Electrical Manual

VM16,17,24,25,30 Electronic Orient Spindle

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

Table Of Contents

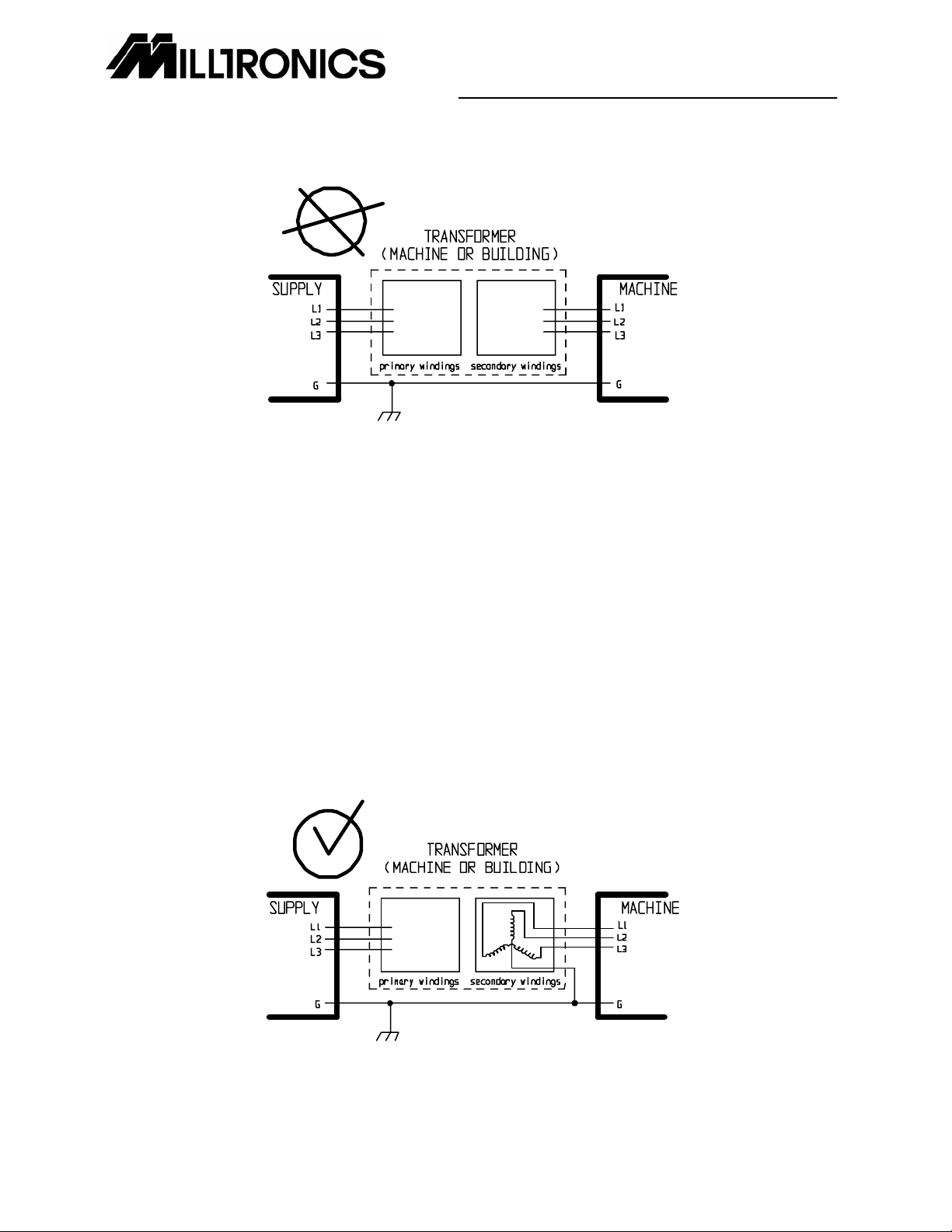

Transformer Connection Alert....................................................................................................................... v

Electrical Safety Rules ................................................................................................................................. vi

