Millipore Exact-Air II Operator's manual

MILLIPORE Exact-Air II

TOC.fm

Table of contents Page: 1

DOCUMENTATION OF THE SYSTEM

Reference: MSP008687

Description: Exact-AirTM II

MILLIPORE Exact-Air II

TOC.fm

Table of contents Page: 2

TABLE OF CONTENTS

Volume Chapter Page

VOL. 1 I INTRODUCTION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -I-1

I.1 Notice . . . . . . . . . . . . I-2

I.2 Safety recommendations . . . . . . . . . I-4

I.3 Glossary . . . . . . . . . . . . I-10

II BEFORE USING THE SYSTEM - - - - - - - - - - - - - - - - - - - - - - - - II-1

II.1 System description . . . . . . . . . . II-2

1. HydroCorr integrity testing - basic theory . . . . II-2

2. Manual vs. automatic filter integrity testing . . . . II-2

3. Functional description . . . . . . II-2

4. System overview . . . . . . . II-3

5. Operating Requirements . . . . . . II-5

5.1. Environment requirements . . . . II-5

5.2. Utilities requirements . . . . . II-5

5.3. Pressure setting . . . . . II-5

6. Description of test sequences . . . . . . II-6

II.2 Control panel description . . . . . . . . . II-7

1. Control panel. . . . . . . . II-7

2. HMI description . . . . . . . II-7

2.1. Welcome screen . . . . . II-7

2.2. Command screen . . . . . II-8

2.3. Main menu screen . . . . . II-9

2.4. Setup menu screen . . . . . II-10

2.5. P&ID screen . . . . . II-11

2.6. Alarm screen . . . . . II-12

2.7. Alarm history screen . . . . . II-13

2.8. Process parameters screen . . . . . II-14

2.9. Language screen . . . . . II-14

2.10. Screen utilities . . . . . II-15

2.11. Setup screen . . . . . . II-16

MILLIPORE Exact-Air II

TOC.fm

Table of contents Page: 3

II.3 Start-up instructions . . . . . . . . . . II-17

1. Precaution . . . . . . . . II-17

2. Start-up check list . . . . . . . II-17

3. Connection . . . . . . . . II-18

4. Instrument preparation . . . . . . II-20

5. Power-up . . . . . . . . II-20

6. Initial flushing procedure . . . . . . II-20

7. Initial start-up and leak test . . . . . . II-22

III OPERATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -III-1

III.1 Operating instructions. . . . . . . . . . III-2

1. Instrument set-up . . . . . . . III-2

2. Instrument preparation . . . . . . III-2

3. Power-up . . . . . . . . III-2

4. Starting a test . . . . . . . III-3

5. Draining of the system . . . . . . III-5

6. Cleaning in place (CIP) . . . . . . III-6

7. Security functions . . . . . . . III-7

III.2 Troubleshooting. . . . . . . . . . . III-8

III.3 System stopping . . . . . . . . . . . III-9

IV SYSTEM MAINTENANCE - - - - - - - - - - - - - - - - - - - - - - - - - - - IV-1

IV.1 General maintenance of the system . . . . . . . IV-2

1. Quarterly check recommendation . . . . . IV-2

2. Annual verification . . . . . . . IV-2

IV.2 Recommended spare parts list . . . . . . . . IV-3

VP&ID-FLOWSCHEMATIC

VI MECHANICAL DRAWING

VII COMPONENTS DATA SHEETS

VIII ELECTRICAL SCHEMATICS

MILLIPORE Exact-Air II

TOC.fm

Table of contents Page: 4

IX COMPONENTS DOCUMENTATION (ONLY AVAILABLE ON CD)

