CONTENTS

1 Overview...................................................................................................................................................... 4

1.1 Product Specifications...................................................................................................................... 4

1.2 Main Functions...................................................................................................................................4

1.3 Measuring Principle...........................................................................................................................4

1.4 Configuration...................................................................................................................................... 5

1.5 Operating Conditions........................................................................................................................ 5

2 Structure Feature.......................................................................................................................................6

2.1 Instrument Appearance.................................................................................................................... 6

2.2 Parts of the Main Body..................................................................................................................... 6

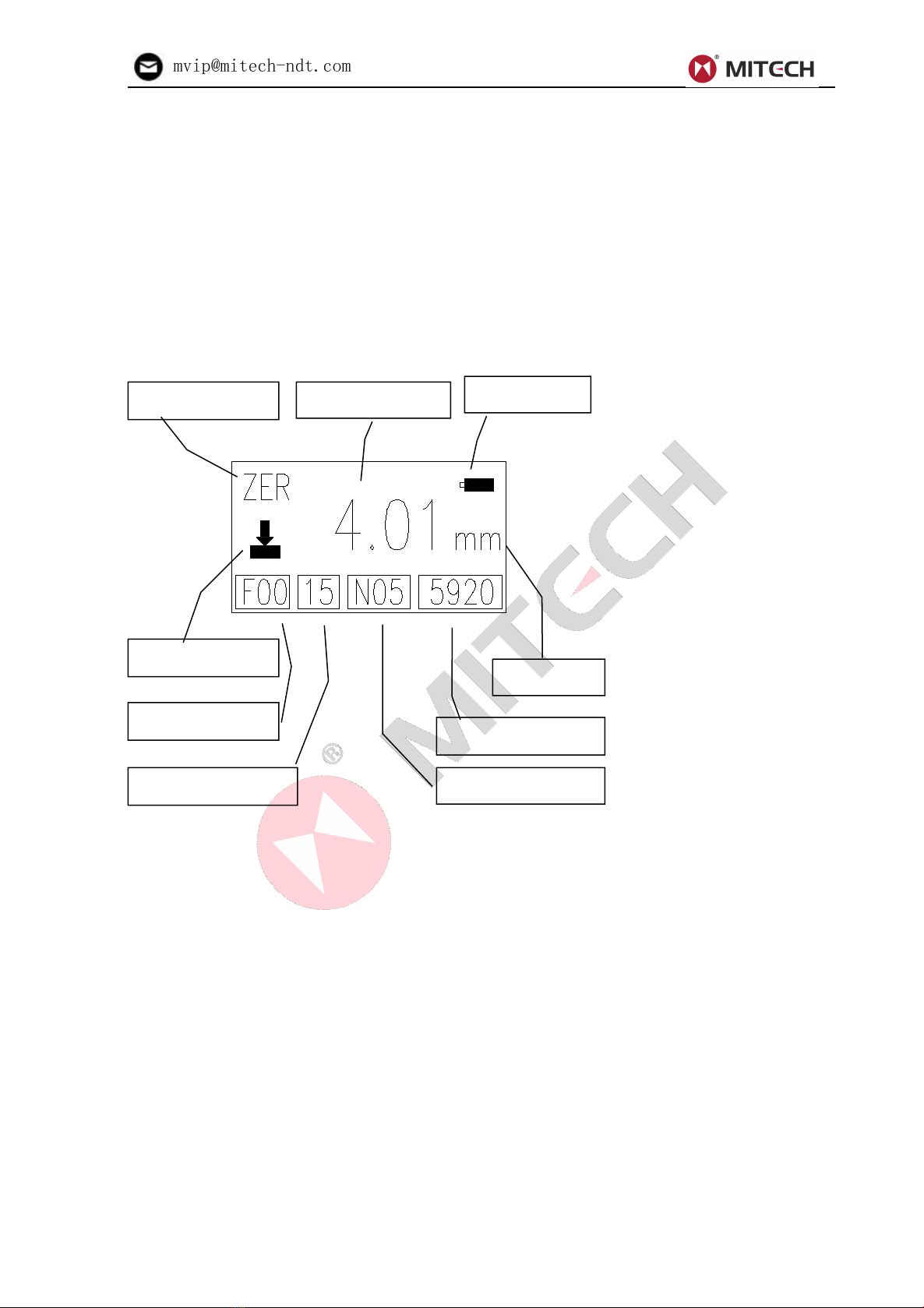

2.3 Measurement Screen....................................................................................................................... 7

