Minco AS8 Series Installation instructions

Minco Document Number 1148912 Page 1 of 5

SPI 75-1087 Appendix A (Rev. F)

Installation & Operation Instructions

AS8xx Flameproof Assemblies

II 2 G Ex db eb IIC TX Gb IP66

IECEx Ex db eb IIC TX Gb IP66

Warning

Avertissement

Warnung

Advertencia

Follow these cautions:

•Do not open while energized.

•Do not open cover when explosive atmosphere is present.

•When measuring the temperatures of fluids above 40°C using assemblies with transmitters, do not

operate in an atmosphere that could ignite at a temperature 45°C above the fluid temperature.

•When measuring the temperature of fluids above 55°C using assemblies without transmitters, do not

operate in an atmosphere that could ignite at a temperature 30°C above the fluid temperature.

•

Ne pas ouvrir sous tension.

•Ne pas ouvrir en presence d’atmosphere dangereuse.

•Assemblages avec transmetteur : lorsque la température du fluide est supérieure à 40°C, ne pas utiliser

dans une atmosphère dont la température d’inflammation est inférieure ou égale à la température du

fluide, augmentée de 45°C.

•Assemblages sans transmetteur : lorsque la température du fluide est supérieure à 55°C, ne pas utiliser

dans une atmosphère qui pourrait s'enflammer à une température inférieure ou égale à la température

du fluide, augmentée de 30°C.

•Deckel nicht unter Spannung öffnen.

•Deckel in explosiver Atmosphäre nicht öffnen.

•Wenn sie die Temperaturen von Flüssigkeiten über 40°C messen (Baugruppen mit Messumformern)

führen sie das nicht in einer Atmosphäre durch, die sich bei 45°C über der Flüssigkeitstemperatur

entzünden könnte.

•Wenn sie die Temperaturen von Flüssigkeiten über 55°C messen (Baugruppen ohne Messumformern)

führen sie das nicht in einer Atmosphäre durch, die sich bei 30°C über der Flüssigkeitstemperatur

entzünden könnte.

•Peligro no lo abra bajo presion.

•No quite la tapa en la presencia de una atomsfera explosiva o inflammable.

•Cuando mida temperaturas de fluidos que sobrepasen los 40°C usando ensamblages sin transmisores

no opere en una atmosfera o ambiente que pueda iniciar fuego a temperatura de 45°C o, que

sobrepase la temperatura del fluido a medirse.

•Cuando mida temperaturas de fluidos que sobrepasen los 55°C usando ensamblages sin transmisores

no opere en una atmosfera o ambiente que pueda iniciar fuego a temperatura de 30°C o, que

sobrepase la temperatura del fluido a medirse.

Declaration

EC Declaration of Conformity

Temperature Detector Assemblies Type: Series AS8xx

The product defined above complies with the following standards:

EN 60079-0:2012 Explosive atmospheres - Part 0: Equipment - General requirements

EN 60079-1:2007Explosive atmospheres - Part 1: Equipment protection by flameproof enclosures "d"

EN 60079-7:2007 Explosive atmospheres - Part 7: Equipment protection by increased safety "e"

IEC 60079-0:2011 Explosive atmospheres - Part 0: Equipment - General requirements

IEC 60079-1:2007-04 Explosive atmospheres - Part 1: Equipment protection by flameproof enclosures "d"

IEC 60079-7:2006-07 Explosive atmospheres - Part 7: Equipment protection by increased safety "e"

Certificate TRAC14ATEX0045X EC-Type Examination Notified Body: DEKRA Certification B.V. (0344)

Certificate IECEx TRC 14.0017X Quality Assurance Notified Body: DEKRA Certification B.V. (0344)

TRaC Global Ltd. (0891)

Unit 1 Pendle Place

Skelmersdale

West Lancashire, WN8 9PN

United Kingdom

04 November 2014

!

Minco Document Number 1148912 Page 2 of 5

AS8xx Flameproof Assemblies, Continued

Marking

Examples

Examples of the marking are pictured below.