IX.1 Instruments documentation

1. Pressure

1.1. PI004

2. Level

2.1. LSH001

3. Temperature (Option)

3.1. TE001

IX.2 Other components

1. Valves

1.1. XV001, XV002, XV003, XV004, XV005, XV006, XV007

2. Tank

2.1. Tank TK001

3. Pressure relief valve

3.1. PRV001

4. Air supply kit

4.1. HV601, PSL001, PCV003, PCV001, PCV002

5. Filter

5.1. FLT001

6. Liquid trap

6.1. LTR001

7. Components of electrical box

8. Operator control touch screen

X MANUFACTURING RECORDS

X.1 ISO 9001, CE and certificate of quality

XI FACTORY ACCEPTANCE TESTS

MILLIPORE Exact-Air II

Vol. 1 Introduction I.1 Notice Page: I-2

Introduction-Notice.fm

TOC

I.1. Notice

The information contained within this document is subject to change and therefore can

not be considered as a commitment on the part of Millipore s.a.s.

The document is considered complete and correct at the time of delivery.

This document can not be considered as legally binding. It is the sole responsibility of

the user for the use of the equipment and to verify that the equipment is used in

accordance with the recommendations contained within the document provided.

Copyright (2007), Millipore s.a.s. Printed in France. All rights reserved. These books or

parts thereof may not be reproduced in any form without the written permission of the

publisher.

MILLIPORE S.A.S

Hardware Systems Operations

Zone Industrielle de la Hardt

BP116 - 67124 MOLSHEIM

FRANCE

Tel: +33 (0)3 90 46 90 00

Fax: +33 (0)3 90 46 80 01

Visit us on Internet @ http://www.millipore.com

DOCUMENTATION REVISION CONTROL:

The documentation has a general revision code shown on the document named "notice".

Each documentation change is described on the notice and the revision code is increase

of one letter, i.e. from "-" to "A" for first revision, then from "A" to "B" for second revision.

Some specific documents (such as electrical schematics, drawings ...) have their own

revision code. This code can be different from the general revision code of the

documentation.

MILLIPORE Exact-Air II

Introduction-Safety.fm

Vol. 1 I.2 Safety recommendations Page: I-4

TOC

I.2. Safety recommendations

ANNEXE 4 , REV.B , SPEC N° 062 558 SO

GB

IRL ATTENTION

This user's manual includes important health and safety aspects, which

require a specific training. Please make sure that all operators before first

use of the equipment know the recommendations.

A

DACHTUNG

Manche Teile betreffen Sicherheits-aspekte die eine Schulung benötigen.

Bitte stellen Sie sicher daβalle diese Elemente von allen Benutzern vor

dem Einschalten der Anlage vollkommen verstanden sind.

B

NL ATTENTIE

Verschillende delen in de handleiding bevatten informatie over

onderwerpen als gezondheid en veiligheid, die een gerichte training

noodzakelijk maken. Overtuigt U ervan, dat al deze aanbevelingen

bekend zijn bij de gebruikers van de apparatuur voor het ingebruik nemen

ervan.

DK ADVARSEL

Flere kapitler indeholder vigtige oplysninger af sikkerhedsmæssig

betydning. Specifik træning af operatører er påkrævet. Venligst sørg for at

vejledningerne er kendt af operatørerne før opstart.

EATENCIÓN

Varios capítulos incluyen aspectos relativos a salud y seguridad en el

trabajo que requieren entrenamiento específico. Por favor, asegúrese de

que antes de comenzar a trabajar con el equipo los operarios conocen

estas recomendaciones.

F

LATTENTION

Certains chapitres traitent des aspects de sécurité et doivent faire l'objet

d'une formation. Veuillez vous assurer que ces points aient été compris

par tous les opérateurs avant toute utilisation la machine.

FIN HUOM

Monessa kohtaa käsitellään tärkeitä terveys- ja turvallisuuskysymyksiä,

jotka vaativat erikoiskou-lutusta. Varmistanette, että kaikki käyttäjät ovat

tietoisia näistä ennen laitteiston käyttöönottoa.

