Minco Heaterstat CT398 Manual

CT398 Heaterstat

TM

Temperature Controller

Technical User Guide

2

CT398 HeaterStat Controller

Contents

CT398 HeaterStat Controller..................................2

Contents .............................................................2

Document Overview...........................................2

For More Information..........................................2

Introduction.............................................................1

Conventions ............................................................1

Installation...............................................................1

Mounting.............................................................1

Wiring .................................................................1

Configuration ..........................................................2

Status .................................................................2

Heater Settings ..................................................3

Output Settings ..................................................4

General Usage.........................................................5

Status/Communication LED ...............................5

Frequently Asked Questions (FAQ)......................6

Specifications .........................................................7

Inputs..................................................................7

Outputs...............................................................7

Communication ..................................................7

General...............................................................7

Glossary ..................................................................8

Document Overview

This document provides an overview of how to use the

CT398 DC HeaterStat.

For More Information

For more information on the contents of this document,

please contact your local Minco representative.

page 1

| © 2015 Minco | 360-00129(-) | minco.com

Introduction

The CT398 is a programmable sensorless temperature controller designed to operate on DC power. When a high TCR

(Temperature Coefficient of Resistance) heater is used with the CT398, the heater element serves as the temperature sensor

which completely eliminates the need for a separate sensor during operation. An optical communication interface allows for

easy configuration on a computer; the included Windows software provides multiple methods of characterizing a heater and

configuring the Setpoint to any desired value.

The CT398 utilizes the same footprint as Minco’s original HeaterStat, the CT198; however, the CT398 is shorter, has a higher

current rating, and has full programmability: All settings can be programmed and changed by the user.

The CT398 utilizes on/off control by applying power to the heater element when the measured heater resistance, which

increases with temperature, is below the Setpoint. When power is applied to the heater, the resistance of the heater is

constantly being measured. When the measured element resistance is above the Setpoint, power is disconnected from the

heater except for during the Measurement Pulse. The Measurement Pulse is a momentary application of heater power for the

purpose of measuring the heater element resistance. See the Output Settings and FAQ sections for more information on the

Measurement Pulse and Pulse Heating.

Depending on the characteristics of the thermal system, the difference between the heater element temperature and the heat

sink may vary significantly. Since the CT398 directly measures the heater element and applies the control output accordingly,

care should be taken to ensure that the overall system is controlled to the desired operation using external validation.

The CT398 is ideal in situations where additional wires for a sensor are undesirable, or where precise temperature control is

unnecessary and simplicity is important.

Conventions

Different typestyles are used throughout this manual to make it easier to convey whether the text refers to a physical feature of

the CT398, or if it refers to a general term.

A word or phrase with first letter capitalization (such as Heater Output) refers to a feature on the CT398 such as a terminal

block connection or a feature such as Device Name.

Installation

All configurations are performed through the optical communication interface (AC221332, available separately) and the

Windows application. The CT398 must be powered, and its LED must be accessible to perform any configuration.

Mounting

The CT398 may be mounted via the mounting hole if desired and may be operated in any position. A minimum of 1 inch (2.5

cm) airspace must be maintained around the sides and top of the CT398. An exception is if a contacted surface is maintained

at or below the assumed ambient temperature.

Wiring

Only three wire connections are required: Power, Ground, and Heater. Each connection is explained in the following sections.

page 2

| © 2015 Minco | 360-00129(-) | minco.com

Power

This connection provides power to the CT398 electronics and is used to monitor the heater voltage. To accurately measure

the heater resistance, this connection must be as close as possible to the heater’s positive side; the preferred method is to

connect this terminal directly to the heater and directly to the power supply using separate wires. See Figure 1 for a

connection diagram.

Ground

This connection is the return path for the heater current and CT398 electronics. Therefore, ensure the wire used is adequately

sized to carry the heater current.

Heater

This connection is for the heater’s negative (return) side. It is an open-drain output that sinks current to the Ground

connection. As with the Ground connection, ensure the wire used is adequately sized to carry the heater current.

Typical Wiring Diagrams

Below is a typical wiring diagram for the CT398.

