3

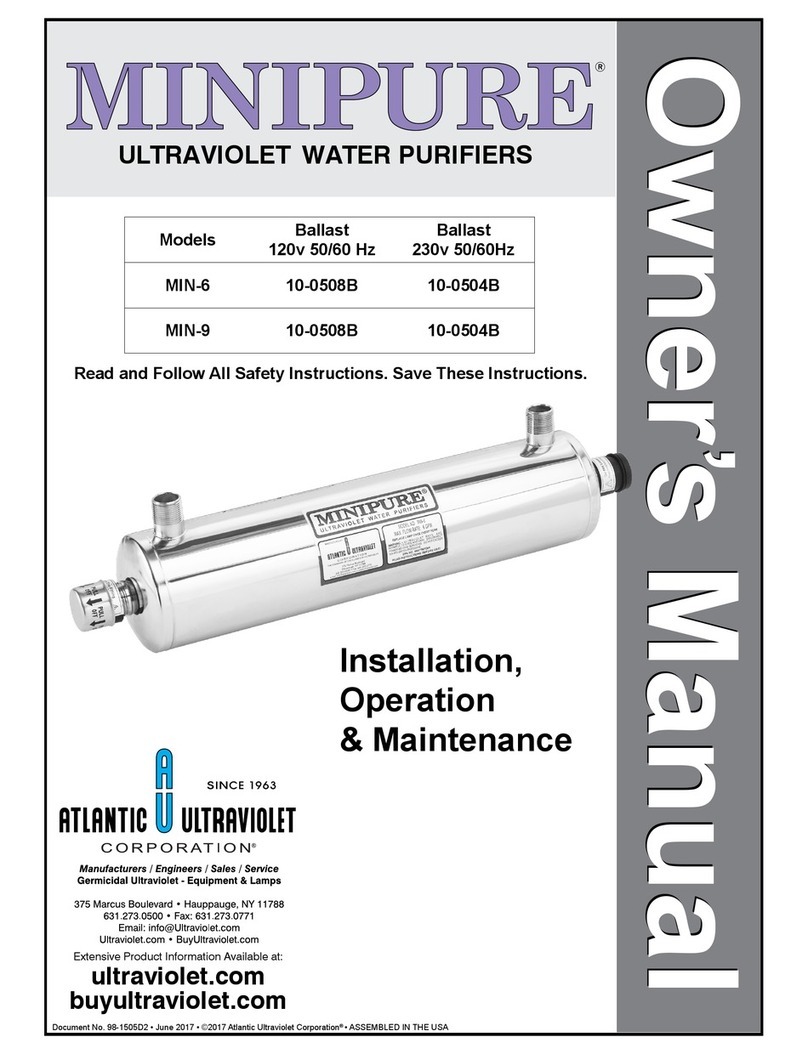

Danger Label: Hazardous Voltage

and Ultraviolet Radiation (00-0199A1)

It is the user’s responsibility to determine and validate the

suitability of this equipment for use in the user’s system or process.

No warranty or representation is made by the manufacturer with

respect to suitability or performance of this equipment or to the

results that may be expected from its use.

The user should periodically inspect, clean as necessary and

conrm the presence and good legibility of the product safety

labels. Contact the factory for replacement labels in the event that

any of the labels are missing or illegible.

Location of Danger Label

(00-0199A1)

SAFETY WARNINGS

• All personnel should be alerted to the potential hazards indicated by the product safety labeling on this unit.

• The following conventions are used to indicate and classify precautions in this manual and on product safety labeling. Failure to

observe precautions could result in injury to people or damage to property.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

SAFETY INSTRUCTIONS

To guard against injury, basic safety precautions should be observed, including the following:

1. Read and follow ALL safety instructions.

2. Do not use this water purier for other than its intended purpose as described in this manual.

3. Do not alter design or construction.

4. Do not remove any labels or devices.

5. To prevent the risk of severe or fatal electrical shock, special precautions must be taken since water

is present near electrical equipment. Always disconnect power before performing any service or maintenance.

6. Avoid exposure to direct or reected germicidal ultraviolet rays. Germicidal ultraviolet rays are

harmful to the eyes and skin.

7. Intended for indoor use only. The water purier should be protected from the elements and from temperatures below freezing.

8. Do not operate water purier if lamp cable, lamp connection, power cord and/or plug are damaged, or if any other damage to

the water purier is visible or suspected

9. Electrical power supplied, to the water purier, MUST match power requirements listed on the water purier.

10. Plug the purier only into an APPROVED GROUND FAULT CIRCUIT INTERRUPT (GFCI) RECEPTACLE.

11. Do not operate without proper electrical ground.

12. Do not exceed water purier’s maximum rated ow capacity.

13. Do not exceed maximum operating pressure of 100 PSI.

14. Read and follow all notices and warnings on the water purier.

15. SAVE THESE INSTRUCTIONS.

SAFETY LABELS CAUTION

This symbol is used to identify the need

to wear protective gloves.

Caution indicates a POTENTIALLY

hazardous situation, which, if not avoided,

MAY result in minor or moderate injury.

Caution used without the safety alert

symbol indicates a potentially hazardous

situation, which, if not avoided, may result

in property damage.

This symbol is used to identify an

ULTRAVIOLET LIGHT hazard.

This symbol is used to identify an ELECTRICAL

SHOCK or ELECTROCUTION hazard.

Warning indicates a POTENTIALLY

hazardous situation, which, if not avoided,

COULD result in death or serious injury.

This symbol is used to identify the need

to wear approved ultraviolet blocking eyewear.

This symbol is used to identify the need to wear approved

ultraviolet blocking face shield.

This symbol is used to identify components which must

not be disposed of in trash

Danger indicates an IMMINENTLY

hazardous situation, which, if not avoided,

WILL result in death or serious injury.