GR

Σε καποια απ τα κεϕαλαια, εμπεριεχονται σημαντικες

πληροϕορες που αϕορουν σε θεματα υγεας και ασϕαλειας, για

τα οποα απαιτεται ειδικη εκπαδευση. Βεβαιωθετε τι πριν απ

καθε χρηση της συσκευης, αυτες οι οδηγες εχουν γνει ηδη

γνωστες.

IATTENZIONE

Alcuni capitoli contengono informazioni riguardanti la sicurezza per la

quale è necessario un particolare addestramento. Occorre assicurarsi che

gli operatori abbiano preso conoscenza delle varie raccomandazioni

contenute prima di operare direttamente sulla macchina in oggetto.

PATENÇÃO

Vários capítulos incluem aspectos relativos à saúde e segurança no

trabalho que requerem formação específico. Por favor, assegure-se de que

antes de começar a trabalhar com o equipamento os utilizadores

conhecem estas recomendações.

SVIKTIGT

Flera ingående kapitel innehåller viktig säkerhetsinformation som kräver

specifik utbildning. Säkerställ att alla rekommendationer förstås och följs

av användande personal innan utrustningen tages i drift.

HFIGYELEM!

Ez az útmutató olyan fontos egészségügyi és biztonsági kifejezéseket

tartalmaz, amelyek speciális oktatást igényelnek. Kérjük, gondoskodjon

arról, hogy az elöírásokat a berendezés elsö használata eltt az összes

kezelö megismerje.

MILLIPORE Exact-Air II

Introduction-Safety.fm

Vol. 1 I.2 Safety recommendations Page: I-5

TOC

EXEMPLE ANNEXE 11 , REV.- , SPEC 0 062 646 SO

Safety recommendations

Generalities

These general recommendations are provided by Millipore to assist in the safe and reliable

operation of the equipment. They do not relieve the client of the need to understand use and

maintain the equipment in a safe way.

The user must at all times satisfy himself of the safety of the equipment in his particular

circumstances. This will include the appropriate training of personnel, safety equipment and

local equipment environment and services.

• Before starting the system, verify the presence and good working condition of all

safety components (button test lamps/buzzer, protection caps...).

• Do not remove the intrinsic securities fitted.

• Place first-aid equipment at operator's disposal.

• Respect all the markings and symbols on the system, lines and tanks.

• MILLIPORE passes off its responsibilities for all inherent risks (toxicity,

contamination...) associated to the products to be filtered.

• Don't exceed the standard operating conditions.

• Respect the parameters of the utilities as defined on the flow schematic (product feed,

air inlet, steam, nitrogen...).

• Make sure that there is no pressure in the lines before any maintenance operation,

dismantling of connections, changing the filters, etc.

• Treat the effluents (drains, filtrate, retentate, cleaning and rinsing solutions) in an

adequate manner before rejecting them.

MILLIPORE Exact-Air II

Introduction-Safety.fm

Vol. 1 I.2 Safety recommendations Page: I-6

TOC

EXEMPLE ANNEXE 11 , REV.- , SPEC 0 062 646 SO

Safety recommendations

Electrical risks

All electrical operation must be done by qualified personnel having the required accreditation.

Preventive Maintenance:

• Verify the good working condition of the emergency stops every day;

• Verify that the covers and electrical box doors are closed every day;

• Verify the state of the cables and electrical connections every month;

• Verify the continuity of earth grounding every month;

• Verify the good connection of the electrical connections every 6 months;

• Verify the water/dust tightness of the electrical boxes every year.

MILLIPORE Exact-Air II

Introduction-Safety.fm

Vol. 1 I.2 Safety recommendations Page: I-7

TOC

EXEMPLE ANNEXE 11 , REV.- , SPEC 0 062 646 SO

Safety recommendations

Mechanical risks

All operation must be done by qualified personnel having the required accreditation.

Before any dismantling or maintenance operation, make sure that all the sources of energy are

shut down (fluid, gas, electricity).

