Minco CT15 Series User manual

1

INSTRUCTIONS FOR THE CT15 SERIES

MICROPROCESSOR BASED

TEMPERATURE CONTROLLER

MODELIDENTIFICATION

Alarm

0 = No

1 = Yes

Input

1=Thermocouple, J, K, T

2=100Ω Platinum RTD

(DIN), element PD

Model CT15

Output

1=SSR

2=5 VDC

3=Relay

Page 12 of 12

LIMITED WARRANTY

Minco Products, Inc. warrants to the Buyer that any equipment sold will be free from

defects in material or workmanship. If, at any time within thirtysix (36) months after

shipment of CT15 Series Controls or within three (3) months after shipment of other

assembliesorparts,theSellerisnotifiedofsuchdefectandthedefectiveitemisreturned

to Seller by Buyer, transportation prepaid, for examination, the Seller will, at his option,

either repair or replace the defective items.

Thiswarrantyshallbeeffectiveonlyifinstallationandmaintenanceisinaccordancewith

Seller's instructions and the defect is not caused by shipping damage, misuse or abuse

by the Buyer. There are no other warranties, written, oral, or implied. The liability of the

Seller is limited to the repair or replacement of the defective item as set forth above.

Itemswhichwearorareperishable bymisusearenotwarranted. Theseinclude, butare

not limited to, relays, contact points, lamps, LEDs, load SCRs, SSRs, and triacs.

(All dimensions in mm with inches in parentheses.)

Panel cutout for all models 45 mm X 45 mm (1.775" X 1.775"). Allow for

13 mm (0.5") clearance at the rear of instrument.

*Present for SSR and 5 VDC output.

G:\MOD\CT15\LIT\759MN.PM5

7/03

360-00066

© 1994, MINCO PRODUCTS, INC. ALL RIGHTS RESERVED. NO PORTION MAY BE COPIED WITHOUT THE

EXPRESS WRITTEN CONSENT OF MINCO PRODUCTS, INC.

DIMENSIONS

Page 2 of 12

TABLE OF CONTENTS

INPUTWIRING .......................................................................................................................3

INSTALLATION.......................................................................................................................3

WIRING ...................................................................................................................................4

FRONT PANEL KEY FUNCTIONS..........................................................................................4

SECURITYLEVELSELECTION .............................................................................................5

MENU SELECTIONS .............................................................................................................6

PRIMARYMENU.....................................................................................................................6

SECONDARYMENU ..............................................................................................................6

SECUREMENU ......................................................................................................................7

ALARM TYPE AND ACTION...................................................................................................8

DIAGNOSTICERRORMESSAGES .....................................................................................10

SPECIFICATIONS.................................................................................................................11

DIMENSIONS........................................................................................................................12

GETTING STARTED

1. Installthe controlas describedon page3.

2. Wireyourcontrol followingtheinstructionson page3and drawingonpage4.

3. Mostcontrolsdonotneedmany(ifany)programchangestoworkonyourprocess. Forbest

results if programming changes are necessary, make all the necessary changes in the

SECUREMENU(page7)beforemakingchangestotheSECONDARYMENU(page6). If

errormessagesoccur,checktheDiagnosticErrorMessagesonpage10forhelp.

Take the example of a Model CT15011 that comes from the factory programmed for type J

thermocouples. SupposeforthisexampleyouwishtochangetheinputtotypeKandlimitthe

setpointrangebetween0° and1000°C.

First,entertheSECUREMENUasinstructedonpage7. PresstheINDEXkeyuntilthedisplay

shows

Inp

andpresstheDOWNARROWuntilthedisplayshows

CA

. Don'tforgettopressthe

ENTERkey toretainyour setting.

Next,presstheINDEXkeytodisplay

F-C

. PresstheDOWNARROWuntilthedisplayshows

C

.

PressENTER.

Next,presstheINDEXkeyuntil

SPL

isdisplayed(passthe

dPt

and

InPt

selections). Pressthe

UP ARROW until the display shows

0

. PressENTER.

Finally, press INDEX key to display

SPH

. Press the DOWN ARROW until the display shows

1000

. PressENTER.

Thenecessary program changes are now complete. After 30 seconds thedisplay will switch

backtothetemperaturereading. Ifyouwanttoreturnfaster,presstheUPARROWandENTER

keys(atthesametime)andthenpresstheDOWNARROWandINDEXkeys(againatthesame

time). Thiswill'back out'ofthemenu andimmediatelydisplay thetemperaturereading.

Page 11 of 12

Input Type

-

Temperature

Range & Unit

of measure

1°F

1°C

Type J

Iron-

Constantan

-100 to +1600

-73 to +871

Type K

Chromel-

Alumel

-200 to +2500

-129 to +1371

Type T

Copper-

Constantan

-350 to +750

-212 to +398

Input Ranges (as ordered)

ThermocoupleTypes

SPECIFICATIONS

Selectable Inputs: Thermocouple or RTD as ordered.

Input Impedance:

Thermocouple = 3 megohms minimum. RTD current = 200 uA.

Sensor Break Protection: De-energizes control output to protect system.

Set Point Range: Selectable (See range chart above).

Display: One; 4 digit, 7 segment, 0.3" high LEDs.

Control Action: Selectable for Reverse (usually heating) or Direct (usually cooling).

Ramp: One ramp time adjustable from 0 to 100 hours.

Proportional Band: 5 to 5000 °F or equivalent °C.

ResetTime (Integral): Off or 0.1 to 99.9 minutes.

RateTime (Derivative): Off or 0.01 to 99.99 minutes.

Cycle Rate: 1 to 80 seconds, and on-off.

On - Off Differential: Adjustable 1° F to 999°F in 1° steps (equivalent °C).

Alarm On - Off Differential: 2° F or equivalent in °C.

Accuracy: ±0.25% of span, ±1 degree.

Resolution: 1 degree or 0.1 degree, selectable.

LineVoltage Stability: ±0.05% over the supply voltage range.

Temperature Stability: 4µV/°C (2.3 µV/°F) typical, 8 µV/°C (4.5 µV°F) maximum.

Common Mode Rejection: 140 db minimum at 60 Hz.

Normal Mode Rejection: 65 db typical, 60 db at 60 Hz.

Isolation: Relay and SSR outputs are isolated. 5VDC output must not share a common

ground with the input.

SupplyVoltage:100to240VAC,nom.,+10-15%,50to400Hz.singlephase;132to240

VDC, nom., +10 -20%.

Power Consumption: 5VA maximum.

OperatingTemperature Range: -10 to +55 °C (+14 to 131 °F).

StorageTemperature Range: -40 to +80 °C (-40 to 176 °F).

Operating Humidity Range: 0 to 90% up to 40 °C non-condensing. 10 to 50% at 55 °C

non-condensing.

Memory Backup: Non-volatile memory. No batteries required.

