Form: MM-A-1C/A-2C Revised: 1-7

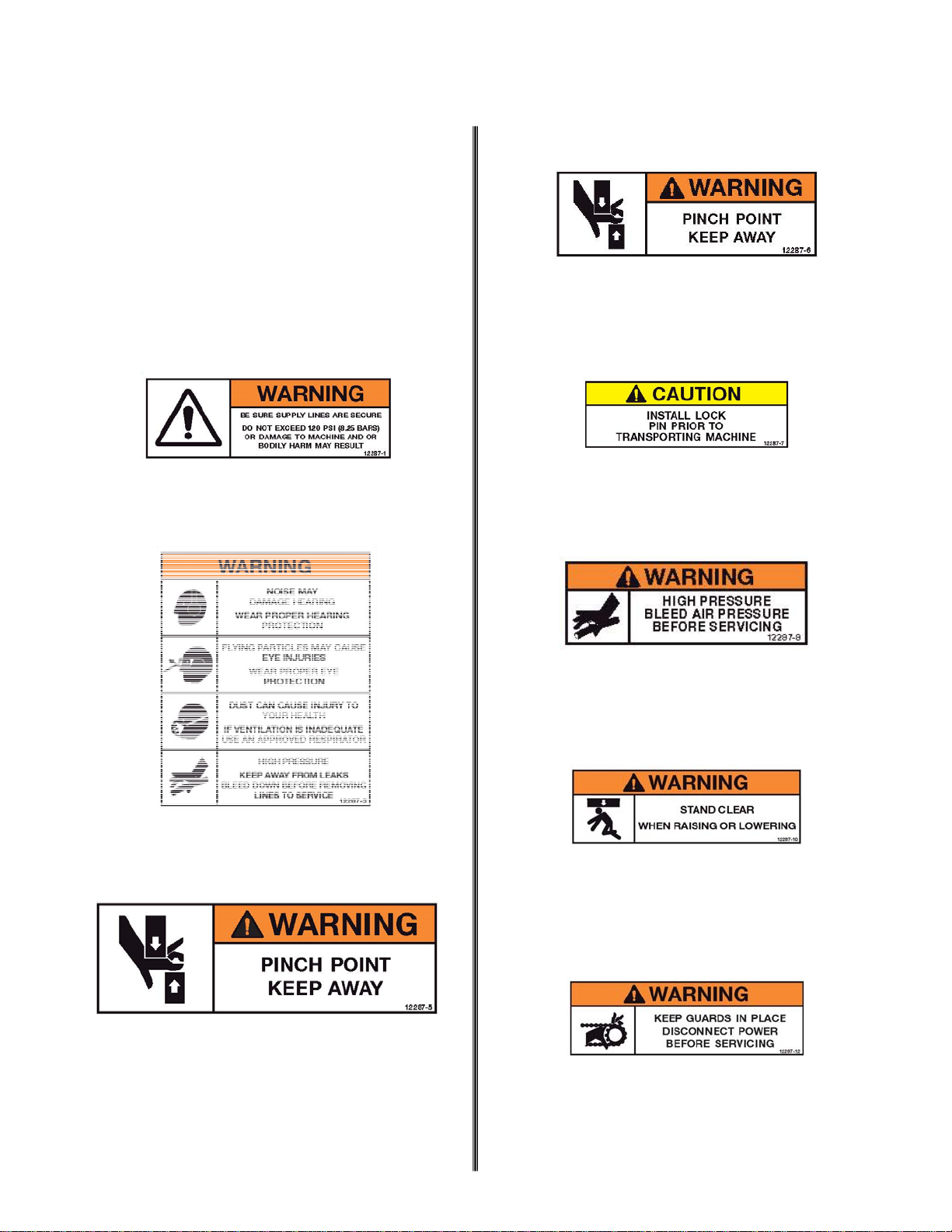

Safety Section

eye and hearing protection. Dust mask,

non-skid safety shoes, hard hat, and/or

hearing protection must be used for ap-

propriate conditions. Prolonged expo-

sure to loud noise can cause impair-

ment or loss of hearing. Wear suitable

hearing protection devices such as ear-

muffs or earplugs.

6. Keep a first-aid kit near the machine.

Safety depends on you.

TOOL USE AND CARE

1. Only qualified persons should operate

the machine. Make sure you operate

and service your machine according to

the instructions listed in this manual.

2. When positioning the machine for drill-

ing, always face the drill. DO NOT op-

erate with your back to the machine.

Facing the machine during positioning

allows the operator to have better con-

trol of the machine.

3. DO NOT force the machine. Use the

correct machine for your application.

The correct machine will do the job bet-

ter and safer at the rate for which it is

designed.

4. DO NOT use the machine if the switch

does not turn it on or off. Any machine

that cannot be controlled with the

switch is dangerous and must be re-

paired.

5. Disconnect the machine from the pow-

er source before making any adjust-

ments, changing accessories or storing

the machine. Such preventative safety

measures reduce the risk of starting

the machine accidentally.

6. Store machines out of reach of children

and other untrained persons. Machines

are dangerous in the hands of un-

trained users.

7. Maintain machines with care and keep

them clean. Properly maintained ma-

chines are less likely to bind and are

easier to control.

8. Check for misalignment or binding of

moving parts, breakage of parts and

any other condition that may affect the

machines operation. If damaged, have

the machine serviced before using.

Many accidents are caused by poorly

maintained tools.

9. Use only accessories that are recom-

mended by the manufacturer for your

model. Accessories that may be suita-

ble for one machine may become haz-

ardous when used on another.

SERVICE

1. DO NOT run the drill unit while you

make adjustments and repairs unless

the procedure is approved.

2. Escaping fluid and air under pressure

can have sufficient force to penetrate

skin causing serious personal injury.

3. Before disconnecting lines, be sure to

relieve all pressure. Before applying

pressure to the system, be sure all

connections are tight and that lines,

tubes and hoses are not damaged.

4. DO NOT use your hand to search for

leaks. Instead, use a piece of card-

board or wood.

5. Tool service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified

personnel could result in injury or

death.

6. When servicing a tool, use only identi-

cal replacement parts. Use of unau-

thorized parts increase injury risk.