Preventive Maintenance:

• Verify the state and the cleanliness of the footbridge, stepboard, ladders and the

circulation zone around the system every day;

• Verify the correct closing and tightness of all the tanks and vessels openings

(porthole, man-hole, drains, connection, lid...) every day;

• Make sure of the correct closing and tightness of all connections every day;

• Verify the state of all seals (connection, pump, valves...) every month;

• Verify the correct working conditions of the pressure regulators (low pressure and

high pressure);

• Verify the correct closing of the mechanical protections (covers, hides...) every 3

months;

• Replace all seals (connection, pump, valves...) every 6 months;

• Verify the state of the flexible tubing (tightness, distortion) every week;

• Replace the flexible hose of peristaltic pumps every second cycle of steam sterilization

or every 10-cycles of production;

• Replace all the flexible tubings every year.

MILLIPORE Exact-Air II

Introduction-Safety.fm

Vol. 1 I.2 Safety recommendations Page: I-8

TOC

EXEMPLE ANNEXE 11 , REV.- , SPEC 0 062 646 SO

Safety recommendations

Chemical risks

The chemical risks are related to the different products used.

It is the responsibility of the client to ensure the adequate training of the operators and to put

individual protection equipment according to the products used at their disposal.

All operation must be done by a person duly informed about the chemical risks of the

products.

Use individual protection during manipulation of the chemicals in agreement with the existing

labelling.

Put safety and first-aid equipment such as shower, rinses eye, etc. at the disposal of the

operators.

Respect the recommended concentrations of chemicals to be used in the system.

MILLIPORE Exact-Air II

Introduction-Safety.fm

Vol. 1 I.2 Safety recommendations Page: I-9

TOC

EXEMPLE ANNEXE 11 , REV.- , SPEC 0 062 646 SO

Safety recommendations

Thermal risks

It is the responsibility of the client to ensure the training of the operators and to put individual

protection equipment at their disposal.

All operations must be done by a person duly informed about thermal risks.

During of the system sterilization cycles, all the lines, valves, tanks, pump heads, etc. are

exposed to high temperatures and present some risks of burn. All manipulation should be

conducted with an appropriate safety equipment such as protection garments, integral mask,

isotherm gloves, etc.

MILLIPORE Exact-Air II

Introduction-Glossary-Exactair.fm

Vol. 1 I.3 Glossary Page: I-10

TOC

I.3. Glossary

CONVERSION TABLE

CIP (clean in place) Refers to procedures or equipment for cleaning membrane systems

without dismantling the equipment.

HydroCorr™ Millipore filter compression test for hydrophobic cartridge.

IT Abbreviation for Integrity Tester.

Length: 1 foot(ft. or ') =0.3048 m = 304.8 mm

1 inch(in. or ") =0.0254 m = 25.4 mm

Surface: 1 square feet (sqft or ft2) =0.0929 m2= 92903 mm2

1 inch² =6.45 cm2

1 m2=10.76 ft²

Pressure: 1 psi =0.0689 bar

1 bar =14.5 psi (pound per square inch)

Temperature: T°F =(9/5.T°C + 32)

T°C =5/9.(T°F - 32)

Weight: 1lb ( = pound) =0.454 kg

Volume: 1 gallon (UK, liq.) =4.546 l

1 gallon (US, liq.) =3.7854 l

1gallon/ft2(US) =40 l/m2

Flow Rate: 1 gallon per minute (GPM) (UK, liq.) =4.546 l/min=272.8 l/h

1 gallon per minute (GPM) (UK, liq.) =3.7854 l/min=227.1 l/h

1 gallon per day (GPD) (UK, liq.) =11.36 l/h

1 gallon per day (GPD) (US, liq.) =9.462 l/h

1 LMH/bar = 1 1/m2.hr.bar

Concentration: 1'000 ppm =1g/l

Torque: 1 in.lb =0.0115 kg.m=0.1130 N.m

1 ft.lb =0.133 kg.m=0.357 N.m

MILLIPORE Exact-Air II

Exactair-description.fm

Vol. 1 Before using the system Page: II-1

TOC

II. Before using the system

MILLIPORE Exact-Air II

Exactair-description.fm

Vol. 1 Before using the system II.1 System description Page: II-2

TOC

II.1. System description

II.1.1. HYDROCORR INTEGRITY TESTING - BASIC THEORY

The water based HydroCorr™ test has been designed and validated to evaluate the integrity