Control Output Ratings:

1. SSR, 3.5 A @ 250 VAC at 25 °C. Derates to 1.25 A @ 55 °C. Minimum 48 VAC and

100 mA required.

2. Switched voltage (non-isolated): 5 VDC @ 25 mA.

3.Relay,FormAcontact(SPST),3A@250VACresistive;1.5A@250VACinductive;

Pilot Duty Rating: 250 VA, 2 A @ 125 VAC or 1 A @ 250 VAC.

Alarm Relay Rating: Same as Control Output Relay.

Weight: 227 g (8 oz).

Agency Approvals: UL E83725, and CSA LR40125.

Front Panel Rating (non-hazardous locations): Designed to meet UL 4X for non-

hazardous locations (equal to NEMA rating).

100 Ohm Platinum

0.00385 DIN Curve

element code PD

-328 to +1607

-200 to +875

RTDType

Page 3 of 12

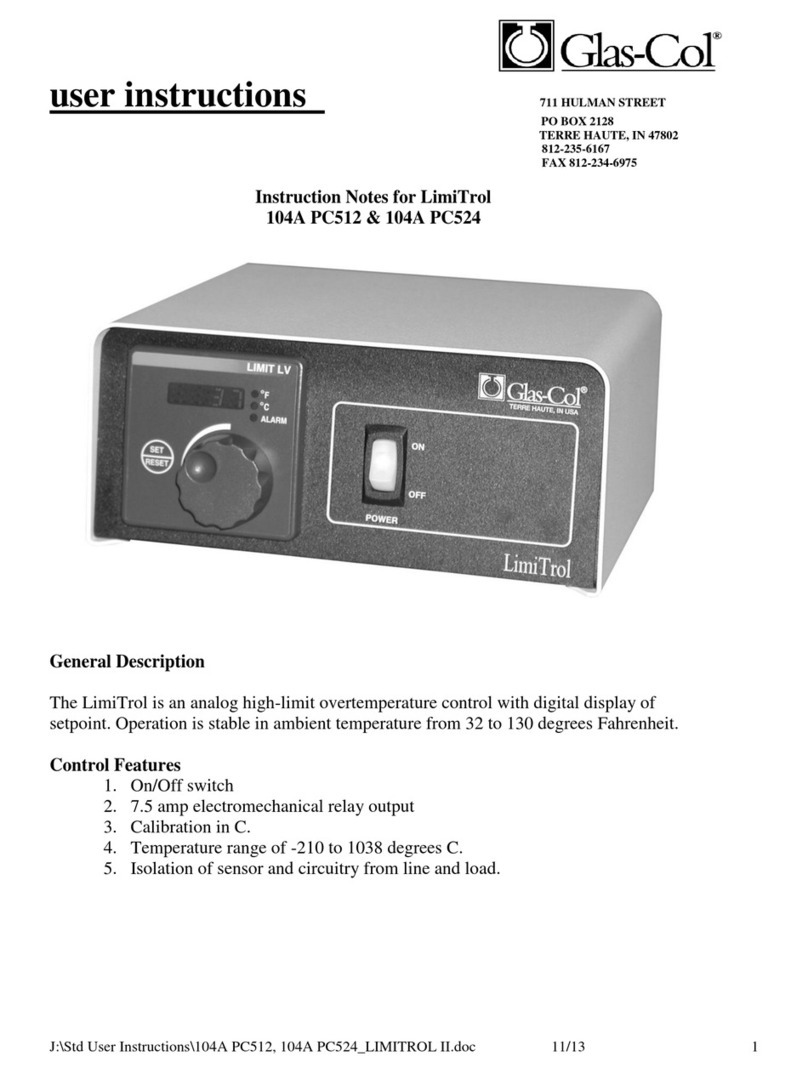

INSTALLATION

Mounttheinstrumentinalocationthatwillnotbesubjecttoexcessivetemperature,shock,

or vibration. All models are designed for mounting in an

enclosedpanel.

Selectthepositiondesiredfortheinstrument onthepanel.

If more than one instrument is required, only two units can

bemountedcloselytogether,eitheroneabovetheotheror

sideby side. When mounted together,the mounting collar

will require modification by removing the inside tab from

each collar.

Prepare the panel by cutting

and deburring the required

opening.

From the front of the panel,

slide the housing through the

cut out. The housing gasket

shouldbe againstthehousing

flange before installing.

From the rear of the panel slide

themountingcollaroverthehous-

ing. Hold the housing with one

hand and using the other hand,

pushthecollarevenlyagainstthe

panel until the spring loops are

slightly compressed. The ratch-

ets will hold the mounting collar

and housing in place.

INPUTWIRING

Donotrunthermocoupleorotherinputwiringinthesameconduitaspowerleads. Useonlythetype

of thermocouple or RTD probe for which the control has been programmed. See the "

SECURE

MENU

" to change between RTD and thermocouple input types.

For thermocouple input always use extension leads of the same type designated for your thermo-

couple.

Page 10 of 12

DIAGNOSTIC ERROR MESSAGES

ACTION REQUIRED

Input signals may normally go above

or below range ends. If not, check

input and correct.

To reset use the

INDEX

&

ENTER

keys. When

InPt

(input fault timer)

has been set for a time, the outputs

will be turned off after the set time.

Setting the time to OFF causes the

outputs to remain active, however

UFL

or

OFL

will still be displayed.

Correct or replace sensor. To reset

use the

INDEX

&

ENTER

keys.

Remove the instrument for service

and/orrecalibration. Toresetusethe

INDEX

&

ENTER

keys.

Remove the instrument for service

and/orrecalibration. Toresetusethe

INDEX

&

ENTER

keys.

Checkthat thepowersupply ison, or

that the external fuses are good.

Thedisplayalternatesbetween

FAIL

tESt

and one of the following mes-

sages:

FACt dFLt

: Memory may be

corrupted. Pressthe

ENTER

keyand

the

DOWN ARROW

key to start the

factory default procedure. Re-check

controller programming.

rEt FACt

:

Can not recover from error, return to

factory for service.

Correct the

SP

or adjust the

SPL

or

SPH

values by programming new

values.

Correct the

SPL

or

SPH

values by

programming new values.

DISPLAY

UFL

or

OFL

bAd

InP

OPEn

InP

CHEC

CAL

No dis-

play

lighted

FAIL

tESt

CHEC SP

CHEC ALLO

CHEC ALHi

CHEC

SPL

or

CHEC

SPH

MEANING

Underflow or Overflow:

Process value has ex-

ceeded input range ends.

UFL

or

OFL

willsequence

to display one of these

messagesifthe

InPt

isset

for a time value.

For RTD inputs RTD is

open or shorted.

ForTHERMOCOUPLEin-

putsthermocoupleisopen.

Checkcalibrationappears

asanalternatingmessage

if the instrument calibra-

tionnearstoleranceedges.