CONDUIT THR: DATE#: Tprocess:

ASSEMBLY/ASSEMBLAGE:

TRAC14ATEX0045X

II 2G Ex db eb IIC TX Gb

Ta: -50 to +55°C

0344 UMAX: 45VDC

IMAX: 30mA

PMAX: 1.35W

DO NOT OPEN WHEN EXPLOSIVE ATMOSPHERE IS PRESENT

NE PAS OUVRIR EN PRESENCE D'ENVIRONNEMENT EXPLOSIF

IECEx TRC 14.0017X

TRAC14ATEX0045X

II 2G Ex db eb IIC TX Gb

Ta: -50 to +55°C

0344

Tprocess: -50 to 260°C

UMAX: 45VDC

IMAX: 30mA

PMAX: 1.35W

IECEx TRC 14.0017X

Flameproof

Assembly

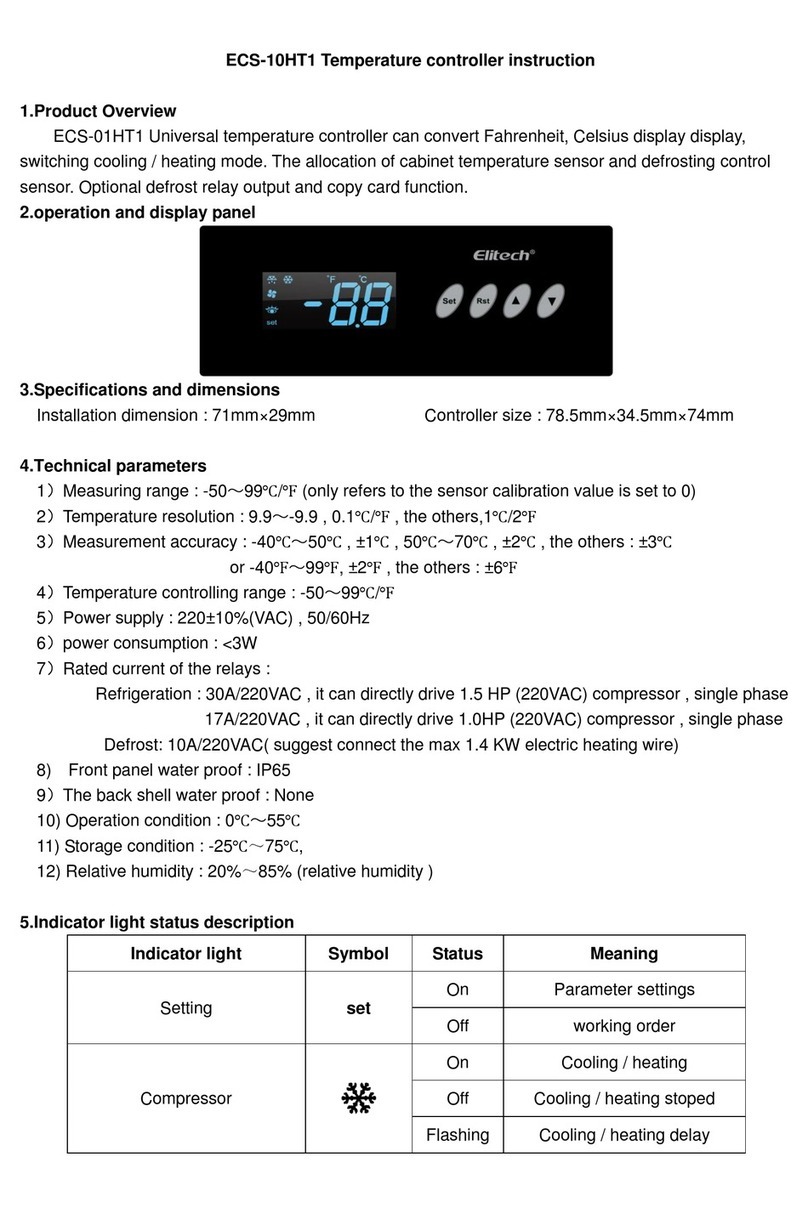

The flameproof assembly is pictured below.

(MODEL CH356, 357 OR 358)

Follow the step below to prepare to install a flameproof assembly.

1.

Unscrew the connection head from the spring-loaded holder or fluid seal fitting. This is hand-tight

and should not require tools.

Conditions for safe use:

Assemblies have been tested and approved with a maximum diametrical gap of 0.13 mm between the

probe and spring loaded holder or fluid seal fitting. Contact the manufacturer when replacing any

components of this assembly.