Figure 1

Configuration

A separate programmer, model AC221332, is necessary to configure the CT398. This device optically communicates with the

CT398 though the Status/Comm LED. To use, connect the programmer to a computer with a USB Cable and place the

programmer LED interface tubing over the CT398’s Status/Comm LED. Then, using the HeaterStat Utilities software, press

“Connect to Device”. If this is successful, the configuration stored on the CT398 is retrieved and displayed, along with the

calculated temperature and output status. The settings are separated into groups: Status, Heater Settings, and Output

Settings.

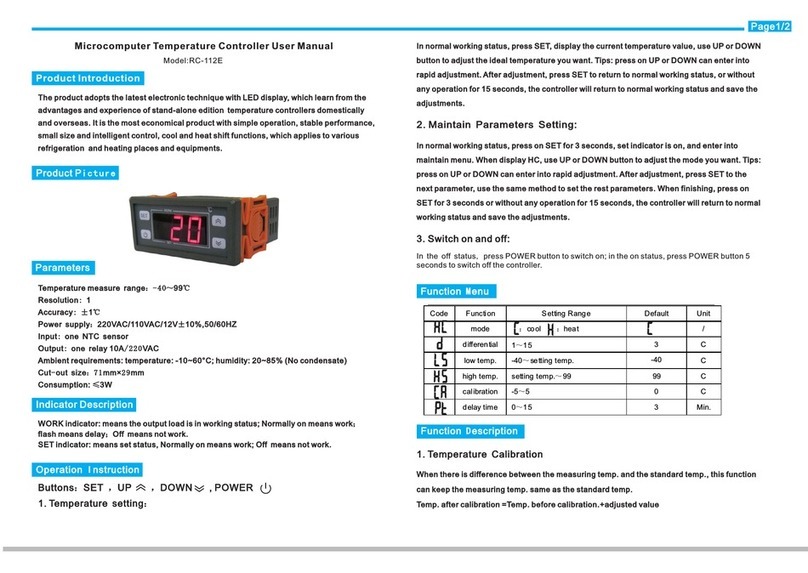

Status

The Status group displays the heater’s measured resistance and output status. The Heater Output status will indicate if the

Heater Output is energized while attempting to increase its temperature, but not while the CT398 is pulsing the output to test

the heater resistance. See Figure 2. If the heater is properly defined within the Heater Settings tab, the status page will also

display the calculated temperature based on the measured resistance.

page 3

| © 2015 Minco | 360-00129(-) | minco.com

Figure 2

Heater Settings

The Heater Settings group contains various methods CT398 Utilities may use to convert heater resistance to temperature.

The different methods are outlined below; only one method is required if this feature is desired by the user. Alternately, the

CT398’s Setpoint may be defined by heater resistance only (See Output Settings), meaning the entire Heater Settings group

may be ignored. Each method is accessed by the tab of the same name. The last selected tab within Heater Settings (Heater

Code, Heater Characteristics, Temperature/Resistance Data, or Equation) defines which method the program uses to convert

resistance to temperatures.

Heater Code: A string of characters which, if provided with the heater, fully describes the heater’s characteristics. This code

must be received from Minco.

Heater Characteristics: The heater element composition, base resistance, and optional calibration data points are used to

characterize the heater.

Temperature / Resistance Data: A set of temperature / resistance pairs are entered and used to characterize the heater. A

minimum of two temperature / resistance pairs are required, although more increases accuracy.

Equation: Polynomial coefficients are entered and used to characterize a heater. The equation relating heater resistance to

temperature must be known to use this method.

page 4

| © 2015 Minco | 360-00129(-) | minco.com

Figure 3

Output Settings

The Output Settings group contains Device Name, parameters which directly control the Heater Output, and parameters which

define Status/Comm LED behavior.

Device Name: A string of up to 20 characters that the user may use to name the device. This may be useful to identify

multiple units.

Pulse Rate: The period of time between Measurement Pulses with which the CT398 tests the heater resistance while the

output is off, i.e. while the heater resistance is above the Setpoint. This value is in milliseconds. When the heater’s resistance

is below the Setpoint, the heater is energized and its resistance is checked continuously at a high, fixed rate.

