Page | 4

SECTION 2: INTRODUCTION

Description

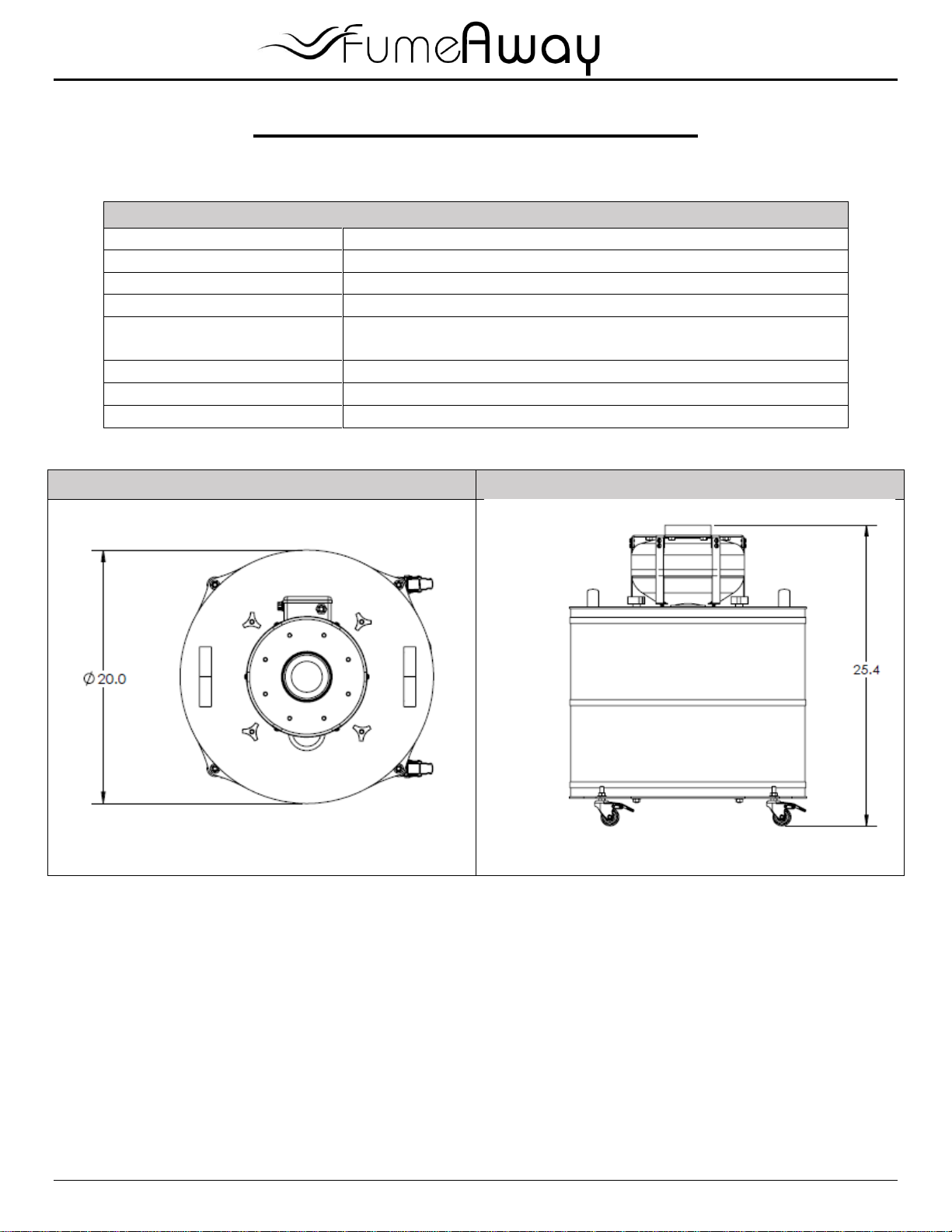

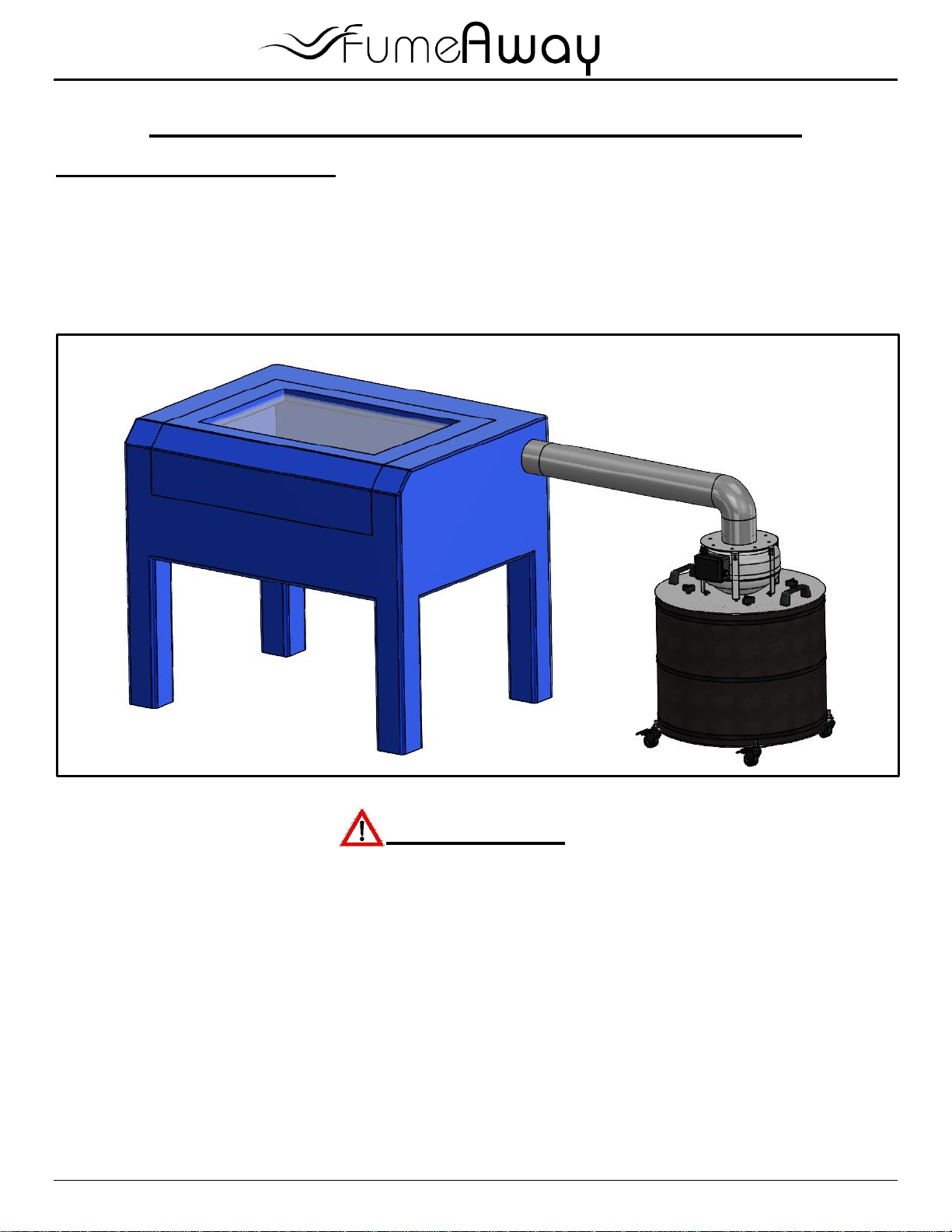

The FumeAway FA200 Extractor is a Portable Fume Filtration unit that is designed to provide high efficiency filtration of

fumes generated from a variety of different applications (see below). The FA-200 is designed to maximize filter life while

remaining as compact, lightweight, and quiet as possible. The low noise fan will be suitable for a quiet environment. The

FA200 is equipped with a Magnehelic differential pressure gauge to accurately monitor filter status. Fumes can be

collected through either a direct vent mounting system, or with the optional extraction arm accessory (see Section 5)

and filtered through a 2 stage HEPA Filter and carbon media layer. The FumeAway includes a speed control knob to be

able control the suction of the Extractor to meet the need of your specific application.

Applications

DISCLAIMER

This section includes some possible applications and DOES NOT GUARANTEE that the unit will work acceptably for

these applications. The FA200 is not designed to be a single solution and additional PPE may be required. The

customer should contact a safety consultant to perform a hazard assessment and use OSHA guidelines on how to

implement, test, and maintain an effective fume control and safety program per their application to protect the

safety of their workers.

Welding Fume Extraction Codes and Standards

Certain operations such as cutting, welding, soldering, and brazing of metals can produce toxic fumes containing a wide

