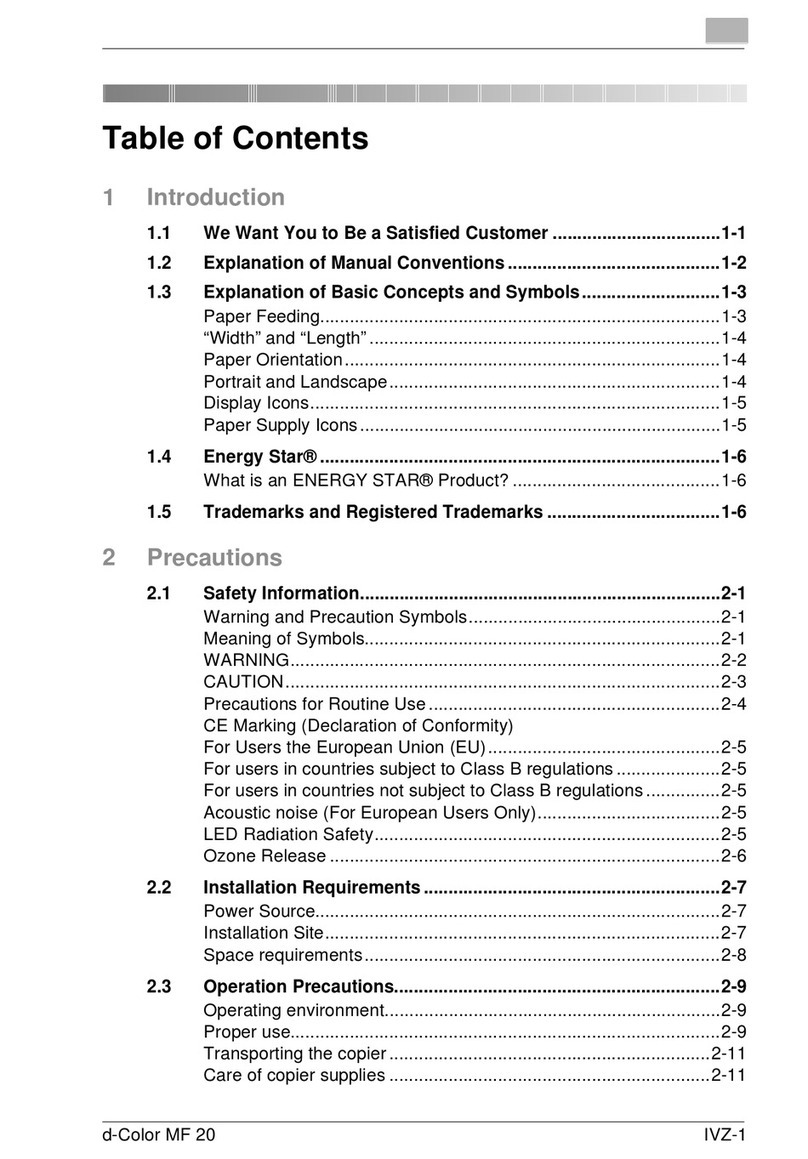

T-6

Symbol Panel Display Parts/Signal Name

Operation Charac-

teristics/Panel Dis-

play IC

No. Port

No. CN/PJ

No.

10

TH1 Fusing

Unit Upper Roller

(°C) Upper Fusing Roller

Thermistor Voltage value

(A/D converted) IC1A ANI0 PJ3A-9B

TH2 Lower Roller

(°C) Lower Fusing Roller

Thermistor Voltage value

(A/D converted) IC1A ANI1 PJ3A-10B

Thermistor Set Thermistor Set

Switch In position Out of

position IC1A P17 PJ3A-1B

UN4 Devel-

oping ATDC-S ATDC Sensor Voltage value

(A/D converted) IC1A ANI3 PJ8A-10B

UN6 AIDC-S AIDC Sensor Voltage value

(A/D converted) IC1A ANI2 PJ10A-1B

S7 Sub Hopper Sub Hopper Toner

Empty Switch Toner

loaded Toner

empty IC5A P303 PJ8A-12B

PC4 Toner Bottle

Set Toner Bottle Home

Position Sensor At home Not at

home IC5A P321 PJ2A-5A

PC16 HV Clean

(Charge) Drum Comb Clean-

ing Home Position

Sensor At home Not at

home IC3A P154 PJ9A-14A

PC17 Clean (Trans.) Transfer/Separator

Wire Cleaning Home

Position Sensor At home Not at

home IC3A P155 PJ3A-4B

PHC-ITI PHC ITI signal ON OFF IC3A P121 PJ12A-29A

PC8 Doors Front (Upper) UpperFrontDoorSet

Sensor When

opened When

closed IC5A P320 PJ2A-2A

S2 Front (Lower) Lower Front Door

Interlock Switch When

opened When

closed IC5A P325 PJ6A-14A

S3 Take-up Right Door Interlock

Switch When

opened When

closed IC4A P247 PJ3A-13B

S4 Exit Upper Left Door

Interlock Switch When

opened When

closed IC5A P300 PJ10A-12B

S5 Turn Over Lower Left Door

Interlock Switch When

opened When

closed IC5A P322 PJ8A-10A

Finisher set Finisher Set Switch In position Out of

position IC5A P301 PJ8A-4A

S1 Power Switch Power Switch ON OFF IC5A P326 PJ6A-15A

S6 Pre-drive Off

(F) Predrive OFF Front

Switch Closed Open IC4A P205 PJ2A-8A

PC5 Pre-drive Off

(R) Predrive OFF Rear

Sensor Blocked Unblocked IC4A P223 PJ9A-11B

PC2 Paper

Pas-

sage

Timing Roller Paper Leading Edge

Sensor Paper

present Paper not

present IC4A P200 PJ3A-2B

PC1 Roller Front Transport Roller Sen-

sor Paper

present Paper not

present IC4A P201 PJ3A-3B

PC13 Trans.

Entrance Duplex Unit Horizon-

tal Transport Entry

Sensor Paper

present Paper not

present IC4A P222 PJ7A-4B

PC12 Horiz. Transprt Duplex Unit Horizon-

tal Transport Sensor Paper

present Paper not

present IC4A P221 PJ7A-3B

S10 Exit Paper Exit Switch Paper

present Paper not

present IC5A P307 PJ2A-13A

PC11 Reverse

Entrance Turnover Feed Entry

Sensor Paper

present Paper not

present IC5A P323 PJ6A-14B

PC14 Reverse Exit Turnover/Exit Sensor Paper

present Paper not

present IC5A P324 PJ6A-6B

PC57 Duplex

Remaining Turnover Feed Jam

Sensor Paper

present Paper not

present IC1A INTP

5PJ6A-11B

PC56 Horiz. Remain-

ing Duplex Unit Horizon-

tal Transport Jam

Sensor Paper

present Paper not

present IC1A S10 PJ7A-5B

VR Universal CD-

VR Universal Tray Width

Detection Resistor Voltage value

(A/D converted) IC1A ANI4 PJ8A-8B

UN13 IR Thermistor Exposure Lamp

Heater Voltage value

(A/D converted) IC1A ANI5 PJ7A-10A