Checkcalibrationappears

as a flashing message if

the instrument calibration

exceeds specification.

Display is blank. Instru-

ment may not be getting

power, or the supply volt-

age is too low.

Fail test appears upon

power up if the internal di-

agnostics detect a failure.

This message may occur

duringoperationifafailure

isdetected. Displaysflash.

This message will appear

upon power up if the set

point is set outside of the

SPL

or

SPH

values.

This message appears at

power up if

SPL

or

SPH

values are programmed

outside the input range

ends.

SP OUTPUTS

Set point output

active

Alarms active

Set point output

inactive

Alarms active

Set point output

active

Alarms active

Set point output

inactive

Alarms active

Set point output

inactive

Alarms inactive

Set point output

inactive

Alarms inactive

Set point output

inactive

Alarms active

Set point output

inactive

Alarms inactive

Page 4 of 12

FRONT PANEL KEY FUNCTIONS

Set Point Lamp

Alarm Lamp

°F Indicator*

°C Indicator* Decimal point

flashes while

*Lamp flashes during ramping function

Self-Tuneoperation. is active.

The1500Seriescontrolshaveonedisplay. Thedisplaymustoccasionallyswitchtoshow

a complete message or menu item and its value. The normal display shows just the

temperature and does not switch. While showing a menu item, the display will alternate

betweenthemenuitemandtheitemvalue. IftheUParrow,DOWNarrow,orENTERkeys

are pressed, the display immediately switches to display the item value.

Key functions are as follows:

1. INDEX: Pressing the INDEX key advances the display to the next menu item. May

also be used in conjunction with other keys as noted below.

2UP ARROW:Increments a value, changes a menu item, or selects the item to ON.

The maximum value obtainable is 9999 or 999.9.

3. DOWN ARROW:Decrements a value,changes a menu item, or selects the item to

OFF. The minimum value obtainable is -1999 or -199.9.

4. ENTER: Pressing ENTER stores the value or the item changed. If not pressed, the

previously stored value or item will be retained. The display will flash once when

ENTER is pressed.

5. UP ARROW & ENTER: Pressing these keys simultaneously brings up the

SECONDARY MENU starting at the alarm, tune, or cycle item (depending on

programming). Pressing these keys for 5 seconds will bring up the SECURE MENU.

WIRING

Page 9 of 12

The following menu items apply only to the alarm.

AL Alarms: Select OFF, Lo, Hi, or HiLo.

OFF AlarmsareturnedOFF.NoAlarmmenuitemsappearintheSecondaryand

Secure menus.

Lo Low Alarm Only. ALLo appears in the Secondary Menu.

Hi High Alarm Only. ALHi appears in the Secondary Menu.

HiLo High and Low Alarms. Both share the same Alarm Relay output.

ALt Alarm Type: Select AbS or dE

AbS AbsoluteAlarmthatmaybesetanywherewithinthevaluesofSPLandSPH

and is independent of SP.

dE DeviationAlarmthatmaybesetasanoffsetfromSP. AsSPischangedthe

Alarm Point will track with SP.

ALrE Alarm Reset: Select OnOF or Hold.

OnOF Automatic Reset.

Hold ManualReset.Acknowledge(reset)bysimultaneouslypressingtheINDEX

& DOWN ARROW keys for 5 sec.

ALPi Alarm Power Interrupt: Select On or OFF.

On Alarm Power Interrupt is ON.

OFF Alarm Power Interrupt is OFF.

ALiH Alarm Inhibit: Select On or OFF.

On Alarm Inhibit is ON. Alarm action is suspended until the process value first

enters a non-alarm condition.

OFF Alarm Inhibit is OFF.

ALSt Alarm Output State: Select CLOS or OPEn.

CLOS Closes Contacts at Alarm Set Point.

OPEn Opens Contacts at Alarm Set Point.

ALLP Alarm Lamp: Select O on or OoFF.

O on Alarm Lamp is ON when alarm contact is closed.

OoFF Alarm Lamp is OFF when alarm contact is closed.

D = deviation

Page 5 of 12

6.INDEX&DOWNARROW:Pressingthesekeyssimultaneouslywillallowbackingup

one menu item, or if at the first menu item they will cause the display to return to the

PRIMARYMENU. Ifanalarmconditionhasoccurred,thesekeysmaybeusedtoreset

the alarm.

7. INDEX &ENTER:Pressing these keys simultaneously and holding them for 5

secondsallowsrecoveryfrom thevariouserrormessages. Thefollowing menuitems

will be reset:

ALiH: Alarm inhibit OPEn InP: Thermocouple error message

bAd InP: RTD error message CHECCAL:Checkcalibrationerrormessage

Correct the problems associated with the above conditions first before using these reset

keys. More than one error could be present. Caution is advised since several items are

reset at one time.

While in the PRIMARYor SECONDARY MENU,if no key is pressed for a period of 30

seconds,thedisplaywillreturntotheHOMEpositiondisplayingthetemperaturevalue.The

time is increased to 1 minute when in the SECURE MENU.

NOTE: To move to the PRIMARY MENU quickly from any other menu, press the UP

ARROW &ENTER keys followed by pressing the INDEX & DOWN ARROW keys.

SECURITY LEVEL SELECTION

NOTE: Lock menus to prevent unauthorized changes to controller settings.

Fourlevelsof security areprovided.The securitylevelcanbe changedunderSECr in the

SECUREMENU. Thedisplayshowsthecurrentsecuritylevel. Refertothepasswordtable

belowforthecorrectvaluetoenterforthesecurityleveldesired. Tochangesecuritylevels,

set the password value using the UP & DOWN ARROW keys and press the ENTER key.

TheSECr menuitem'ssecurity levelmaybeviewedorchangedat anytimeregardlessof

the present security level. The password values shown in the table cannot be altered, so

retain a copy of this page for future reference. This will be the only reference made to

password values in this instruction book.

PASSWORD TABLE

DISPLAYEDVALUE

WHEN VIEWED

1

2

3

4

SECURITY LEVEL

MENU SECURITY

Primary Locked

Secondary Locked

Secure Locked

Primary Unlocked

Secondary Locked

Secure Locked

Primary Unlocked

Secondary Unlocked

Secure Locked

Primary Unlocked

Secondary Unlocked

Secure Unlocked

PASSWORD

VALUE TO ENTER

1110

1101

1011

111

Page 8 of 12

InPt Input Fault Timer: Select OFF, 0.1 to 540.0 minutes. Whenever an Input is out of

range(UFL or OFLdisplayed), shorted,or open thetimer willstart. When thetime

has elapsed, the controller will revert to a safe condition (Output Off, Flashing

Display). If OFF is selected, the Input Fault Timer will not be recognized (time =

infinite).

