he instructions for assembling with Mini-Stops

1. Safety instructions

Caution !

Assembly of the machine must only be carried out by appropriately trained technician.

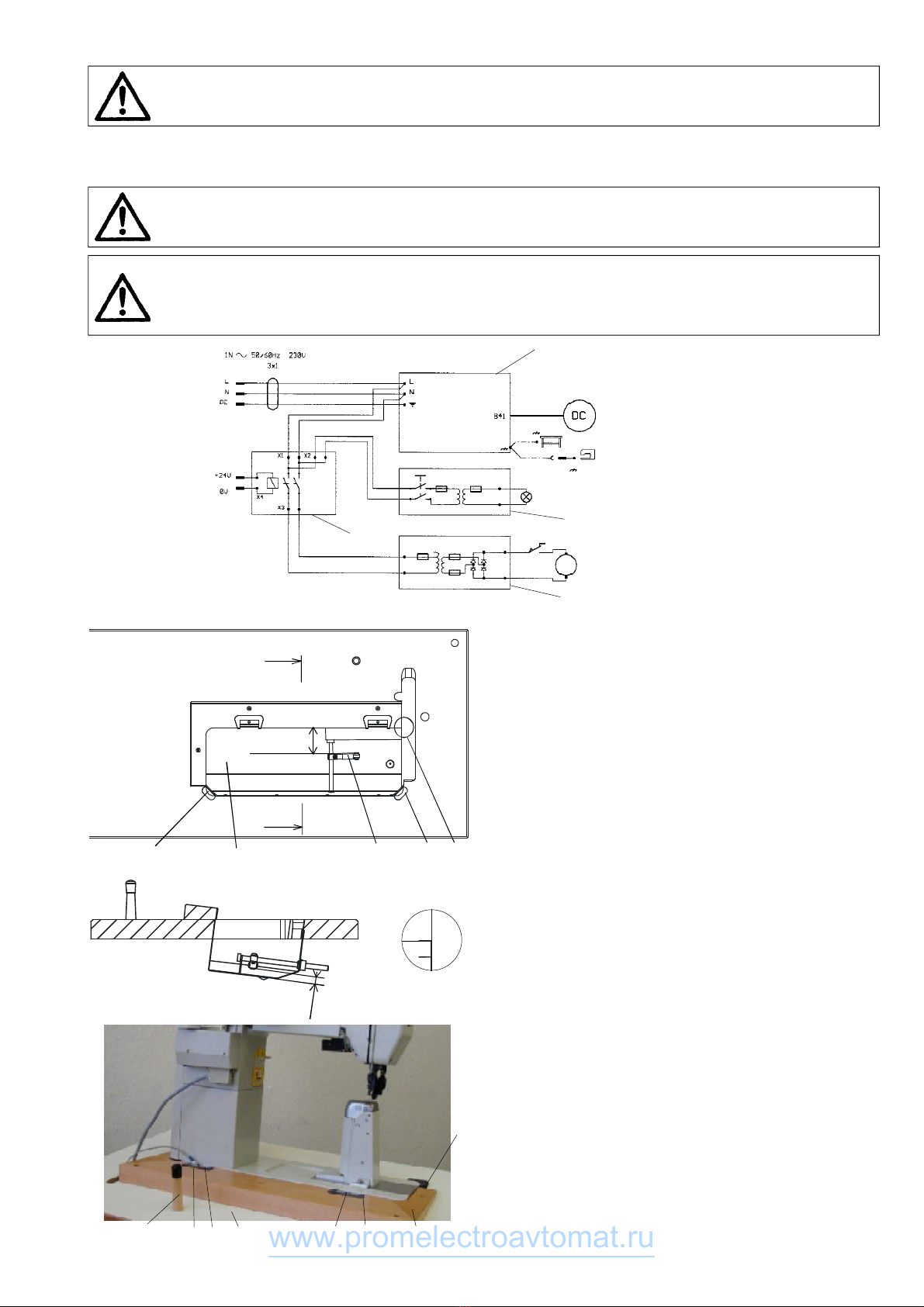

Any operations to be performed on the electric installation of the sewing machine are to be done only by a compe-

tent electrician.