Fluid Seal

Fitting Assembly

A probe sensor with a fluid seal fitting is pictured below.

Follow the steps below to install a fluid seal fitting assembly.

1.

Loosen sealing nut on fitting and remove probe.

2.

Thread fluid seal fitting into place and slide the probe, tip first, into place.

3.

Tighten using an open-end or adjustable wrench.

4.

Screw the connection head onto the back of the spring-loaded holder and hand-tighten.

Continued on next page

Minco Document Number 1148912 Page 3 of 5

AS8xx Flameproof Assemblies, Continued

Spring-Loaded

Holder Assembl

y:

Adjustable

S

et Screw Style

A probe sensor with an adjustable set screw style of spring-loaded holder is pictured below.

Follow the steps below to install the adjustable set screw type of spring-loaded holder assembly.

1.

Loosen set screw on spring-loaded holder release knob and remove probe.

2.

Thread spring-loaded holder into place and tighten with an open-end or adjustable wrench.

3.

Slide probe, tip first, through spring-loaded holder into place until it bottoms out.

4.

Pull back release knob approximately 1/2" and tighten set screw to secure probe.

5.

Screw connection head onto the back of spring-loaded holder and hand-tighten.

Spring-Loaded

Holder Assembl

y:

Release

Knob Style

The motions for operating a spring-loaded holder are pictured below.

Follow the steps below to install the release knob type of spring-loaded holder assembly.

1.

Grasp release knob, pull it out, and twist approximately 1/2 turn clockwise against the stop. Push in

to lock open.

2.

Remove the probe.

CAUTION: Do not pull on probe leadwires.

3.

Install the spring-loaded holder into a 1/2-14 NPT female thread in the machining housing.

4.

Insert the probe (tip first) through the hole in release knob of spring-loaded holder. Push the probe

slowly through o-ring seal until it contacts the surface to be sensed.

NOTE: Spring loading is only required when surface or bearing temperature is being monitored.

When monitoring liquid or gas temperature, spring-loading is not required, however probe should

be inserted 1/4" short of desired depth.

5.

Grasp release knob, pull out, twist it approximately 1/2 turn counter clockwise against the stop and

release.

NOTE: If the probe is not bearing against a surface, the knob will move fully inward,

(approximately 1/4" when release), and will lock the probe in position.

6.

After installation, probe depth may be adjusted or probe may be removed by operating release

knob as in steps 1-5.

7.

Screw the connection head onto the 3/4-14 NPT thread of the spring-loaded holder and tighten.

Continued on next page

Minco Document Number 1148912 Page 4 of 5

AS8xx Flameproof Assemblies, Continued

Spring-Loaded

Holder Assembly

:

Fixed

-Spring Style

This holder is factory installed in the correct position and cannot be removed from, or repositioned on the

probe. A fixed-spring probe sensor with a probe fitting is pictured below.

MOUNTING PLATE

Follow the steps below to install the fixed-spring holder assembly.

1.

Thread the holder into the thermowell.

2.

Tighten using a 7/8" open-end or adjustable wrench.

3.

Screw the connection head onto the back of the spring-loaded holder and hand-tighten.

4.

Slide the probe, tip first, into thermowell.

5.

Secure mounting plate to the inside of the connection head using the two #6-32 screws provided.

Conditions for safe use:

The IP66 rating does not apply to the fixed-spring holder assembly.

Welded Fitting

This fitting is factory-welded in the correct position and cannot be removed from, or repositioned on the

probe. A probe with a welded fitting is pictured below.

Follow the steps below to install a probe with a welded fitting.

1.

Slide the probe, tip first, into position.

2.

Thread the fitting into the process connections.

3.

Tighten using a 7/8" open-end or adjustable wrench.