SPL Set Point Low: Select from the lowest input range value to SPH value.This willset

theminimumSP valuethatcanbeentered.ThevalueforSPwillstopmovingwhen

this value is reached.

SPH SetPointHigh:SelectfromthehighestinputrangevaluetoSPLvalue.Thiswillset

themaximumSPvaluethatcanbeentered.ThevalueforSPwillstopmovingwhen

this value is reached.

SPSt Set Point State: Select dir or rE.

dir Direct Action. As the input increases the output will increase. Most com-

monly used in cooling processes.

rE Reverse Action. As the input increases the output will decrease. Most

commonly used in heating processes.

SPOL SetPointOutputLowLimit:Select0to100%butnotgreaterthanSPOH.Thisitem

limitsthe lowest output value. Thisis useful foradding a biasto the process when

needed.

SPOH Set Point Output High Limit: Select 0to 100% but not less than SPOL. This item

allowssettingthemaximumoutputlimit.Thisisusefulwithprocessesthatareover-

powered.

SPLP Set Point Lamp: Select O on or OoFF.

O on Lamp ON when Output is ON.

OoFF Lamp OFF when Output is ON.

ALARMTYPE AND ACTION (if present)

Caution: In any critical application where failure could cause expensive

product loss or endanger personal safety, a redundant limit controller is

required.

When setting an alarm value for an absolute alarm (ALt = AbS), simply set the value at

which the alarm is to occur.

When setting the alarm value for a deviation alarm (ALt = dE), set the difference in value

from the Set Point (SP) desired. For example, if a low alarm is required to be 5 degrees

belowtheSP,thensetALLoto-5.Ifahighalarmisrequired20degreesabovetheSP,then

setALHi to+20.IfSPis changed, thealarmwillcontinuetoholdthesamerelationshipas

originally set.

The diagram at the top of the next page shows the action and reset functions for both

absolute and deviation alarms.

When Alarm Power Interrupt, ALPi, is programmed ON and Alarm Reset, ALrE, is

programmed for Hold, the alarm will automatically reset upon a power failure and

subsequent restoration if no alarm condition is present.

IfAlarmInhibit,ALiH,isselectedON,analarmconditionissuspendeduponpowerupuntil

theprocess value passes through thealarm set point once.Alarm inhibit can be restored

as if a power up took place by pressing both the INDEX and ENTER keys for 5 seconds.

Warning:Resetting a high alarm inhibit will not cause an alarm to occur

if the Process Value does not first drop below the high alarm setting. Do

not use the Alarm Inhibit feature if a hazard is created by this action. Be

suretotestallcombinationsofhighand low alarm inhibit actions before

placing control into operation.

Page 6 of 12

MENU SELECTIONS

PRIMARY MENU

Press INDEX to advance to the next menu item. Press UP ARROW or DOWN ARROW

to change the value in the display. Press ENTER to retain the value.

SP Set Point Adjust, Control Point.

SECONDARY MENU

Press UP ARROW &ENTER simultaneously.PressINDEX to advanceto the nextmenu

item. Press UP ARROW or DOWN ARROW to change the value in the display. Press

ENTER to retain the value.

ALLo Alarm Low: The Low Alarm point is usually set below the Set Point.

ALHi Alarm High: The High Alarm Point is usually set above the Set Point.

CY CycleRate andoutput selection:Select OnOF, 1, 2 to80 secondstotal cycletime.

ONOF A setting of ONOF allows the control to operate as a simple on/off mode.

Thissettingforcesthecontroltoturnoffatsetpoint,andonatthesetpoint

plus the differential (SP_d). When selected, the tunE, Pb, rES, OFS, rtE,

and ArUP selections in the Secondary menu and the SPOL and SPOH

selections in the Secure menu are suppressed.

1A setting of 1 is recommended for solid state outputs (SSR or 5VDC).

2 to 80TimeProportioningControlisadjustablein1sec.steps.Recommendedfor

mechanical outputs (relays, solenoids, etc.). For best contact life, a time

shouldbe selected thatis aslong as possiblewithout causingthe process

to wander.

SP_d SetPointOn-OffDifferential. (OnlyappearsifCYissettoONOF.)Select1to999°F.

Thisvaluewillbenegativeforreverseactingsetpoints,andpositivefordirectacting

outputs. Set the value for the amount of temperature difference between the turn

off point (set point) and the turn on point.

tunE Tuning Choice: Select SELF or Pid.

SELF The Controller will evaluate the Process and select the PID values to

maintain good control. The ramp function (rt) cannot be selected while

SELFtunEisactive. ThetemperaturedescriptorwillflashwhileSELFtunE

is active. The control will switch to Pid tunE when the tuning function is

complete.

Pid Manually adjust the PID values. PID control consists of three basic

parameters, Proportional Band (Gain), Reset Time (Integral), and Rate

Time (Derivative).

Pb Proportional Band (Bandwidth): Select 5to 5000 °F(3to 2778 °C).

rES AutomaticResetTime:SelectOFF,0.1to99.9minutes.SelectOFF

to switch to OFS.

OFS Manual Offset Correction: Select OFF, 0.1 to 99.9%. Select OFF to

switch to rES.

rtE Rate Time. Select OFF, 0.01 to 99.99 minutes (Derivative).

Page 7 of 12

ArUP Anti- Reset Wind-up Feature: Select On or OFF.

On If ArUP is On the accumulated Reset Offset value will be cleared to 0%

when the process input is not within the Proportional Band.

OFF IfArUP isOFF,theaccumulatedResetOffsetValueisretainedinmemory

when the process input is not within the Proportional Band.

rt RampTime: SelectOFF,00.01to99.59(HH.MM). Whenvalueisentered,control

calculatesarampslope fromthecurrenttemperatureto SPoverthetimeentered.

Changing rt or SP (or pressing ENTER at either menu item) restarts the ramp

function, and re-calculates the slope. The right hand decimal point of the display

willflash while the rampfunction is active. Self tunE cannotbe selectedwhile the

rampfunctionisactive. SelectingOFFwillstopacurrentrampanddrivetheoutput

as necessary to reach set point

InPC Input Correction: Select ±500 °F(±278 °C). This feature allows the input value to

bechangedtoagreewithanexternalreferenceortocompensateforsensorerror.

Note: InPC is reset to zero when the input type is changed, or when decimal

position is changed.

FiLt Digital Filter: Select OFF,1 to 99. In some cases the time constant of the sensor,

or noise could cause the display to jump enough to be unreadable. A setting of 2

is usually sufficient to provide enough filtering for most cases, (2 represents

approximately a 1 second time constant). When the 0.1 degree resolution is

selected this should be increased to 4. If this value is set too high, controllability

will suffer.

SECURE MENU

HoldUPARROW&ENTERfor5Seconds. PressINDEXtoadvancetothenextmenuitem.

Press UP ARROW or DOWN ARROW to changethe value in the display. Press ENTER

to retain the value.