of hydrophobic vent filters. The HydroCorr™ test takes advantage of the fact that water does

not spontaneously wet hydrophobic membranes. Since the HydroCorr™ test only involves

upstream measurements and manipulations, it is recommended when on-line integrity testing

is needed.

The HydroCorr™ test consists of filling the filter housing with water until the upper level of

the filter cartridge. Subsequently, an automatic filter integrity tester is attached to the upstream

side of the housing. The tester measures the pressure drop in the gas headspace that is in

contact with water upstream of the filter. At the end of the test the HydroCorr™ value is

calculated and expressed in ml/min, which is directly proportional to the pressure drop

observed in the compressed air chamber.

Many parameters can influence and affect the HydroCorr™ test. The temperature in the gas

volume upstream of the water is a critical factor and must remain stable whilst testing to

produce reliable, accurate and reproducible integrity test results. The pressure in this required

gas volume undergoes dramatic variations when temperature changes. On the other hand,

water is less sensitive to temperature because its physical expansion and compression during

temperature changes is of low importance. Hence, Millipore has developed an automated

system designed with a remote volume, so that only water is present in the critical temperature

area. The filter housing and the connecting tubing are completely filled with water, and the air

volume is maintained at constant room temperature. The Exact-Air™ system allows

conducting automatic HydroCorr test under actual processing conditions and ensures reliable

test results under critical temperature conditions.

II.1.2. MANUAL VS. AUTOMATIC FILTER INTEGRITY TESTING

Advantages of using automated test equipment are that method variation is eliminated, and

reproducible filling conditions are observed. The Exact-Air™ system can be used to conduct

pre-use integrity testing even after the filter has been sterilized. This is accomplished without

compromising the sterility of the filtration system, because all connections are made upstream

of the filter, unlike alcohol-based test methods.

II.1.3. FUNCTIONAL DESCRIPTION

The Millipore Exact-Air™ system is a microprocessor-controlled unit designed to facilitate

filter integrity tests. The design boundaries for the Exact-Air™ system are that the unit can

conduct the test on hydrophobic filter systems ranging from 4” filters to 3 times 30”

cartridges. A Siemens PLC controls the filling and testing operations. The control panel starts

the draining, drying and cleaning procedures.

MILLIPORE Exact-Air II

Exactair-description.fm

Vol. 1 Before using the system II.1 System description Page: II-3

TOC

The automatic filter integrity test instrument that is to be coupled to the Exact-Air™ system

is capable of producing a hard copy printout of the filtration system parameters and the

generated test data, and indicates if a filter has passed or failed its specified integrity test.

Performing the HydroCorr™ test with the Exact-Air™ system offers users a unique

opportunity to improve ease, reliability, accuracy, reproducibility and frequency of air filter

testing and to meet the increasingly demanding regulatory requirements.

II.1.4. SYSTEM OVERVIEW

The Exact-Air™ system is equipped with:

• Gas supply with low pressure alarm

• Pressure regulators

• Pneumatic diaphragm valves

• Liquid trap

• Aervent 50 hydrophobic filter

• Internal remote volume

• Water level sensor

• Water feed tank with pressure gauge and relief valve

• Operator control touch screen

• Electrical box

• Siemens PLC type S7-200

• Mobile frame with Staubli connections

All components are mounted on a mobile frame.

