Teflon

washer.

Each

assembly

is

packaged

separately

and

identified

by

part

number

and/or

range.

Valve

(Mass

Flow

Controllers

only)

The

control

valve

is

a

normally

closed

or

normally

open

solenoid

valve

which

is

extremely

fast,

easily

adjusted,

and

has

2%

or

better

shutoff

capability.

Except

for

the

dynamic

plunger,

all

£

19

W

Wan

General

|

wetted

metal

surfaces

are

of

type

316L

stainless

steel.

The

plunger

is

constructed

of

type

446

stainless

steel.

The

range

of

the

valve

is

determined

by

the

size

of

the

control

orifice,

which

is

screwed

into

the

controller

base.

These

precision

valve

seats

are

type

316L

stainless

steel

and

provide

excellent

control

resolution

by

engagement

with

the

Teflon

face

of

the

valve

poppet.

The

valve

seats

are

easily

replaceable

for

cleaning

and

instrument

range

changing.

The

valve

seat

is

designed

to

provide

a

relatively

constant

control

range

(stroke)

over

the

entire

flow

range.

Different

ranges

within

the

full

range

of

a

particular

valve

seat

are

accommodated

by

the

amount

of

voltage

applied

to

the

valve.

This

arrangement

provides

consistent

dynamic

response

and

static

stability

with

only

a

minimal

need

for

electronic“

tuning.”

An

adjustment

on

top

of

the

valve

is

provided

to

allow

for

setting

the

relative

position

between

the

valve

poppet

and

valve

seat

following

re-assembly

after

cleaning

or

seat

replacement

(see

Adjustment

Procedures).

This

adjusting

nut

may

also

be

used

to

mechanically

open

the

valve

for

purging

purposes

in

the

event

of

a

power

failure

or

an

instrument

malfunction,

which

may

necessitate

removing

the

instrument

from

the

gas

system.

Electronics

The

electronics

consist

of

a

circuit

board

with

a

hybrid

autozero

circuit

soldered

in

place.

Surface

mount

technology

is

utilized

in

the

FC-2900

series.

Referring

to

the

Electrical

Hook-Up

Diagram,

JO

is

a

card

edge,

9-pin

“D”

or

15-pin

“D”

connector

that

interfaces

with

the

external

control

system.

A

positive

5

volt

regulator

supplies

power

to

the

Auto-Zero

circuit

and

also

provides

the

reference

voltage

required

for

the

“Valve

OFF”

function.

The

negative

5

volt

regulator

provides

the

reference

for

the

sensor

bridge

constant

current

source

and

the

linearization

circuit.

The

Current

Sonrce

delivers

a

constant

12.7

milliamps

to

the

sensor

bridge

which

“floats”

between

the

plus

and

minus

supplies.

This

arrangement

gives

extremely

high

common-mode

rejection

and

allows

insensitive

operation

over

a

wide

range

of

supply

voltage

levels.

The

Sensor

Bridge

circuit

contains

the

zero

and

span

temperature

compensation

networks.

The

Flowmeter

Amplifier

circuit

amplifies

the

sensor

output

signal,

the

gain

of

which

is

adjusted

by

RP2

at

50%

full

scale

flow

rate.

This

circuit

also

incorporates

a

speed-up

filter

which

provides

for

matching

the

sensor

response

to

the

actual

flow

rate

response

during

a

transient

flow

condition.

The

AC

gain

versus

frequency

is

adjusted

by

RP3.

This

adjustment

is

fine-tuned

by

observing

the

output

waveform

in

response

to

step

changes

in

setpoint

and

actual

flow

rate.

The

Linearity

circuit

provides

a

variable

gain

versus

input

voltage

allowing

correction

for

any

non-linearity

of

the

sensor

output

signal.

The

adjustment

is

made

by

RP4

at

100%

full-

scale

flow

rate.

The

Auto-Zero

circuit

provides

periodic

correction

of

zero

offset

due

to

long

term

sensor

drift,

temperature

and

pressure

variations,

or

other

environmental

causes.

This

feature

ensures

long

term

calibration

accuracy

and

eliminates

the

need

for

periodic

manual

zero

adjustment.