SECr Security Code: See the Security Level Selection and the Password Table in this

manual in order to enter the correct password.

InP InputType: Select one of the following. The selections are limited to the input type

youordered. Ifyouorderedathermocoupleinputcontrol,makeyourselectionfrom

the thermocouple list. If you ordered an RTD input, select from the RTD list.

Thermocouple selections:

J-IC Type “J” Thermocouple, Iron/Constantan (NIST)

CA Type “K” Thermocouple Chromel/Alumel

t- Type “T” Thermocouple Copper/Constantan

RTD selection:

P385 100 ohm Platinum (DIN 0.00385 Ω/Ω/°C), element code PD.

F-C Select temperature descriptor for Fahrenheit or Celsius.

F°F descriptor is On and temperature inputs will be displayed in actual

degrees Fahrenheit.

C°C descriptor is On and temperature inputs will be displayed in actual

degrees Celsius.

dPt DecimalPointPositioning:Select0or0.0.ThisonlyaffectstheProcessValue,SP,

ALLo, ALHi, and InPC.

0No decimal Point is selected.

0.0 One decimal place is selected. If the Process Value moves outside of the

decimalpointrangeends(-199.9to+999.9),theProcessValuedisplaywill

autorangetowholedegreeresolution. WhentheProcessValuereturnsto

the decimal point range, the display will autorange back to tenth degree

resolution.

Page 6 of 12

MENU SELECTIONS

PRIMARY MENU

Press INDEX to advance to the next menu item. Press UP ARROW or DOWN ARROW

to change the value in the display. Press ENTER to retain the value.

SP Set Point Adjust, Control Point.

SECONDARY MENU

Press UP ARROW &ENTER simultaneously.PressINDEX to advanceto the nextmenu

item. Press UP ARROW or DOWN ARROW to change the value in the display. Press

ENTER to retain the value.

ALLo Alarm Low: The Low Alarm point is usually set below the Set Point.

ALHi Alarm High: The High Alarm Point is usually set above the Set Point.

CY CycleRate andoutput selection:Select OnOF, 1, 2 to80 secondstotal cycletime.

ONOF A setting of ONOF allows the control to operate as a simple on/off mode.

Thissettingforcesthecontroltoturnoffatsetpoint,andonatthesetpoint

plus the differential (SP_d). When selected, the tunE, Pb, rES, OFS, rtE,

and ArUP selections in the Secondary menu and the SPOL and SPOH

selections in the Secure menu are suppressed.

1A setting of 1 is recommended for solid state outputs (SSR or 5VDC).

2 to 80TimeProportioningControlisadjustablein1sec.steps.Recommendedfor

mechanical outputs (relays, solenoids, etc.). For best contact life, a time

shouldbe selected thatis aslong as possiblewithout causingthe process

to wander.

SP_d SetPointOn-OffDifferential. (OnlyappearsifCYissettoONOF.)Select1to999°F.

Thisvaluewillbenegativeforreverseactingsetpoints,andpositivefordirectacting

outputs. Set the value for the amount of temperature difference between the turn

off point (set point) and the turn on point.

tunE Tuning Choice: Select SELF or Pid.

SELF The Controller will evaluate the Process and select the PID values to

maintain good control. The ramp function (rt) cannot be selected while

SELFtunEisactive. ThetemperaturedescriptorwillflashwhileSELFtunE

is active. The control will switch to Pid tunE when the tuning function is

complete.

Pid Manually adjust the PID values. PID control consists of three basic

parameters, Proportional Band (Gain), Reset Time (Integral), and Rate

Time (Derivative).

Pb Proportional Band (Bandwidth): Select 5to 5000 °F(3to 2778 °C).

rES AutomaticResetTime:SelectOFF,0.1to99.9minutes.SelectOFF

to switch to OFS.

OFS Manual Offset Correction: Select OFF, 0.1 to 99.9%. Select OFF to

switch to rES.

rtE Rate Time. Select OFF, 0.01 to 99.99 minutes (Derivative).

Page 7 of 12

ArUP Anti- Reset Wind-up Feature: Select On or OFF.

On If ArUP is On the accumulated Reset Offset value will be cleared to 0%

when the process input is not within the Proportional Band.

OFF IfArUP isOFF,theaccumulatedResetOffsetValueisretainedinmemory

when the process input is not within the Proportional Band.

rt RampTime: SelectOFF,00.01to99.59(HH.MM). Whenvalueisentered,control

calculatesarampslope fromthecurrenttemperatureto SPoverthetimeentered.

Changing rt or SP (or pressing ENTER at either menu item) restarts the ramp

function, and re-calculates the slope. The right hand decimal point of the display

willflash while the rampfunction is active. Self tunE cannotbe selectedwhile the

rampfunctionisactive. SelectingOFFwillstopacurrentrampanddrivetheoutput

as necessary to reach set point

InPC Input Correction: Select ±500 °F(±278 °C). This feature allows the input value to

bechangedtoagreewithanexternalreferenceortocompensateforsensorerror.

Note: InPC is reset to zero when the input type is changed, or when decimal

position is changed.

FiLt Digital Filter: Select OFF,1 to 99. In some cases the time constant of the sensor,

or noise could cause the display to jump enough to be unreadable. A setting of 2

is usually sufficient to provide enough filtering for most cases, (2 represents

approximately a 1 second time constant). When the 0.1 degree resolution is

selected this should be increased to 4. If this value is set too high, controllability

will suffer.

SECURE MENU

HoldUPARROW&ENTERfor5Seconds. PressINDEXtoadvancetothenextmenuitem.

Press UP ARROW or DOWN ARROW to changethe value in the display. Press ENTER

to retain the value.

SECr Security Code: See the Security Level Selection and the Password Table in this

manual in order to enter the correct password.

InP InputType: Select one of the following. The selections are limited to the input type

youordered. Ifyouorderedathermocoupleinputcontrol,makeyourselectionfrom

the thermocouple list. If you ordered an RTD input, select from the RTD list.

Thermocouple selections:

J-IC Type “J” Thermocouple, Iron/Constantan (NIST)

CA Type “K” Thermocouple Chromel/Alumel

t- Type “T” Thermocouple Copper/Constantan

RTD selection:

P385 100 ohm Platinum (DIN 0.00385 Ω/Ω/°C), element code PD.

F-C Select temperature descriptor for Fahrenheit or Celsius.

F°F descriptor is On and temperature inputs will be displayed in actual

degrees Fahrenheit.

C°C descriptor is On and temperature inputs will be displayed in actual

degrees Celsius.

dPt DecimalPointPositioning:Select0or0.0.ThisonlyaffectstheProcessValue,SP,

ALLo, ALHi, and InPC.

0No decimal Point is selected.