MILLIPORE Exact-Air II

Exactair-description.fm

Vol. 1 Before using the system II.1 System description Page: II-4

TOC

Note:

The automatic filter integrity tester (like a Millipore Integritest® 4 instrument) is independent

from the Exact-AirTM system and has to be ordered separately.

LIST OF COMPONENTS

List of delivered accessories:

• 2 power cords

• Two tubing assemblies for Filter top and Filter bottom: a grey one and a blue one

• Bypass tubing assembly (filter top/bottom)

• All counter connectors (without tubing)

List of required equipment (not delivered):

• Inlet tubing (air inlet)

• Integritest® inlet tubing assembly

• Integritest® outlet tubing assembly

• Automatic filter integrity tester

Item n° Description and function

TK001 10 L feed water tank equipped with quick connectors for air inlet, water outlet,

venting and pressure relief valve.

The stainless steel water tank is removable and can be autoclaved.

Use WFI or RO water at 23°C +/- 3°C.

TK002 The remote volume must be maintained at constant room temperature.

LSH001 Level sensor located on TK002 to detect water level and control the filling

operation. This function is inactivated for the cleaning procedure.

PI004 Pressure gauge for TK001 (must be removed when autoclaving the tank).

LTR001 Liquid trap to protect integrity tester from potential water ingress.

PSL001 Low pressure alarm. Lock the system when inlet pressure is below 6 bar

XV001 to XV007 PP pneumatic diaphragm valves driven by PLC and electro-valves.

HV601 Manual shut off valve on air inlet connection.

PCV001 Gas supplies control unit for filling, draining and drying the system following

each HydroCorr test.

PCV002 Gas supplies control unit for automatic integrity tester.

PCV003 Gas supplies control unit for pneumatic valves.

PRV001 Safety relief valve for TK001.

FLT001 Aervent 50 hydrophobic sterilising grade air filter.

TI001/TE001

(option)

Temperature sensor located on TK002.

MILLIPORE Exact-Air II

Exactair-description.fm

Vol. 1 Before using the system II.1 System description Page: II-5

TOC

II.1.5. OPERATING REQUIREMENTS

II.1.5.1. Environment requirements

Realising that Exact-Air™ system may be subjected to adverse environmental conditions in

the field, it was designed and constructed using internal components that function properly at

the following conditions:

II.1.5.2. Utilities requirements

The Exact-Air™ system requires a 240 V, 50 Hz electrical source. It is preferred to have the

electrical line isolated and protected from power surges. With respect to the gas inlet, it

requires a clean, dry and regulated compressed air or nitrogen source at an inlet pressure of at

least 6 bar. The pneumatic components of the system should be protected from possible

contamination in the gas source. Hence the gas filter in the inlet connection should be changed

on a regular basis. All required utilities are listed below.

II.1.5.3. Pressure setting

Three pressure regulators fitted with gauges are available for adjusting the required operating

pressures. The system is delivered with pre-set values that must be controlled during initial

start up. PCV001 is used to fill the filter housing and drain the system after testing. The initial

set pressure is 2.0 bar and can be lowered when small filter are involved, or when the filter is

located at a height below 2 m. PCV002 supplies the tester device and PCV003 is used to

actuate the pneumatic diaphragm valves via the coupled electro-valves driven by the PLC.

PARAMETER OPERATING STORAGE

Temperature + 4°to + 40°C0°to + 40°C

Humidity 20% to 80%

non-condensing

20% to 80%

non-condensing

Atmospheric pressure Stable during the test No specification

Utilities Specifications

Electrical 100 / 240 V, 50/60 Hz, 200 VA

Inlet Gas Pressure > 6 bar

Type Nitrogen or air

Condition Clean and dry

Item Required set pressure

PCV001 (feed water tank) 1 – 2.5 bar

PCV002 (Integrity tester) 5 – 7 bar

PCV003 (pneumatic valves) 6 – 7 bar

MILLIPORE Exact-Air II

Exactair-description.fm

Vol. 1 Before using the system II.1 System description Page: II-6

TOC

II.1.6. DESCRIPTION OF TEST SEQUENCES

The filling operation and HydroCorr™ test is performed in an automatic sequence after

starting the integrity tester. Using the touch screen starts the draining operation. The valve

opening/shutting sequence is described in the table below.

