3-A 128-57 3mm Tray Mount 11

3-A 129-44 Battery Mount Rail Support 2

3-A 131-53 C/F Gyro Plate 2

3-A 131-382 C/F Spacer 3

3-A 134-127 Front Battery Tray 1

3-A 134-132 Bottom Battery Tray 1

3-A 134-134 Battery Plate 1

3-A 134-443 Battery Mount Rail 2

3-Hardware 0032-2 M3x8 Self Tapping Screw 4

3-Hardware 0058-7 M4x10 Socket Set Screw 2

3-Hardware 0062-2 M3x12 Tapered Socket Bolt 4

3-Hardware 0081 M4x16 Socket Bolt 2

3-Hardware 0088 M3x8 Tapered Socket Bolt 6

3-Hardware 0088-2 M3x6 Tapered Socket Bolt 16

3-Frames 134-10 C/F Left Frame - Electro 1

3-Frames 134-11 C/F Right Frame - Electro 1

3-Hardware 0003 3mm Washer 20

3-Hardware 0009 3mm Washer small 10

3-Hardware 0032 2.9x9.5 Tapping Screw 4

3-Hardware 0060-1 M3x6 Socket Bolt 30

3-Hardware 0061 M3x8 Socket Bolt 40

3-Hardware 0063 M3x10 Socket Bolt 5

3-B 128-58 Frame Spacer 11

3-B 131-46 P/A Servo Rail 2

3-B 131-47 C/F Servo Rail Spacer 2

3-B 131-186 C/F Anti-rotation Bracket 1

3-B 131-420 Mid Main Bearing Block 1

3-B 131-429 C/F X-Brace 1