0.0 One decimal place is selected. If the Process Value moves outside of the

decimalpointrangeends(-199.9to+999.9),theProcessValuedisplaywill

autorangetowholedegreeresolution. WhentheProcessValuereturnsto

the decimal point range, the display will autorange back to tenth degree

resolution.

Page 5 of 12

6.INDEX&DOWNARROW:Pressingthesekeyssimultaneouslywillallowbackingup

one menu item, or if at the first menu item they will cause the display to return to the

PRIMARYMENU. Ifanalarmconditionhasoccurred,thesekeysmaybeusedtoreset

the alarm.

7. INDEX &ENTER:Pressing these keys simultaneously and holding them for 5

secondsallowsrecoveryfrom thevariouserrormessages. Thefollowing menuitems

will be reset:

ALiH: Alarm inhibit OPEn InP: Thermocouple error message

bAd InP: RTD error message CHECCAL:Checkcalibrationerrormessage

Correct the problems associated with the above conditions first before using these reset

keys. More than one error could be present. Caution is advised since several items are

reset at one time.

While in the PRIMARYor SECONDARY MENU,if no key is pressed for a period of 30

seconds,thedisplaywillreturntotheHOMEpositiondisplayingthetemperaturevalue.The

time is increased to 1 minute when in the SECURE MENU.

NOTE: To move to the PRIMARY MENU quickly from any other menu, press the UP

ARROW &ENTER keys followed by pressing the INDEX & DOWN ARROW keys.

SECURITY LEVEL SELECTION

NOTE: Lock menus to prevent unauthorized changes to controller settings.

Fourlevelsof security areprovided.The securitylevelcanbe changedunderSECr in the

SECUREMENU. Thedisplayshowsthecurrentsecuritylevel. Refertothepasswordtable

belowforthecorrectvaluetoenterforthesecurityleveldesired. Tochangesecuritylevels,

set the password value using the UP & DOWN ARROW keys and press the ENTER key.

TheSECr menuitem'ssecurity levelmaybeviewedorchangedat anytimeregardlessof

the present security level. The password values shown in the table cannot be altered, so

retain a copy of this page for future reference. This will be the only reference made to

password values in this instruction book.

PASSWORD TABLE

DISPLAYEDVALUE

WHEN VIEWED

1

2

3

4

SECURITY LEVEL

MENU SECURITY

Primary Locked

Secondary Locked

Secure Locked

Primary Unlocked

Secondary Locked

Secure Locked

Primary Unlocked

Secondary Unlocked

Secure Locked

Primary Unlocked

Secondary Unlocked

Secure Unlocked

PASSWORD

VALUE TO ENTER

1110

1101

1011

111

Page 8 of 12

InPt Input Fault Timer: Select OFF, 0.1 to 540.0 minutes. Whenever an Input is out of

range(UFL or OFLdisplayed), shorted,or open thetimer willstart. When thetime

has elapsed, the controller will revert to a safe condition (Output Off, Flashing

Display). If OFF is selected, the Input Fault Timer will not be recognized (time =

infinite).

SPL Set Point Low: Select from the lowest input range value to SPH value.This willset

theminimumSP valuethatcanbeentered.ThevalueforSPwillstopmovingwhen

this value is reached.

SPH SetPointHigh:SelectfromthehighestinputrangevaluetoSPLvalue.Thiswillset

themaximumSPvaluethatcanbeentered.ThevalueforSPwillstopmovingwhen

this value is reached.

SPSt Set Point State: Select dir or rE.

dir Direct Action. As the input increases the output will increase. Most com-

monly used in cooling processes.

rE Reverse Action. As the input increases the output will decrease. Most

commonly used in heating processes.

SPOL SetPointOutputLowLimit:Select0to100%butnotgreaterthanSPOH.Thisitem

limitsthe lowest output value. Thisis useful foradding a biasto the process when

needed.

SPOH Set Point Output High Limit: Select 0to 100% but not less than SPOL. This item

allowssettingthemaximumoutputlimit.Thisisusefulwithprocessesthatareover-

powered.

SPLP Set Point Lamp: Select O on or OoFF.

O on Lamp ON when Output is ON.

OoFF Lamp OFF when Output is ON.

ALARMTYPE AND ACTION (if present)

Caution: In any critical application where failure could cause expensive

product loss or endanger personal safety, a redundant limit controller is

required.

When setting an alarm value for an absolute alarm (ALt = AbS), simply set the value at

which the alarm is to occur.

When setting the alarm value for a deviation alarm (ALt = dE), set the difference in value

from the Set Point (SP) desired. For example, if a low alarm is required to be 5 degrees

belowtheSP,thensetALLoto-5.Ifahighalarmisrequired20degreesabovetheSP,then

setALHi to+20.IfSPis changed, thealarmwillcontinuetoholdthesamerelationshipas

originally set.

The diagram at the top of the next page shows the action and reset functions for both

absolute and deviation alarms.

When Alarm Power Interrupt, ALPi, is programmed ON and Alarm Reset, ALrE, is

programmed for Hold, the alarm will automatically reset upon a power failure and

subsequent restoration if no alarm condition is present.

IfAlarmInhibit,ALiH,isselectedON,analarmconditionissuspendeduponpowerupuntil

theprocess value passes through thealarm set point once.Alarm inhibit can be restored

as if a power up took place by pressing both the INDEX and ENTER keys for 5 seconds.

Warning:Resetting a high alarm inhibit will not cause an alarm to occur

if the Process Value does not first drop below the high alarm setting. Do

not use the Alarm Inhibit feature if a hazard is created by this action. Be

suretotestallcombinationsofhighand low alarm inhibit actions before

placing control into operation.

Page 4 of 12

FRONT PANEL KEY FUNCTIONS

Set Point Lamp

Alarm Lamp

°F Indicator*

°C Indicator* Decimal point

flashes while

*Lamp flashes during ramping function

Self-Tuneoperation. is active.

The1500Seriescontrolshaveonedisplay. Thedisplaymustoccasionallyswitchtoshow

a complete message or menu item and its value. The normal display shows just the

temperature and does not switch. While showing a menu item, the display will alternate

betweenthemenuitemandtheitemvalue. IftheUParrow,DOWNarrow,orENTERkeys

are pressed, the display immediately switches to display the item value.

Key functions are as follows:

1. INDEX: Pressing the INDEX key advances the display to the next menu item. May

also be used in conjunction with other keys as noted below.

2UP ARROW:Increments a value, changes a menu item, or selects the item to ON.

The maximum value obtainable is 9999 or 999.9.

3. DOWN ARROW:Decrements a value,changes a menu item, or selects the item to

OFF. The minimum value obtainable is -1999 or -199.9.

4. ENTER: Pressing ENTER stores the value or the item changed. If not pressed, the

previously stored value or item will be retained. The display will flash once when

ENTER is pressed.

