Chapter 2: Introduction to Safety Regulations

2.1 The Importance of Testing (User Safety)

In today's world with high consumer awareness, every manufacturer of electrical and electronic products must do their best to

ensure product safety. The design of each product must try its best to prevent the user from getting an electric shock, even if the user

uses it incorrectly, there should be no chance of getting an electric shock. In order to meet generally accepted safety requirements, an

AC ground resistance tester must be used. At present, safety regulations such as UL, CSA, IEC, BSI, VDE and JSI require

manufacturers to use "AC grounding resistance tester" as a safety test when

designing and producing electronics or electronic products.

2.2 The AC Ground Continuity Test

The ground resistance test is mainly to measure the ground resistance between the ground wire of the appliance and the casing.

The measurement method is according to Ohm's law: a current flows through the contact point, and then the current and the voltage

value of the contact point are measured respectively, and then the resistance value is calculated according to Ohm's law. Usually, a

large current flows through, and the condition of the abnormal current generated when the appliance is abnormal is used as the basis

for the test. If the contact resistance of the grounding wire on the appliance can pass the test in this harsh environment, the appliance

should be relatively safe under normal use. In the following situations, the "AC ground resistance tester" must be used to measure the

ground resistance of the ground wire on the appliance:

· Functional test during design: to confirm that the designed product can meet the required conditions.

· Specification testing during production: to confirm that the manufactured products meet the required standards.

· Confirmation test during quality assurance: to confirm that the quality of the product can meet the standards of safety

regulations.

· Safety test after repair: to confirm that the repaired product can meet the safety standards.

Different products have different technical specifications. Basically, safety regulations require a constant current to

flow through the contact point, and this current must be maintained for a specified period of time. If the resistance of

the contact points remains within the specified specifications within the specified time, it can be determined that the

appliance is operating under normal conditions and the appliance should be relatively safe. Proper design and proper

construction can protect users from the threat of electric shock. Although the ground resistance can be measured with a

general resistance meter, the output current of the resistance meter is usually very small, which does not meet the

requirements of safety regulations and cannot be approved by the security inspection agency. It must be measured with a

ground resistance tester. Generally, users will often touch the appliance. The grounding resistance test specification requires

30 amps except for the CSA specification. Most security inspection agencies (such as UL, BSA, TUV, VDE, etc.) require

25 amps, and the resistance value of the contact point must be lower than 100mΩ. At the same time, the current must last

for 60 seconds, and the resistance value must be maintained below 100mΩ. The specifications of appliances that are not

easy to be touched by users are usually looser, generally requiring a current of 10 amperes, and the resistance value of the

contact point is lower than 500 mΩ, but the time is still 60 seconds. There are still some international standards higher

than the above-mentioned standards, and the standard is tested with 5 times the rated input current of the appliance, and

the resistance value of the contact point is still 100 mΩ, and the test time is 60 seconds. Most of these electrical

appliances are dangerous, so the specification requirements are higher than those of ordinary appliances.

In the current safety regulations in the world, some special requirements are first to measure the grounding resistance of the

grounding wire, and the resistance of the contact point must meet the requirements before the "withstanding voltage/insulation test".

This is important to prevent the mistaken belief that the voltage resistance or insulation is good because the ground wire is not

properly connected.

The ground resistance tester has two forms of output AC and DC, both of which can correctly measure the contact resistance

value. But the destructiveness of the two forms to bad contact points is significantly different. Because the calculation basis of the

resistance value is the effective value of voltage and current, and the effective value of DC is the same as the peak value, but the

peak value of AC is 1.414 times of the effective value. Therefore, at the peak of AC, its current value is also 1.414 times of DC. .

When comparing the energy generated by the two at the contact point with the peak point of the AC, according to the power theorem

(power = the square of the current X resistance), the energy generated by the AC peak moment for the contact point is twice that of

the DC.

At present, although the security inspection agency allows the use of both types of grounding test instruments, it especially

recommends the use of AC testers in the selection of ground resistance tester specifications. The above is the main reason. Secondly:

Most of the general appliances use commercial power supply (mains) as the power supply, and the commercial power supply itself is

alternating current, so alternating current is used as the test method.