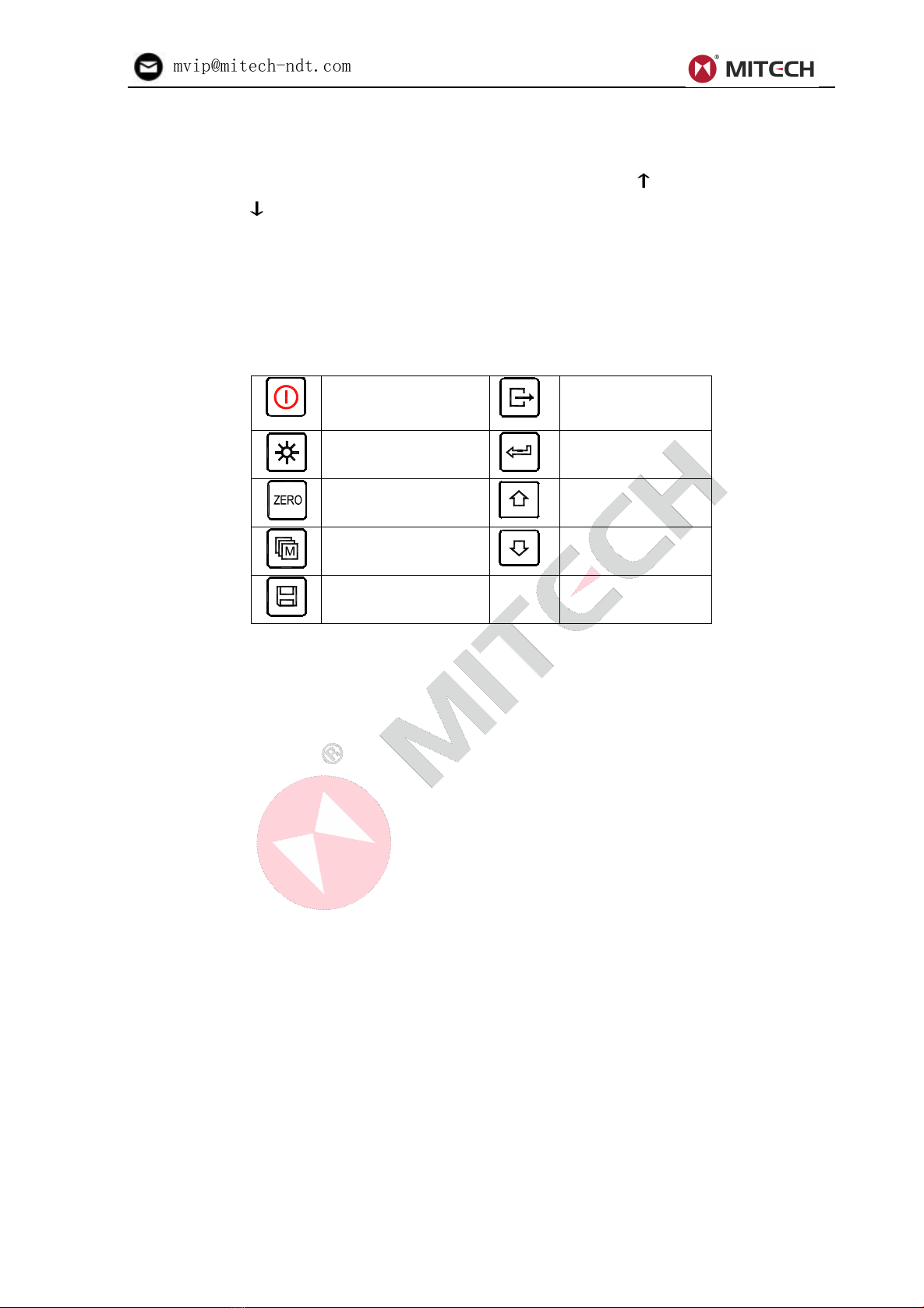

2.4 Keypad Definitions............................................................................................................................ 8

3 Preparation..................................................................................................................................................8