Continued on next page

7300 Commerce Lane North

Minneapolis, MN 55432

Tel 763.571.3121 | Fax 763.571.0927

AS8xx Flameproof Assemblies, Continued

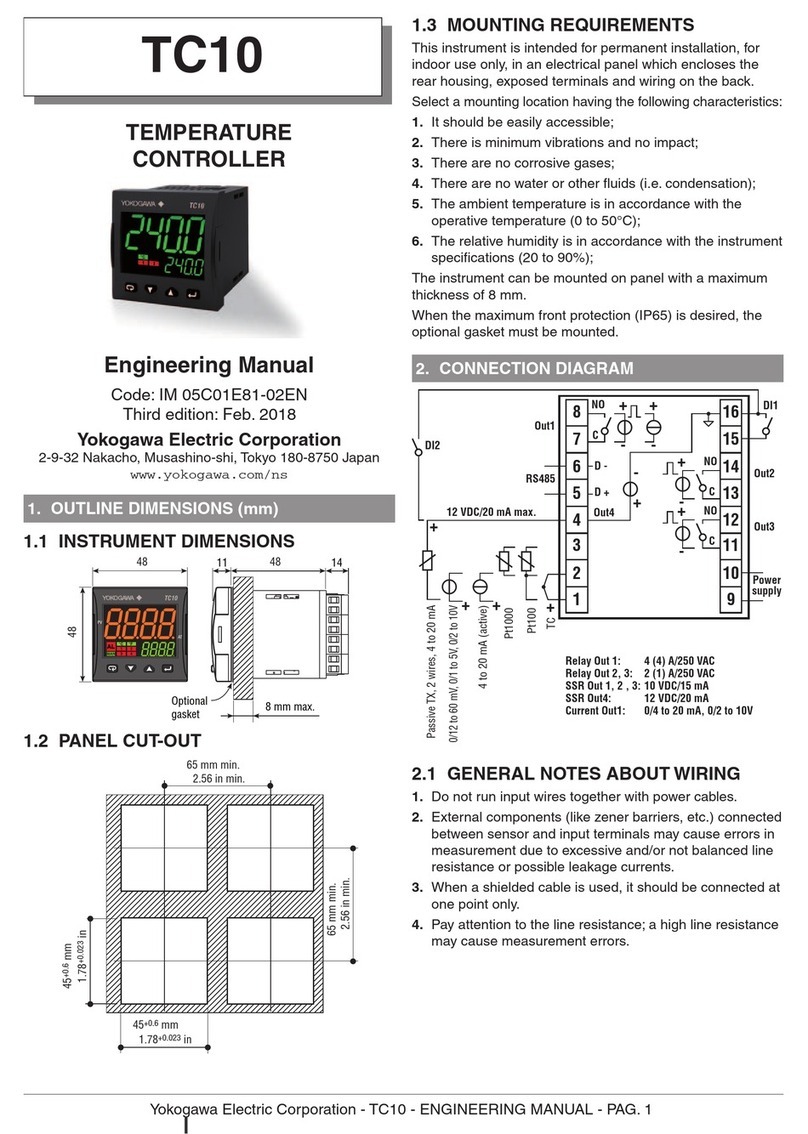

Diagrams of electrical connections are below.

Electrical

Connections

Single Element RTD

Dual Element RTD

Follow these guidelines to connect the RTD probe to external wiring.

NOTE: If assembly contains a transmitter, skip this section and see special instructions, manual number 974MN,

4-20 mA Current Transmitters with Wire Leads or Terminal Block Connections.

•Make connection to external wiring using connectors provided (terminals or wire nuts). See the schematic

diagrams above for probe leadwire color code. External wiring and conduit must be in accordance with all

applicable electrical codes for the specific hazardous atmosphere.

•The cable entry devices shall be of a certified flameproof type, suitable for the conditions of use and correctly

installed.

•With the use of conduit, a suitable certified sealing device such as a stopping box with compound shall be

provided immediately at the entrance to the flameproof enclosure.

Special Conditions of Safe Use

1. Overall temperature class of the assemblies is determined by process temperature as stated below.

Tprocess [°C]

Temperature class of

the assembly

Max. surface temperature

of the assembly [°C]

80

T6

85

95

T5

100

130

T4

135

190

T3

200

290

T2

300

440

T1

450

< 440

-

Tprocess +10

Alternatively the temperature class may be determined by temperature measurement on the actual

installation. This must be performed when no flammable atmosphere is present. The hottest point

shall be established – typically the closest part to where the equipment passes through a boundary

wall into the hot zone.

2. Set Screw or Release Knob type fittings shall not be used with process temperatures ≥260°C.

Magnesium oxide probe types may be used for process temperatures up to 600°C.

Si ngl eJunct i onTher mocoupl e Dual Junc t i onTher mocoupl e

Page 5 of 5

Other Minco Temperature Controllers manuals