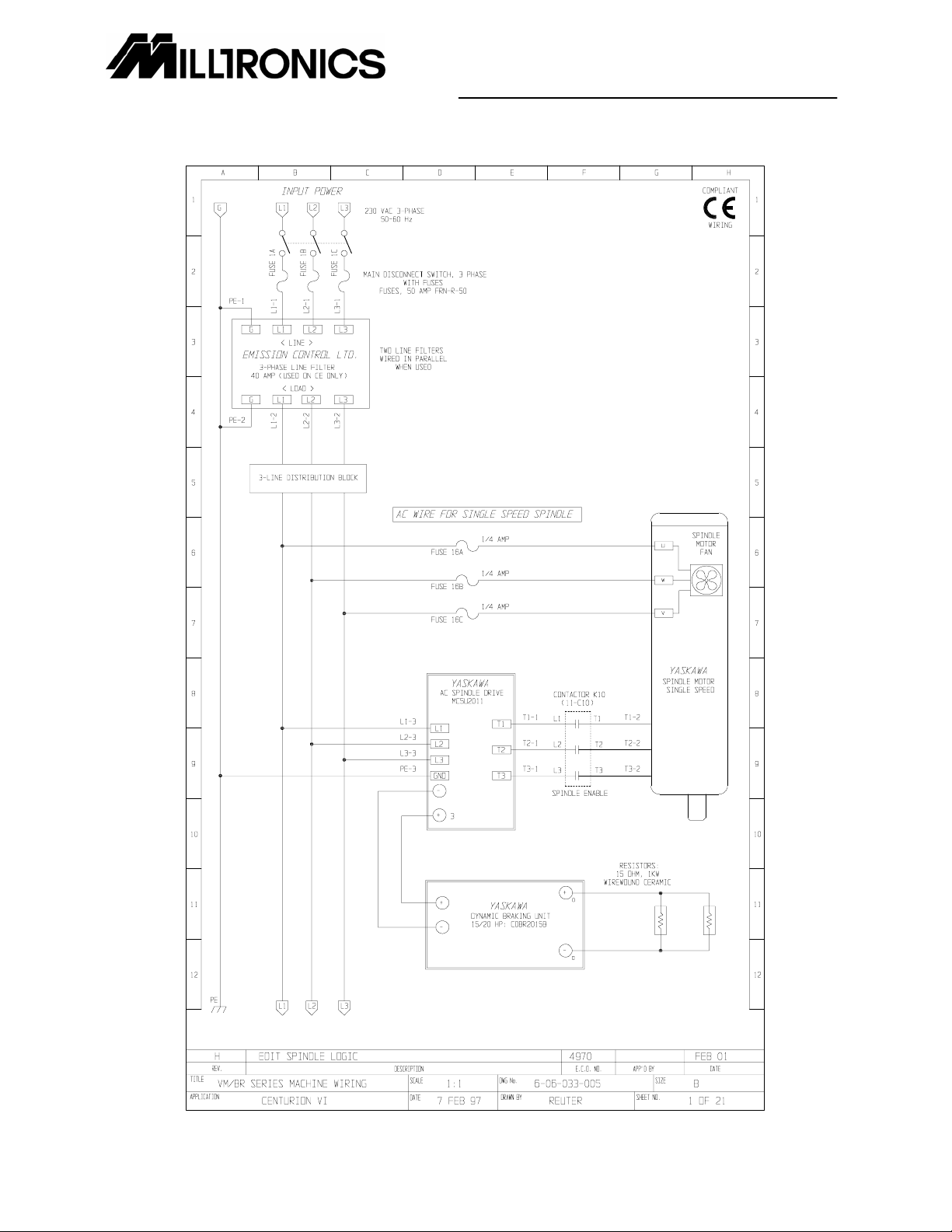

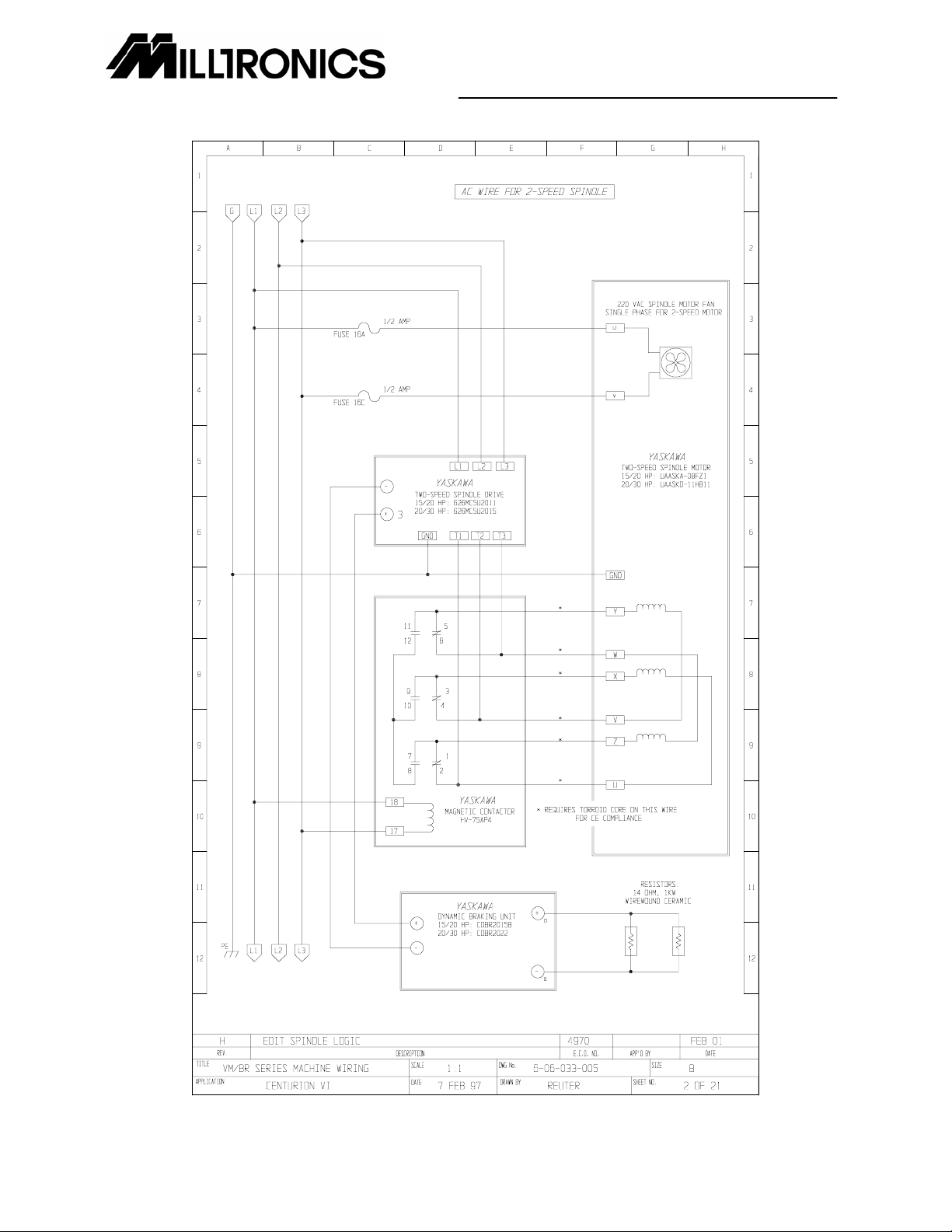

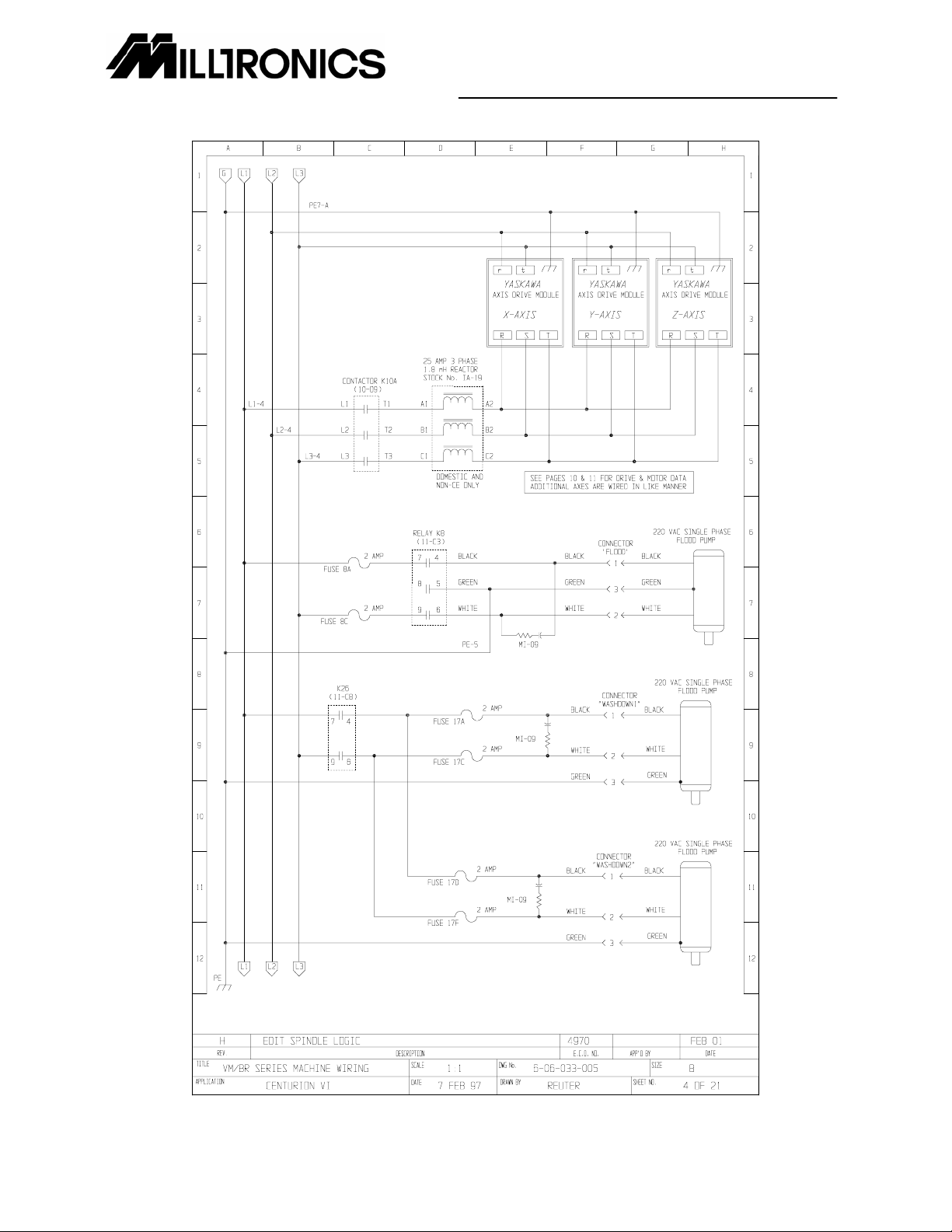

Machine Schematic....................................................................................................................................... 1

Electrical Panel Layout................................................................................................................................ 22

MC5 Spindle Drive Parameters - Single speed 15/10 HP .......................................................................... 26

MC5 Spindle Drive Parameters 22/15 HP .................................................................................................. 29

MC5 Spindle Drive Parameters 30/22 HP .................................................................................................. 32

Yaskawa Axis Drive Parameters................................................................................................................. 35

Partner VM16 & 17 X and Y Drives Model SGDB-10ADG, Z SGDB 15ADG ......................................... 35

Partner VM24 X and Y Drives Model SGDB-10ADG, Z 15ADG ............................................................. 36

Partner VM25 & 30 All Drives Model SGDB-15ADG .............................................................................. 37

Yaskawa Axis Drive Parameters for Troyke Indexers............................................................................. 38

Card Cage Gain Setting Procedure......................................................................................................... 39

Drive Setting Procedure .......................................................................................................................... 40

Centurion 6 CNC Connector Signal Listing................................................................................................. 41

Connector X-Input ................................................................................................................................... 41

Connector Y-Input ................................................................................................................................... 41

Connector Z-input.................................................................................................................................... 41