The

range

of

correction

is

limited

to

+2.5%

of

full

scale

to

prevent

erroneous

correction

of

an

undetectable

leak

or

defective

sensor.

The

auto-zero

function

is

activated

either

by

commanding

<1%

of

full

scale

flow

rate

which

automatically

closes

the

control

valve

or

connecting

pin

L

to

common.

After

80

to

100

seconds,

the

output

signal

is

compared

with

(and

driven

to)

zero

within

2.5

seconds.

This

correction

is

maintained

until

the

next

update.

The

current

or

latest

correction

can

be

permanently

stored

in

memory

by

an

external

command

such

that

in

the

event

of

power

loss,

the

output

will

return

to

zero

when

power

is

re-applied.

The

auto-zero

functions

may

be

inhibited

either

externally

by

connecting

pin

J

to

common

(See

Electrical

Hook-Up

Diagram)

or

internally,

by

removing

jumper

JP2.

See

Appendix

C

for

more

information.

The

Valve

Control

circuit

compares

the

flowmeter

output

signal

with

the

command

voltage

(setpoint)

and

varies

the

voltage

to

the

valve

to

throttle

the

flow

to

the

commanded

level

via

closed

loop

control.

The

ramp

circuit

limits

the

rate

of

change

of

the

setpoint

allowing

the

sensor

output

to

“Кеер-ир”,

thus

minimizing

overshoot

during

step

changes

in

commanded

flow

rate.

If

a

slower

response

is

desired,

jumper

JP1

can

be

removed

to

give

a

10-15%

per

second

rate

of

change

to

the

desired

flow

rate.

?

While

the

integral

and

derivative

functions

of

the

PID

control

circuit

are

relatively

fixed,

the

proportional

band

(gain)

of

the

circuit

is

adjusted

by

the

ratio

of

R52

to

R50.

The

values

of

these

resistors

are

selected

during

dynamic

response

testing

to

optimize

the

transient

response

of

the

control

loop,

and

vary

depending

on

the

range,

gas,

and

intended

operating

conditions

of

the

instrument.

The

control

logic

can

be

overridden

externally

to

either

open

or

close

the

valve

in

accordance

with

specific

process

requirements.

(See

Electrical

Hook-Up

Diagram).

NOTE:

While

connecting

pin

D

to

common

will

partially

open

the

normally

closed

valve

and

partially

close

the

normally

open

valve,

connecting

pin

D

to

+15

VDC

will

drive

the

normally

closed

valve

to

the

full

“purge”

position

and

close

the

normally

open

valve.

$

Wan

General

The

Balanced

Power

Load

circuit

has

been

designed

to

limit

the

current

in

the

common

line

to

a

maximum

of

+5

milliamps.

This

limits

the

control

error

to

less

than

0.296

per

100

feet

of

interconnect

cable

between

the

flow

controller

and

its

setpoint/readout

control

system.

This

is

a

20:1

improvement

over

most

conventional

designs.

Cover

The

cover

is

made

of

steel

and

is

grounded

to

the

flow

base

and

the

chassis

ground

connection.

This,

in

conjunction

with

the

roll-off

and

filter

capacitors

in

the

electronics

provides

excellent

EMI

protection.

INSTALLATION

For

maximum

performance

and

service

life,

the

instrument

should

be

installed

in

a

clean,

dry

atmosphere,

relatively

free

of

shock

and

vibration.

Sufficient

room

for

access

to

the

electronics

and

plumbing

should

be

provided

to

facilitate

maintenance

and

removal

for

cleaning.

Fitting

caps

should

not

be

removed

from

the

instrument

until

installation.

Gas

Connections

Since

the

control

valve

in

the

instrument

is

not

intended

to

provide

positive

shut-off,

it

is

recommended

that

a

separate

shut-

off

valve

be

installed

in

series

(upstream

to

eliminate

a

flow

surge

during

turn-on,

downstream

to

prevent

back

migration

of

contaminants

into

the

control

valve,

or

both).

