1

READ THIS FIRST

For your safety, read this Owner’s Manual and understand it

thoroughly before operating this HEDGE TRIMMER.

General

A hedge trimmer is high-speed, fast-cutting power tool, not a

toy. For your own safety and the safety of others, read and be

sure you understand all of the safety precautions contained in

the Owner’s Manual before operating the hedge trimmer. Retain

the Owner’s Manual, and make it available to all persons who

will be using the hedge trimmer. Periodically, review the manual

to refresh your understanding of the safety instructions

contained in it.

●Careless or improper use can cause serious or fatal

injury.

Obey the safety instructions contained in this manual as well

as all applicable governmental and workplace safety

standards, regulations and ordinances. Your authorized

equipment dealer can show you how to operate your hedge

trimmer properly.

●Contact with the moving cutter blade will cause severe

injury and the moving cutter blade can hurl objects,

causing injury.

Keep bystanders, children and animals away from the area

where the hedge trimmer is in use.

●Do not allow children to operate the hedge trimmer.

Operators must have sufficient size, strength and maturity to

be able lift and operate the hedge trimmer correctly for

extended periods of use. They must also be able to read,

understand and follow the safety instructions in this manual.

●Exhaust fumes contain poisonous carbon monoxide gas.

Operate your hedge trimmer only outdoors in a well-

ventilated area. Stop the engine immediately if exhaust fumes

cause you to experience symptoms of headache or nausea.

●Gasoline is highly ammable and can be explosive under

certain conditions.

Before refueling, stop engine and allow it to cool. Do not

smoke. Make sure area is well ventilated and free from any

source of flame or sparks, including appliances with a pilot

light. Wipe up fuel spills immediately. Check for and repair

any fuel leaks before starting hedge trimmer.

Operator

●Inattention or fatigue can lead to serious or fatal injury.

Never operate the hedge trimmer under the influence of

drugs or alcohol. Do not use the hedge trimmer if you are sick

or taking medication that causes drowsiness. If you get tired

while using the hedge trimmer, take a break.

●Always wear appropriate protective gear to avoid injury.

Eye protection in the form of goggles or properly fitted safety

glasses must be worn. Hearing protection, such as earplugs,

should also be used. Have your hearing checked regularly.

Protect your hands and feet by always wearing heavy-duty

boots and non-slip gloves when operating the hedge trimmer.

●Loose clothing or hair can lead to injury.

Long hair and loose articles of clothing such as scarves,

neckties, jewelry, and so forth, can become caught in nearby

branches or in moving parts of the hedge trimmer itself.

Always wear sturdy close-fitting long-sleeve shirts and long

pants that still allow freedom of movement. Secure hair so

that it is above shoulder level.

●Maintain your balance to avoid loss of control and injury.

Take care on loose uneven ground. Keep both feet firmly on

the ground while operating the hedge trimmer. Never work on

a ladder, in a tree or any other insecure support. Keep both

hands on the hedge trimmer and do not overreach. Never

attempt to cut overhead or with one hand.

●Always be aware of your surroundings and stay alert for

possible hazards that you may not hear due to the noise

of the hedge trimmer.

