Part No. 4801-5331 Rev 2-2015 Evolution 1200 Table of Contents

Table of Contents

Section Title Page

1. Warranty........................................................................................................................................................4

2. Warnings........................................................................................................................................................5

3. Ratings and Specifications.............................................................................................................................5

4. Introduction ...................................................................................................................................................6

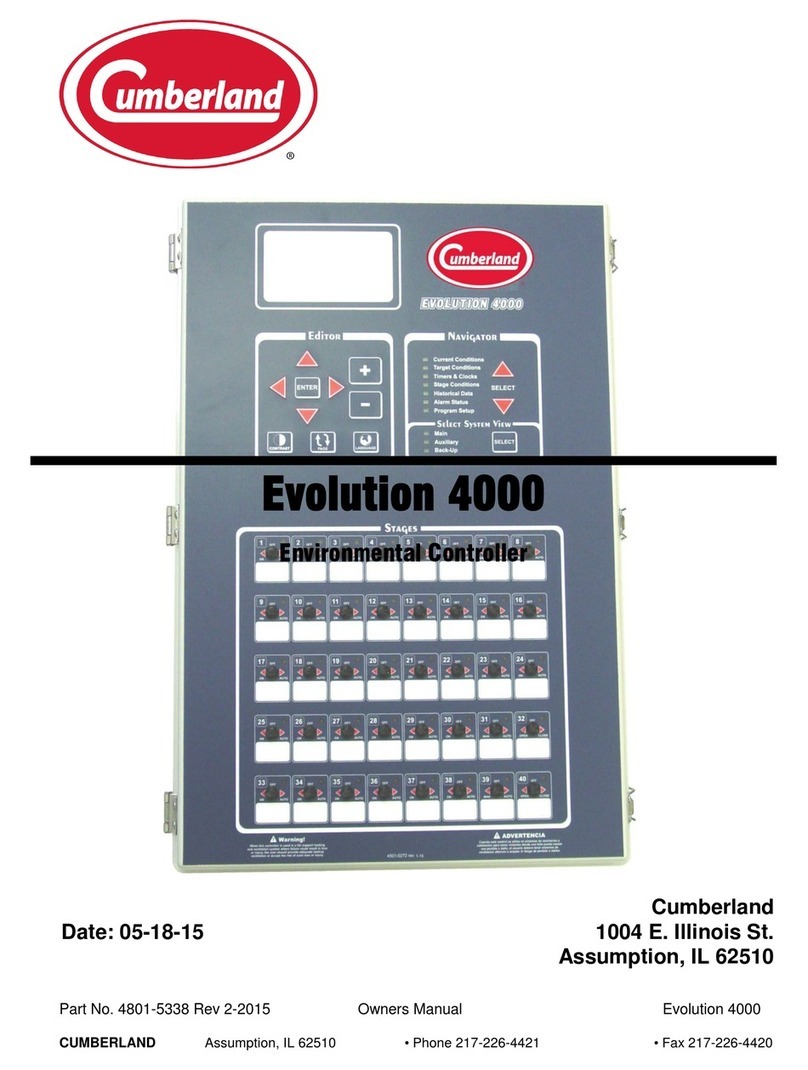

5. Evolution Front Panel....................................................................................................................................6

5.1 Navigator Panel ......................................................................................................................................7

5.2 Editor Panel............................................................................................................................................7

5.3 Main Display Contrast............................................................................................................................8

5.4 Inlet Stages .............................................................................................................................................8

5.5 Status Display.........................................................................................................................................9

5.6 Stage Switch ...........................................................................................................................................9

5.7 Locks ....................................................................................................................................................10

6. Viewing Navigator Status Screens...............................................................................................................10

6.1 Current Conditions................................................................................................................................10

6.2 Target Conditions .................................................................................................................................11

6.2.1 Target Conditions - Standard Screen With Optimum Mode OFF.................................................11

6.2.2 Target Conditions - Optimum Screen With Optimum Mode ON .................................................12

6.3 Minimum Vent......................................................................................................................................13

6.4 Stage Conditions...................................................................................................................................14

6.4.1 Inlet Conditions ............................................................................................................................14

6.4.2 Onboard Stages.............................................................................................................................15

6.4.3 Natural Ventilation Stages............................................................................................................15

6.4.4 Variable Stages.............................................................................................................................16

6.5 Historical Data......................................................................................................................................16

6.5.1 Room Temperature.......................................................................................................................16

6.5.2 Humidity Sensor ...........................................................................................................................17

6.5.3 Water Usage (#1 or #2) ................................................................................................................17

6.5.4 Ventilation Mode..........................................................................................................................17

6.5.5 Feed History .................................................................................................................................18

6.5.6 Stage Run Times...........................................................................................................................18

6.5.7 Power Track Run Times ...............................................................................................................18

6.5.8 Alarm Log.....................................................................................................................................19

6.6 Back-Up Status.....................................................................................................................................19

6.7 Alarm Status .........................................................................................................................................20

6.7.1 High Temperature Alarm Details..................................................................................................21

6.7.2 Low Temperature Alarm Details ..................................................................................................21

6.7.3 Tunnel Vent Alarm Details...........................................................................................................22

6.8 Network Status......................................................................................................................................23

6.9 Program Set-Up....................................................................................................................................23

7. Setting Programming Functions...................................................................................................................24

7.1 General Settings....................................................................................................................................24

7.2 Temperature Sensors ............................................................................................................................24

7.3 Feed Level Sensors...............................................................................................................................25

7.4 Ventilation Inlets ..................................................................................................................................25

7.5 Natural Ventilation ...............................................................................................................................26

7.6 Growout Curve .....................................................................................................................................27

7.6.1 Growout Curve with Optimum Mode Off.....................................................................................27

7.6.2 Growout Curve With Optimum Mode ON ...................................................................................29

7.7 Tunnel Ventilation................................................................................................................................32

7.8 Onboard ON/OFF Stages......................................................................................................................33

7.8.1 On/Off Stage Details.....................................................................................................................34

7.9 Variable Stage Outputs.........................................................................................................................34