- 2 -

www.mineralpro.com

System Maintenance

Just because you can not taste it, does not mean that it is not there. Contaminants such as lead, chromium,

VOC’s and arsenic are undetectable to the taste. Additionally, over time if you do not replace the filter elements,

other bad tastes and odors will be apparent in your drinking water.

This is why it is important to change out your filter at the recommended intervals as indicated in this system

manual. Should you have any further questions please contact the dealer from whom you purchased the unit.

With proper installation and maintenance, this system will provide you with high quality water for years to

come.

Table of Contents

Operational Parameters:.................................................................................................................................... 3

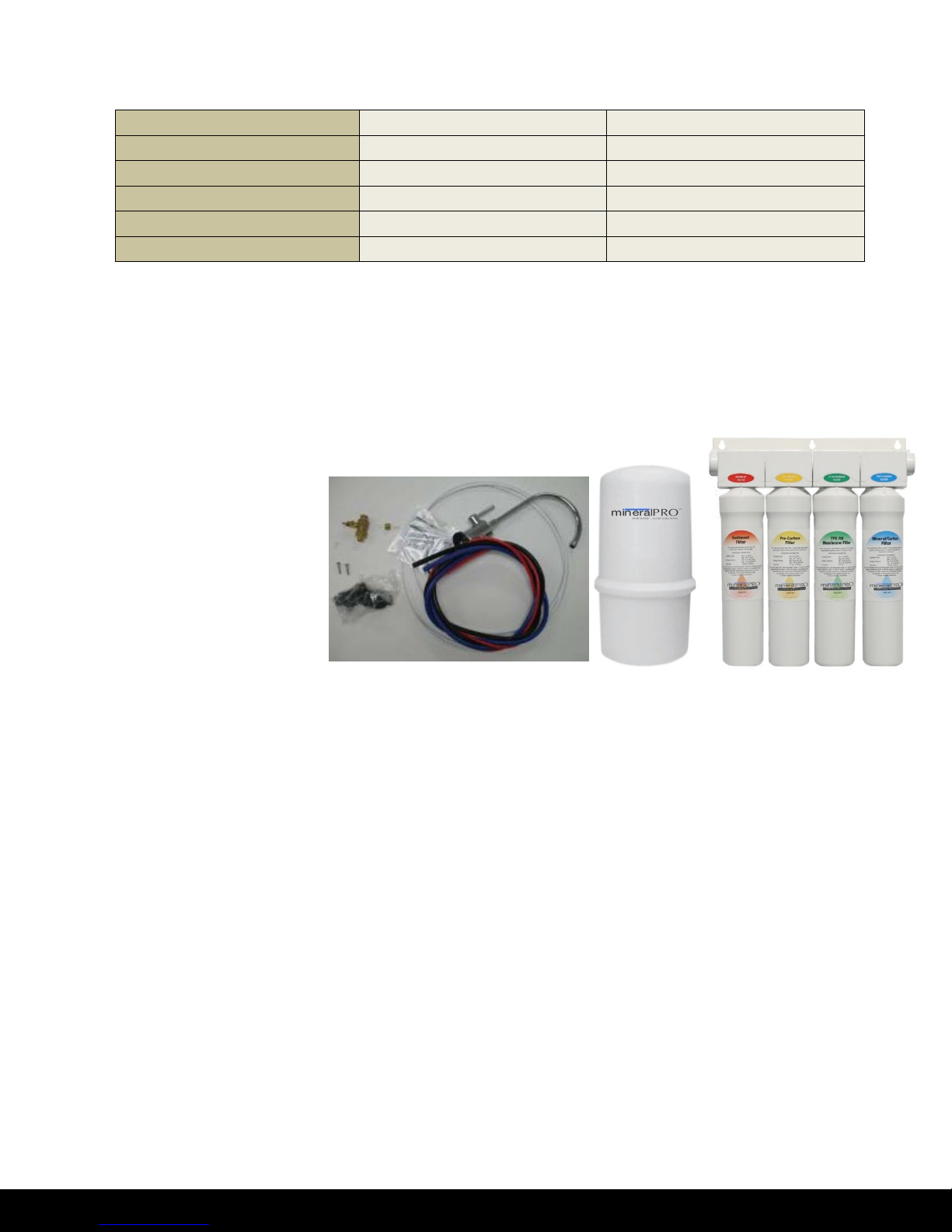

Contents of MINERALPRO .................................................................................................................................... 3