ELASTOMER

SEALED

INSTRUMENTS:

Three

types

of

fittings

are

available

including

ҮСЕТМ,

VCOIM

and

Swagelok™,

Tubing

should

be

pre-cleaned

and

polished

to

eliminate

particulate

contamination

and

ensure

leak-tight

operation.

After

installation

of

the

instrument

and

prior

to

its

use,

the

plumbing

system

should

be

thoroughly

leak-tested

and

purged.

FC-2900M

METAL

SEALED:

Two

types

of

ultra-high

vacuum

fittings

are

available

including

VCR™

and

tube

weld.

Due

to

the

degree

of

electropolishing

and

ultraclean

preparation,

the

FC-

2900M

should

be

installed

in

a

prepared

ultrapure

gas

delivery

system.

After

installation

of

the

instrument

and

prior

to

its

use,

the

gas

delivery

system

should

be

thoroughly

leak

tested

and

purged.

If

positive

shut-off

is

required

it

is

recommended

that

a

pneumatic

positive

shut-off

valve

be

installed

in

series

with

the

mass

flow

controller.

VCR,

Swagelok

and

VCO

are

Trademarks

of

Crawford

Fitting

Co.

Electrical

Connections

Refer

to

the

appropriate

electrical

hookup

diagram.

POWER:

Any

+15

VDC

power

supply

meeting

the

requirements

as

designated

in

the

specifications

may

be

used

to

energize

the

instrument.