SAFEY INSRUCIONS OF HE DRIVE MANUFACURER

The drive for the MINI-STOP sewing machines is manufactured and tested according to the valid safety regulations and enables

in this way a safe and dependable operation. For maintaining this condition and a safe running, the user needs to be acquainted

with all hints and cautions contained in these instructions, as well as in the instructions of the drive manufacturer.

The MINI-STOP is destined for the sewing industry and for being run in clean and dry rooms. It may not be put into operation

when the machine, in which it is incorporated, does not comply with all regulations and provisions. It is not allowed to use the

drive in outer humid spaces or in spaces with possible explosion risk. It is necessary to observe the hints of the manufacturer

concerning the running, attendance and maintenance. The MINI-STOP works in a safe and dependable way when there are

maintained the hints of the instructions and the purpose of the driver use. These instructions should be carefully read before

unpacking and putting the drive into operation. Before the first putting of the MINI-STOP, its accessories and supplements into

operation, be sure in being acquainted with the hints concerning the assembly, attendance, running and maintenance. All

activities connected with the drive may be carried out only when observing the respective regulations and when respecting the

given safety rules descreibed in the following parts of the indstructions. All persons concerned must be acquainted with these

safety warnings. The inobservance of these hints may cause injuries of persons, damage of objects or breakdowns or damage of

the drive.

It is necessary to observe the regulations concerning accidents, safety and skilled labour being in force in the given country.

The MINI-STOP may be installed and put into operation only by qualified persons. This will reduce to a minimum the consequences

of breakdowns with the possible health injury of persons.

Operations carried out on the machine or on its parts under high voltage are not allowed. Exceptions thereof are regulated by the

EN 500 standard.

Before removing guards, assembling additional devices or accessories, e.g. sensors of the pedal position, photocell etc., the

drive must be disconnected from the mains and the drive must be put ito its idle condition. The operating box may be oppened

only after having run 0 minutes! wing to the risk of burning, fire, electric chock or injury, any reconstructions or eventual

modifications of the MINI-STOP are prohibited. During the running thereof, its guards or protective devices may not be removed.

Before leaving the work place, the mains switch must be out into the OFF condition. When the drive is out of use for some time,

the mains plug is to be disconnected from the mains and the drive must be secured against an accidental switching on.

In the event of having connected additional devices or operational means to the drive, these may be fed only with low voltage

from a safety transformer.

Never operate the drive when the air vents there of are clogged. Be sure in avoiding the presence of dust or fibres therein. Do not

insert and avoid falling of any object, e.g. needles, into these vents. Do not use MINI-STOP when working with aerosols and

sprays or with oxygen. The cautions mentioned in the following parts serve for ensuring further safety.

The MINI-STOP may be operated only with a protective conductor connected on a protective system which complies with all

regulations and service provisions.