Tools Recommended For Installation ................................................................................................................ 3

Step 1 –Determine Location for the Faucet...................................................................................................... 4

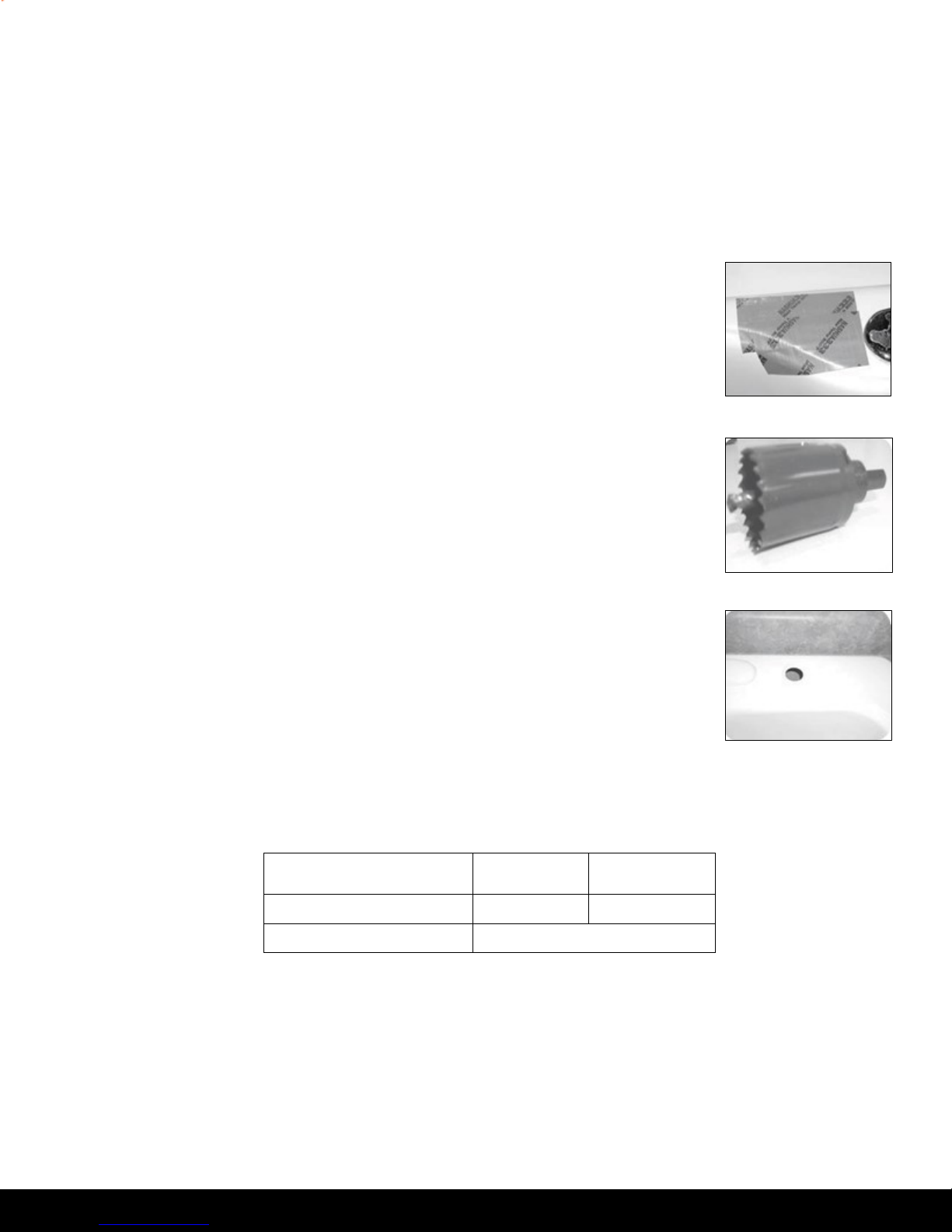

Step 2 –Drill a Hole for the Faucet in a Stainless Steel Sink.............................................................................. 4

Step 3 –Drill a Hole for the Faucet in a Porcelain, Enamel, Ceramic on Metal or Cast Iron............................. 5