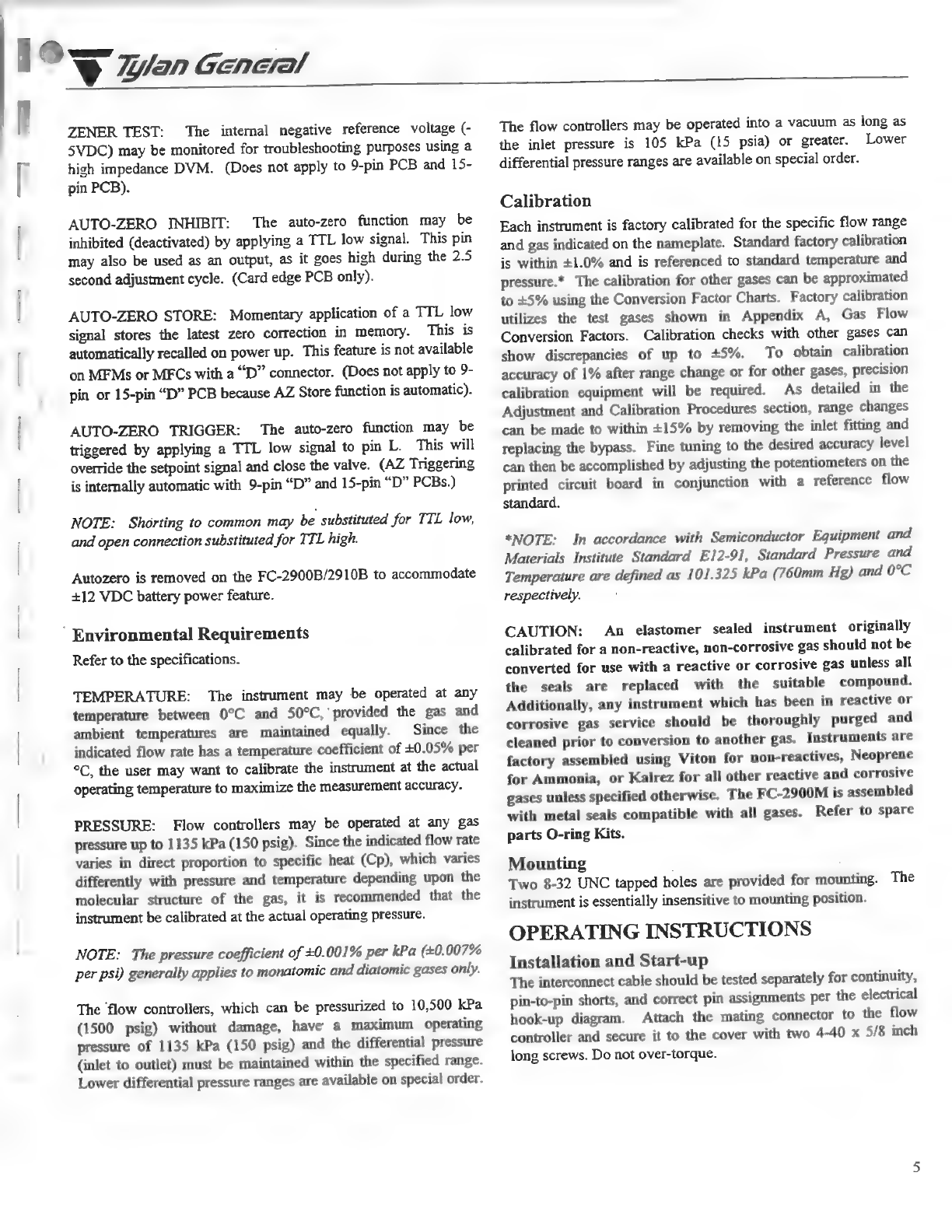

==

Figure

3

Swagelok

Compression

Gas

Fitting

Configuration

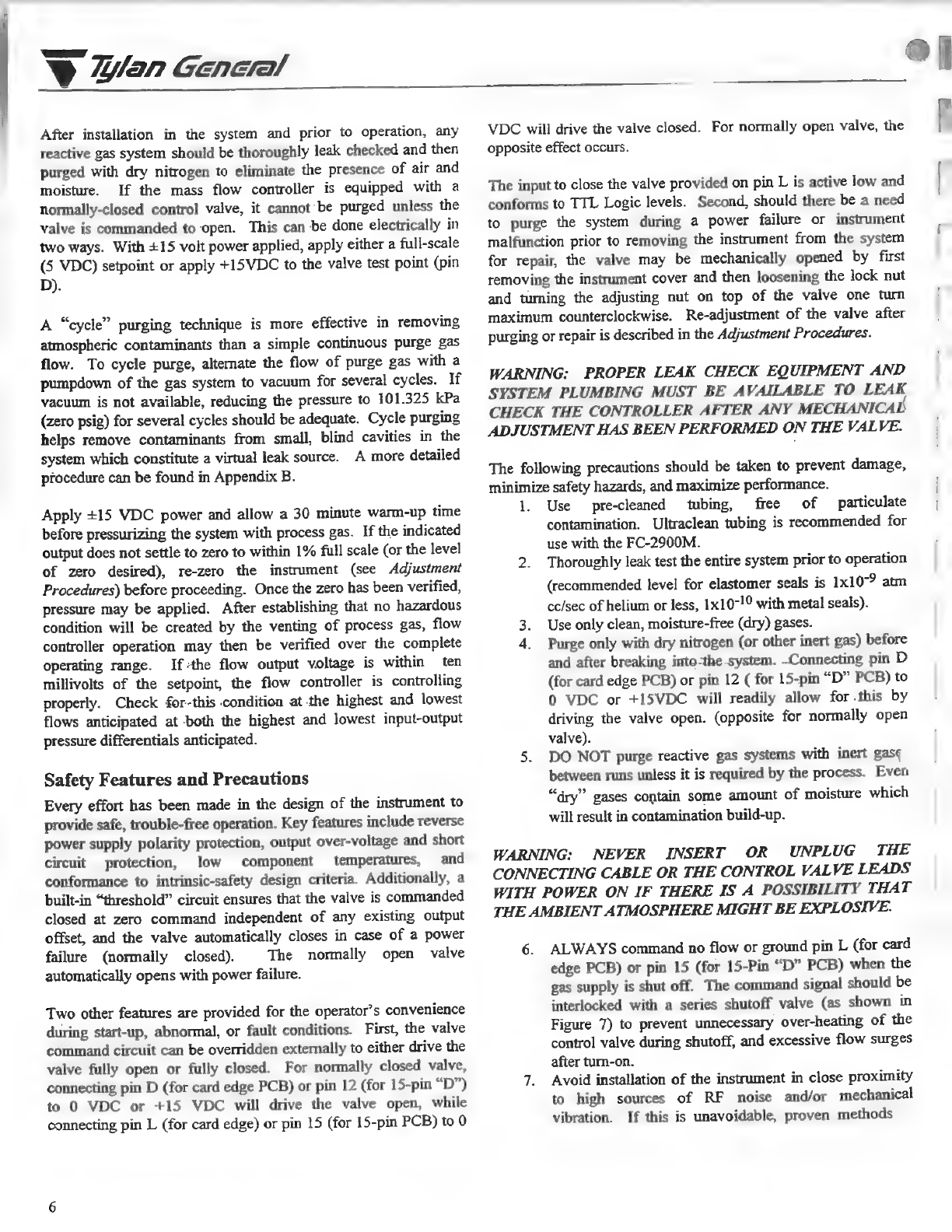

Figure

4

VCR

Vacuum

Gas

Fitting

Configuration

CONTROL

SIGNAL:

Any

0

to

5.0

VDC

command

voltage

having

a

source

impedance

of

2500

ohms

or

less

may

be

used.

The

input

impedance

of

the

flow

controller

is

0.5

megohm

(minimum).

4-20

mA

current

option

is

available

on

the

FC-2901

and

FC-2911.

OUTPUT

INDICATION:

Any

0

to

5.0

VDC

meter

with

at

lez

1000

ohms/volt

can

be

used

to

provide

visual

indication

of

th~

mass

flow

rate.

Recorders,

voltage

dividers

(for

conversion

to

engineering

units),

and

other

instrumentation

may

be

added,

provided

the

total

load

impedance

is

no

less

than

2000

ohms.

The

source

impedance

of

the

flowmeter

output

signal

is

less

than

0.5

ohm.

VALVE

OFF:

А

TTL

low

signal

will

override

the

control

signal,

close

the

valve

and

trigger

the

autozero

function.

TTL

high

(or

open

connection)

allows

normal

control

operation.

(Does

not

apply

to

9-pin

“D”

РСВ).

VALVE

TEST

(OVERRIDE):

The

valve

voltage

may

be

monitored

during

normal

operation

using

a

high

input

impedance

DVM.

Connecting

this

pin

to

common

or

the

+15VDC

supply

will

override

the

control

signal

and

open

the

valve.

(A

maximum

current

of 75

milliamps

is

required).

(For