Generally a lower Pulse Rate period is better since it should theoretically result in tighter control; however, the lower the Pulse

Rate period, the greater the Pulse Heating effect. A Pulse Rate period of 1000ms is a recommended starting point.

LED Behavior: Determines the LED behavior when used as a status indicator (when not being used for PC communication).

The options are as follows:

•Mode 1: LED to remain off during normal operation.

•Mode 2: LED indicates when output is on for the purpose of heating, but not including the Measurement Pulses.

•Mode 3: LED indicates when output is on for the purpose of heating, including the Measurement Pulses.

•Mode 4: LED displays a “fade on-fade off” behavior when the heater resistance / temperature falls within the

Process Value Range and there are no errors. This is useful as a quick visual check to ensure the CT398 is

operating as desired.

Additionally, if the Heater Shutdown range is violated or Analog to Digital Converter fails, the associated error code will be

displayed on the LED regardless of the Mode chosen.

Control Units: Selectable between Resistance and Temperature. This setting controls whether resistance or temperature is

used to configure the Setpoint, Process Value Range, and Heater Shutdown limits. If Temperature is used, the Heater

Settings information must be entered. If Resistance is used, no information about the heater is required by the utility program.

The Setpoint, Process Value Range, and Heater Shutdown values on the same screen will be displayed / entered in the

selected units.

page 5

| © 2015 Minco | 360-00129(-) | minco.com

Setpoint: The desired resistance or temperature of the heater. If this value is higher than the heater’s measured value, the

heater is energized until this is no longer true. If this value is lower than the heater resistance, the Heater Output is pulsed to

monitor the resistance.

Process Value Range: The lower and upper limit at which the LED will “fade on-fade off” when configured to do so.

Heater Shutdown: The lower and upper limit at which normal operation will continue. If the heater falls outside of these limits,

the CT398 goes into Heater Shutdown and power must be cycled to resume operation. It’s recommended to set these to

values that would indicate a problem with the heater. This feature is temporarily suppressed when HeaterStat Utilities is

connected to a CT398.

Figure 4

General Usage

Status/Communication LED

The LED present on the CT398 serves as a status indicator by default, but will switch into communications mode if a Minco

Optical Communication Accessory (model AC221332) is attached to the LED. This is the method by which information is

moved to and from the CT398 via the Windows CT398 Utilities.

The LED is capable of different behaviors, configurable by the user. It also will display various error messages should that

occur, see Table 1.

NOTE: It is normal for the Status LED to exhibit a slight periodic flicker when lit. This is a result the CT398

periodically checking for communication attempts from the Optical Communication Accessory.

page 6

| © 2015 Minco | 360-00129(-) | minco.com

Pattern

Meaning

Three flashes, each of

increasing length

In manufacturing mode. This should not occur during normal operation.

Alternating low

brightness and high

brightness

Analog to Digital Converter failure. This is easily caused by low supply voltage,

but could also indicate hardware failure. Ensure supply voltage is within

specification and cycle power.

Brief high brightness

flashes

An out of bounds error has occurred due to the Heater Shutdown limits. This can

also occur if the maximum current rating is exceeded.

Fade On/Fade Off Heater resistance/temperature is within Process Value Range limits, and no errors

are active. Available only in LED Mode 4.

On solid or semi-random

flashes of low brightness

Power is applied to heater. Available only in LED Modes 2 and 3.

Off No power applied, Heater Output is de-energized, or LED in Mode 1.

Table 1

Frequently Asked Questions (FAQ)

Q: How long will the CT398 maintain configuration in non-volatile memory?

A: The specification states the retention is at least 20 years and will withstand at least 1 million writes.

Q: Why isn’t the measured temperature of the heater surface the same as what is reported in the utility program?

A: The CT398 uses the resistance of the heater’s element to determine the heater’s temperature. It is not uncommon for this

measured value to be higher than the heater’s surface temperature. External characterization of the setup is often required to

correlate heater element and heatsink temperature.

Q: Why does the temperature slowly increase despite already exceeding the Setpoint?

A: Try increasing the Pulse Rate period. In order to measure the heater’s resistance, power is briefly supplied to the heater

and the current and voltage are measured. If the CT398 checks too frequently and the heater / heat sink is relatively small,

this will result in excessive heating.