variety of hazardous substances. This unit is designed to be a PART of a welding fume extraction system, and not to be

used as the only solution. Factors that may affect this are workspace size, volume of work, type of material to be

welded, or other special circumstances. Proper PPE is required such as respirators, masks, hood, and other Personal

Protective Equipment.

Please contact the following organizations for more information.

Occupational Safety and Health Administration (OSHA). —Code of Federal Regulations, Title 29 Labor, Parts 1910.1 to

1910.1450, available from the U.S. Government Printing Office, Superintendent of Documents, P.O. Box 371954,

Pittsburgh, PA 15250- 7954 (telephone: 800-321-6742; web site: www.osha.gov)

American National Standards Institute (ANSI). —Safety in Welding, Cutting, and Allied Processes (ANSI Z49.1), available

from Global Engineering Documents, 15 Inverness Way East, Englewood, CO 80112-5776 (telephone: 800-854-7179;

web site: www.global.ihs.com).

American Welding Society (AWS). —Fumes and Gases in the Welding Environment, available from Global Engineering

Documents, 15 Inverness Way East, Englewood, CO 80112-5776 (800-854-7179; web site: www.global.ihs.com).

National Fire Protection Association (NFPA), P. O. Box 9101, 1 Battery March Park, Quincy, MA 02269-9101, (617) 770-

3000, Website: www.nfpa.org and www.sparky.org. —National Electrical Code, NFPA Standard 70 —Standard for Fire

Prevention During Welding, Cutting, and Other Hot Work, NFPA Standard 51B