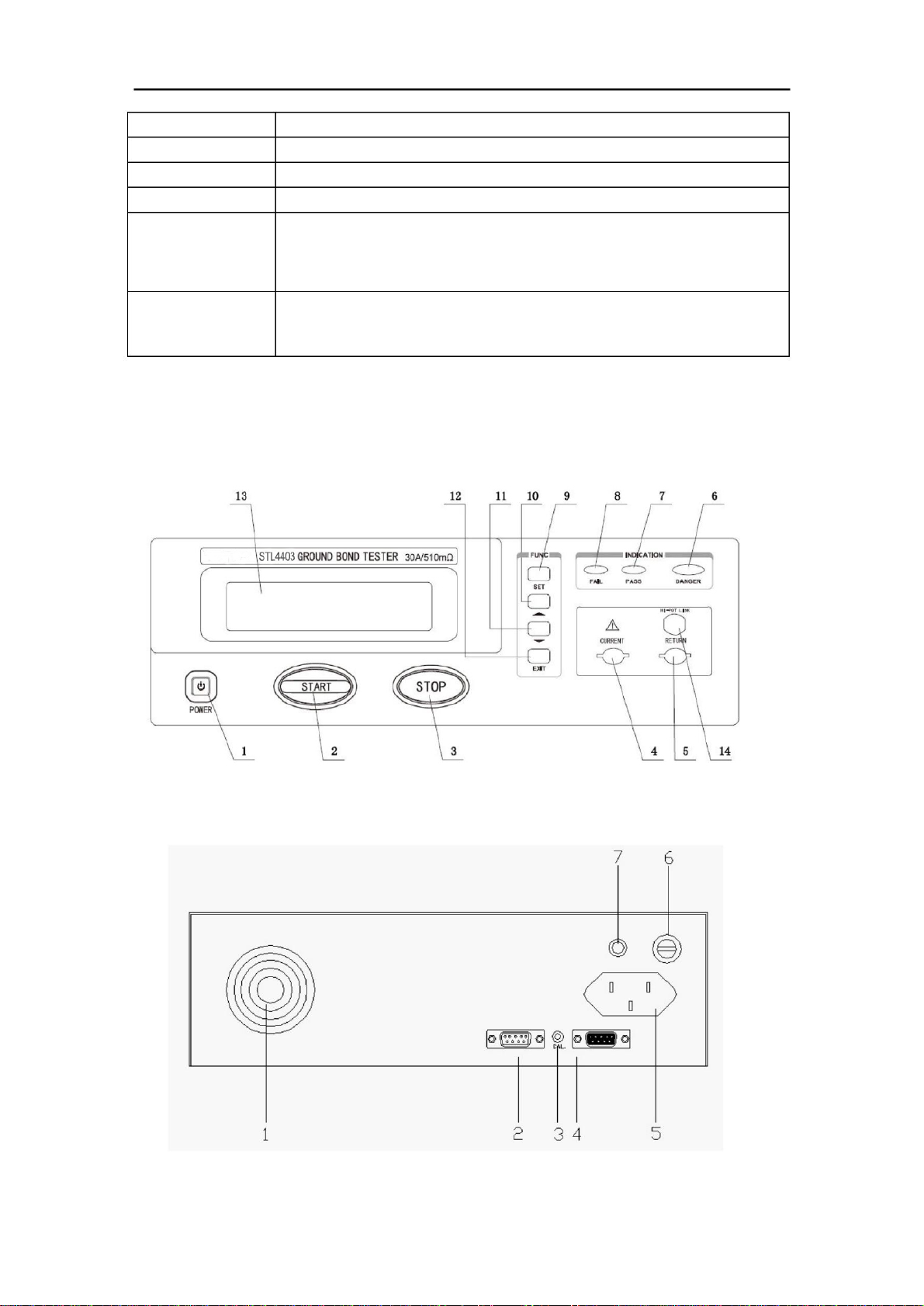

STL4403 Series Ground Bond Tester Operation Manual

2