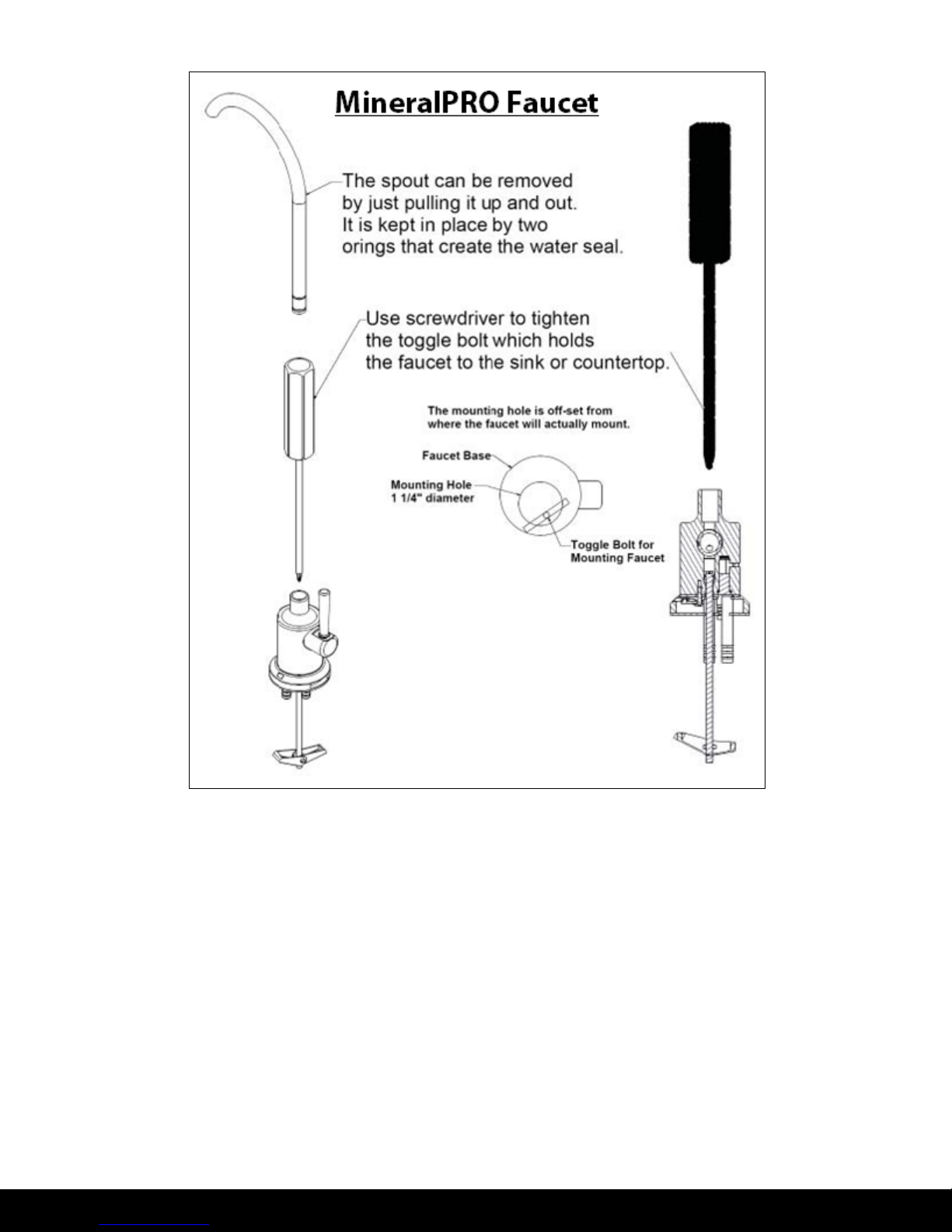

Step 4 –Faucet Installation................................................................................................................................ 5