Connector A-Input ................................................................................................................................... 41

Connector X-Output................................................................................................................................. 41

Connector Y-Output................................................................................................................................. 41

Connector Z-Output................................................................................................................................. 42

Connector A-Output................................................................................................................................. 42

Connectors X, Y, Z, A and B Axis (DC Brush Drives) ............................................................................. 42

Connectors X, Y, Z, A and B Axis (Yaskawa Brushless Drives)......................................................... 42

Axis Home Connector.............................................................................................................................. 42

Spindle Drive Connector.......................................................................................................................... 43

Spindle Encoder Connector..................................................................................................................... 43

Miscellaneous Connector (Misc) ............................................................................................................. 43

Front Panel Connector (FPP) and J2 on keyboard encoder card ........................................................... 43

Power Connector ..................................................................................................................................... 43

Connector Handwheel for remote handwheel option ......................................................................... 43

Connector Tool Changer ......................................................................................................................... 43

Connector COM1 (Card Cage)................................................................................................................ 44

Connector COM2 For rigid tapping option............................................................................................... 44

Connector Floppy Disk ............................................................................................................................ 44

Connector CRT (Video) ........................................................................................................................... 44

Connectors in the CNC control box ............................................................................................................ 44

Connector CRT (Monitor Power)............................................................................................................. 44

Connector FPACC................................................................................................................................... 44

Connector P2........................................................................................................................................... 44

Keyboard DIN Connector (J1) ................................................................................................................. 45

Connectors in the Mag Box......................................................................................................................... 45

Connectors ATC1 and 1-1E .................................................................................................................... 45

Connector ATC2...................................................................................................................................... 45

Connector on +24 VDC Regulated Power Supply .................................................................................. 45

Connector COM1 (on Mag Panel) ........................................................................................................... 45

Card Cage Assembly .................................................................................................................................. 46

LCD Front Panel Assembly......................................................................................................................... 52

LCD Chassis Assembly............................................................................................................................... 54