Q: Can any heater be used with the CT398?

A: Provided the applied voltage and heater resistance does not exceed the CT398’s output current rating, yes any heater may

be used as long as it uses a high TCR element. If a high TCR element is not used, the heater’s resistance may not change

enough relative to temperature to be useful.

page 7

| © 2015 Minco | 360-00129(-) | minco.com

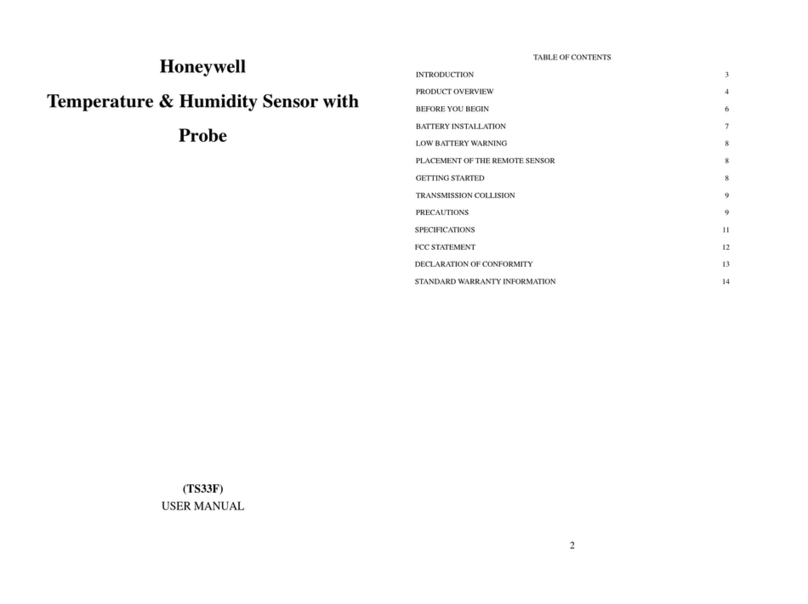

Specifications

Inputs

Power Input

5 – 80VDC

Outputs

Heater Output

Ambient 25°C 55°C 70°C

Current

Rating

, 60

VDC Supply 10 amps 6.5 amps 3 amps

Current Rating, 80

VDC Supply 10 amps 6.5 amps Not

recommended

For de-rating curve, see Figure 5.

Heater Setpoint Range

0.5Ωto 500Ω

Pulse Rate

100ms to 60s

Communication

Optically via Status LED

General

Resistance/Temperature Setpoint Resolution

1 milliohm

Resistance Measurement Accuracy

+/-3%: up to 55°C and at least 0.25 amp load.

+/-4%: up to 70°C and at least 0.5 amp load.

Dimensions

1.50"L x 1.00"W x 1.00"D (3.81cm L x 2.54cm W x 2.54cm D).

Weight

Approximately 0.7 oz (20 g)

Environmental

Operating temperature: -25 to 70°C (-13 to 158°F) @ 90% relative humidity, non-condensing

Storage temperature: -40 to 85°C (-40 to 185°F) @ 90% relative humidity, non-condensing

Construction

Epoxy potted polycarbonate case with one off-center mounting hole.

Mounting

Mounting hole for #6 screw or #8 thread-forming screw

page 8

| © 2015 Minco | 360-00129(-) | minco.com

Figure 5

Glossary

Term Definition

LED Light Emitting Diode: A solid state device that converts electricity directly into light.

Measurement

Pulse

The momentary application of heater power that is used only to measure heater resistance.

Pulse Heating Heating that occurs not due to the request for heat, but due to the heater being energized

momentarily to check its temperature.

SSR Solid State Relay: A type of relay without mechanical contacts constructed from solid state

components.

TCR Temperature Coefficient of Resistance: The relationship between the temperature and resistance of

a heater.

USB Universal Serial Bus: A common computer interface on computers for interfacing to various

peripherals.

0

2

4

6

8

10

12

-25 -15 -5 5 15 25 35 45 55 65

Rated DC Switching Current

Ambient Temperature (°C)

60 VDC

80 VDC

Table of contents

Other Minco Temperature Controllers manuals