ii Pellerin Milnor Corporation

Figure 6 Stanchions to Floor ...................................................................................................16

Figure 7 Unistrut Beam Brackets and Hardware ....................................................................16

Figure 8 Example of Unistrut Cross Bracing ..........................................................................17

Figure 9 Additional Unistrut Beam Connectors......................................................................17

Figure 10 Upper Elevator Connected to Unistrut .....................................................................18

Figure 11 Bracket Assemblies by Height and Direction...........................................................20

Figure 12 Unistrut to Unistrut Support Bracket Lengths ..........................................................21

Figure 13 Rail Slope for Design and Installation......................................................................22

Figure 14 Slope of Rail Sections...............................................................................................22

Figure 15 Bracket Assemblies by Height and Direction...........................................................23

Figure 16 Unistrut to Rail Support Brackets.............................................................................24

Figure 17 Unistrut to Rail Support Brackets, Continued ..........................................................25

Figure 18 Discharger to Rail Installation ..................................................................................34

Figure 19 Discharger Parts and Cylinder Adjustments.............................................................35

Figure 20 Elevator Components, Soft Sling & Hard Ring........................................................38

Figure 21 Hoist, Frame, & Covers ............................................................................................39

Figure 22 Rail Carrier ...............................................................................................................40

Figure 23 Double Chain Hoist Drive ........................................................................................41

Figure 24 Hoist Switch Settings................................................................................................42

Figure 25 Pneumatic Elevator Frame Components...................................................................46

Figure 26 Elevator Frame Settings and Cylinder Mounting .....................................................47

Figure 27 Carriage Sub-Assembly ............................................................................................48

Figure 28 Rail Settings, Hardware, and Alignment ..................................................................49

Figure 29 Stops and Rail Alignment .........................................................................................56

Figure 30 Stop Components and Air Cylinder Setting .............................................................57

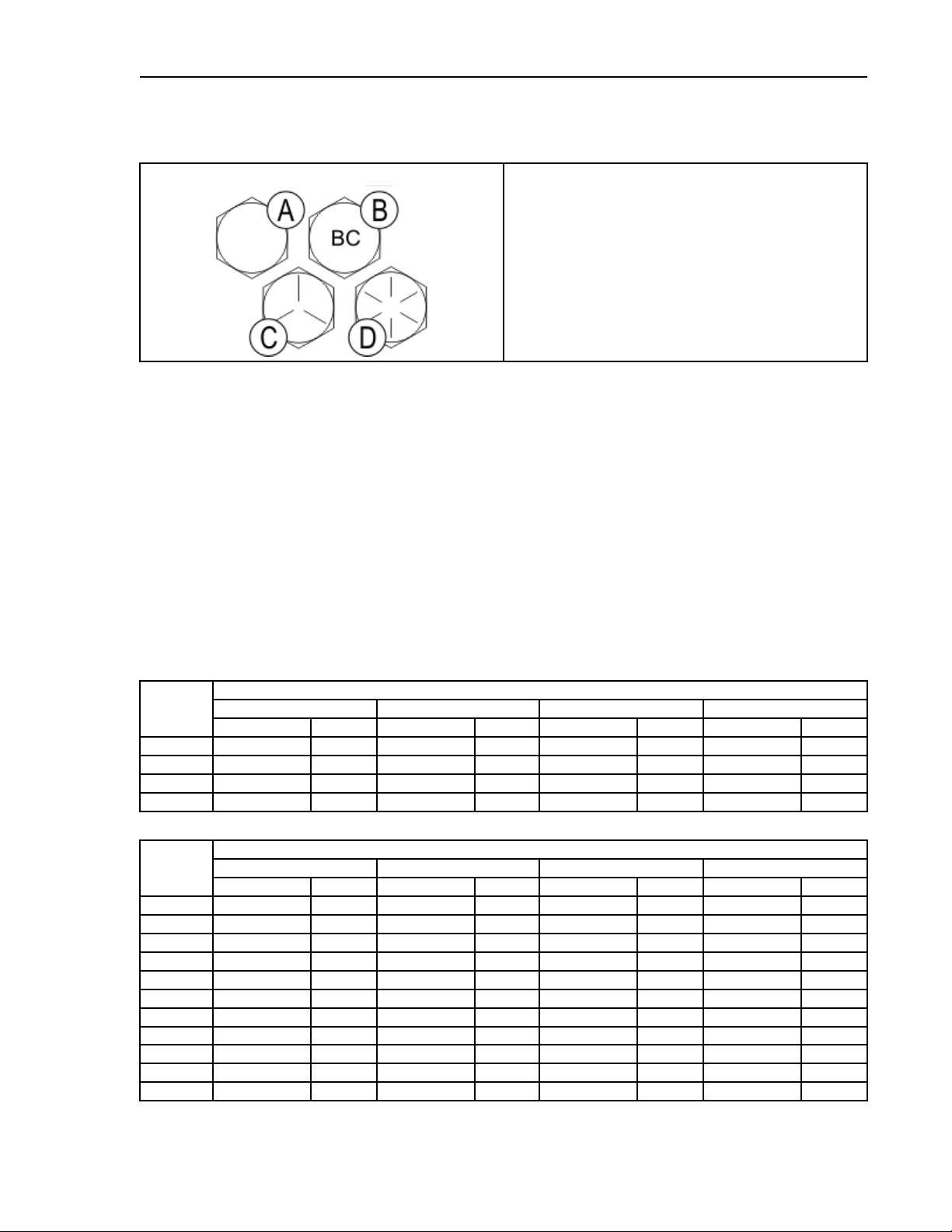

Tables

Table 1 Torque Values for Standard Fasteners with Maximum 5/16-inch Diameters and