3-Hardware 0060-1 M3x6 Socket Bolt 4

3-Hardware 0063 M3x10 Socket Bolt 2

3-Hardware 0065 M3x12 Socket Bolt 2

3-S 0818-3 Mounting Block 2

3-S 131-50 Elevator Servo Mount 2

3-S 131-148 C/F Servo Plates 14

S-Hardware 0059-1 M2.5x6 Socket Bolt 4

S-Hardware 0059-4 M2.5x12 Socket bolt 16

S-Hardware 0059-7 M2.5x20 Socket Bolt 4

S-Hardware 0116 M2.5 Threaded Steel Ball 5

3-C 134-100 Motor Mount 1

3-C 134-101 Lower Pinion Bearing Block 1

3-C 134-102 Motor Mount Support Left 1

3-C 134-103 Motor Mount Support Right 1

3-C 134-112 Helical Pinion 1

3-Hardware 0061 M3x8 Socket Bolt 8

3-Hardware 0063 M3x10 Socket Bolt 2

3-Hardware 0078-4 M4x8 Socket Bolt 4

3-Hardware 0003 3mm Washer 4

3-Hardware 0058-1 M4x6 Socket Set Screw 4

3-Hardware 0073 M3x20 Socket Bolt 4

3-Hardware 0078-5 M4x10 Socket Bolt 4

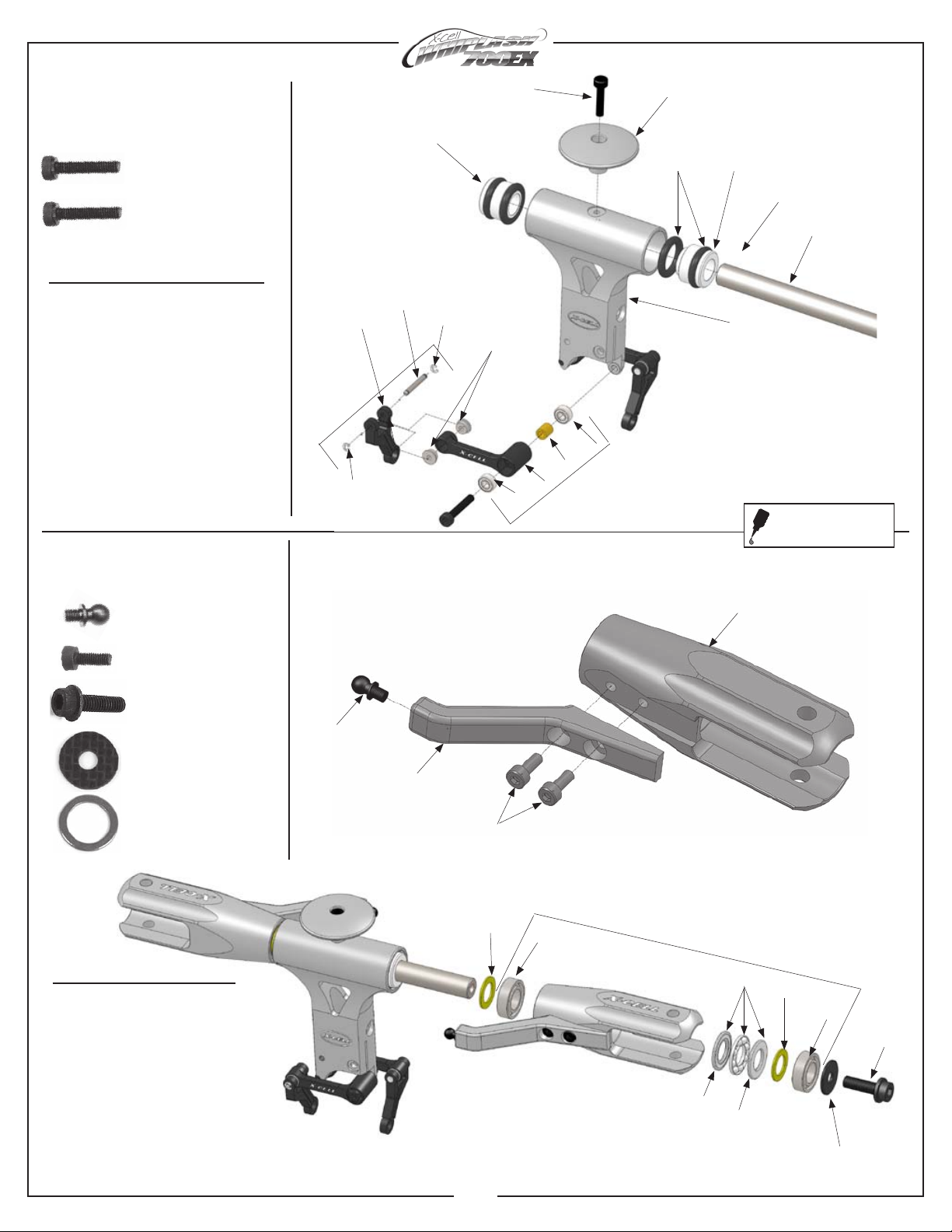

3-E 0390 Wire Retainers 5

3-E 0875-1 10mm Split Main Shaft Collar 2

3-E 131-424 Main Gear Hub 1

3-E 131-440 Lower Main Bearing Block 1

3-E 131-466 Auto Hub 1

3-E 131-469-1 Gear Support 1