9-pin

PCB,

see

Figure

8

options

“W”

or

“Y”

for

valve voltage

monitoring).

19

$

Zan

General

|

ZENER

TEST:

The

internal

negative

reference

voltage

(-

5ҮРС)

may

be

monitored

for

troubleshooting

purposes

using

a

high

impedance

DVM.

(Does

not

apply

to

9-pin

PCB

and

15-

pin

PCB).

AUTO-ZERO

INHIBIT:

The

auto-zero

function

may

be

inhibited

(deactivated)

by

applying

a

TTL

low

signal.

This

pin

may

also

be

used

as

an

output,

as

it

goes

high

during

the

2.5

second

adjustment

cycle.

(Card

edge

PCB

only).

AUTO-ZERO

STORE:

Momentary

application

of

a

TTL

low

signal

stores

the

latest

zero

correction

in

memory.

This

is

automatically

recalled

on

power

up.

This

feature

is

not

available

on

MFMs

or

MFCs

with

a

“D”

connector.

(Does

not

apply

to

9-

pin

or

15-pin

“D”

PCB

because

AZ

Store

function

is

automatic).

AUTO-ZERO

TRIGGER:

The

auto-zero

function

may

be

triggered

by

applying

a

TTL

low

signal

to

pin

L.

This

will

override

the

setpoint

signal

and

close

the

valve.

(AZ

Triggering

is

internally

automatic

with

9-pin

“D”

and

15-pin

“D”

PCBs.)

NOTE:

Shorting

to

common

may

be

substituted

for

TTL

low,

and

open

connection

substituted

for

TTL

high.

Autozero

is

removed

on

the

FC-2900B/2910B

to

accommodate

+12

VDC

battery

power

feature.

`

Environmental

Requirements

Refer

to

the

specifications.