Description of valve opening sequences:

Valve n° Stand-by Filling Testing

20 min

Draining

and drying

CIP

XV001-NC Closed Closed Closed Open Closed

XV002-NC Closed Closed Open Closed Closed

XV003-NC Closed Open Closed Closed Open

XV004-NC Closed Open Closed Closed Open

XV005-NC Closed Closed Closed Open Closed

XV006-NC Closed Open Closed Closed Open

XV007-NO Open Closed Open Open Closed

VA

PCV002

WATER

XV001-NC

XV004-NC

XV006-NC

VC

VD

VB

XV002-NC

XV003-NC

Integrity Tester

PCV001

XV005-NC

XV007-NO

DRAIN

Table of contents

Other Millipore Test Equipment manuals

Popular Test Equipment manuals by other brands

Urrea

Urrea UBORVI User manual and warranty

Vibration Research Corporation

Vibration Research Corporation VibrationVIEW manual

Hioki

Hioki 3008 instruction manual

Saluki

Saluki STL4403 Series Operation manual

Associated Research

Associated Research HYAMP III quick start guide

NIEUWKOOP

NIEUWKOOP EC2620 user manual

natus

natus Madsen Zodiac user guide

SmartSafe

SmartSafe iSmartEV RT100 user manual

Test Equipment Depot

Test Equipment Depot FHT-801 instruction manual

BGS technic

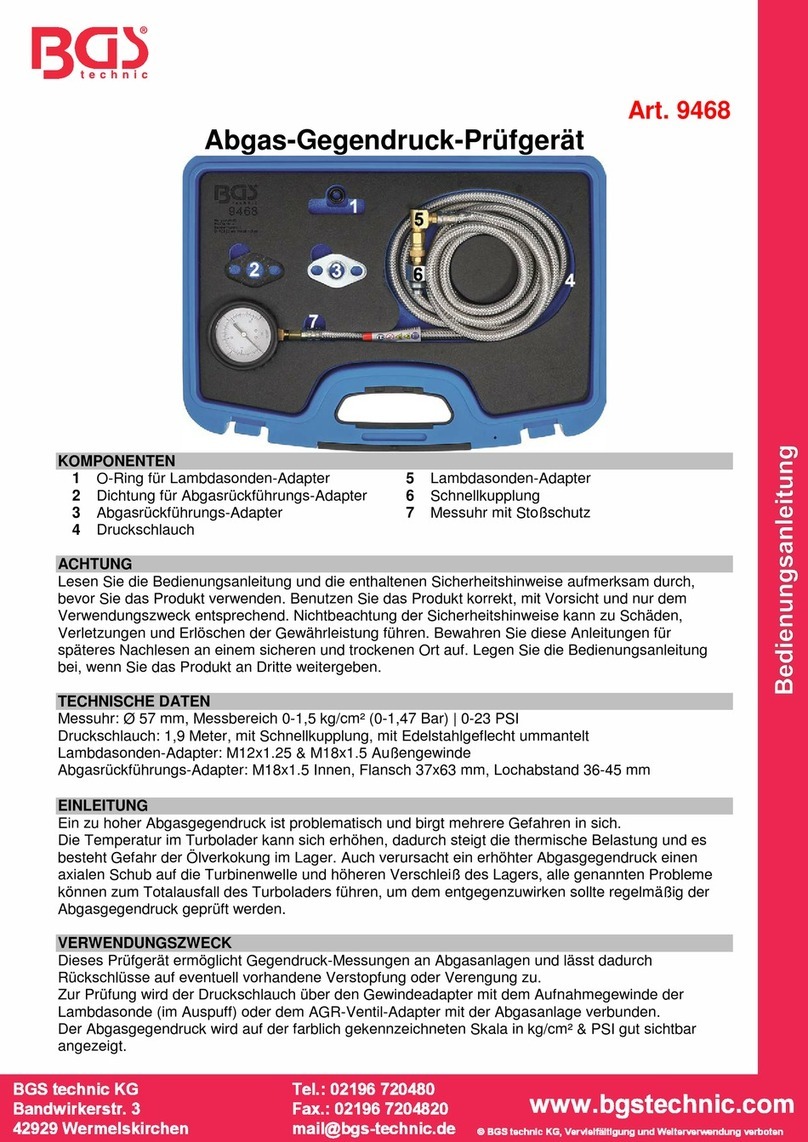

BGS technic 9468 quick start guide

VIAVI Solutions

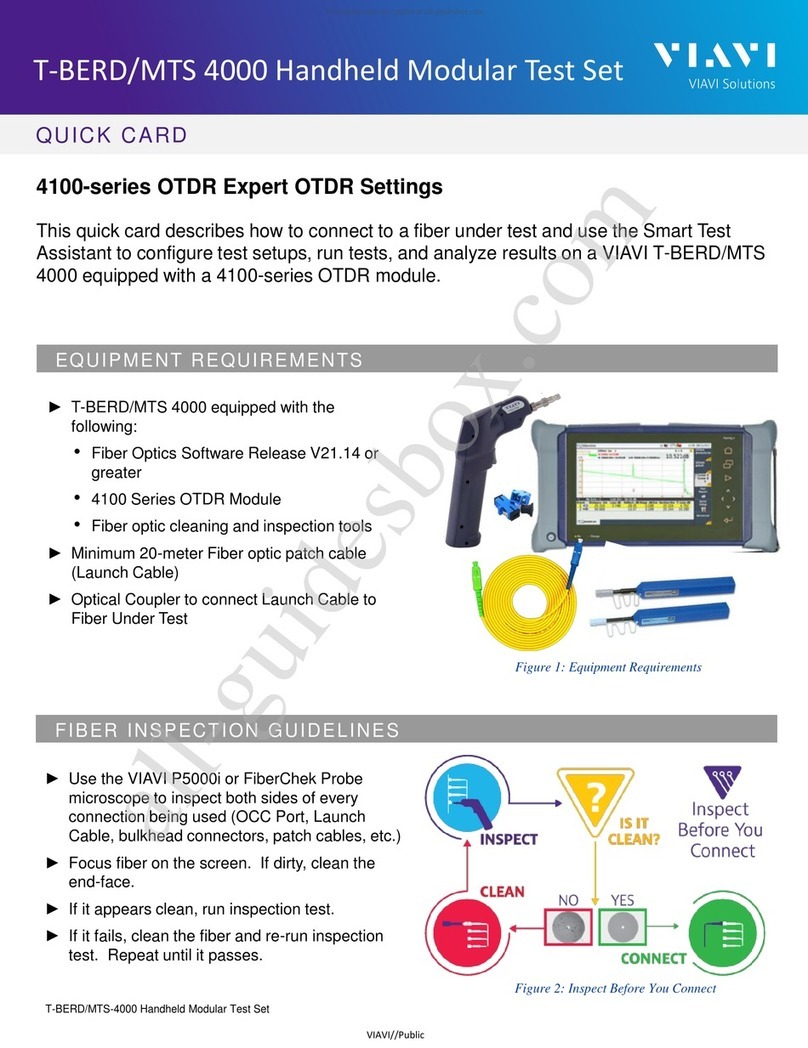

VIAVI Solutions T-BERD/MTS-4000 manual

DATREND Systems

DATREND Systems ES601-US operating manual