PELLERIN MILNOR CORPORATION

2.2. Kit 08PSS3401N (for Older Machines)

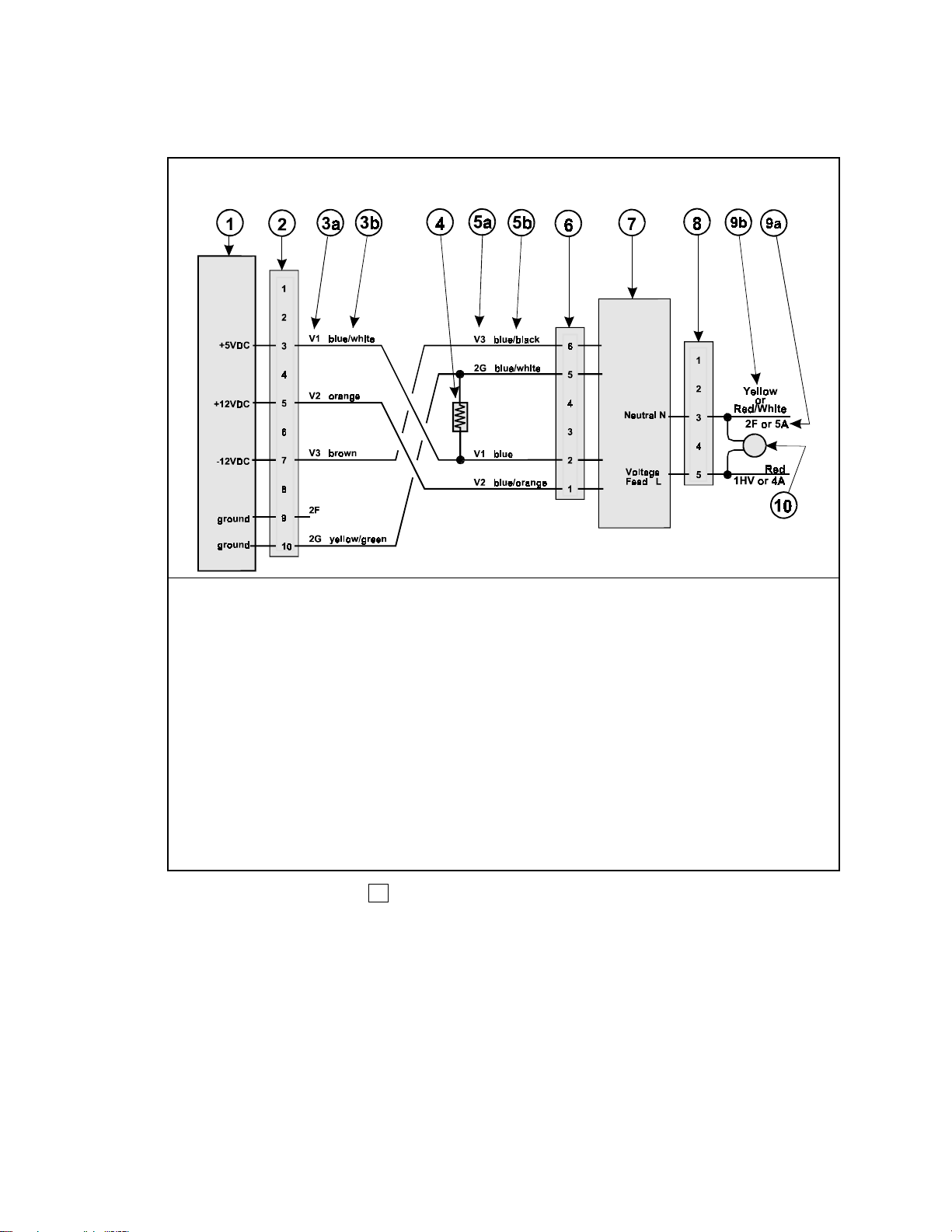

2.2.1. Power Supply-to-Power Source Connections—All Machines—Even if the old

connector (the one that was attached to the old power supply) matches the one supplied with the

kit, cut it off to facilitate installing the MOV. The MOV must be installed across the power

supply's incoming power conductors as shown in Figure 2. Splice the new harness and the leads

of the MOV to the wires from the power source using two of the white caps provided with the

kit. Match the wires as shown in Figure 2. The incoming power conductors are polarity-sensitive

but the MOV is not.

2.2.2. Processor-to-Power Suppl

Connections—Coin, Sin

le Formula, S

stem 7

and

E-P Plus®Type Washer-Extractors—The regulating resistor shown in Figure 2 must be

included when installing a new power supply on these machines. Attach this resistor across wires

2G (blue/white, ground) and V1 (blue, +5VDC) on the six-pin wire harness supplied with the kit,

using two of the white caps provided. Cut off the old connector (the one that was attached to the

old power supply) and splice the new harness to the wires from the connector on the processor

board, matching the wires as shown in Figure 2.

2.2.3. Processor-to-Power Supply Connections—Other Machines—If your original

processor-to-power supply wire harness has the same six-pin connector and same color wires as

the one supplied with the kit, you may simply attach the existing connector to the new power

supply. If not, cut off the old connector (the one that was attached to the old power supply) and

splice the new harness to the wires from the connector on the processor board using two of the

white caps provided, matching the wires as shown in Figure 2.

3. Testing and Adjusting the New Power Supply

The new power supply will need to be tested and adjusted when first installed. It may also need to

be tested and adjusted in the future, if problems with the microprocessor controller are

encountered. Adjustment instructions are provided on tag B2TAG92078, supplied with the kit.

Please install this tag inside the Processor box, for reference, and observing the precautions given

in warning statement 1 and caution statement 4 , perform the procedures explained on this

tag.

CAUTION 4 : Machine Malfunction Hazard—The power supply was adjusted at the

factory for 120VAC input and will not function properly with 240VAC input until re-adjusted.

• Test and adjust as explained on the tag supplied.

— End of BICUUR01 —