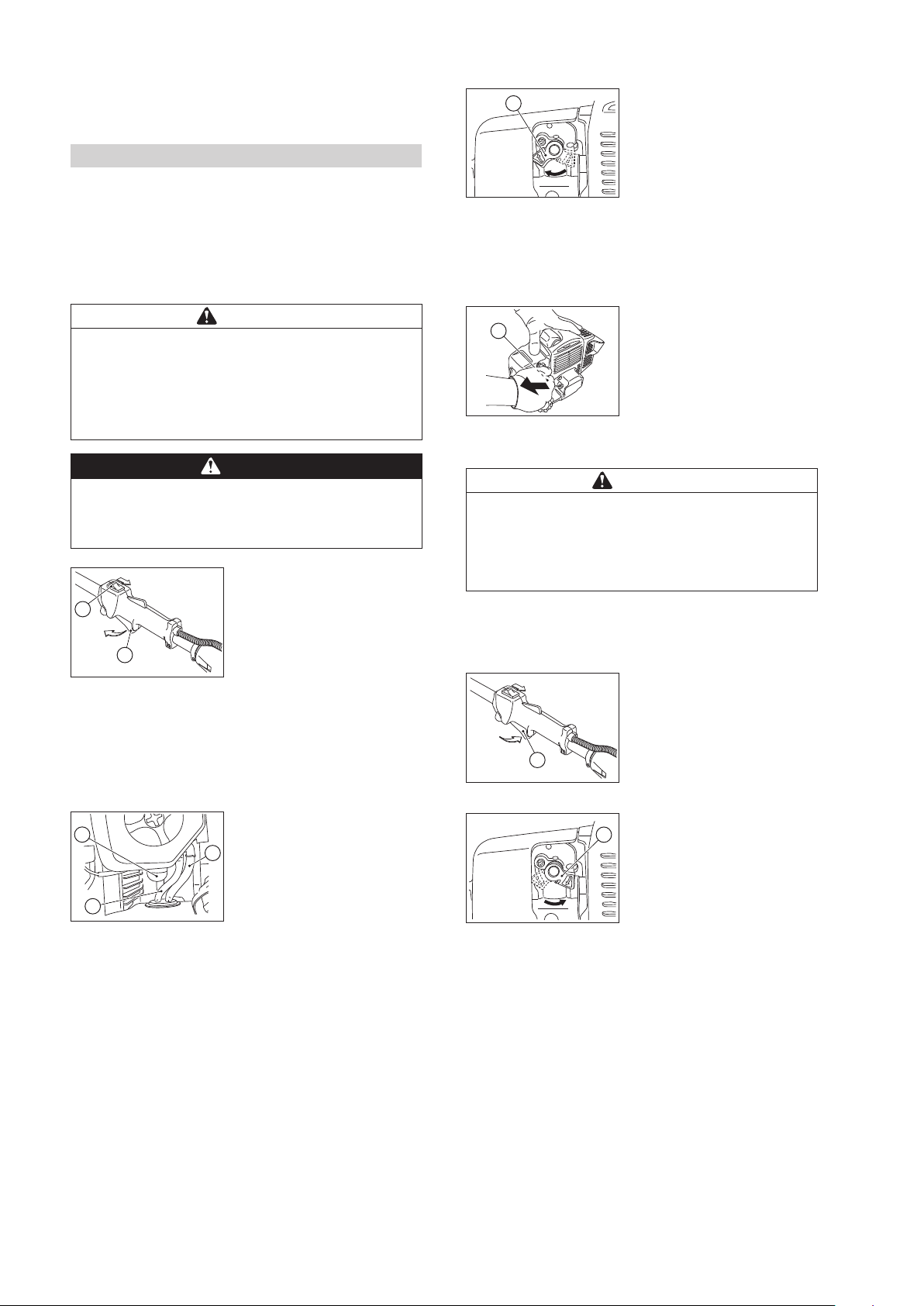

●Stop the engine and make sure that the cutting blade is

stopped when cleaning, checking, maintenance or

working on the hedge trimmer.

●Gasoline is highly ammable and can burn or irritate

skin. Change clothing immediately if fuel is spilled on it.

Never remove fuel cap while the engine is running.

●Be alert for signs of repetitive stress injury.

Using a hedge trimmer or any vibrating machinery over a

period of time may cause numbness, burning sensations, or

other indications of injury. If you experience any such

symptoms, discontinue use of the hedge trimmer and consult

your doctor.

Hedge Trimmer

●Modifying the hedge trimmer may make it unsafe.

Never modify your hedge trimmer, except as advised by

Manufacturer in writing. Use only Manufacturer supplied or

approved attachments and repair parts.

●Damaged or loose parts can break off and injure operator

or bystanders.

Always inspect your hedge trimmer before each use. Check

to be sure the throttle works smoothly and snaps to a closed

position when it is released. Never use a hedge trimmer with

a sticking throttle lever. Be sure the cutting tool is fastened in

place properly and is not cracked, bent, warped or broken.

●Blade cover must be tted on cutting blade when the

hedge trimmer is not in operation.

●To reduce re hazard keep the engine and mufer free of

debris, leaves or excessive lubricant.