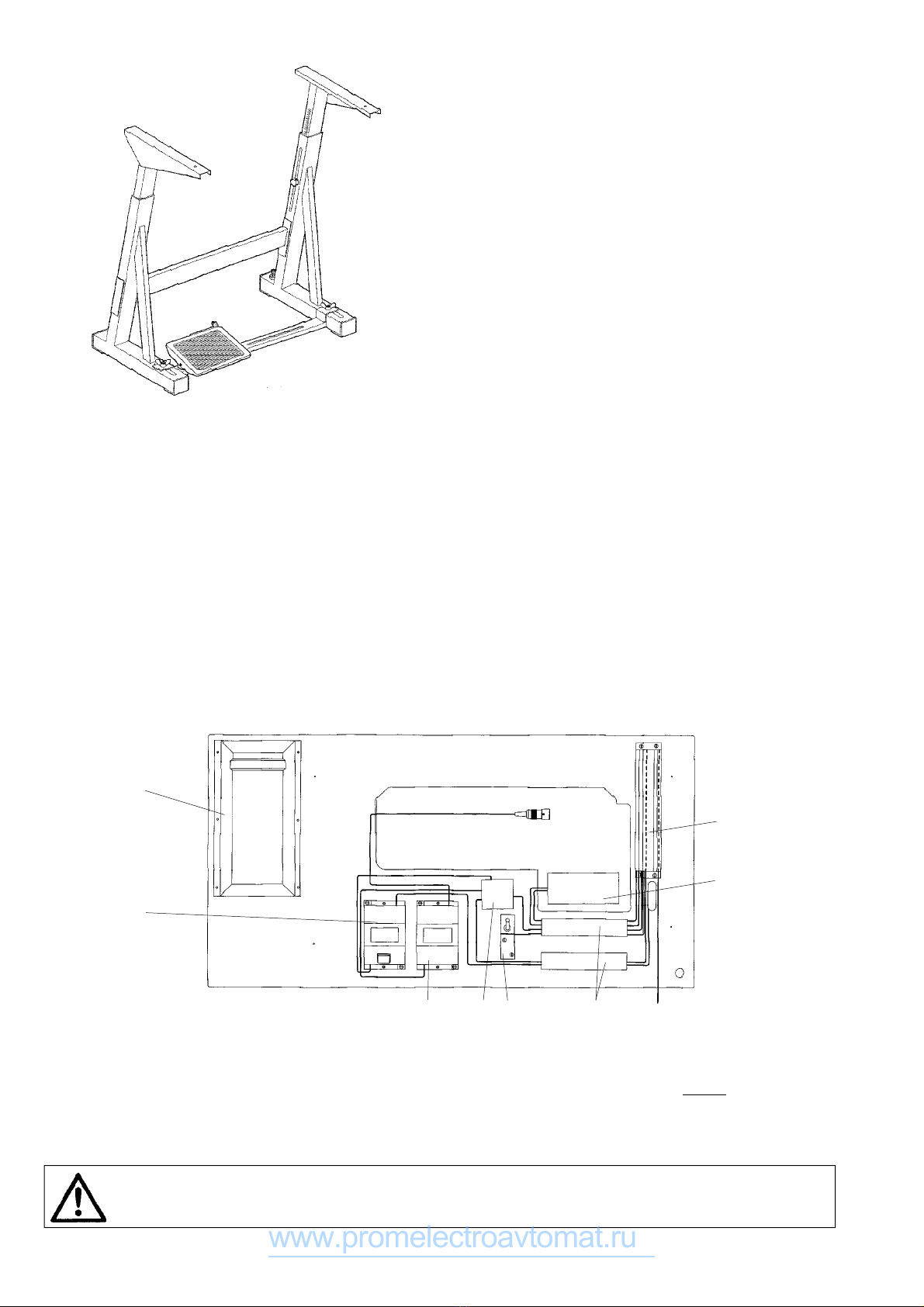

2. he way of machine supply

The contents of supply will be determined in agreement between the supplier and buyer. There are following possibilities:

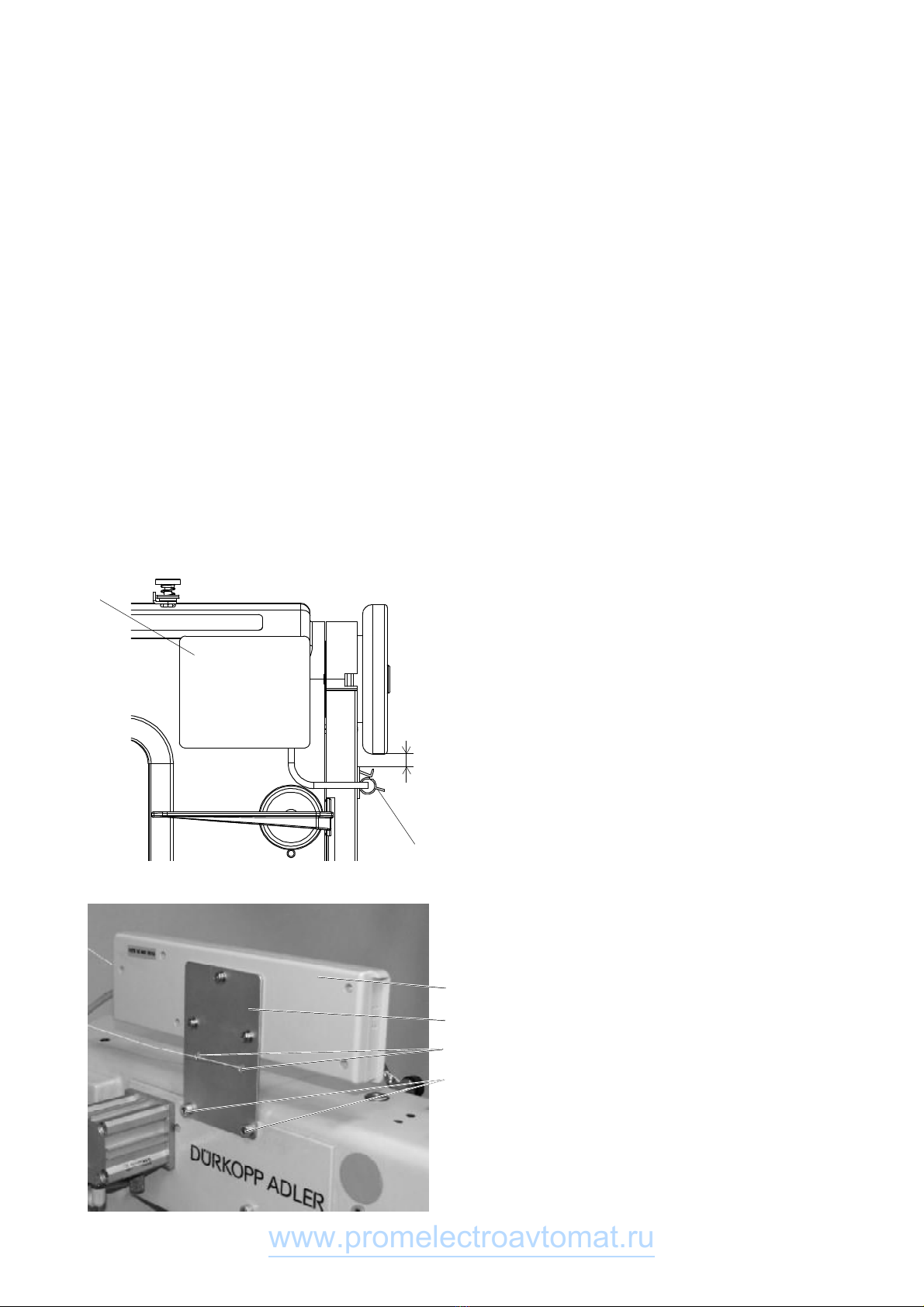

2.1Complete head with accessories

In this case the supply contains:

-Complete head with motor, control electronics and connecting head cable.

-Chosen spare parts in the bag under the presser element (see parts indicated * in catalogue of spare parts).

-Standard accessories (it contains tools-see module in catalogue of spare parts).

-Special accessories (it contains some components of a stand and upper belt cover-see module in catalogue of spare parts).

The supply like this is not complete. Buyer will provide missing components himself or he can put in an extra order to get them

according to the following paragraphs.

2.2Stand

Delivery contains components of a stand, however, without components of a stand included in special accessories supplied with

machine head (see par. 2.) and without any electrical components. If it hasn‘t been agreed otherwise, the stand is supplied in

separate pieces. If the assembled stand is asked, special accessories are used from head supply.

Stand (ordered number S400 09000 for subclasses with Mini-stop) contains following items:

MG55 00050 Stand frame

MG53 00250 Big treadle

MG53 0075Set of parts for a stand

S65 00038 Table top

www.promelectroavtomat.ru