3-E 131-470 70T Machined Crown Gear 1

3-E 132-117-B 124T Main Gear 1

3-E 3200-30 20” Spiral Band for Wire and Cable 1

3-E 3200-48 20” 3/4 Hook and Loop Tape 1

3-E 3200-54 17” Adhesive Hook and Loop 1

3-Hardware 0059-2 M2.5x8 Socket Bolt 2

3-Hardware 0088 M3x8 Tapered Socket Bolt 13

3-Hardware 0620-01 15x21x.10 Shim Washer 1

3-Hardware 0620-02 15x21x.20 Shim Washer 1

3-Hardware 0620-03 15x21x.30 Shim Washer 2

3-Hardware 131-202 Jesus Bolt OWB V2 1

3-E-1 106-22 Rubber Canopy Grommet 4

3-E-1 128-59 M4 Front Boom Support Brace 1

3-E-1 131-150 Front Canopy Post 2

3-E-1 131-151 Rear Canopy Post 2

3-E-1 131-153 C/F Canopy Breakaway Tabs 4

3-E-1 131-154 Thumb Screw 4

3-Hardware 0003 3mm Washer 2

3-Hardware 0016-2 M4 Lock Washer 2

3-Hardware 0063 M3x10 Socket Bolt 4

3-Hardware 0081 M4x16 Socket Bolt 2

3-Hardware 0103 2mm Threaded Steel Ball 1

BOX 134-230 730E Frame Assembly Manual 1

BOX 3000-73 MA Towel 1

BOX 3700-160 Blade Holder 1

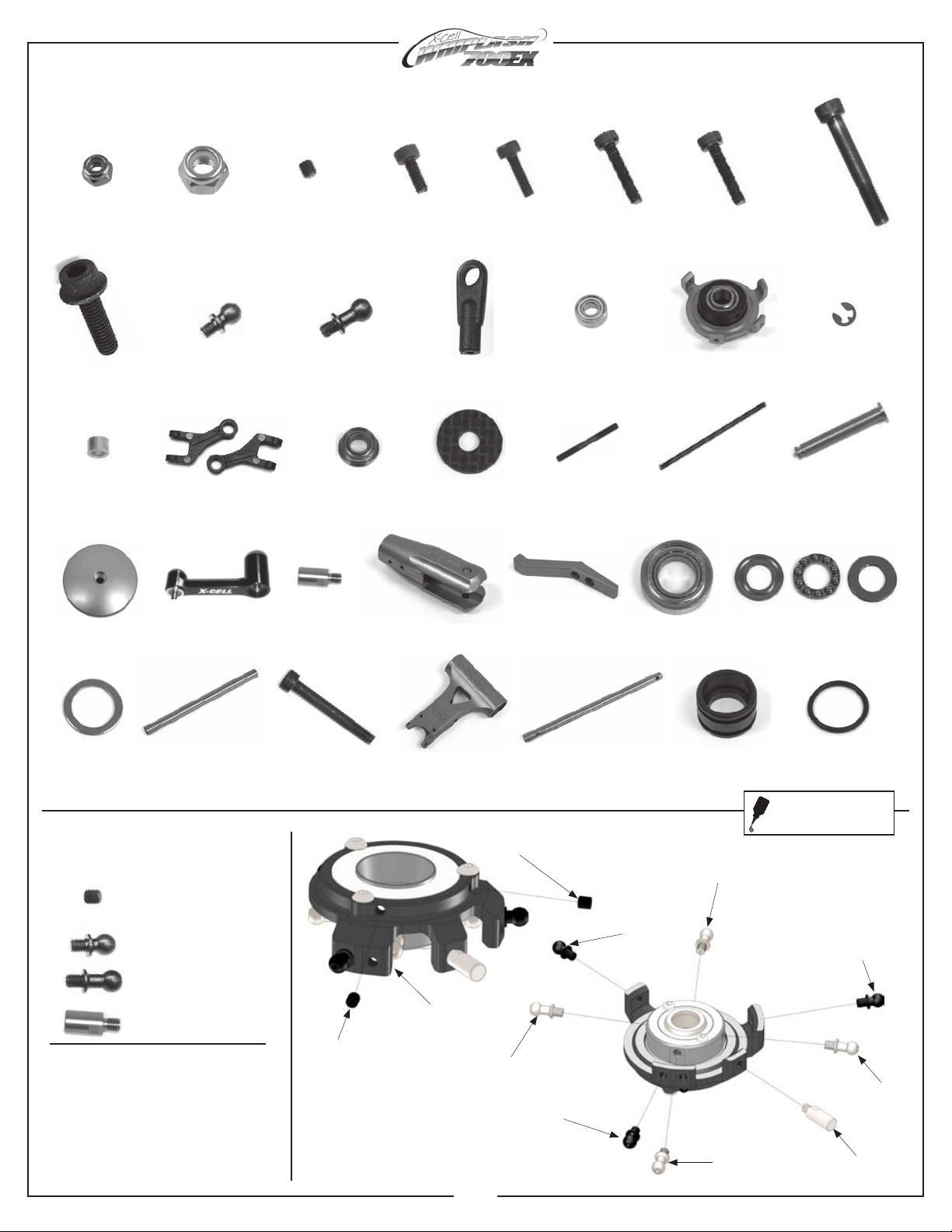

Bag 3 - 730 Electro Frame Assembly (MA1034-1)

8