5. UP ARROW & ENTER: Pressing these keys simultaneously brings up the

SECONDARY MENU starting at the alarm, tune, or cycle item (depending on

programming). Pressing these keys for 5 seconds will bring up the SECURE MENU.

WIRING

Page 9 of 12

The following menu items apply only to the alarm.

AL Alarms: Select OFF, Lo, Hi, or HiLo.

OFF AlarmsareturnedOFF.NoAlarmmenuitemsappearintheSecondaryand

Secure menus.

Lo Low Alarm Only. ALLo appears in the Secondary Menu.

Hi High Alarm Only. ALHi appears in the Secondary Menu.

HiLo High and Low Alarms. Both share the same Alarm Relay output.

ALt Alarm Type: Select AbS or dE

AbS AbsoluteAlarmthatmaybesetanywherewithinthevaluesofSPLandSPH

and is independent of SP.

dE DeviationAlarmthatmaybesetasanoffsetfromSP. AsSPischangedthe

Alarm Point will track with SP.

ALrE Alarm Reset: Select OnOF or Hold.

OnOF Automatic Reset.

Hold ManualReset.Acknowledge(reset)bysimultaneouslypressingtheINDEX

& DOWN ARROW keys for 5 sec.

ALPi Alarm Power Interrupt: Select On or OFF.

On Alarm Power Interrupt is ON.

OFF Alarm Power Interrupt is OFF.

ALiH Alarm Inhibit: Select On or OFF.

On Alarm Inhibit is ON. Alarm action is suspended until the process value first

enters a non-alarm condition.

OFF Alarm Inhibit is OFF.

ALSt Alarm Output State: Select CLOS or OPEn.

CLOS Closes Contacts at Alarm Set Point.

OPEn Opens Contacts at Alarm Set Point.

ALLP Alarm Lamp: Select O on or OoFF.

O on Alarm Lamp is ON when alarm contact is closed.

OoFF Alarm Lamp is OFF when alarm contact is closed.

D = deviation

Page 3 of 12

INSTALLATION

Mounttheinstrumentinalocationthatwillnotbesubjecttoexcessivetemperature,shock,

or vibration. All models are designed for mounting in an

enclosedpanel.

Selectthepositiondesiredfortheinstrument onthepanel.

If more than one instrument is required, only two units can

bemountedcloselytogether,eitheroneabovetheotheror

sideby side. When mounted together,the mounting collar

will require modification by removing the inside tab from

each collar.

Prepare the panel by cutting

and deburring the required

opening.

From the front of the panel,

slide the housing through the

cut out. The housing gasket

shouldbe againstthehousing

flange before installing.

From the rear of the panel slide

themountingcollaroverthehous-

ing. Hold the housing with one

hand and using the other hand,

pushthecollarevenlyagainstthe

panel until the spring loops are

slightly compressed. The ratch-

ets will hold the mounting collar

and housing in place.

INPUTWIRING

Donotrunthermocoupleorotherinputwiringinthesameconduitaspowerleads. Useonlythetype

of thermocouple or RTD probe for which the control has been programmed. See the "

SECURE

MENU

" to change between RTD and thermocouple input types.

For thermocouple input always use extension leads of the same type designated for your thermo-

couple.

Page 10 of 12

DIAGNOSTIC ERROR MESSAGES

ACTION REQUIRED

Input signals may normally go above

or below range ends. If not, check

input and correct.

To reset use the

INDEX

&

ENTER

keys. When

InPt

(input fault timer)

has been set for a time, the outputs

will be turned off after the set time.

Setting the time to OFF causes the

outputs to remain active, however

UFL

or

OFL

will still be displayed.

Correct or replace sensor. To reset

use the

INDEX

&

ENTER

keys.

Remove the instrument for service

and/orrecalibration. Toresetusethe

INDEX

&

ENTER

keys.

Remove the instrument for service

and/orrecalibration. Toresetusethe

INDEX

&

ENTER

keys.

Checkthat thepowersupply ison, or

that the external fuses are good.

Thedisplayalternatesbetween

FAIL

tESt

and one of the following mes-

sages:

FACt dFLt

: Memory may be

corrupted. Pressthe

ENTER

keyand

the

DOWN ARROW

key to start the

factory default procedure. Re-check

controller programming.

rEt FACt

:

Can not recover from error, return to

factory for service.

Correct the

SP

or adjust the

SPL

or

SPH

values by programming new

values.

Correct the

SPL

or

SPH

values by

programming new values.

DISPLAY

UFL

or

OFL

bAd

InP

OPEn

InP

CHEC

CAL

No dis-

play

lighted

FAIL

tESt

CHEC SP

CHEC ALLO

CHEC ALHi

CHEC

SPL

or

CHEC

SPH

MEANING

Underflow or Overflow:

Process value has ex-

ceeded input range ends.

UFL

or

OFL

willsequence

to display one of these

messagesifthe

InPt

isset

for a time value.

For RTD inputs RTD is

open or shorted.

ForTHERMOCOUPLEin-

putsthermocoupleisopen.

Checkcalibrationappears

asanalternatingmessage

if the instrument calibra-

tionnearstoleranceedges.

Checkcalibrationappears

as a flashing message if

the instrument calibration

exceeds specification.

Display is blank. Instru-

ment may not be getting

power, or the supply volt-

age is too low.

Fail test appears upon

power up if the internal di-

agnostics detect a failure.

This message may occur

duringoperationifafailure

isdetected. Displaysflash.

This message will appear

upon power up if the set

point is set outside of the

SPL

or

SPH

values.

This message appears at

power up if

SPL

or

SPH

values are programmed

outside the input range

ends.

SP OUTPUTS

Set point output

active

Alarms active

Set point output

inactive

Alarms active

Set point output

active

Alarms active

Set point output

inactive

Alarms active

Set point output

inactive

Alarms inactive

Set point output

inactive

Alarms inactive

Set point output

inactive

Alarms active

Set point output

inactive

Alarms inactive

Page 2 of 12

TABLE OF CONTENTS

INPUTWIRING .......................................................................................................................3

INSTALLATION.......................................................................................................................3

WIRING ...................................................................................................................................4

FRONT PANEL KEY FUNCTIONS..........................................................................................4

SECURITYLEVELSELECTION .............................................................................................5

MENU SELECTIONS .............................................................................................................6

PRIMARYMENU.....................................................................................................................6

SECONDARYMENU ..............................................................................................................6

SECUREMENU ......................................................................................................................7

ALARM TYPE AND ACTION...................................................................................................8

DIAGNOSTICERRORMESSAGES .....................................................................................10

SPECIFICATIONS.................................................................................................................11

DIMENSIONS........................................................................................................................12

GETTING STARTED

1. Installthe controlas describedon page3.

2. Wireyourcontrol followingtheinstructionson page3and drawingonpage4.

3. Mostcontrolsdonotneedmany(ifany)programchangestoworkonyourprocess. Forbest

results if programming changes are necessary, make all the necessary changes in the

SECUREMENU(page7)beforemakingchangestotheSECONDARYMENU(page6). If

errormessagesoccur,checktheDiagnosticErrorMessagesonpage10forhelp.