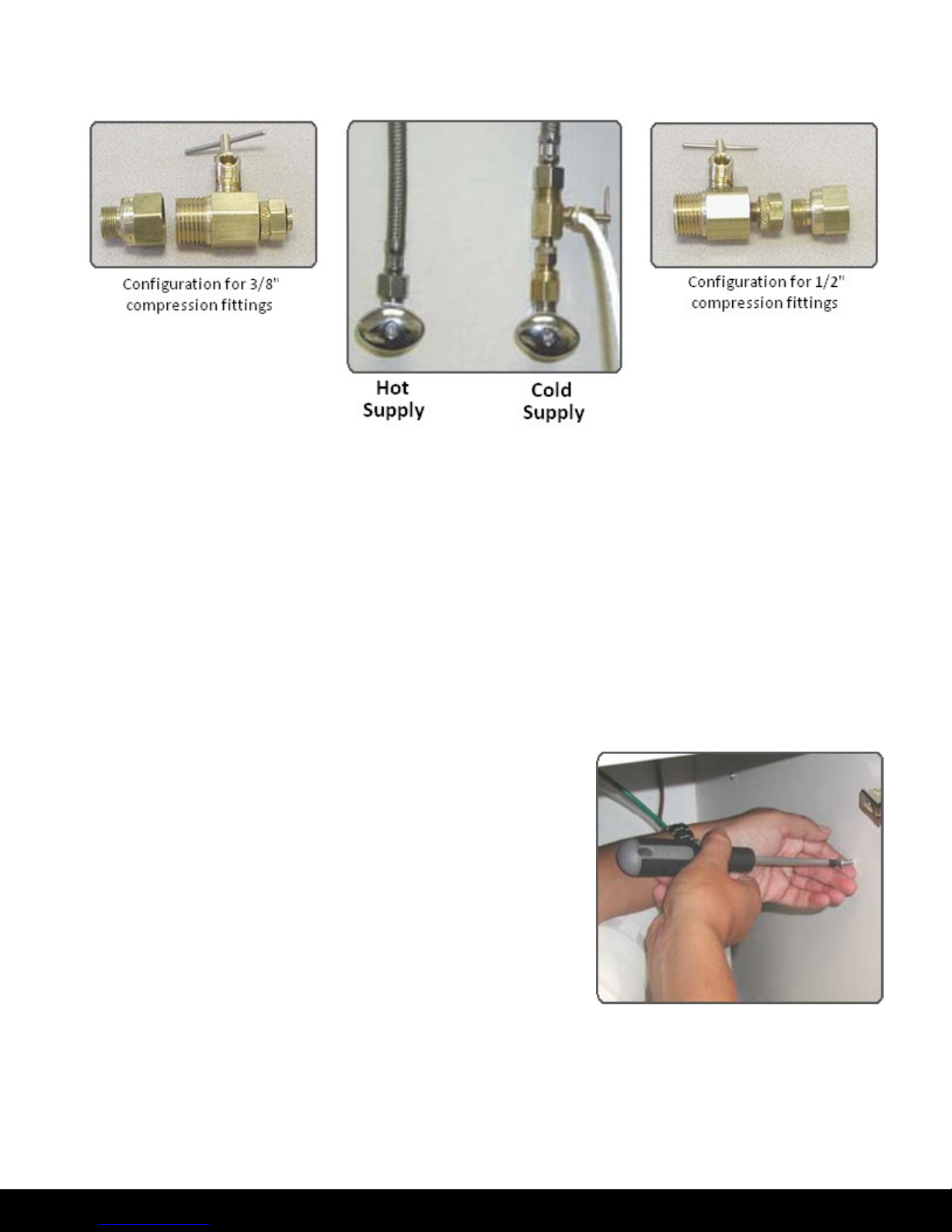

Step 5 –Water Valve (Adapta-Valve) Installation.............................................................................................. 7

Step 6 –MINERALPRO Module Mounting............................................................................................................ 7

Step 7 –Drain Saddle Installation ...................................................................................................................... 8

Step 8 –Tank Valve Installation ......................................................................................................................... 9