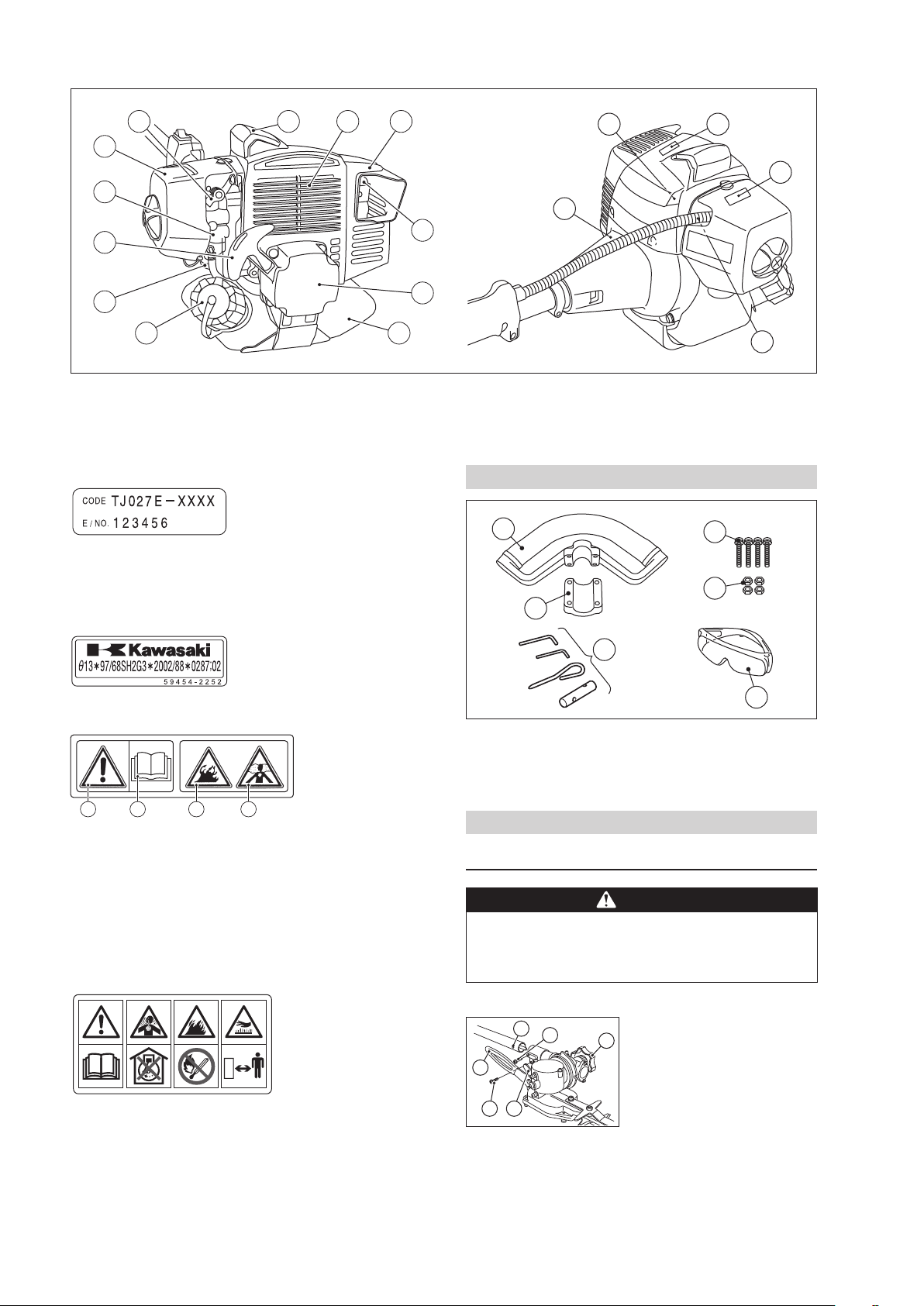

●Recoil starter rope can injure you if released suddenly.

When starting the engine, grasp the recoil starter firmly by the

grip. Do not grasp the starter rope itself. Always control the

rope during rewind into the housing. Releasing the starter

rope suddenly may allow the rope to whip around and injure

you or damage the recoil starter mechanism.

●Proper maintenance is essential for safety.

A well-maintenance hedge trimmer is safer and operates

more efficiently. Regularly check hedge trimmer adjustments

and replace worn or damaged parts. If engine idle speed is

set too high, the cutting blade will not stop when the operator

releases the throttle. A worn out or damaged muffler can emit

sparks and cause a fire. Increased noise levels can lead to

hearing loss. A dull cutting blade is more likely to snag than a

sharp blade. Observe maintenance schedule in the Owner’s

Manual.

●Store hedge trimmer safely to prevent re or equipment

damage.

To avoid fuel leakage and fire hazard, always empty the fuel

tank and run carburetor dry before storing your hedge

trimmer. Old fuel can clog the carburetor and lead to hard

starting or poor running conditions Store hedge trimmer in a

dry, secure location out of the reach of children. When

transporting hedge trimmer in a vehicle, take precautions to

secure it against damage from falling over and fuel spillage.