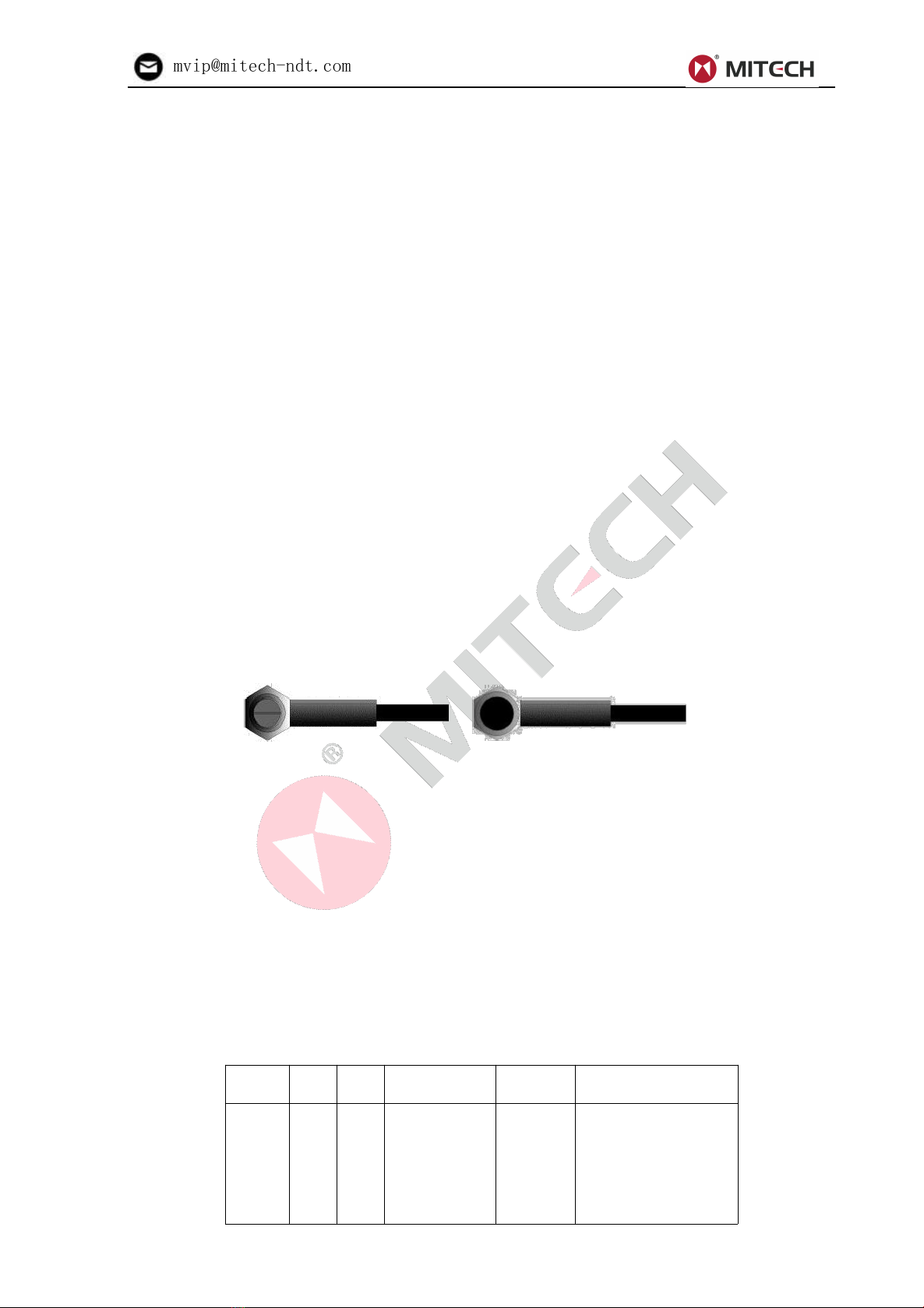

3.1 Transducer Selection........................................................................................................................ 8

3.2 Condition and Preparation of Surfaces....................................................................................... 10

4 Operation................................................................................................................................................... 10

4.1 Power On/Off................................................................................................................................... 10

4.2 Transducer Set................................................................................................................................ 10

4.3 Probe Zero........................................................................................................................................11

4.4 Sound Velocity................................................................................................................................. 11

4.5 Making Measurements...................................................................................................................12

4.6 Two Point Calibration......................................................................................................................13

4.7 Scan mode....................................................................................................................................... 14

4.9 Resolution.........................................................................................................................................14

4.10 Unit Scale....................................................................................................................................... 14

4.11 Memory Management...................................................................................................................15

4.12 Data Printing.................................................................................................................................. 16

4.13 System Set.....................................................................................................................................16

4.14 System information....................................................................................................................... 17

4.15 EL Backlight................................................................................................................................... 17

4.16 Battery Information....................................................................................................................... 17

4.17 Auto Power Off.............................................................................................................................. 17

4.18 System Reset................................................................................................................................ 17

4.19 Connecting to a Computer.......................................................................................................... 17

5 Menu Operation....................................................................................................................................... 18

5.1 Enter the Main Menu...................................................................................................................... 18

5.2 Enter the Sub menu........................................................................................................................18

5.3 Change the Parameter...................................................................................................................18

5.4 Numeric Digit Input......................................................................................................................... 18

5.5 Save and Exit...................................................................................................................................18

5.6 Cancel and Exit................................................................................................................................18

6 Servicing....................................................................................................................................................18

7 Transport and Storage........................................................................................................................... 19