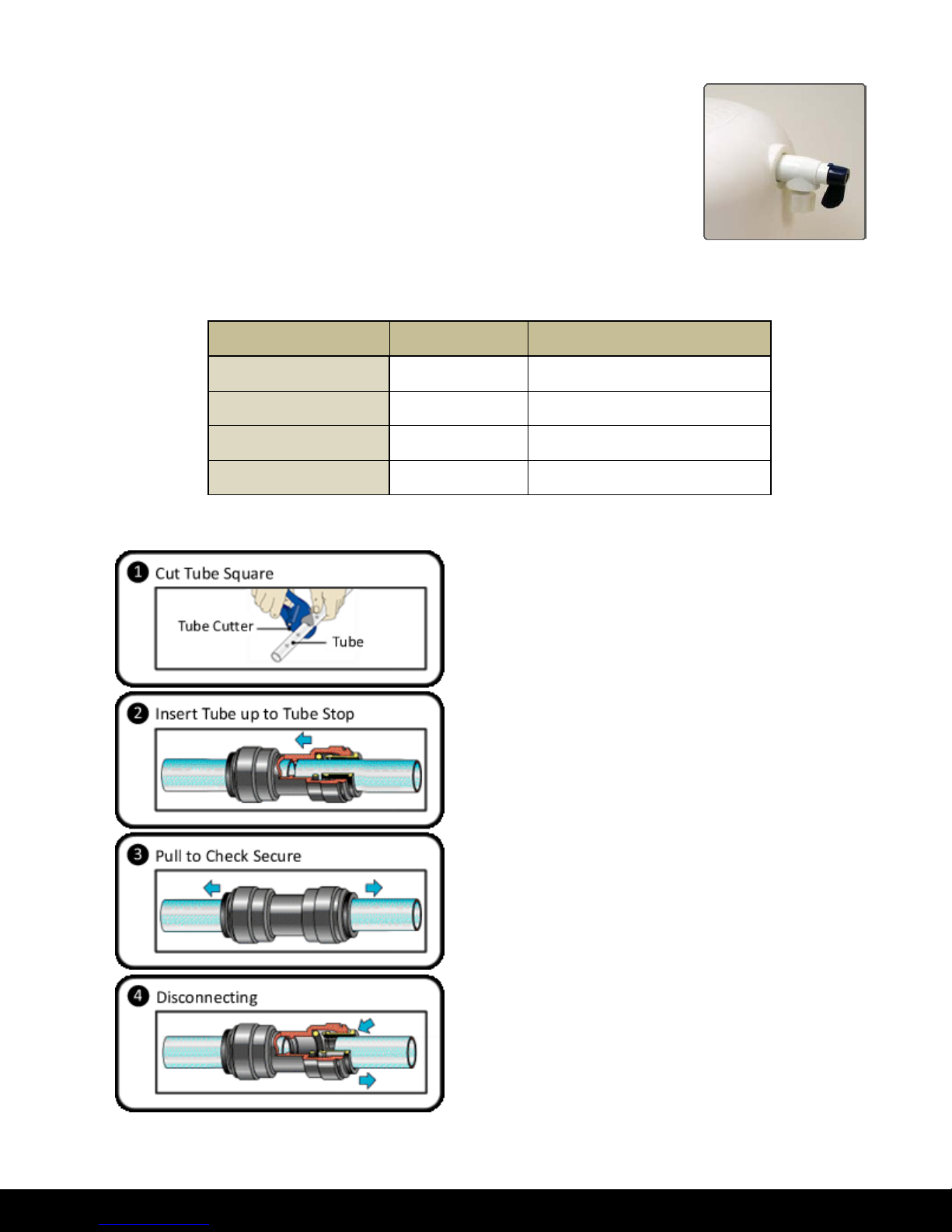

Steps 9 through 12 (Tube Connections)............................................................................................................. 9

Quick Reference Tube Connections ............................................................................................................... 9

How to Use the Quick Connect Fittings on the RO Module ........................................................................... 9

Step 9 –White 3/8” Tube Connection (Tank <---> MINERALPRO)..................................................................... 10

Step 10 –White ¼” Tube Connection (Adapta-Valve <---> MINERALPRO)........................................................ 10

Step 11 –Blue 3/8” Tube Connection (Faucet <---> MINERALPRO)................................................................... 10

Step 12 –Red ¼” Tube Connection (Drain <---> MINERALPRO)......................................................................... 10

Step 13 –Install Cartridges .............................................................................................................................. 11

Step 14 –Start-Up Instructions........................................................................................................................ 11

Maintenance Instructions ................................................................................................................................ 12

Cartridge Replacement Instructions ............................................................................................................ 12

Cartridge Replacement Schedule................................................................................................................. 13

Annual Maintenance ................................................................................................................................... 13

Storage Tank Sanitization ............................................................................................................................................. 13

Drain Line Flow Restrictor............................................................................................................................................. 13

Tank Air Pressure .......................................................................................................................................................... 14

Procedure for Extended Non-Use (2 months or longer) .............................................................................................. 14

Troubleshooting ............................................................................................................................................... 15

Service Record .................................................................................................................................................. 16

Limited Warranty ............................................................................................................................................. 17