TEMPERATURE:

The

instrument

may

be

operated

at

any

temperature

between

09С

and

50°C,

provided

the

gas

and

ambient

temperatures

are

maintained

equally.

Since

the

indicated

flow

rate

has

a

temperature

coefficient

of

+0.05%

рег

°C,

the

user

may

want

to

calibrate

the

instrument

at

the

actual

operating

temperature

to

maximize

the

measurement

accuracy.

PRESSURE:

Flow

controllers

may

be

operated

at

any

gas

pressure

up

to

1135

kPa

(150

psig).

Since

the

indicated

flow

rate

varies

in

direct

proportion

to

specific

heat

(Cp),

which

varies

differently

with

pressure

and

temperature

depending

upon

the

molecular

structure

of

the

gas,

it

is

recommended

that

the

instrument

be

calibrated

at

the

actual

operating

pressure.

NOTE:

The

pressure

coefficient

of

+0.001%

per

kPa

(+0.

007%

per

psi)

generally

applies

to

monatomic

and

diatomic

gases

only.

The

flow

controllers,

which

can

be

pressurized

to

10,500

kPa

(1500

psig)

without

damage,

have

a

maximum

operating

pressure

of

1135

kPa

(150

psig)

and

the

differential

pressure

(inlet

to

outlet)

must

be

maintained

within

the

specified

range.

Lower

differential

pressure

ranges

are

available

on

special

order.

The

flow

controllers

may

be

operated

into

a

vacuum

as

long

as

the

inlet

pressure

is

105

kPa

(15

psia)

or

greater.

Lower

differential

pressure

ranges

are

available

on

special

order.

Calibration

Each

instrument

is

factory

calibrated

for

the

specific

flow

range

and

gas

indicated

on

the

nameplate.

Standard

factory

calibration

is

within

+1.0%

and

is

referenced

to

standard

temperature

and

pressure.*

The

calibration

for

other

gases

can

be

approximated

to

+5%

using

the

Conversion

Factor

Charts.

Factory

calibration

utilizes

the

test

gases

shown

in

Appendix

A,

Gas

Flow

Conversion

Factors.

Calibration

checks

with

other

gases

can

show

discrepancies

of

up

to

+5%.

To

obtain

calibration

accuracy

of

1%

after

range

change

or

for

other

gases,

precision

calibration

equipment

will

be

required.

As

detailed

in

the

Adjustment

and

Calibration

Procedures

section,

range

changes

can

be

made

to

within

+15%

by

removing

the

inlet

fitting

and

replacing

the

bypass.

Fine

tuning

to

the

desired

accuracy

level

can

then

be

accomplished

by

adjusting

the

potentiometers

on

the

printed

circuit

board

in

conjunction

with

a

reference

flow

standard.

*NOTE:

In

accordance

with

Semiconductor

Equipment

and

Materials

Institute

Standard

E12-91,

Standard

Pressure

and

Temperature

are

defined

as

101.325

kPa

(760mm

Hg)

and

0°C

respectively.

CAUTION:

An

elastomer

sealed

instrument

originally

calibrated

for

a

non-reactive,

non-corrosive

gas

should

not

be

converted

for

use

with

a

reactive

or

corrosive

gas

unless

all

the

seals

are

replaced

with

the

suitable

compound.

Additionally,

any

instrument

which

has

been

in

reactive

or

corrosive

gas

service

should

be

thoroughly

purged

and

cleaned

prior

to

conversion

to

another

gas.

Instruments

are

factory

assembled

using

Viton

for

non-reactives,

Neoprene

for

Ammonia,

or

Kalrez

for

all

other

reactive

and

corrosive

gases

unless

specified

otherwise.

The

FC-2900M

is

assembled

with

metal

seals

compatible

with

all

gases.

Refer

to

spare

parts

O-ring

Kits.

Mounting

|

Two

8-32

UNC

tapped

holes

are

provided

for

mounting.

The

instrument

is

essentially

insensitive

to

mounting

position.

OPERATING

INSTRUCTIONS

Installation

and

Start-up

The

interconnect

cable

should

be

tested

separately

for

continuity,

pin-to-pin

shorts,

and

correct

pin

assignments

per

the

electrical

hook-up

diagram.