No Lubricant ..............................................................................................................7

Table 2 Torque Values for Standard Fasteners Larger Than 5/16-inch Diameters and

No Lubricant ..............................................................................................................7

Table 3 Torque Values for Plated Fasteners with Maximum 5/16-inch Diameters and

No Lubricant ..............................................................................................................8

Table 4 Torque Values for Plated Fasteners Larger Than 5/16-inch Diameters and No

Lubricant ....................................................................................................................8

Table 5 Threadlocker by the Diameter of the Bolt (see below Note ) ....................................9

Table 6 Torque Values if You Apply LocTite 222 ..................................................................9

Table 7 Torque Values if You Apply LocTite 242 ..................................................................9

Table 8 Torque Values if You Apply LocTite 262 ................................................................10

Table 9 Torque Values if You Apply LocTite 272 (High-Temperature) ...............................10

Table 10 Torque Values if You Apply LocTite 277 ................................................................10

Table 11 Torque Values for Stainless Steel Fasteners 5/16-inch and Smaller ........................11

Table 12 Torque Values for Stainless Steel Fasteners Larger Than 5/16-inch .......................11

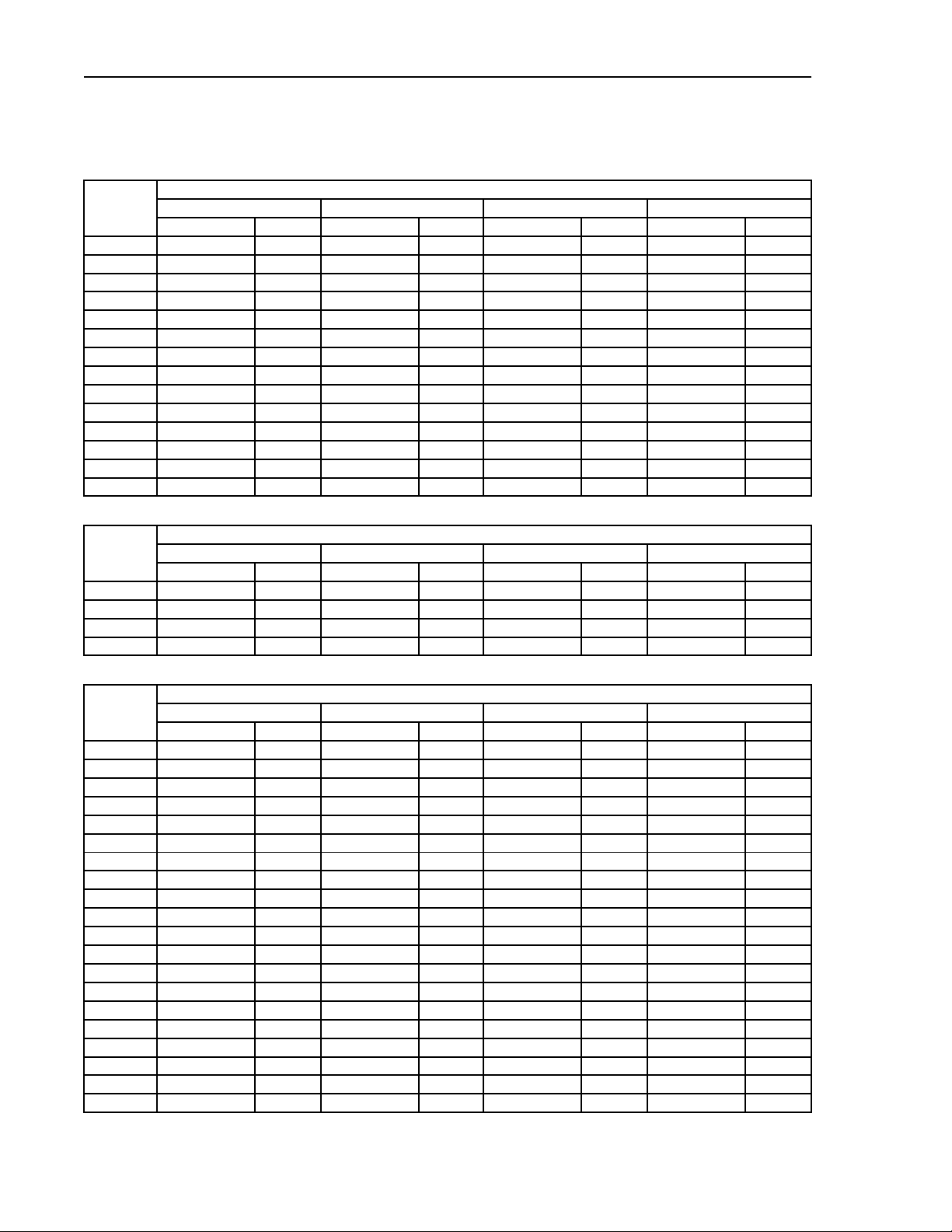

Table 13 Parts List—Stanchion and Beam Connections ........................................................18

Table 14 Parts List—Unistrut Support Brackets Hardware ....................................................21

Table 15 Parts List—Rail Support Brackets ...........................................................................26

Table 16 Parts List—Rail Joiner .............................................................................................27

Contents