Take the example of a Model CT15011 that comes from the factory programmed for type J

thermocouples. SupposeforthisexampleyouwishtochangetheinputtotypeKandlimitthe

setpointrangebetween0° and1000°C.

First,entertheSECUREMENUasinstructedonpage7. PresstheINDEXkeyuntilthedisplay

shows

Inp

andpresstheDOWNARROWuntilthedisplayshows

CA

. Don'tforgettopressthe

ENTERkey toretainyour setting.

Next,presstheINDEXkeytodisplay

F-C

. PresstheDOWNARROWuntilthedisplayshows

C

.

PressENTER.

Next,presstheINDEXkeyuntil

SPL

isdisplayed(passthe

dPt

and

InPt

selections). Pressthe

UP ARROW until the display shows

0

. PressENTER.

Finally, press INDEX key to display

SPH

. Press the DOWN ARROW until the display shows

1000

. PressENTER.

Thenecessary program changes are now complete. After 30 seconds thedisplay will switch

backtothetemperaturereading. Ifyouwanttoreturnfaster,presstheUPARROWandENTER

keys(atthesametime)andthenpresstheDOWNARROWandINDEXkeys(againatthesame

time). Thiswill'back out'ofthemenu andimmediatelydisplay thetemperaturereading.

Page 11 of 12

Input Type

-

Temperature

Range & Unit

of measure

1°F

1°C

Type J

Iron-

Constantan

-100 to +1600

-73 to +871

Type K

Chromel-

Alumel

-200 to +2500

-129 to +1371

Type T

Copper-

Constantan

-350 to +750

-212 to +398

Input Ranges (as ordered)

ThermocoupleTypes

SPECIFICATIONS

Selectable Inputs: Thermocouple or RTD as ordered.

Input Impedance:

Thermocouple = 3 megohms minimum. RTD current = 200 uA.

Sensor Break Protection: De-energizes control output to protect system.

Set Point Range: Selectable (See range chart above).

Display: One; 4 digit, 7 segment, 0.3" high LEDs.

Control Action: Selectable for Reverse (usually heating) or Direct (usually cooling).

Ramp: One ramp time adjustable from 0 to 100 hours.

Proportional Band: 5 to 5000 °F or equivalent °C.

ResetTime (Integral): Off or 0.1 to 99.9 minutes.

RateTime (Derivative): Off or 0.01 to 99.99 minutes.

Cycle Rate: 1 to 80 seconds, and on-off.

On - Off Differential: Adjustable 1° F to 999°F in 1° steps (equivalent °C).

Alarm On - Off Differential: 2° F or equivalent in °C.

Accuracy: ±0.25% of span, ±1 degree.

Resolution: 1 degree or 0.1 degree, selectable.

LineVoltage Stability: ±0.05% over the supply voltage range.

Temperature Stability: 4µV/°C (2.3 µV/°F) typical, 8 µV/°C (4.5 µV°F) maximum.

Common Mode Rejection: 140 db minimum at 60 Hz.

Normal Mode Rejection: 65 db typical, 60 db at 60 Hz.

Isolation: Relay and SSR outputs are isolated. 5VDC output must not share a common

ground with the input.

SupplyVoltage:100to240VAC,nom.,+10-15%,50to400Hz.singlephase;132to240

VDC, nom., +10 -20%.

Power Consumption: 5VA maximum.

OperatingTemperature Range: -10 to +55 °C (+14 to 131 °F).

StorageTemperature Range: -40 to +80 °C (-40 to 176 °F).

Operating Humidity Range: 0 to 90% up to 40 °C non-condensing. 10 to 50% at 55 °C

non-condensing.

Memory Backup: Non-volatile memory. No batteries required.

Control Output Ratings:

1. SSR, 3.5 A @ 250 VAC at 25 °C. Derates to 1.25 A @ 55 °C. Minimum 48 VAC and

100 mA required.

2. Switched voltage (non-isolated): 5 VDC @ 25 mA.

3.Relay,FormAcontact(SPST),3A@250VACresistive;1.5A@250VACinductive;

Pilot Duty Rating: 250 VA, 2 A @ 125 VAC or 1 A @ 250 VAC.

Alarm Relay Rating: Same as Control Output Relay.

Weight: 227 g (8 oz).

Agency Approvals: UL E83725, and CSA LR40125.

Front Panel Rating (non-hazardous locations): Designed to meet UL 4X for non-

hazardous locations (equal to NEMA rating).

100 Ohm Platinum

0.00385 DIN Curve

element code PD

-328 to +1607

-200 to +875

RTDType

1

INSTRUCTIONS FOR THE CT15 SERIES

MICROPROCESSOR BASED

TEMPERATURE CONTROLLER

MODELIDENTIFICATION

Alarm

0 = No

1 = Yes

Input

1=Thermocouple, J, K, T

2=100Ω Platinum RTD

(DIN), element PD

Model CT15

Output

1=SSR

2=5 VDC

3=Relay

Page 12 of 12

LIMITED WARRANTY

Minco Products, Inc. warrants to the Buyer that any equipment sold will be free from

defects in material or workmanship. If, at any time within thirtysix (36) months after

shipment of CT15 Series Controls or within three (3) months after shipment of other

assembliesorparts,theSellerisnotifiedofsuchdefectandthedefectiveitemisreturned

to Seller by Buyer, transportation prepaid, for examination, the Seller will, at his option,

either repair or replace the defective items.

Thiswarrantyshallbeeffectiveonlyifinstallationandmaintenanceisinaccordancewith

Seller's instructions and the defect is not caused by shipping damage, misuse or abuse

by the Buyer. There are no other warranties, written, oral, or implied. The liability of the

Seller is limited to the repair or replacement of the defective item as set forth above.

Itemswhichwearorareperishable bymisusearenotwarranted. Theseinclude, butare

not limited to, relays, contact points, lamps, LEDs, load SCRs, SSRs, and triacs.

(All dimensions in mm with inches in parentheses.)

Panel cutout for all models 45 mm X 45 mm (1.775" X 1.775"). Allow for

13 mm (0.5") clearance at the rear of instrument.

*Present for SSR and 5 VDC output.

G:\MOD\CT15\LIT\759MN.PM5

7/03

360-00066

© 1994, MINCO PRODUCTS, INC. ALL RIGHTS RESERVED. NO PORTION MAY BE COPIED WITHOUT THE

EXPRESS WRITTEN CONSENT OF MINCO PRODUCTS, INC.

DIMENSIONS

This manual suits for next models

1

Table of contents

Other Minco Temperature Controllers manuals