Attach

the

mating

connector

to

the

flow

controller

and

secure

it

to

the

cover

with

two

4-40

x

5/8

inch

long

screws.

Do

not

over-torque.

$

Wan

General

After

installation

in

the

system

and

prior

to

operation,

any

reactive

gas

system

should

be

thoroughly

leak

checked

and

then

purged

with

dry

nitrogen

to

eliminate

the

presence

of

air

and

moisture.

If

the

mass

flow

controller

is

equipped

with

a

normally-closed

control

valve,

it

cannot

be

purged

unless

the

valve

is

commanded

to

open.

This

can

be

done

electrically

in

two

ways.

With

+15

volt

power

applied,

apply

either

a

full-scale

(5

VDC)

setpoint

or

apply

+15VDC

to

the

valve

test

point

(pin

D).

A

"cycle"

purging

technique

is

more

effective

in

removing

atmospheric

contaminants

than

a

simple

continuous

purge

gas

flow.

To

cycle

purge,

alternate

the

flow

of

purge

gas

with

a

pumpdown

of

the

gas

system

to

vacuum

for

several

cycles.

If

vacuum

is

not

available,

reducing

the

pressure

to

101.325

kPa

(zero

psig)

for

several

cycles

should

be

adequate.

Cycle

purging

helps

remove

contaminants

from

small,

blind

cavities

in

the

system

which

constitute

a

virtual

leak

source.

A

more

detailed

procedure

can

be

found

in

Appendix

B.

Apply

+15

VDC

power

and

allow

a

30

minute

warm-up

time

before

pressurizing

the

system

with

process

gas.

If

the

indicated

output

does

not

settle

to

zero

to

within

1%

full

scale

(or

the

level

of

zero

desired),

re-zero

the

instrument

(see

Adjustment

Procedures)

before

proceeding.

Once

the

zero

has

been

verified,

pressure

may

be

applied.

After

establishing

that

no

hazardous

condition

will

be

created

by

the

venting

of

process

gas,

flow

controller

operation

may

then

be

verified

over

the

complete

operating

range.

Ifthe

flow

output

voltage

is

within

ten

millivolts

of

the

setpoint,

the

flow

controller

is

controlling

properly.

Check

for-this

condition

at

the

highest

and

lowest

flows

anticipated

at

both

the

highest

and

lowest

input-output

pressure

differentials

anticipated.

Safety

Features

and

Precautions

Every

effort

has

been

made

in

the

design

of

the

instrument

to

provide

safe,

trouble-free

operation.

Key

features

include

reverse

power

supply

polarity

protection,

output

over-voltage

and

short

circuit

protection,

low

component

temperatures,

and

conformance

to

intrinsic-safety

design

criteria.

Additionally,

a

built-in

“threshold”

circuit

ensures

that

the

valve

is

commanded

closed

at

zero

command

independent

of

any

existing

output

offset,

and

the

valve

automatically

closes

in

case

of

a

power

failure

(normally

closed).

The

normally

open

valve

automatically

opens

with

power

failure.

Two

other

features

are

provided

for

the

operator’s

convenience

during

start-up,

abnormal,

or

fault

conditions.

First,

the

valve

command

circuit

can

be

overridden

externally

to

either

drive

the

valve

fully

open

or

fully

closed.

For

normally

closed

valve,

connecting

pin

D

(for

card

edge

PCB)

or

pin

12

(for

15-pin

“D”)

to

0

VDC

or

+15

VDC

will

drive

the

valve

open,

while

connecting

pin

L

(for

card

edge)

or

pin

15

(for

15-pin

PCB)

to

0

VDC

will

drive

the

valve

closed.

For

normally

open

valve,

the

opposite

effect

occurs.

The

input

to

close

the

valve

provided

on

pin

L

is

active

low

and

conforms

to

TTL

Logic

levels.

Second,

should

there

be

a

need

to

purge

the

system

during

a

power

failure

or

instrument

malfunction

prior

to

removing

the

instrument

from

the

system